Professional Documents

Culture Documents

Báo cáo robot công nghiệp11111

Báo cáo robot công nghiệp11111

Uploaded by

bongtd08Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Báo cáo robot công nghiệp11111

Báo cáo robot công nghiệp11111

Uploaded by

bongtd08Copyright:

Available Formats

ROBOT MITSUBISHI MELFA RV-2AJ

Bo thiet b Robot MELFA RV-2AJ cua hang Mitsubishi gom Mot canh tay may Main Body. Bo ieu khien CR1-571. Hop ieu khien bang tay Teaching box R28TB. Day cap va cac phu tung thiet b khac i kem Ngon ng lap trnh cho Robot dung ngon ng MELFA-BASIC IV hoac MOVEMASTER COMMANDS. S dung phan mem COSIMIR e giao tiep Robot vi may tnh, lap trnh ieu khien va

A.PHAN CNG CUA ROBOT MITSUBISHI RV-2AJ

I.CANH TAY ROBOT MITSUBISHI RV-2AJ

Thong so ky thuat cua canh tay may Cau truc ben trong cua cac truc

Cac ngo vao / ra tren canh tay may

S o he thong ien va kh nen cua canh tay Robot

Thong so ky thuat cua canh tay may

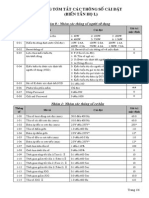

Tham so Loai tay may So bac t do Lap at Cau truc He thong lai Cong suat ong c cac truc n v Thong so ky thuat. RV-2AJ 5 Lap at tren san hay treo tren tng Thang ng, loai co nhieu khp noi ong c AC servo Truc J1 (truc Waist): phanh ham). Truc J2 (truc Shouder): phanh ham). Truc J3 (truc Elbow): phanh ham). Truc J5 (truc Pitch): phanh ham). 50W (co 50W (co 50W (co 15W (co

Thong so ky thuat cua canh tay may o dai canh tay Upper arm Fore arm Co tay (Wrist) mm 250 160 72

Tam hoat ong

Truc J1 Truc J2 Truc J3 Truc J5 Truc J6

300 (-150 en +150) 180 (-60 en +120)

Toc o

Truc J1 Truc J2

230 (-110 en +120) 180 (-90 en +90) 400 (-200 en +200) o/ 180 s 90

Thong so ky thuat cua canh tay may

Tong van toc toi a Tai cc ai tot nhat Sai so lap lai ong tac Nhiet o xung quanh Khoi lng Moment Truc J5 tai cho Truc J6 phep Quan tnh cho phep Truc J5 Truc J6 mm 410 4 tn hieu ngo vao (phan ban tay), 4 tn hieu ngo ra (phan e), ngo ra cho tay gap c kh (phan ban tay). mm/s kg mm o C

N.m

Xap x 2100 mm/s. 2 1.5 0.02 mm 0 - 40 Xap x 17 kg. 2.16 1.10

Ban knh canh tay co the vn ti He thong day ien cua dung cu

Thong so ky thuat cua canh tay may

S o canh tay Robot

Cau truc ben trong cua cac truc

Cau truc ben trong cua cac truc

Cau truc ben trong cua cac truc

S o bo tr ong c cac truc trong canh tay Robot

Cac ngo vao / ra tren canh tay may

S o he thong ien va kh nen cua canh tay Robot

II.THANH PHAN CUA TAY MAY

Cap may Bo van Solenoid Cap au vao

Ong xoan Bo tay ieu khien bang kep kh

Bo ket noi ham kep

Cap may

c thay oi tuy theo tieu chuan cua cap may, co o phu tung e m rong khoang cach gia bo ieu khien va tay may ac iem ky thuat cua cap: + Ban knh uon cong toi thieu: 100 lan ban knh cap hay hn. + Toc o truyen toi a: 2000 mm/s hay t hn. + Thi gian hoat ong: 7,5 trieu lan truyen. + Chong lai tac ong cua moi trng: vo boc chong tac ong cua dau

Cap may va ket noi

Bo van Solenoid

ac iem ky thuat cua van: + So v tr: 2. + Port: 5 + Chc nang van: 2 bo solenoid. + Chat long hoat ong: khong kh sach. + Phng phap hoat ong: loai co ng dan. + Vung mat cat co hieu qua: 1.5mm. + Day ap suat hoat ong: 0.2 0.7MPa. + Ap suat co the chu c: 1.0MPa hay hn. + Thi gian hoi ap: 12ms hay nhanh hn. + Tan so hoat ong toi a: 5 c/s. + Nhiet o moi trng xung quanh: -50C en 500C

Bo van Solenoid

ac iem ky thuat cua cuon Solenoid: + Phng phap hoat ong: gan lien diode fly wheel vi bao ve tran. + ien ap hoat ong: 24VDC 10%. + Gia tr dong ien: 40mA. + S cach ien: loai B. + ien tr cach ien: 100M hay hn. + Bao ve tran: dung diode fly wheel

Bo van Solenoid

Bo van Solenoid

Cap au vao Cap au vao: c dung e ngi s dung thiet ke cho tay gap kh nen. ac iem ky thuat: + Kch thc x so loi cap: 0.02 mm2 x 8 loi. + Tong chieu dai: 370mm (bao gom oan xoan 150mm).

Ong xoan

Ong xoan: dung cho tay gap ieu khien bang kh nen. ac iem ky thuat: + Vat lieu: Urethane. + Kch thc: ng knh ngoai 4 x ng knh trong 2.5

Bo tay ieu khien bang kep kh

Bo tay gap ieu khien bang kh nen Kieu: 4A-HP01E (source type) Tay gap kh nen va cac bo phan khac cua no tao thanh mot bo. Tay gap co thi gian song la 10 trieu chu ky. Co cam bien tai iem cuoi cua trang thai m / ong.

Bo tay ieu khien bang kep kh

ac iem ky thuat:

Chat long hoat ong: khong kh sach. Pham vi ap suat hoat ong: 0.04MPa en 0.7 MPa. Pham vi nhiet o hoat ong: 00C en 400C. Thi hoat ong: 10 trieu chu ky. Phng phap hoat ong: tac ong kep. Khoi lng: 0.45 kg (bao gom ca adapter). Cam ben xac nhan trang thai ong / m: dung bien ong va bien m. Kch thc ong kh: 4 (ng knh ong noi). Tai cc ai cho ngon tay (khi lap at cac phu tung cho ngon tay, tranh va cham hay moment tha cho au mut ngon tay).

+ + + +

Radial: 700N Mpo moment: 6.2 N.m Mro moment : 10.8 N.m Myo moment : 6.0 N.m

Bo tay ieu khien bang kep kh

Bo tay ieu khien bang kep kh

Cac thanh phan trong bo tay gap kh nen: + Tay gap kh nen: 1A - HP01 + Cap xoan tay gap: 1A ST0402C + Cap xoan: 1A - HP01E + Be mat tay may ieu khien bang kh nen: 2A RZ365 + 2A RZ375 + Bo van solenoid: 1E VD01 + 1E VD01E + Adapter: 1A HA01

Bo ket noi ham kep

Kieu: 1A HA01 ac iem ky thuat: Khoi lng: 0.07 kg Vat lieu: hp kim nhom Thanh phan: Adapter: BUI164D1693H01 Lo lap at: M3 x 8

III.THIET B IEU KHIEN

Thiet b ieu khien bao gom bo ieu khien CR1-571 va hop ieu khien bang tay Teaching pendant (T/B) R28TB, s dung ngon ng Movemaster Command va MELFA-BASIC IV e lap trnh ieu khien

Tham so Loai So truc ieu khien CPU Dung V tr lap lng trnh bo nhSo bc

n v iem Bc

Thong so ky thuat CR1 571 ieu khien ong thi toi a la 6 truc 64 bit RISC, va DSP 2500 5000

So chng trnh Ngon ng lap trnh

88 MELFA BASIC IV hay MOVEMASTER COMMAND

Bo ieu khien CR1-571

Phng phap day Cac Ngo vao / ngo ra vao / Ngo vao / ra ra chuyen ben dung ngoai Ngo vao / ra ong m tay gap Ngo vao nut dng khan cap Ngo vao cong tac ca iem iem Phng phap day t the 16 / 16 c an nh vi ngo vao / ra chung. (STOP la 1 iem c ket noi trc) 0 iem vao va 4 iem ra.

iem

iem iem

1 (ng truyen khan cap n) 1 (cong tac ca n)

Bo ieu khien CR1-571

Nguon Mc cap ien ap au vao Cong suat Kch thc ben ngoai Khoi lng Cau truc Nhiet o hoat ong o am xung quanh S tiep at Mau V 1 pha AC: 90 132V 1 pha AC:180 230 V

KVA mm

0.7 212(W) x 290(D) x 151(H) (gom nhng v tr nho ra) 8 Loai oc lap tren san, kieu m 0 en 40 45 en 85 (khong co sng) 100 hay t hn xam trang

kg

%RH

Bo ieu khien CR1-571

Bo ieu khien CR1-571

1.Cong tac nguon: Bat / tat nguon. 2.Nut nhan START: Thc thi chng trnh va Robot hoat ong. 3.Nut nhan STOP: Dng Robot ngay lap tc. Servo khong tat. 4.Nut nhan RESET: Reset loi. No cung reset chng trnh b tam dng va reset lai chng trnh. 5.Nut tat khan cap: Dng Robot trong tnh trang khan cap. Servo tat. 6.Cong tat thao T / B: c s dung e ket noi hay khong ket T / B ma khong tat nguon cua bo ieu khien. 7.Nut CHNGDISP: Thay oi nhng tham so chi tiet c hien th tren man hnh hien th theo th t: van toc so th t chng trnh so th t dong lenh.

Bo ieu khien CR1-571

8.Nut END: Dng chng trnh ang c thc hien tai dong lenh cuoi cung hay cau lenh END. 9.Nut SVO.ON: Bat nguon servo. 10.Nut SVO.OFF: Tat nguon servo. 11.STATUS NUMBER: Hien th so th t loi, chng trnh, van toc, dong lenh 12.T / B connection connector: Ngo vao e ket noi vi bo ieu khien T/ B. 13.Persional computer connection connector: Ngo ket noi RS 232C, e ket noi vi may tnh ca nhan. 14.MODE key Switch: Cong tac thay oi che o hoat ong cua Robot. AUTO (Op): Ch cho phep thao tac tren bo ieu khien. TEACH: Ch cho phep thao tac t bo T / B. AUTO (Ext): Ch cho phep ieu khien bang cac thiet b ben ngoai. 15.Nut UP / DOWN: Cuon len hay cuon xuong cac tham so chi tiet c hien th tren STATUS NUMBER cua

Bo ieu khien CR1-571

1.Ngo noi cap may (dung cho nguon ong c, cong CN1). 2.Ngo noi cap may (dung cho tn hieu ong c, cong CN2). 3.Cong cap nguon. 4.Hop cau ch. 5.Cong ket noi tn hieu vao / ra ben ngoai. 6.Ngo ket noi cap mang cho n v vao / ra song song m rong. 7.au ket noi cong tac dng khan cap

M a t s a u -57 o1 i e u k h b

Teaching box R28TB

Thong so ky thuat: + Kch thc bao ngoai: 95(W) x 236(H) x 34(D) + Mau: Xam trang. + Khoi lng: Xap x 0.5kg. + Phng thc ket noi: Ket noi vi bo ieu khien theo chuan RS-422. + Cach trnh bay: Phng phap LCD (16 ky t x 4 dong). + Phan ieu khien: 28 phm. + Phan bao ve: Chuan IP65.

Teaching box R28TB

Teaching box R28TB

Teaching box R28TB

1.Cong tac [EMG.STOP]: Nut nhan dng khan cap. Khi nut EMG.STOP c nhan servo se bat sang che o OFF va Robot dng ngay lap tc bat ke trang thai Enable / Disable cua bo ieu khien T/B. e huy trang thai nay th xoay cong tac theo chieu kim ong ho. 2.Cong tac [ENABLE/DISABLE]: co tac dung cho phep hay khong cho phep cac phm tren bo T/B hoat ong. e s dung bo T/B ieu khien hoat ong cua Robot cong tac [ENABLE / DISABLE] phai c e che o ENABLE. 3.Man hnh hien th _ LCD: hien th chng trnh va trang thai Robot vi hoat ong cua cac phm tren bo T/B.

Teaching box R28TB

6. Phm [STOP]: dng chng trnh va giam hoat ong cua canh tay Robot en khi dng, tng t phm STOP tren bo ieu khien, co the dung khi T/B che o DISABLE. 7. Phm [STEP/MOVE]: Nhan phm nay va nhan cac phm ieu khien di chuyen 12) e co the thc hien thao tac di chuyen. Bc nhay se c thc thi khi nhan ong thi vi phm [INP/EXE]. Ngoai ra phm nay cung bat servo ON. 8. Phm [+/FORWD]: Bc ke c thc hien khi nhan ong thi vi phm [INP/EXE]. Tren man hnh soan thao, dong lenh chng trnh tiep theo c hien th. Con khi nhan ong thi vi phm [STEP/MOVE] toc o di chuyen cua Robot se tang len. 9. Phm [-/BACKWD]: Tren man hnh soan thao, dong lenh chng trnh trc o c hien th.

e viet chng trnh ieu khien Robot hoat ong ta co the dung 2 loai ngon ng MOVERMASTER COMMAND va MELFA BASIC IV

B. NGON NG LAP TRNH MOVERMASTER COMMAND

Hng dan lap trnh bang bo Teaching Pendant T/B

Thao bo T/B vi nguon ieu khien ON Bat cong tac [ENABLE / DISABLE] tren T/B sang DIASABLE. Nhan cong tac [REMOVE T/B] tren Controller. Gi au noi T/B mot cach chac chan va xoay ve pha trai cho en khi no ri ra. Lay au noi ra trong khoang 5 giay sau khi LED bat au chp. LED cua cong tac se tat khi cong viec a hoan thanh.

Hng dan lap trnh bang bo Teaching Pendant T/B

Hng dan lap trnh bang bo Teaching Pendant T/B

Lap at bo T/B vi nguon ieu khien ON Bat cong tac [ENABLE / DISABLE] tren T/B sang DIASABLE. Ket noi au noi bo T/B. LED cua cong tac bat au chp. Nhan cong tac [REMOVE T/B] tren Controller trong khoang 5 giay sau khi lap at bo T/B. LED cua cong tac se sang khi cong viec hoan thanh.

Hng dan lap trnh bang bo Teaching Pendant T/B

Cac phng thc di chuyen

Phng thc Di chuyen khp (JOINT JOG) Di chuyen XYZ (XYZ JOG) Di chuyen dung cu (TOOL JOG) ng dung chnh Di chuyen tng khp. Di chuyen tay may mc o ln. Thay oi the cua Robot. Tm v tr day chnh xac. Di chuyen truc thang theo he toa o XYZ (he toa o gan e Robot). Di chuyen thang ma van gi the cua Robot. Thay oi the trong khi van duy tr v tr ban tay. Tm v tr day chnh xac. Di chuyen truc thang theo hng ban tay (theo he toa o gan ban tay). Thay oi the trong khi van duy tr v tr ban tay. Quay ban tay trong khi van duy tr v tr ban tay.

Hng dan lap trnh bang bo Teaching Pendant T/B

Cach ong m tay gap e m tay gap: nhan phm [ HAND] + [ +C (J6) ]. e ong tay gap: nhan phm [ HAND ] + [ -C (J6) ].

You might also like

- Bai Giang May Phay VMC 650 SPKTDocument45 pagesBai Giang May Phay VMC 650 SPKTDuc Thang LeNo ratings yet

- Cpu Design-2Document15 pagesCpu Design-2Nguyễn HàoNo ratings yet

- Thuyet minh-M&E-Tan Tao Lo ADocument29 pagesThuyet minh-M&E-Tan Tao Lo Alinh vănNo ratings yet

- Hướng Dẫn Sử Dụng Biến Tần Delta VFD - LDocument6 pagesHướng Dẫn Sử Dụng Biến Tần Delta VFD - LPhong TrongNo ratings yet

- May Dien 2Document66 pagesMay Dien 2Phú NguyễnNo ratings yet

- Sách hướng dẫn bảo trì xe Future 125 (chương 1 - 1)Document20 pagesSách hướng dẫn bảo trì xe Future 125 (chương 1 - 1)Lê Ngọc PhốNo ratings yet

- Tai Lieu Tra Cuu Nhanh SJ700-TV-New2008Document64 pagesTai Lieu Tra Cuu Nhanh SJ700-TV-New2008Cơ Hương NguyễnNo ratings yet

- 08 BanhxevavoxeDocument32 pages08 BanhxevavoxeTrần MạnhNo ratings yet

- Bé Biõn TÇN Cpi I-Giíi Thiöu ChungDocument9 pagesBé Biõn TÇN Cpi I-Giíi Thiöu ChungVũ Đình HòaNo ratings yet

- 8 - Chat Boi Tron, Luu ChatDocument5 pages8 - Chat Boi Tron, Luu ChatqtyvtcdhrvNo ratings yet

- Tien FanucDocument69 pagesTien FanucheoxinhsieudethuongNo ratings yet

- Chu Trinh Gia CongDocument73 pagesChu Trinh Gia CongThanh NgoNo ratings yet

- Lap Trinh Hipath 3000Document41 pagesLap Trinh Hipath 3000Nguyễn SơnNo ratings yet

- TCVN Iso 10555-1 - 1995Document19 pagesTCVN Iso 10555-1 - 1995nlongsisvnNo ratings yet

- TCVN 6447 - 1998Document23 pagesTCVN 6447 - 1998CHANH NGUYENNo ratings yet

- CH03 Ô tô cẩuDocument10 pagesCH03 Ô tô cẩuHà Đẹp zaiNo ratings yet

- Máy Điện TimDocument53 pagesMáy Điện TimTan BuiNo ratings yet

- Hanyoung Nux Tai Lieu Huong Dan Cai Dat Dong Ho nx9Document3 pagesHanyoung Nux Tai Lieu Huong Dan Cai Dat Dong Ho nx9Hau NguyenNo ratings yet

- Thuyet Minh (REV.1)Document10 pagesThuyet Minh (REV.1)Minh Đinh HoàngNo ratings yet

- DiendongcoDocument286 pagesDiendongcoapi-299147036No ratings yet

- HT Treo Khi DTDocument125 pagesHT Treo Khi DT21145324No ratings yet

- Tìm hiểu máy xét nghiệm sinh hóa Hitachi 704Document20 pagesTìm hiểu máy xét nghiệm sinh hóa Hitachi 704Tran Trong NghiaNo ratings yet

- Đồ Án Thiết Kế Cầu Bê Tông Cốt Thép Dự Ứng Lực L=28mDocument40 pagesĐồ Án Thiết Kế Cầu Bê Tông Cốt Thép Dự Ứng Lực L=28mTieu Ngoc LyNo ratings yet

- 2 elcoring-VNDocument25 pages2 elcoring-VNSói CaNo ratings yet

- Huong Dan Su Dung Bien Tan SiemensDocument45 pagesHuong Dan Su Dung Bien Tan SiemensHanami Nui ThanhNo ratings yet

- Ren-MoiGhepRenDocument11 pagesRen-MoiGhepRenHung QuangNo ratings yet

- TM Ong ConDocument25 pagesTM Ong ConNguyễn Minh ĐứcNo ratings yet

- Báo cáo Môn TH KHUNG GẦMDocument60 pagesBáo cáo Môn TH KHUNG GẦMngconghau113445No ratings yet

- Kien Thuc Co Ban Ve Sua Chua o To - ISUZUDocument77 pagesKien Thuc Co Ban Ve Sua Chua o To - ISUZUBảo Toàn LêNo ratings yet

- GIÁO TRÌNH - Trang bị điện điện tử trên động cơ đốt trong (Phạm Văn Kiêm)Document73 pagesGIÁO TRÌNH - Trang bị điện điện tử trên động cơ đốt trong (Phạm Văn Kiêm)Hiếu PhanNo ratings yet

- catalogue samwha tiếng việt PDFDocument13 pagescatalogue samwha tiếng việt PDFĐào Duy PhướcNo ratings yet

- Mitsubishi Jolie EWD (VN)Document196 pagesMitsubishi Jolie EWD (VN)Duc TrongNo ratings yet

- 4 Treo khí điện tử.TOYOTA VÀ TREO KHÍpdfDocument49 pages4 Treo khí điện tử.TOYOTA VÀ TREO KHÍpdfvtu9046No ratings yet

- Huong - Dan - Dô Án CTMDocument14 pagesHuong - Dan - Dô Án CTMdddlyNo ratings yet

- May Han Va May Do OTDRDocument35 pagesMay Han Va May Do OTDRtrantrungnghia100% (1)

- HDSD Geomax Zip10proDocument10 pagesHDSD Geomax Zip10proThắng NguyễnNo ratings yet

- Chuong 5Document50 pagesChuong 5Kael The InvokerNo ratings yet

- HDSD Maybod2Document4 pagesHDSD Maybod2ta quang khanhNo ratings yet

- HDSD DST 4400Document22 pagesHDSD DST 4400Danh TrầnNo ratings yet

- TLieu TapHuan RecloserDocument61 pagesTLieu TapHuan RecloserGò Đào Xóm NhỏNo ratings yet

- 1.2.TEMS1 (Compatibility Mode)Document54 pages1.2.TEMS1 (Compatibility Mode)Shorlly NamNo ratings yet

- So Tay Vo Tau Thuy HVSDocument39 pagesSo Tay Vo Tau Thuy HVSbluedawn08ktttNo ratings yet

- TCVN 6016 1995 (IZO 679 - 89 (E) ) - Xi Mang PP Thu Xac Dinh Do BenDocument19 pagesTCVN 6016 1995 (IZO 679 - 89 (E) ) - Xi Mang PP Thu Xac Dinh Do BenVăn Long NguyễnNo ratings yet

- Dieu Hoa Nhiet Do Mitsubishi SRK 2005Document43 pagesDieu Hoa Nhiet Do Mitsubishi SRK 2005sunhuynhNo ratings yet

- Điện tử công suất 2-Nguyễn Văn NhờDocument100 pagesĐiện tử công suất 2-Nguyễn Văn NhờKhoa TrầnNo ratings yet

- Ung Dung Mastercam Lap Trinh Gia CongDocument13 pagesUng Dung Mastercam Lap Trinh Gia CongThanh NgoNo ratings yet

- Gây Mê Cấp Cứu BN CTSNDocument9 pagesGây Mê Cấp Cứu BN CTSNRùa’s Anesthesia HanoiNo ratings yet

- Hướng dẫn lập trình CNC of NCDocument21 pagesHướng dẫn lập trình CNC of NCchuthoong010No ratings yet

- Trang 90104chuong 11 ELwZd 20130517043143Document14 pagesTrang 90104chuong 11 ELwZd 20130517043143XUÂN THIÊNNo ratings yet

- Thuyet Minh KC TM4-Mau M4Document175 pagesThuyet Minh KC TM4-Mau M4tung ngoNo ratings yet

- 22 TCN 336-06Document7 pages22 TCN 336-06Thanh Dao BaNo ratings yet

- Cnc7 Lap Trinh Tien CNC Fanuc 1496Document71 pagesCnc7 Lap Trinh Tien CNC Fanuc 1496Reiko SakurakoNo ratings yet

- GT Colour TV JVC 1 8966Document7 pagesGT Colour TV JVC 1 8966lizhi0007No ratings yet

- Giao Trinh Dong CoDocument366 pagesGiao Trinh Dong CoĐức NguyễnNo ratings yet

- Bảng tra mã lỗi máy photo ToshibaDocument70 pagesBảng tra mã lỗi máy photo ToshibaKẻ Lãng DuNo ratings yet

- THUCHANH - DTCB 135 Tiet Chinh Lai - TuMinhDocument84 pagesTHUCHANH - DTCB 135 Tiet Chinh Lai - TuMinhNguyen HaNo ratings yet