Professional Documents

Culture Documents

Jsa (Autosaved) Store 4

Jsa (Autosaved) Store 4

Uploaded by

vigines890 ratings0% found this document useful (0 votes)

3 views2 pagesJSA AND HIRARC

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentJSA AND HIRARC

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pagesJsa (Autosaved) Store 4

Jsa (Autosaved) Store 4

Uploaded by

vigines89JSA AND HIRARC

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 2

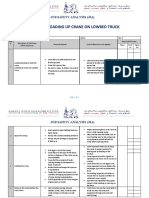

JOB SAFETY ANALYSIS SHEET

Job : Heavy Lifting in Hazardous Area

Job Site : On Semi SCG Industries

Malaysia Sdn. Bhd. (Senawang)

Equipments : Demag 500t crane, Tadano 120t crane, 30m Skylift, 2 sets of 10 axle 2 file

Cometto trailer, 10 axle Drop deck Cometto trailer and 10t lorry.

Personel Protective Equipment & Tools needed for work activities : Safety Hat,

Safety Shoes & Hand Gloves

Sequence of Basic

Job Steps

Potential Hazards

Yes / No

Precautions

Verify the suitability of shackles, slings &

crane for the load to be handled.

Check the Lifting Tools; shackles, slings

and crane certificates.

PRE - WORK

Collapse of the Crane & Load

NO

Ensure the area is free from obstacles for

crane operations.

Confirm the stability of crane at work site.

Conduct safety check of the crane prior

to start lifting.

Ensure that the load is secured for safe

lifting.

Check the slings, chain, ropes, shackles

are not damaged and safe for lifting.

Injury to Workers

NO

Verify the workers are trained for heavy

lifting operations and non essential person

leave the area before lifting operations

starts.

Confirm the signal between crane operator

& signal man. Only trained signal man to

give signal.

Ensure no one rides the load and nobody

goes below the load.

LIFTING &

ERECTION

Ensure the load before lifting and never

overload more than the capacity of crane,

shackle, sling, chain or ropes etc.

Damage to the Load

NO

Lift the load slowly & check the slings /

ropes or chain are not twisted keeping

the load in central position.

Use the rope for guiding the load if required.

Falling Tools

NO

Barricade work area at ground level to

prevent people entering in the danger zone

for falling objects.

ADDITIONAL

HAZARDS (other

than stated above)

JSA NO : JSA - AL - 00

JSA REV: 0

DATE : 16 JUNE 2011

PREPARED BY : SYKT. LOW KIM CHUAN

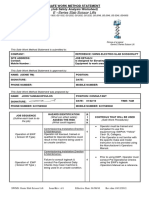

JOB SAFETY ANALYSIS SHEET

Job : Lifting of 5 units gas cylinder

Job Site : Texas Instrument, Ulu Klang

Equipments : 1 UNIT OF KATO 35T MOBILE CRANE

Personel Protective Equipment & Tools needed for work activities : Safety Helmet,

Safety Shoes,Hand Gloves & Long Sleeve Jacket

Sequence of Basic

Job Steps

Potential Hazards

Yes / No

Precautions

Verify the suitability of shackles, slings &

crane for the load to be handled.

Check the Lifting Tools; shackles, slings

and crane certificates.

PRE - WORK

Collapse of the Crane & Load

NO

Ensure the area is free from obstacles for

crane operations.

Confirm the stability of crane at work site.

Conduct safety check of the crane prior

to start lifting.

Ensure that the load is secured for safe

lifting.

Check the slings, chain, ropes, shackles

are not damaged and safe for lifting.

Injury to Workers

NO

Verify the workers are trained for heavy

lifting operations and non essential person

leave the area before lifting operations

starts.

Confirm the signal between crane operator

& signal man. Only trained signal man to

give signal.

Ensure no one rides the load and nobody

goes below the load.

LIFTING &

ERECTION

Ensure the load before lifting and never

overload more than the capacity of crane,

shackle, sling, chain or ropes etc.

Damage to the Load

NO

Lift the load slowly & check the slings /

ropes or chain are not twisted keeping

the load in central position.

Use the rope for guiding the load if required.

Falling Tools

NO

Barricade work area at ground level to

prevent people entering in the danger zone

for falling objects.

ADDITIONAL

HAZARDS (other

than stated above)

JSA NO : JSA - AL - 06

JSA REV: 0

DATE : 17 JULY 2015

PREPARED BY : CFW

You might also like

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocument2 pagesJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- Hira - Mobile CraneDocument4 pagesHira - Mobile CraneSantosh SinghNo ratings yet

- Course Material For Rigger-Latest - Final CHVR 2010Document138 pagesCourse Material For Rigger-Latest - Final CHVR 2010Tarek Ahmed100% (1)

- Jsa For Pre-Cast Column ErectionDocument19 pagesJsa For Pre-Cast Column ErectionKhuda BukshNo ratings yet

- Boom Lift - Daily ChecklistDocument1 pageBoom Lift - Daily Checklistpawankumar100% (2)

- Jsa Lifting of PitsDocument8 pagesJsa Lifting of PitseslamNo ratings yet

- JSA For Scissor Lift, Rev-6Document2 pagesJSA For Scissor Lift, Rev-6Mahamudul HasanNo ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- JSA For Screeding With MeshDocument4 pagesJSA For Screeding With MeshMohammed Minhaj100% (1)

- Work Method Statement: Confined SpaceDocument3 pagesWork Method Statement: Confined SpaceKarthik babu0% (1)

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- TenetsDocument9 pagesTenetsMary Ann Pateño100% (4)

- 07 - JSA Compaction and BackfillingDocument4 pages07 - JSA Compaction and Backfillingsatti100% (2)

- Lifting Hoisting Hazard HuntDocument1 pageLifting Hoisting Hazard Hunt曹庆园100% (1)

- Chipping Work (Manually)Document1 pageChipping Work (Manually)ChandruNo ratings yet

- JSA ElectricalToolsElectricityDocument3 pagesJSA ElectricalToolsElectricityCristina Rican50% (2)

- Overhead Crane Study 1Document12 pagesOverhead Crane Study 1shahrilmr6934No ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- 09 JSA For Excavation and Blinding at Pump House 1 & 3Document4 pages09 JSA For Excavation and Blinding at Pump House 1 & 3Hilbrecht De Pedro100% (1)

- Rigging JSA RiggerDocument12 pagesRigging JSA RiggeraQiLGunawanNo ratings yet

- ULSADO-JSA - Installation of Temporary Fence GateDocument2 pagesULSADO-JSA - Installation of Temporary Fence GateKelvin TanNo ratings yet

- Pre Crane Lift ChecklistDocument1 pagePre Crane Lift ChecklistmiaicarbaNo ratings yet

- AOTA Occupational Profile Template PDFDocument2 pagesAOTA Occupational Profile Template PDFCrys Paola Alvarez Gonzalez100% (1)

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Carpentry NC Ii: Trainer: Ve-Vanne D. LazaroDocument22 pagesCarpentry NC Ii: Trainer: Ve-Vanne D. LazaroGlaiza Shane MontenegroNo ratings yet

- Company Profile PT SAILS INDONESIADocument12 pagesCompany Profile PT SAILS INDONESIArumahbelajarNo ratings yet

- JACK IN Piling WorkDocument9 pagesJACK IN Piling WorkShaheed AzharNo ratings yet

- 11 - JSA (Tower Crane) 12-9-06Document11 pages11 - JSA (Tower Crane) 12-9-06sattiNo ratings yet

- Mobile Crane Monthly InspectionDocument1 pageMobile Crane Monthly Inspectionvigines89No ratings yet

- The Resume Critique The Gentle ArtDocument4 pagesThe Resume Critique The Gentle ArtAndrew SeguelNo ratings yet

- Equipment Data Sheet - SPMTDocument1 pageEquipment Data Sheet - SPMTvigines89No ratings yet

- BP Toledo Inert EntryDocument32 pagesBP Toledo Inert EntrySam Mebarek100% (1)

- Job Safety Analysis Erection SiloDocument3 pagesJob Safety Analysis Erection SiloDanangNo ratings yet

- SAB-JSA - Loading Crane On The TruckDocument3 pagesSAB-JSA - Loading Crane On The TruckaymenmoatazNo ratings yet

- Work Method Statement: Wms Rev. NoDocument5 pagesWork Method Statement: Wms Rev. NoKarthik babu100% (1)

- Concrete Bucket Safety2 PDFDocument3 pagesConcrete Bucket Safety2 PDFMuhammad Hamzah Habibburrahman100% (2)

- Genie E Series Slab Scissor Lift Operation PDFDocument11 pagesGenie E Series Slab Scissor Lift Operation PDFRajesh gpNo ratings yet

- Operating A Telescoping Aerial Boom LiftDocument1 pageOperating A Telescoping Aerial Boom LiftTFattahNo ratings yet

- Sop LiftingDocument5 pagesSop LiftingShaiful AnnuarNo ratings yet

- Job Safety Analysis - Piling WorkDocument11 pagesJob Safety Analysis - Piling WorkAhmad MensaNo ratings yet

- JSA For Concrete PouringDocument1 pageJSA For Concrete PouringHSE fahadNo ratings yet

- Hirarc Form: Hazard Identification Risk Analysis Risk ControlDocument5 pagesHirarc Form: Hazard Identification Risk Analysis Risk Controlvigines890% (1)

- Manpower SupplyDocument19 pagesManpower Supplyshipraasrivastav67% (3)

- 004 Piling JSADocument5 pages004 Piling JSAmidozotyNo ratings yet

- Noble Denton Loadout GuidelinesDocument35 pagesNoble Denton Loadout GuidelinesyeefonglimNo ratings yet

- BASF Inert EntryDocument17 pagesBASF Inert EntryTammanurRaviNo ratings yet

- JSA NO 3-Pile CapDocument8 pagesJSA NO 3-Pile Capknabpsho50% (2)

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDocument3 pagesGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- JSA NO 2 Piling WorkDocument6 pagesJSA NO 2 Piling WorkfadliNo ratings yet

- HSE Joke BookDocument12 pagesHSE Joke Bookroyal highprince100% (2)

- Jsa PolypipeDocument2 pagesJsa PolypipeHow Chin Engineering Sdn BhdNo ratings yet

- 04 Appendix 2 To PTC - Bill of MeterialsDocument18 pages04 Appendix 2 To PTC - Bill of Meterialsvigines89No ratings yet

- CV For ExampleDocument4 pagesCV For ExampleArifin Ardhi100% (1)

- LashCon IMO - Rev 9.0 - tcm144-287975Document4 pagesLashCon IMO - Rev 9.0 - tcm144-287975vigines89No ratings yet

- JSA For Blinding and De-Blinding (Opening Process Equipment)Document11 pagesJSA For Blinding and De-Blinding (Opening Process Equipment)Thái Đạo Phạm Lê100% (1)

- Safety: JOB AnalysisDocument4 pagesSafety: JOB AnalysisAjay kumar100% (1)

- DLF RCC HiraDocument8 pagesDLF RCC HiraskfahimuddinNo ratings yet

- File - 20200905 - 105458 - Jsa Wind PowerDocument10 pagesFile - 20200905 - 105458 - Jsa Wind PowerMon Trang NguyễnNo ratings yet

- JSA FOR Crane OperationDocument6 pagesJSA FOR Crane OperationDenease CrummieNo ratings yet

- Jha Confined SpaceDocument6 pagesJha Confined SpaceArun ArunbolluNo ratings yet

- Job Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Document5 pagesJob Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Madhan KannanNo ratings yet

- Rigging Up Checklist: Rig ModelDocument2 pagesRigging Up Checklist: Rig Model89simbuNo ratings yet

- Trial Pit During ExcavationDocument3 pagesTrial Pit During Excavationmujahid1137No ratings yet

- Working at Height (Lifting Gear Inspection)Document1 pageWorking at Height (Lifting Gear Inspection)Hamdi RafiekNo ratings yet

- Nasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetDocument2 pagesNasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetRaza Muhammad SoomroNo ratings yet

- PT-03 JSA Dismantling of Slip Form (22-05-09)Document10 pagesPT-03 JSA Dismantling of Slip Form (22-05-09)M Waqas HabibNo ratings yet

- Topic For TBMDocument19 pagesTopic For TBMdauxomNo ratings yet

- Jsa Slip FormDocument5 pagesJsa Slip Formputrasejahtra50% (2)

- Jsa-0001 - Excavation Cipp RapidDocument11 pagesJsa-0001 - Excavation Cipp RapidMohamad Afif100% (1)

- Grating RemovalDocument1 pageGrating RemovalKishor KoshyNo ratings yet

- HIRADC Installation PipeDocument4 pagesHIRADC Installation PipeamizanNo ratings yet

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- JHA - Excavation, Pile Hacking and Construction of Lean ConcreteDocument13 pagesJHA - Excavation, Pile Hacking and Construction of Lean ConcreteJansen SungaNo ratings yet

- CraneDocument24 pagesCranezawmoe aungNo ratings yet

- Title: 9801 High-Impact Crane Safety: Length: 18 Minutes Production Year: 1998 Program SynopsisDocument2 pagesTitle: 9801 High-Impact Crane Safety: Length: 18 Minutes Production Year: 1998 Program Synopsisg665013No ratings yet

- Fine Desander PackageDocument9 pagesFine Desander Packagevigines89No ratings yet

- Internal Road Modification - Location 6: Road Curbs To Be Dismantle 1.5m (Trees On The Curbs To Be Remove)Document1 pageInternal Road Modification - Location 6: Road Curbs To Be Dismantle 1.5m (Trees On The Curbs To Be Remove)vigines89No ratings yet

- Gurun: Drive 445 KM, 4 H 40 Min Directions From Gurun To Port Klang Free Zone (M)Document3 pagesGurun: Drive 445 KM, 4 H 40 Min Directions From Gurun To Port Klang Free Zone (M)vigines89No ratings yet

- Initial Positioning/Lifting Simulation-Loading From Trailer: 6th CoachDocument1 pageInitial Positioning/Lifting Simulation-Loading From Trailer: 6th Coachvigines89No ratings yet

- Sides Inside Outside Pi GuessDocument2 pagesSides Inside Outside Pi Guessvigines89No ratings yet

- 45T Load ChartDocument1 page45T Load Chartvigines89No ratings yet

- Tadano TG 1200Document1 pageTadano TG 1200vigines89No ratings yet

- Chart 1 - Ramunia Jetty To Rapid SiteDocument1 pageChart 1 - Ramunia Jetty To Rapid Sitevigines89No ratings yet

- 02 - JOTUN - Job Application Form (New)Document4 pages02 - JOTUN - Job Application Form (New)RazakPakauNo ratings yet

- Labo SafeDocument36 pagesLabo SafetemterNo ratings yet

- Assistant Human Resources Officer - Educational Services Department - The Salvation Army - Hong Kong - JobsDBDocument2 pagesAssistant Human Resources Officer - Educational Services Department - The Salvation Army - Hong Kong - JobsDBBerberber YffNo ratings yet

- Internship Advert - EditedDocument1 pageInternship Advert - EditedMAGU_MWENYEWENo ratings yet

- OOSCY Survey As of 2016Document2,876 pagesOOSCY Survey As of 2016rubieann_danzalanNo ratings yet

- FormworkDocument11 pagesFormworkcoolczoneNo ratings yet

- PRC Related LawsDocument7 pagesPRC Related LawsRiah Mae MertoNo ratings yet

- Frequency: Lesson 4 Frequency Ability, Quality and AchievementDocument4 pagesFrequency: Lesson 4 Frequency Ability, Quality and Achievementsimmona2101No ratings yet

- Topic 5 The Value of Work Employees ResponsibilitiesDocument39 pagesTopic 5 The Value of Work Employees Responsibilitiesnazlia880% (1)

- Eric Daniel Germovsek For Hambden Township TrusteeDocument2 pagesEric Daniel Germovsek For Hambden Township TrusteeThe News-HeraldNo ratings yet

- English Novice 1stDocument13 pagesEnglish Novice 1stnoviNo ratings yet

- Values QuestionnaireDocument3 pagesValues QuestionnairePsychologyEnergyNo ratings yet

- Burnout and Depression (Dentists)Document9 pagesBurnout and Depression (Dentists)FranzNo ratings yet

- Borderless WorldDocument2 pagesBorderless WorldChim PalmarioNo ratings yet

- Professional Gatekeeping As A Function of Role FidelityDocument2 pagesProfessional Gatekeeping As A Function of Role FidelityNURSETOPNOTCHER100% (3)

- Spanish1 PDFDocument2 pagesSpanish1 PDFrafaelmariasanchezNo ratings yet

- AISE Guidelines For The Safe Handling of Enzymes in Detergent ManufacturingDocument130 pagesAISE Guidelines For The Safe Handling of Enzymes in Detergent ManufacturingAnonymous CoGUaJNo ratings yet

- Checklist of Required Documents For Retirement ClaimDocument3 pagesChecklist of Required Documents For Retirement ClaimNoreena Twinkle FajardoNo ratings yet

- Frequently Asked Questions - New Points TestDocument8 pagesFrequently Asked Questions - New Points Testdhimant09No ratings yet

- Change Roller Track and Change Bolt of Shoe Track CraneDocument2 pagesChange Roller Track and Change Bolt of Shoe Track CraneaneshseNo ratings yet