Professional Documents

Culture Documents

HK 40

HK 40

Uploaded by

Praful PatilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HK 40

HK 40

Uploaded by

Praful PatilCopyright:

Available Formats

25 Commerce Road, Orillia, Ontario, Canada L3V 6L6

Phone (705) 325-2781

Fax (705) 325-5887

ALLOY DATA SHEET

HEAT RESISTANT ALLOY

HK

REVISION: 04/91

DESCRIPTION

HK alloy, more well known as HK 40, is an austenitic Fe-Cr-Ni alloy that has been a standard heat resistant

material for over four decades. With moderately high temperature strength, oxidation resistance and

carburization resistance the alloy is used in a wide variety of industrial applications.

COMPOSITION

Min %

Max %

C

0.35

0.45

Mn

0.4

1.5

Si

0.5

1.5

Cr

23

27

Ni

19

22

P

0.03

S

0.03

APPLICATIONS

Ammonia, methanol and hydrogen reformers; ethylene pyrolysis coils and fittings; steam superheater tubes and

fittings; tube supports and hangers; tube sheets; heat treatment fixtures and trays; refractory supports; furnace

skids; furnace rolls; rabble arms.

PRODUCT FORMS

Horizontal and vertical centrifugal castings; static castings.

PHYSICAL PROPERTIES

Density (lbs/in3)

CARBURIZATION

0.280

RESISTANCE

Melting Point(oF)

2540

(Gas-1064 hours @ 1760oF)

Thermal Conductivity

(Btu/h/ft2/ft/oF)

7.9

Thermal Expansion

(10-6in/in oF)

ALLOY

15.7

@ 212oF

@ 1600oF

GRADE

WEIGHT GAIN

mg/mm2

17.1

@ 1800oF

HF

0.81

9.8

HH

0.58

10.0

@ 70-1400oF

@ 70-1600oF

HK

0.56

10.2

@ 70-1800oF

HP

0.20

MECHANICAL PROPERTIES (Typical Values)

Centrifugal Castings

U.T.S.

Y.S.

El.

K.S.I.

K.S.I.

%

70

84

44

20

1400

38

24

13

1600

24

16

16

1800

15

9

42

2000 oF

5.6

5

55

Static Castings

70 oF

74

45

17

SERVICE TEMPERATURE

The alloy is suitable for service at temperatures up to approximately 2000 oF.

COMPARATIVE OXIDATION RATES (mm / year)

(500 hour cyclic tests)

GRADE

HH

HK

HT

1832

<0.1

<0.1

0.20

1922

0.22

0.22

0.54

2012

0.92

0.95

1.4

2102

3.9

3.5

3.2

2204 oF

12.7

7.2

HEAT RESISTANT ALLOY HK40 Page 2

WELDABILITY

HK40 alloy has good weldability by the SMAW, GTAW and GMAW processes using filler metal of matching

composition.

CREEP-RUPTURE PROPERTIES

Long term creep-rupture properties were extrapolated from Larson-Miller Parameter versus stress plots.

RUPTURE-STRESS-KSI

HOURS

1400

1500

1600

1700

1800

1900

1,000.

AVG.

MIN.

11.9

9.39

8.75

6.97

6.18

4.98

4.34

3.48

3.05

2.35

2.09

1.54

10,000.

AVG

MIN

8.75

6.96

6.04

4.84

4.10

3.27

2.67

2.10

1.74

1.34

1.05

0.85

100,000

AVG.

MIN.

6.11

4.84

4.12

3.20

2.58

2.06

1.59

1.28

0.96

0.78

oF

CREEP-STRESS-KSI

%/HOUR

0.01

0.001

0.0001

AVG.

AVG.

AVG

1400

1500

1600

1700

1800

1900

11.6

9.0

11.8

9.5

6.85

9.9

7.4

5.0

8.0

5.7

3.35

6.35

3.93

2.05

4.75

2.68

1.05

oF

Note: Creep and rupture stresses are subject to periodic revisions as the results from long term tests become

available.

RELATED SPECIFICATIONS

ASTM: A 297 (HK); A 351(HK30 and HK40); A 567 (HK40 and HK50 - specification discontinued in 1987); A608

(HK30 and HK40)

Nearest wrought grade: AISI 310. The composition of the wrought grade differs from that of the cast alloy and

has different properties. The cast alloy designation should always be used to identify castings.

HEAD OFFICE, FOUNDRY & INTERNATIONAL SALES

Kubota Metal Corporation, Fahramet Division

25 Commerce Road, P.O. Box 1700,

Orillia, Ontario, Canada, L3V 6L6.

Phone (705) 325-2781

Fax (705) 325 5887

You might also like

- NRR Power of AttorneyDocument2 pagesNRR Power of AttorneyedwinNo ratings yet

- Material P NumberDocument11 pagesMaterial P NumberChaitanya Sai TNo ratings yet

- Fire Tube Boiler Thermodynamic Calculation: 15 MW, 23 T/H, 10 Bar / 145 Psi STEAM BOILER WITH Superheater and EconomizerDocument6 pagesFire Tube Boiler Thermodynamic Calculation: 15 MW, 23 T/H, 10 Bar / 145 Psi STEAM BOILER WITH Superheater and Economizer266870idNo ratings yet

- Process Safety Leadership Engaging With Senior ManagersDocument26 pagesProcess Safety Leadership Engaging With Senior Managerssl1828No ratings yet

- Ch20 - Quantity Theory of MoneyDocument18 pagesCh20 - Quantity Theory of MoneyLê Đặng Minh ThảoNo ratings yet

- Mroy Pump Catalogue PDFDocument6 pagesMroy Pump Catalogue PDFTitus FelixNo ratings yet

- Astm A216Document3 pagesAstm A216Ruth Sarai YañezNo ratings yet

- 1) Tube & Pipe Comparison TableDocument2 pages1) Tube & Pipe Comparison Tablevalli raju100% (1)

- Financial Reporting and Analysis 7th Edition Ebook PDFDocument61 pagesFinancial Reporting and Analysis 7th Edition Ebook PDFjerry.wolff991100% (46)

- Boiler Material and Typical ApplicationsDocument1 pageBoiler Material and Typical Applicationsmtbecerrap100% (1)

- S275JR PDFDocument1 pageS275JR PDFEmrahCayboylu100% (1)

- Pipe SpecDocument84 pagesPipe SpecAbdullahNo ratings yet

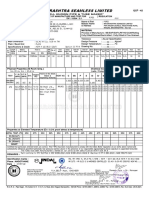

- Maharashtra Seamless LimitedDocument1 pageMaharashtra Seamless LimitedTushar KasabeNo ratings yet

- 39 Ni CR Mo 3Document2 pages39 Ni CR Mo 3Lokesh Krishnappa100% (2)

- Astm A-297 HPDocument2 pagesAstm A-297 HPeduardo_exsys100% (1)

- API 530 Tube Thickness Design: CV. Alpha Omega Mohammad FirmansyahDocument3 pagesAPI 530 Tube Thickness Design: CV. Alpha Omega Mohammad FirmansyahagusnurcahyoNo ratings yet

- ASTM C592-22aDocument9 pagesASTM C592-22a22238.spoNo ratings yet

- Flat Head Calculation: According To ASME VIII Div.1Document4 pagesFlat Head Calculation: According To ASME VIII Div.1AlliaNo ratings yet

- 각국 재질 비교표 (ASTM)Document2 pages각국 재질 비교표 (ASTM)Tommy Sung100% (1)

- Fact Sheets JournalismDocument6 pagesFact Sheets JournalismRIO JOY GALLONo ratings yet

- P # NumberDocument4 pagesP # NumberManzar KhanNo ratings yet

- Condensate in HRSG PDFDocument15 pagesCondensate in HRSG PDFCoalhouse Walker JuniorNo ratings yet

- En 10028 2 P265GH - Boiler Plate Steel - ProductsDocument2 pagesEn 10028 2 P265GH - Boiler Plate Steel - ProductsShankey JAlanNo ratings yet

- CASE #104 Bureau of Internal Revenue, Et. Al. vs. Lepanto Ceramics, Inc. G.R. No. 224764, April 24, 2017 FactsDocument2 pagesCASE #104 Bureau of Internal Revenue, Et. Al. vs. Lepanto Ceramics, Inc. G.R. No. 224764, April 24, 2017 FactsHarleneNo ratings yet

- ASTM F1545 Plastic Lined Pipe 0803Document6 pagesASTM F1545 Plastic Lined Pipe 0803JabranYounasNo ratings yet

- Material Information Sheet For Plates: Erndtebrücker EisenwerkDocument2 pagesMaterial Information Sheet For Plates: Erndtebrücker EisenwerkAhmad KamilNo ratings yet

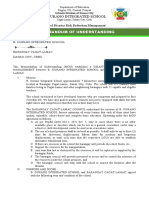

- Memorandum of Understanding: B. Durano Integrated SchoolDocument3 pagesMemorandum of Understanding: B. Durano Integrated SchoolKEICHIE QUIMCONo ratings yet

- ASTM C401 - Std. Classification of Alumina & Alumina-Silicate Castable RefactoriesDocument2 pagesASTM C401 - Std. Classification of Alumina & Alumina-Silicate Castable RefactoriesAtif RabbNo ratings yet

- 17-4PH Technical DataDocument7 pages17-4PH Technical DataKir VinNo ratings yet

- ASTM A240-A240M-05aDocument12 pagesASTM A240-A240M-05aNadhiraNo ratings yet

- QIP-PDI-G.3 - Design Instruction For Standard Pipe Support SelectionDocument1 pageQIP-PDI-G.3 - Design Instruction For Standard Pipe Support Selectiondimas prasetyoNo ratings yet

- Boiler Performance & Technical Data JT-K13467-E01-0Document15 pagesBoiler Performance & Technical Data JT-K13467-E01-0Puntanata Siagian0% (1)

- Pressure Temperature Chart According To ASME B16.34 ASME B PV CodeDocument5 pagesPressure Temperature Chart According To ASME B16.34 ASME B PV CodeDwayne YiiNo ratings yet

- NBT 47003.1-2009 钢制焊接常压容器Document177 pagesNBT 47003.1-2009 钢制焊接常压容器Nguyen Duc Anh100% (1)

- Astm A 335Document8 pagesAstm A 335Ruben Dario Espinoza Vasquez100% (1)

- Q245R PDFDocument2 pagesQ245R PDFAnonymous 9zykaX6T100% (1)

- Technical Presentation From LJUNGSTROM On Advance Heat Recovery in Rotary Air Preheaters-WBPDCL PDFDocument2 pagesTechnical Presentation From LJUNGSTROM On Advance Heat Recovery in Rotary Air Preheaters-WBPDCL PDFLipika Ghosh BiswasNo ratings yet

- Jun 2018 153707867T2JQPG3GPFRDocument61 pagesJun 2018 153707867T2JQPG3GPFRANIL KUMARNo ratings yet

- Rockwool Insulation LRB MatressDocument1 pageRockwool Insulation LRB MatressJaveed KhanNo ratings yet

- Chemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateDocument2 pagesChemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateVarun Malhotra100% (1)

- b2020-Tdc-Fas-004 Fasteners r3Document2 pagesb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranNo ratings yet

- Morflo 170Document2 pagesMorflo 170baselNo ratings yet

- P17-1TS-KBR Bolting Types Carbon & Alloy SteelDocument2 pagesP17-1TS-KBR Bolting Types Carbon & Alloy Steelyulianus_sr100% (1)

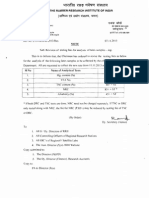

- Rubber Research Institute Testing FeeDocument15 pagesRubber Research Institute Testing FeemoumonaNo ratings yet

- Catalytic Activated Ceramic Dust Filter For Removal of Dust NOx Dioxin and VOCs 2006Document5 pagesCatalytic Activated Ceramic Dust Filter For Removal of Dust NOx Dioxin and VOCs 2006Joseph RileyNo ratings yet

- Dinflo DFCSDocument2 pagesDinflo DFCSvictorharijantoNo ratings yet

- Attachment #01 DEP 30.10.73.10-Gen. Cathodic ProtectionDocument3 pagesAttachment #01 DEP 30.10.73.10-Gen. Cathodic ProtectionArun Sudarshan0% (1)

- Firelite 124Document1 pageFirelite 124pamelataboadalozanoNo ratings yet

- Refractory Datasheet 2 - KS-4V PLUSDocument2 pagesRefractory Datasheet 2 - KS-4V PLUSSubrata DasNo ratings yet

- Tema StandardsDocument1 pageTema Standardsjose_alberto2No ratings yet

- Pressure Vessel Inspection and Test Plan Sample: WWW - Inspection-For-Industry.c OmDocument4 pagesPressure Vessel Inspection and Test Plan Sample: WWW - Inspection-For-Industry.c OmMuh FarhanNo ratings yet

- Asme - HeaderDocument3 pagesAsme - HeaderReadersmoNo ratings yet

- Manurite 900bDocument2 pagesManurite 900bAhtsham AhmadNo ratings yet

- Defects in Seamless TubesDocument4 pagesDefects in Seamless TubesAgniva DuttaNo ratings yet

- Advanced Centrifugal Casting Alloys For Dri ProcessesDocument12 pagesAdvanced Centrifugal Casting Alloys For Dri ProcessesDavid RodriguesNo ratings yet

- Calde™ Gun M 60Document1 pageCalde™ Gun M 60Yoo Kyungsik100% (1)

- Sfa-5.01 Filler Metal Procurement GuidelinesDocument10 pagesSfa-5.01 Filler Metal Procurement GuidelinesCesar Agustin LimousinNo ratings yet

- Boiler Data (Texmoco BoilersDocument6 pagesBoiler Data (Texmoco Boilersamitdharne100% (1)

- Dev Energy - GASIFIERDocument33 pagesDev Energy - GASIFIERvinay1999No ratings yet

- BWG SWG Tube Wall Thickness Conversion MM and InchDocument2 pagesBWG SWG Tube Wall Thickness Conversion MM and InchSupratik RoyNo ratings yet

- AI I 4145 Allo Teel (UN G41450) : Topics CoveredDocument3 pagesAI I 4145 Allo Teel (UN G41450) : Topics CoveredUmerNo ratings yet

- CompAir L23 - 26A 50Hz Compressor Performance Data PDFDocument1 pageCompAir L23 - 26A 50Hz Compressor Performance Data PDFbulentbulut100% (1)

- QU AL ITY: Material Data SheetDocument5 pagesQU AL ITY: Material Data SheetAlex007No ratings yet

- Asme Ix QW MTDocument57 pagesAsme Ix QW MTharabiNo ratings yet

- l6ll2l20L8: Fifth 2018Document16 pagesl6ll2l20L8: Fifth 2018dileepNo ratings yet

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 04/91Document2 pagesAlloy Data Sheet: Heat Resistant Alloy REVISION: 04/91Azize RazamNo ratings yet

- KHR 35Ct: Alloy Data SheetDocument2 pagesKHR 35Ct: Alloy Data SheetFebri Ramdani NugrahaNo ratings yet

- Smart Hotel Reservation ConfirmDocument1 pageSmart Hotel Reservation ConfirmhawyegNo ratings yet

- UntitledDocument1 pageUntitledhawyegNo ratings yet

- Hard Chromium Plated Th.0.03: Skl01-Deflector - Roll - AssyDocument1 pageHard Chromium Plated Th.0.03: Skl01-Deflector - Roll - AssyhawyegNo ratings yet

- How Does Redex Differential Drive WorkDocument26 pagesHow Does Redex Differential Drive WorkhawyegNo ratings yet

- Pipe Flow Design 1: Results DataDocument7 pagesPipe Flow Design 1: Results DatahawyegNo ratings yet

- Submission Confirmation: Entry Received: v12.01.00 Applicant Entry SystemDocument1 pageSubmission Confirmation: Entry Received: v12.01.00 Applicant Entry SystemhawyegNo ratings yet

- Split Plummer Block Housings SNL and SE Series For Bearings On An Adapter Sleeve With Standard Seals - SNL 524-62Document2 pagesSplit Plummer Block Housings SNL and SE Series For Bearings On An Adapter Sleeve With Standard Seals - SNL 524-62hawyegNo ratings yet

- Airmotor CatalogDocument33 pagesAirmotor CataloghawyegNo ratings yet

- NICRO Company Presentation 2015Document27 pagesNICRO Company Presentation 2015hawyegNo ratings yet

- ConsoDocument4 pagesConsojai ebuenNo ratings yet

- Fb4B & Fc4C Fan Coils: Maximize Comfort and Efficiency With A Matched Carrier Fan CoilDocument2 pagesFb4B & Fc4C Fan Coils: Maximize Comfort and Efficiency With A Matched Carrier Fan CoilMegaHyperMaxNo ratings yet

- Written Report - IndexingDocument12 pagesWritten Report - IndexingGS LibraryNo ratings yet

- Food Network Magazine - March 2014 (Food Network) (Z-Library)Document163 pagesFood Network Magazine - March 2014 (Food Network) (Z-Library)Stephanie ANo ratings yet

- Educational PolicyDocument3 pagesEducational PolicyAISHWARYA SINHA0% (1)

- Thoery of Structure - STEELDocument5 pagesThoery of Structure - STEELRiyaNo ratings yet

- Advantages of Social Media For College Students - CollegeDocument5 pagesAdvantages of Social Media For College Students - CollegefatinNo ratings yet

- Press Release: Laser Quantum's Latest Video: The Gem Laser vs. The ArcticDocument2 pagesPress Release: Laser Quantum's Latest Video: The Gem Laser vs. The ArcticMary Joy Dela MasaNo ratings yet

- Modern Business Statistics With Microsoft Excel 5th Edition Anderson Solutions Manual DownloadDocument22 pagesModern Business Statistics With Microsoft Excel 5th Edition Anderson Solutions Manual DownloadHassan Mccoy100% (30)

- Lectures - 1. Const OrganizationDocument31 pagesLectures - 1. Const OrganizationRyanNo ratings yet

- Y Combinator's Pocket Guide To Seed FundraisingDocument1 pageY Combinator's Pocket Guide To Seed FundraisingsarahansaripkNo ratings yet

- A Report of The Vocational TrainingDocument14 pagesA Report of The Vocational TrainingAvijit palNo ratings yet

- MM1DM1 2008-2009 Exam With SolutionsDocument10 pagesMM1DM1 2008-2009 Exam With SolutionsMuhd NazmiNo ratings yet

- Trabajo Autónomo InglésDocument80 pagesTrabajo Autónomo InglésMacarena Farías0% (1)

- Zitter and Hoeve - Hybrid LearningDocument28 pagesZitter and Hoeve - Hybrid LearningCinthya OliveraNo ratings yet

- Free Legal Study MaterialDocument17 pagesFree Legal Study MaterialABHI TIWARINo ratings yet

- Coursework Authentication Form EdexcelDocument4 pagesCoursework Authentication Form Edexcelafazbsaxi100% (2)

- Course Plan Ukmb1013 PibDocument21 pagesCourse Plan Ukmb1013 PibalittlemomoNo ratings yet

- By Mounika Lakkakula & Nidhi DhangiDocument46 pagesBy Mounika Lakkakula & Nidhi DhanginidhidNo ratings yet

- Welding Procedure Specification ExampleDocument2 pagesWelding Procedure Specification ExampleShajahan ShagulNo ratings yet

- EVO PDF Tools DemoDocument2 pagesEVO PDF Tools DemoMeena ThiruppathiNo ratings yet

- Using Remote Display Technologies With ANSYS Workbench ProductsDocument10 pagesUsing Remote Display Technologies With ANSYS Workbench ProductsprashanthNo ratings yet

- Harvard Architecture Von Neumann Architecture: Program CounterDocument12 pagesHarvard Architecture Von Neumann Architecture: Program CounterOmkar DixitNo ratings yet