Professional Documents

Culture Documents

Hot Work Inspection Check List: Area: Location

Uploaded by

Deepak NallendranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Work Inspection Check List: Area: Location

Uploaded by

Deepak NallendranCopyright:

Available Formats

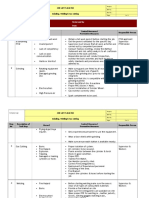

HOT WORK INSPE

AREA: S.No I 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 II 1 2 3 4 5 6 7 8 9 10 11 III 1 2 3 4 5 6 LOCATION: Description WELDING CHECKLIST Verify the power supply is from nearest point? Ensure the supply been protected by ELCB? Check the cable routed properly & healthy? Verify the welding machine on / off switch is working? Ensure the machine is earthed properly? Check the supply and return cable connected by lug? check the cable conditions are good Ensure the welding holders & return holder is good Check all the combustible material near by is removed Check the welder is approved by contractor Ensure the welding shield, gloves & aprons worn by welder Check all the welding spent rods are stored away Check the welding rays shield provided to protect nearby Check for dry chemical fire extinguisher near by Check one fire watch with red jacket at site. GAS CUTTING CHECKLIST Check both the cylinders are stored on trolley? Verify the cylinders pressure gauge and valve in place Check flash back arrestors at cylinder & upstream of torch Check the gas hoses are free from defects / damages Check both cylinders stored vertical & secured Ensure oxygen cylinder free from oil, grease etc Check the cylinders are in well ventilated and shaded area Check cylinder valve on/off wrench available at site Verify PPE such as goggle, gloves, apron, helmet, shoes. Check for dry chemical fire extinguisher near by Check one fire watch with red jacket at site. CYLINDER STORAGE Check oxygen & acetylene is stored in 6 m distance Verify Full & Empty cylinders stored separate Check the storage is shaded and well ventilated Verify two fire extinguishers in each shed Check No Smoking sign in place near the storage Check the display of MSDS of cylinders stored. OK

Inspected By: Safety Officer

Reviewed By:

HOT WORK INSPECTION CHECK LIST

DATE: NOT OK NA REMARKS

Engineer/supervisior

You might also like

- PRESPUD CHECKLISTDocument8 pagesPRESPUD CHECKLISTAgus Alexandri100% (2)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingQomarudin Comenk100% (2)

- Safety IN LPG Storage, Bottling & TransportationDocument28 pagesSafety IN LPG Storage, Bottling & TransportationkavehNo ratings yet

- All ChecklistDocument31 pagesAll Checklistsunil KumarSwainNo ratings yet

- Construction Safety Guidelines No. 11b Gas Welding & CuttingDocument1 pageConstruction Safety Guidelines No. 11b Gas Welding & CuttingJuju FernsNo ratings yet

- Welding safety checklistDocument1 pageWelding safety checklistMuhd Khir RazaniNo ratings yet

- SWM For Welding and Gas CuttingDocument2 pagesSWM For Welding and Gas CuttingdsttangaNo ratings yet

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRana Waseem Khan82% (79)

- Safe Welding TrainingDocument13 pagesSafe Welding TrainingMartine OtienoNo ratings yet

- Reference 1 PDFDocument10 pagesReference 1 PDFJanicka Palencia AgaNo ratings yet

- EHS PPE and Gas Leakage ProceduresDocument6 pagesEHS PPE and Gas Leakage ProceduresSharif KhanNo ratings yet

- GN8 Oxy-Fuel Gas Daily Checklist1a1Document1 pageGN8 Oxy-Fuel Gas Daily Checklist1a1sanketpavi21No ratings yet

- Lava Heat Italia - Ember Mini Patio Heater - Owners ManualDocument18 pagesLava Heat Italia - Ember Mini Patio Heater - Owners ManuallavaheatitaliaNo ratings yet

- GL 15 Air ReceiversDocument1 pageGL 15 Air Receiverstp101267No ratings yet

- CGA Safety Checklist for Compressed Gas CylindersDocument4 pagesCGA Safety Checklist for Compressed Gas CylindersKhairul AmilinNo ratings yet

- CGC SafetyDocument9 pagesCGC SafetySOLY_POP_10No ratings yet

- Method Statement For Refrigerant Piping Installation and Pressure TestingDocument3 pagesMethod Statement For Refrigerant Piping Installation and Pressure TestingDong Vanra100% (1)

- Owners Service Manual NO. 05602 Installation, Operating & Servicing InstructionsDocument10 pagesOwners Service Manual NO. 05602 Installation, Operating & Servicing Instructionsrommel76No ratings yet

- HVAC Refrigerant Piping Installation MOSDocument4 pagesHVAC Refrigerant Piping Installation MOSanwer_210No ratings yet

- Owners Service Manual NO. 05618: Installation, Operating & Servicing Instructions ForDocument8 pagesOwners Service Manual NO. 05618: Installation, Operating & Servicing Instructions ForNego1975No ratings yet

- Suburban Furnace NT-16SE NT-20SEDocument8 pagesSuburban Furnace NT-16SE NT-20SEJack SheaNo ratings yet

- Compressed Gas Cylinders Safety ChecklistDocument4 pagesCompressed Gas Cylinders Safety Checklistfathul syaafNo ratings yet

- 50 100 LB Carbon Dioxide Wheeled Extinguishers E77fc9faDocument6 pages50 100 LB Carbon Dioxide Wheeled Extinguishers E77fc9faEra ErmerraNo ratings yet

- Electrical Installation Inspection ReportDocument16 pagesElectrical Installation Inspection ReportAnkit VyasNo ratings yet

- Welding Safety TrainingDocument23 pagesWelding Safety TrainingTinna Puspita Marita SariNo ratings yet

- Auscrown Ring Burners July15Document7 pagesAuscrown Ring Burners July15Elbin Antonio EspinalNo ratings yet

- Method Statement For Refrigerant Piping Installation and Pressure TestingDocument4 pagesMethod Statement For Refrigerant Piping Installation and Pressure TestingRyan WongNo ratings yet

- Standard Operating Procedures: Prepared By: Approved By: Date: Department: Page NoDocument2 pagesStandard Operating Procedures: Prepared By: Approved By: Date: Department: Page NovictorNo ratings yet

- Safety ProceduresDocument17 pagesSafety ProceduresBhupender RamchandaniNo ratings yet

- High Impact Welding SafetyDocument10 pagesHigh Impact Welding SafetyZulkifly HassanNo ratings yet

- Dayva Premier Natural Gas Patio Heater Owners ManualDocument19 pagesDayva Premier Natural Gas Patio Heater Owners ManuallamanepalNo ratings yet

- 01.metron UK - SOP For Welding and CutingDocument2 pages01.metron UK - SOP For Welding and CutingSAMUEL EDUKU ERZUAH NYAMEKEH BAIDOONo ratings yet

- High-Pressure Boiler Inspection Procedures: A Complete ChecklistDocument6 pagesHigh-Pressure Boiler Inspection Procedures: A Complete ChecklistROHITNo ratings yet

- Oxy Acetylene Cutting TorchDocument2 pagesOxy Acetylene Cutting TorchChristian Makande100% (1)

- Takudzwa M. Mteliso Support Rig Drilling and InstallationDocument14 pagesTakudzwa M. Mteliso Support Rig Drilling and InstallationTakudzwa MtelisoNo ratings yet

- MDDE Dryer ManualDocument87 pagesMDDE Dryer ManualQuang Bách100% (2)

- #1 Welding SafetyDocument78 pages#1 Welding SafetyHakim Yahiaoui100% (1)

- Checklist of Rig EquipmentDocument11 pagesChecklist of Rig EquipmentKachur AlekseyNo ratings yet

- Compressed Gas Cylinder SafetyDocument36 pagesCompressed Gas Cylinder Safetyelvis hidalgoNo ratings yet

- Inspect Fire Extinguishers & Hoses Under 40 CharactersDocument2 pagesInspect Fire Extinguishers & Hoses Under 40 CharactersRafael Da Rosa SiqueiraNo ratings yet

- Sec A Maintenance PractiseDocument29 pagesSec A Maintenance PractiseNurul HisyamNo ratings yet

- How To Do Mechanical WalkthroughDocument6 pagesHow To Do Mechanical WalkthroughPulung Dwi AnggoroNo ratings yet

- Welding and Cutting ProcedureDocument5 pagesWelding and Cutting ProcedureRoger SimbhooNo ratings yet

- Compressed Gas Cylinder SafetyDocument35 pagesCompressed Gas Cylinder SafetyAnonymous i3lI9MNo ratings yet

- (Open Front Cooler) : User Manual Manual de UsuarioDocument16 pages(Open Front Cooler) : User Manual Manual de UsuarioNINo ratings yet

- Manual For Hand Portable Halon 1211 ExtinguishersDocument8 pagesManual For Hand Portable Halon 1211 ExtinguishersMatthew ShalkNo ratings yet

- Safety in Work Place Safety in WeldingDocument25 pagesSafety in Work Place Safety in WeldingRahul SiwakotiNo ratings yet

- Work Permit Conditions and Firewatch DutiesDocument40 pagesWork Permit Conditions and Firewatch DutiesClarissa Edwards75% (4)

- EHS Moment - Compressed Gases - Inspection of Gas Cylinder - 12 Oct 23Document2 pagesEHS Moment - Compressed Gases - Inspection of Gas Cylinder - 12 Oct 23sanalkumar24No ratings yet

- Compressed Gas SafetyDocument54 pagesCompressed Gas SafetyHerwan SantosoNo ratings yet

- Compressed Gas Safety: East Carolina University Training ProgramDocument18 pagesCompressed Gas Safety: East Carolina University Training ProgramMusharaf ShahNo ratings yet

- Compressed GasDocument3 pagesCompressed GassherinNo ratings yet

- N2-MSDS (Energas)Document3 pagesN2-MSDS (Energas)haranus2000No ratings yet

- Portatil AmerexDocument8 pagesPortatil AmerexGrillin GmNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Ultimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsFrom EverandUltimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsRating: 3 out of 5 stars3/5 (8)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Welder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamFrom EverandWelder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamNo ratings yet

- Ultimate Guide: Wiring, 8th Updated EditionFrom EverandUltimate Guide: Wiring, 8th Updated EditionRating: 3.5 out of 5 stars3.5/5 (4)

- Monthly Review - BTG Centre & Site MeetingDocument14 pagesMonthly Review - BTG Centre & Site MeetingDeepak NallendranNo ratings yet

- IBTPL Safety Day EventsDocument3 pagesIBTPL Safety Day EventsDeepak NallendranNo ratings yet

- Online EN 120307 Napo Teachers Lesson3 pt1 HW PDFDocument9 pagesOnline EN 120307 Napo Teachers Lesson3 pt1 HW PDFDeepak NallendranNo ratings yet

- Annual Safety Budget OpgDocument1 pageAnnual Safety Budget OpgDeepak NallendranNo ratings yet

- 2.5.2.1 Environmental Aspects and Impacts - Oct-09 - Issue 2Document4 pages2.5.2.1 Environmental Aspects and Impacts - Oct-09 - Issue 2Deepak NallendranNo ratings yet

- RRT LH: Gt'R:Ut (TLDocument75 pagesRRT LH: Gt'R:Ut (TLkl equipmentNo ratings yet

- 4684Document2 pages4684Harish Kumar M0% (1)

- Nord Stage Factory Patches v3 v4 v5Document18 pagesNord Stage Factory Patches v3 v4 v5Danilo Giuliani DobermannNo ratings yet

- Keto Food List for BodybuildingDocument8 pagesKeto Food List for Bodybuildingharris81No ratings yet

- New Translation and Deciphering of ChineDocument14 pagesNew Translation and Deciphering of ChineRémyNo ratings yet

- Thermo Safety Cabinets MSC-Advantage - User ManualDocument53 pagesThermo Safety Cabinets MSC-Advantage - User ManualAhmed SalamaNo ratings yet

- Maam Approve Na Pls HuhuDocument28 pagesMaam Approve Na Pls HuhuErica Joy Escopete100% (1)

- COSMETOLOGY-9 Q1 W3 Mod2Document15 pagesCOSMETOLOGY-9 Q1 W3 Mod2Christian Elliot DuatinNo ratings yet

- Lab Practice # 01 An Introduction To MatlabDocument10 pagesLab Practice # 01 An Introduction To MatlabGhulam Abbas LashariNo ratings yet

- My CV - Rose ChebetDocument5 pagesMy CV - Rose ChebetSammy WatimaNo ratings yet

- Manjit Thapp ResearchDocument24 pagesManjit Thapp ResearchDough RodasNo ratings yet

- S7 - Q2 - Answer KeyDocument11 pagesS7 - Q2 - Answer KeyRaniel LacuarinNo ratings yet

- Jurnal Mira FixDocument16 pagesJurnal Mira Fixarisanto micoNo ratings yet

- The Control of Building Motion by Friction Dampers: Cedric MARSHDocument6 pagesThe Control of Building Motion by Friction Dampers: Cedric MARSHAlam Mohammad Parvez SaifiNo ratings yet

- HORIZONTAL DISTRIBUTION OF FORCES - Part 1-2Document1 pageHORIZONTAL DISTRIBUTION OF FORCES - Part 1-2Inna PotesNo ratings yet

- Living Together TestDocument2 pagesLiving Together TestProfu' de biologieNo ratings yet

- Sony STR Da80esDocument66 pagesSony STR Da80estelstarservicesNo ratings yet

- MMC Fiori Cheat Sheet PDFDocument2 pagesMMC Fiori Cheat Sheet PDFAleksandar KNo ratings yet

- Haloalkanes and Haloarenes Notes GoodDocument21 pagesHaloalkanes and Haloarenes Notes GoodAnitesh DharamNo ratings yet

- Goethe Zertifikat b1 HorenDocument2 pagesGoethe Zertifikat b1 HorenLevent75% (4)

- 6.4 Permutations and CombinationsDocument14 pages6.4 Permutations and CombinationsAns SembiringNo ratings yet

- Sapamine CSN Textile Softener: Technical Data SheetDocument5 pagesSapamine CSN Textile Softener: Technical Data SheetsaskoNo ratings yet

- Price Action - Japanese Candlestick Patterns SheetDocument4 pagesPrice Action - Japanese Candlestick Patterns SheetVicaas VSNo ratings yet

- TL 496 DatasheetDocument7 pagesTL 496 DatasheetAnonymous vKD3FG6RkNo ratings yet

- Chapter 9: Operating SystemsDocument166 pagesChapter 9: Operating SystemsGazzzeeNo ratings yet

- S1.4.5.) Datasheet PRESSURE GAUGEDocument3 pagesS1.4.5.) Datasheet PRESSURE GAUGEEkoNo ratings yet

- How To Critique A Photograph - Facebook PDFDocument1 pageHow To Critique A Photograph - Facebook PDFpeterNo ratings yet

- Examining The Structural Relationships of Destination Image, Tourist Satisfaction PDFDocument13 pagesExamining The Structural Relationships of Destination Image, Tourist Satisfaction PDFAndreea JecuNo ratings yet

- Boston Globe Article - Jonnie Williams & Frank O'DonnellDocument3 pagesBoston Globe Article - Jonnie Williams & Frank O'DonnellFuzzy PandaNo ratings yet

- Feasibility in Ergonomics AutosavedDocument63 pagesFeasibility in Ergonomics AutosavedMichael AsinguaNo ratings yet