Professional Documents

Culture Documents

Blocks PDF

Blocks PDF

Uploaded by

Abu NijamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blocks PDF

Blocks PDF

Uploaded by

Abu NijamCopyright:

Available Formats

April 2007

Data Sheet 1

Uniclass

L3221:A4

CI/SfB

Aggregate Concrete Blocks

EPIC

F611:X221

Ff2

(Ajv)

A Guide to Selection & Specification

Block Types

Introduction

This guide has been produced to assist designers and specifiers with the selection and

specification of building blocks, which are manufactured in accordance with BS EN 771-3.

The appropriate CBA Data Sheets should be consulted for more detailed information,

including the selection of the UHB (Universal Housing Block) for housing projects.

BS EN 771-3 contains many more properties than its predecessor BS 6073-1 but not

all these are required for use in the UK. Therefore only those properties specifically

needed for an application should be specified.

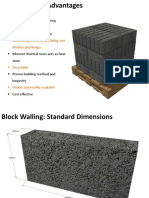

Solid blocks

Blocks which contain

no formed voids.

(Group 1)

Care should be taken to ensure that the mix of properties specified are mutually

compatible and therefore available in a single block type.

Block Specification

For convenience blocks may be categorized using the following block details for

all specifications:

Cellular blocks

Blocks which contain one or

more formed voids which do

not fully penetrate the block.

(Group 1 or Group 2 according

to void percentage.)

Block description (e.g. standard common blocks)

Dimensions (e.g. 440mm x 100mm x 215mm)

Tolerance category (e.g. D1)

Strength (e.g. 7.3 N/mm)

Net dry density (e.g. 2000kg/m)

Configuration (e.g. solid/Group 1)

Within these categories there are three configurations, solid, cellular and hollow: see opposite.

Block Description

Block types are available in various ranges produced by CBA manufacturers, which may be

generally described as follows:

Standard common blocks

Blocks suitable for general building work, offering excellent all round performance and

normally available in 440 x 215mm face size. In addition to their loadbearing capabilities,

they provide an excellent background for plastering and rendering as well as for fixings.

This type of block is not normally intended for use in facing applications as variations in

colour and texture may occur.

Hollow blocks

Blocks which contain one or

more formed voids which

fully penetrate the block.

(Group 1 or Group 2 according

to void percentage.)

Blocks are available in various

strengths and surface textures.

Close textured/Paint grade common blocks

Blocks manufactured with a close texture and suitable for direct painting.

Standard facing blocks

Blocks manufactured for applications where shape and texture consistency are of prime

importance. Slight variations in colour may be discernible.

Architectural masonry facing blocks

Blocks manufactured to high standards of dimensional accuracy and consistency of colour

and texture. The blocks are intended for use in situations where the visual appearance

of the wall is of primary concern. The blocks are available in a range of colours, textures,

finishes and shapes.

See back for Special Block shapes.

Dimensions

Dimensions of commonly

Face sizes/co-ordinating dimensions

Concrete Block Association

60 Charles Street, Leicester LE1 1FB

Tel: 0116 253 6161 Fax: 0116 251 4568

Email: enquiries@cba-blocks.org.uk

Website: www.cba-blocks.org.uk

Block dimensions should be specified in the order

length x width x height.

Intermediate widths may be available from

some manufacturers.

available blocks are:

Face size (mm)

Width

Aggregate concrete blocks are typically available in two

standard face sizes (length x height) of 440 x 215mm

and 390 x 190mm. Other face sizes are available to aid

manual handling. To obtain the co-ordinating dimensions

add the specified joint thickness (normally 10mm)

to the height and length of the block.

440 x 215

390 x 190

75

90

90

100

100

140

140

190

190

215

A Guide to Selection & Specification

Special Blocks

Blocks produced to form an

extensive kit-of-parts which

gives the designer-specifier

greater flexibility.

Dimensional tolerances

Tolerances permitted by BS EN 771-3 are:

Tolerance

Category

Length

Width

Sill

Height

D1

D2

+3

+1

-5

-3

+3

+1

-5

-3

+3

+2

-5

-2

Limiting deviations in millimetres.

Blocks will generally be supplied to D1 tolerance category unless otherwise specified.

Manufacturers are permitted to supply to tighter tolerances on any dimension within

a tolerance category.

Block Strengths

Blocks are available in compressive strengths from 2.9N/mm to 40N/mm (Solid) and

2.9N/mm to 22.5N/mm (cellular and hollow). Common strengths are 3.6N/mm and 7.3N/mm.

Lintel

Density

Aggregate concrete blocks are available in the net dry density range of 650 2400kg/m with

a tolerance of 10%.

The full range of densities will not necessarily be available from all manufacturers.

Gross dry densities are typically used for cellular and hollow units and for the same products

will be lower than net dry densities.

Configuration

Bond Beam

Units to BS EN 771-3: Aggregate concrete masonry units will fall within one of the 4 groups

specified in BS EN 1996-1-1: Eurocode 6 Design of masonry structures.

Group

Group

Group

Group

1

2

3

4

<

>

>

>

25%

25%

25%

25%

formed voids

< 60% formed vertical voids

< 70% formed vertical voids

< 50% formed horizontal voids

Generally units will fall within Group 1 and Group 2 configurations.

Additional Details (when relevant)

Quoin/Return

Cavity closers

Block description

Density or unit weights

Flatness of surface (only applicable to facing units)

Thermal resistance

Durability

Water absorption (not required for specification in the UK)

Moisture movement (not required for specification in the UK)

Water vapour permeability (not required for specification in the UK)

Reaction to fire (designated non-combustible by UK Building Regulations)

Shear bond strength (not required for specification in the UK)

Flexural bond strength (not required for specification in the UK)

Visit www.cba-blocks.org.uk for the latest information, news and views from the CBA.

CBA Technical Helpline 0116 222 1507

The Concrete Block Association 2007

Although The Concrete Block Association does its best to ensure that any advice,

recommendation or information it may give is accurate, no liability or responsibility of any

kind (including liability for negligence) is accepted in this respect by the Association, its

servants or agents.

Fixing/Coursing

This datasheet is manufactured from ECF (Elemental Chlorine Free) pulp sourced from

certified or well managed forests and plantations. It is totally recyclable, biodegradable

and acid-free.

You might also like

- Shadows On The Moon by Zoe Marriott ExtractDocument20 pagesShadows On The Moon by Zoe Marriott ExtractWalker Books100% (1)

- Mortar Less Block SystemsDocument4 pagesMortar Less Block SystemsCarlos Alejandro Molina Paz100% (2)

- Concrete Block DescriptionDocument6 pagesConcrete Block DescriptionMitesh PunjaniNo ratings yet

- Concrete Blocks Walling Masterblock Tds PDFDocument38 pagesConcrete Blocks Walling Masterblock Tds PDFMohamedRaahimNo ratings yet

- Guide For Making HollowblockDocument4 pagesGuide For Making HollowblockShammir Tabayag MangidaNo ratings yet

- Blocks Brochure - July 17Document44 pagesBlocks Brochure - July 17AjdinNo ratings yet

- 2 Block SystemDocument25 pages2 Block SystemSovia DumiyantiNo ratings yet

- Guide To Best Practice For External Rendering: Data Sheet 14Document3 pagesGuide To Best Practice For External Rendering: Data Sheet 14Dmytro VaslchNo ratings yet

- Responsibility For Controlling Slab CurlingDocument1 pageResponsibility For Controlling Slab CurlingProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNo ratings yet

- FP McCann Fencing BrochureDocument9 pagesFP McCann Fencing BrochureNguyen Trong NghiaNo ratings yet

- Structural DesignDocument2 pagesStructural DesigncustomerxNo ratings yet

- Blast Resistant Equipment CentersDocument4 pagesBlast Resistant Equipment Centers1mmahoneyNo ratings yet

- Prestressed Concrete Fencing PostsDocument3 pagesPrestressed Concrete Fencing Postsexi johnsonNo ratings yet

- Concrete Unit MasonryDocument13 pagesConcrete Unit MasonryShanelle MacajilosNo ratings yet

- Nov. 21, 1961 C, H, Burnside 3,009,385: Method of Loading A Rocket Motor With Solid PropellantDocument7 pagesNov. 21, 1961 C, H, Burnside 3,009,385: Method of Loading A Rocket Motor With Solid PropellantSeenu CnuNo ratings yet

- Vertical Extensions Technical Challenges and Carbon ImpactDocument4 pagesVertical Extensions Technical Challenges and Carbon ImpactMyo Min ThuNo ratings yet

- Steel Roof TrussesDocument1 pageSteel Roof TrussesjackNo ratings yet

- Concrete Masonry UnitsDocument18 pagesConcrete Masonry UnitskuzemdooNo ratings yet

- Base Concrete Placement: 1. SubgradeDocument1 pageBase Concrete Placement: 1. Subgradeapuhapuh_153349No ratings yet

- Slab Deflections: ST George Wharf Case StudyDocument3 pagesSlab Deflections: ST George Wharf Case StudyHayyan JarboueNo ratings yet

- Ghid de Calcul Presiune Beton in CofrajeDocument59 pagesGhid de Calcul Presiune Beton in CofrajeArziv EstoNo ratings yet

- UFC 3-310-05A Masonry Structural Design For Buildings (03!01!2005)Document169 pagesUFC 3-310-05A Masonry Structural Design For Buildings (03!01!2005)Bob VinesNo ratings yet

- Rethinking ToolkitDocument12 pagesRethinking ToolkitelcivilengNo ratings yet

- Understanding Existing Buildings Five Studies To Complete Before Design Work StartsDocument4 pagesUnderstanding Existing Buildings Five Studies To Complete Before Design Work StartsJosh AmuraoNo ratings yet

- Thomas Armstrong - Concrete Blocks Brochure Jan 2013 - Web VersionDocument44 pagesThomas Armstrong - Concrete Blocks Brochure Jan 2013 - Web VersionTrilok Chand GuptaNo ratings yet

- Ask The Engineer Proper Bedding For PVC Pressure PipeDocument5 pagesAsk The Engineer Proper Bedding For PVC Pressure PipeUnibellNo ratings yet

- Fema259 Complete RevDocument510 pagesFema259 Complete RevHanna HernantiNo ratings yet

- GMM CasasLlogari TFG Mem 14Document16 pagesGMM CasasLlogari TFG Mem 14José Eduardo CostaNo ratings yet

- 01 - Mortarless Masonry Wall SystemDocument2 pages01 - Mortarless Masonry Wall SystemdiogesodreNo ratings yet

- Australian Bomb Data Centre Philippine Bomb Data Center: To Explosive TheoryDocument46 pagesAustralian Bomb Data Centre Philippine Bomb Data Center: To Explosive Theoryrattan62100% (1)

- 4996 RCC Fence PostDocument28 pages4996 RCC Fence Postnaveen100% (1)

- Business Practice Notes: Building Information ModellingDocument2 pagesBusiness Practice Notes: Building Information ModellingΤε ΧνηNo ratings yet

- 134 - As Struck Finishes PDFDocument2 pages134 - As Struck Finishes PDFJonathan KeoughNo ratings yet

- Effect of Cracking On Corrosion of Steel in Concrete PDFDocument12 pagesEffect of Cracking On Corrosion of Steel in Concrete PDFSteve NolaNo ratings yet

- Chapter 3 FormworkDocument11 pagesChapter 3 FormworkSue IlaNo ratings yet

- Moment Resisting Wood Post-To-Concrete Peir ConnectionDocument86 pagesMoment Resisting Wood Post-To-Concrete Peir ConnectionFidan DaskalovNo ratings yet

- 14 Comparison of Geotechnic Softwares Geo FEM Plaxis Z-SoilDocument6 pages14 Comparison of Geotechnic Softwares Geo FEM Plaxis Z-SoilWondwosen BelayNo ratings yet

- First Block Casting ProcedureDocument4 pagesFirst Block Casting Procedurealec63636No ratings yet

- Why Steel Reinforcement Is Needed in Concrete SlabsDocument2 pagesWhy Steel Reinforcement Is Needed in Concrete SlabsAuYongTheanSengNo ratings yet

- Masonry Army FM 5-428Document119 pagesMasonry Army FM 5-428calayflorNo ratings yet

- Solid Propellant For MissileDocument51 pagesSolid Propellant For MissileArmando Mateo100% (2)

- Concrete Column FormworkDocument19 pagesConcrete Column FormworkLuke ObusanNo ratings yet

- Use of Expanded Polystyrene in Road EmbankmentsDocument6 pagesUse of Expanded Polystyrene in Road EmbankmentsmikadituNo ratings yet

- Tower Crane Footing Structural Design For All Cranes PDF - CompressDocument14 pagesTower Crane Footing Structural Design For All Cranes PDF - CompressJoséNo ratings yet

- United States Patent (191: WinerDocument5 pagesUnited States Patent (191: WinerwewewewNo ratings yet

- Tek 17-01B PDFDocument4 pagesTek 17-01B PDFJacky LeongNo ratings yet

- Monitoring Methods of Concrete From Early Age Strength Gain of Concrete A ReviewDocument8 pagesMonitoring Methods of Concrete From Early Age Strength Gain of Concrete A ReviewAmit Sharma IPS AcademyNo ratings yet

- Rebuild - Repair and Maintenance Needs of Concrete StructuresDocument20 pagesRebuild - Repair and Maintenance Needs of Concrete StructuresAbhishek NarasimhanNo ratings yet

- Floor Plan LayoutDocument6 pagesFloor Plan Layoutaranetasquare100% (1)

- Layout PlanningDocument26 pagesLayout PlanningArnaldoNo ratings yet

- A146814 PDFDocument82 pagesA146814 PDFvttrlcNo ratings yet

- CBA 2pp Selection Spec Datasheet rnd3Document2 pagesCBA 2pp Selection Spec Datasheet rnd3Ramon FreixesNo ratings yet

- Versatile, Durable and Strong: Fire ResistantDocument41 pagesVersatile, Durable and Strong: Fire ResistantTasneem JraiNo ratings yet

- External Walls: Aggregate Concrete BlocksDocument2 pagesExternal Walls: Aggregate Concrete Blockspmullins_11No ratings yet

- Block WorkDocument16 pagesBlock WorkMzee Boydd Mkaka MwabutwaNo ratings yet

- Bison Beam and BlockDocument8 pagesBison Beam and Blockcolinbooth91No ratings yet

- Ncma Tek: Architectural Concrete Masonry Units Tek 2-3ADocument4 pagesNcma Tek: Architectural Concrete Masonry Units Tek 2-3AjerryNo ratings yet

- Eb8 PDFDocument7 pagesEb8 PDFAndyPalmerNo ratings yet

- 2185 4 2008 Reff2019Document16 pages2185 4 2008 Reff2019Siva GuruNo ratings yet

- Unit Masonry 4.1 General 4.1.1 ScopeDocument5 pagesUnit Masonry 4.1 General 4.1.1 ScopeشاهنوازحيدرNo ratings yet

- Lintels 040115Document3 pagesLintels 040115Syamil DzulfidaNo ratings yet

- Treasury Management CourseDocument10 pagesTreasury Management Coursenick21_347No ratings yet

- 153 InplantcgDocument172 pages153 InplantcgFrancisco CifuentesNo ratings yet

- Devnet Session 1 Intro To Software ProgrammabilityDocument29 pagesDevnet Session 1 Intro To Software ProgrammabilityIgo FernandesNo ratings yet

- KJJGHJFDocument66 pagesKJJGHJFkultardeepNo ratings yet

- Influence Lines For IndeterminateDocument43 pagesInfluence Lines For IndeterminateRaphael KennethNo ratings yet

- Object-Oriented Programming Lab ProblemsDocument6 pagesObject-Oriented Programming Lab ProblemsAnjana MagantiNo ratings yet

- English SolutionDocument90 pagesEnglish SolutionJay100% (1)

- TCM IO520 MaintManualDocument242 pagesTCM IO520 MaintManualleather_nun100% (1)

- Avanged SevenfoldDocument27 pagesAvanged SevenfoldAry WicakNo ratings yet

- Science Quarter 1 Week 3.1: CapsletDocument6 pagesScience Quarter 1 Week 3.1: CapsletWesley M. PerezNo ratings yet

- CN Question Bank Module 1 2Document2 pagesCN Question Bank Module 1 2Sushmitha ChikkamaduNo ratings yet

- CH 11Document12 pagesCH 11Bushra HaqueNo ratings yet

- Service Managament Practices of Fast Food Chain in Cotabato CityDocument37 pagesService Managament Practices of Fast Food Chain in Cotabato CityYara ABNo ratings yet

- PDMS - PIPING Component Naming Rule-EnDocument57 pagesPDMS - PIPING Component Naming Rule-EnHieu MaiNo ratings yet

- q2 - Second Summative Test-Tle He6Document5 pagesq2 - Second Summative Test-Tle He6Cecilia Tolentino100% (3)

- Audio TranDocument2 pagesAudio TranKeval PatelNo ratings yet

- Hannans Quarterly Report 2011 - Q3Document42 pagesHannans Quarterly Report 2011 - Q3Hannans Reward LtdNo ratings yet

- IAD (DV-2010) : USER ManualDocument46 pagesIAD (DV-2010) : USER ManualStein ChenNo ratings yet

- Pharmacy Training ChecklistDocument4 pagesPharmacy Training ChecklistSaul RuizNo ratings yet

- Perbandingan Kinerja Simpang Menggunakan PTV Vistro Dan Mkji Pada Kawasan Perkotaan LumajangDocument11 pagesPerbandingan Kinerja Simpang Menggunakan PTV Vistro Dan Mkji Pada Kawasan Perkotaan Lumajangafif burhanNo ratings yet

- Avishek Recent RecallsDocument43 pagesAvishek Recent RecallsPritam RoyNo ratings yet

- Ciocirlan, C. E. (2017) - Environmental Workplace Behaviors, Definition Matter. Organization & Environment, 30 (1) 51-70Document9 pagesCiocirlan, C. E. (2017) - Environmental Workplace Behaviors, Definition Matter. Organization & Environment, 30 (1) 51-70Ikhmatul Rizkya FitrianiNo ratings yet

- Calculate The Power That Can Be Transmitted Saf...Document4 pagesCalculate The Power That Can Be Transmitted Saf...Muhammad Taimoor0% (1)

- DCT6 EN Test Report PARIAS EN 50131-6.31840Document26 pagesDCT6 EN Test Report PARIAS EN 50131-6.31840interhamNo ratings yet

- WebquizDocument57 pagesWebquizRaman BhullarNo ratings yet

- Compression MemberDocument41 pagesCompression MemberSourav HossainNo ratings yet

- Vestibular Vertigo: Texts: Text ADocument2 pagesVestibular Vertigo: Texts: Text AMihir AnkolaNo ratings yet

- College Application SadikDocument1 pageCollege Application SadikMahfuz AlamNo ratings yet

- Program Name: Master's inDocument19 pagesProgram Name: Master's insureshNo ratings yet