Professional Documents

Culture Documents

Warehouse Risk Analysis

Uploaded by

a1an_wongOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Warehouse Risk Analysis

Uploaded by

a1an_wongCopyright:

Available Formats

Health and Safety Executive

Example risk assessment for a warehouse

Setting the scene

The warehouse manager carried out a risk assessment of the warehouse. The warehouse employed 12 staff, some were part of a union. 3 For each hazard identified, the manager recorded what controls, if any, were in place to manage these. She then compared these controls to the good practice guidance laid out in Warehousing and storage: A guide to health and safety (www.hsebooks.com ISBN 978 0 7176 6225 8) and Essentials of health and safety at work publications. Where existing controls did not meet good practice, the manager wrote down what further actions were needed to manage the risk. 4 Putting the findings of the risk assessment into practice, the warehouse manager decided who was responsible for implementing the further actions and when it should be done. She wrote this down and when each action was completed it was ticked off and the date recorded. 5 The warehouse manager discussed the findings with the safety representative. They decided to review and update the assessment at least annually, or at any time when major changes to the workplace occurred. The warehouse manager gave out copies of the risk assessment to all members of staff.

Important reminder

This example risk assessment shows the kind of approach a small business can take. Use it as a guide to think through some of the hazards in your business and the steps you need to take to control the risks. Please note that it is not a generic risk assessment that you can just put your company name on and adopt wholesale without any thought. This would not satisfy the law and would not be effective in protecting people. Every business is different you need to think through the hazards and controls required in your business for yourself.

How was the risk assessment done?

The manager followed the guidance in Five steps to risk assessment (www.hse.gov.uk/pubns/indg163.pdf). 1 To identify the hazards, the manager:

read the Essentials of health and safety at work publication to learn where hazards can occur (www.hsebooks.com ISBN 978 0 7176 6179 4); walked around the warehouse, noting activities that might pose a risk and taking into consideration what she learnt from HSEs guidance; talked through the issues with the union safety representative and asked about concerns that staff had on health and safety; talked to supervisors to learn from their detailed knowledge of particular jobs and areas; and looked at the accident book to gather information on past problems.

2 The manager then wrote down who could be harmed by the hazards and how.

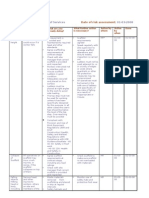

Example risk assessment: A warehouse

1 of 6 pages

Health and Safety Executive

Company name: GHI Warehouse

What are the hazards? Who might be harmed and how? Falls from height Staff could suffer severe or even fatal injuries if they fell whilst climbing racking. Staff could suffer severe or even fatal injuries if they fell whilst changing light bulbs etc in the high ceiling. Staff or contractor could suffer severe or fatal injuries falling through fragile roof lights when looking for/ repairing leaks.

Date of risk assessment: 10/1/06

What are you already doing? All staff are given strict instructions never to climb racking monitored by supervisors. What further action is necessary? Action by who? Action by Done when?

Proprietary forklift cage used by maintenance worker for changing bulbs. Cage suppliers information shows it is manufactured to standard. No controls in place.

Train maintenance worker to check cage is in good condition and properly secured before each use. Put up fragile roof signs, one on each side of the building and at access points to roof. Agree with maintenance worker that a contractor will be used for any access to the roof. Require contractor to provide an assessment before access is allowed if any roof work is required. No further action required.

RB

17/1/06

20/1/06

RB SP SP

13/1/06 28/2/06 15/3/06

14/1/006 28/2/06

Worker falling from roof of internal warehouse office used for storage. Manual handling Regular movement of cartons to pallets. Rolls of stretch-wrap and flat pallets All warehouse staff could suffer from back pain if regularly lifting/carrying heavy or awkward objects.

The internal warehouse roof is load bearing, has full rails and boards around its edge. It has adequate lighting and access is by permanent steps with a handrail. Conveyor system used to reduce manual handling materials in and out of delivery trucks. Lift trucks used for most manual handling. A range of manual handling tasks still required.

Manual handling training to be given to all warehouse staff. Remaining manual handling tasks to be risk assessed using HSEs Manual handling assessment charts INDG383.

SP JB

6/2/06 20/1/06

1/2/06 20/1/06

Example risk assessment: A warehouse

2 of 6 pages

Health and Safety Executive

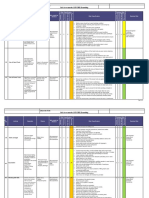

What are the hazards? Who might be harmed and how? Slips, trips and falls All staff may suffer sprains or fractures if they trip over debris or slip on spillages.

What are you already doing? Flooring kept dry and quality maintained. All staff trained to maintain good housekeeping standards and ensure stock does not project into gangways. Cleaner empties bins and removes loose debris daily. Pallets stored safely in designated area. Protective non-slip footwear supplied and worn. Racking is designed to be suitable for the loads carried and has not been modified. Staff report any damage to racking immediately. System in place to make sure defective pallets withdrawn from use immediately. Protective footwear used by all entering warehouse. Protective gloves provided to handle pallets. All operators trained and competent for use of the lift truck. Trucks serviced regularly and examined by suppliers every six months. Drivers instructed to keep keys with them at all times. System in place for refresher training of drivers. Gangways and aisles of sufficient space to enable lift trucks to load and unload from the racking safely. System in place to keep vehicles and pedestrians separated. Access to warehouse restricted to staff. Floor condition maintained on a regular basis, housekeeping standards maintained by cleaner and workforce. Warning signs located around the traffic route. Trucks have seat belts and roll cages.

What further action is necessary? Suitable absorber to be made available for liquid spills. Staff to be trained to clean and dry any spillages immediately. Extra bins to be provided for waste material near loading bays. Sign fixed to racking stating maximum loads/ configuration.

Action by who? RB JB RB RB

Action by Done when? 18/1/06 11/1/06 12/1/06 14/7/06 16/1/06 11/1/06 12/1/06

Falling objects From racking and during movement

A member of staff or any other person in the warehouse may suffer serious injury if struck by a falling object.

Operation of lift trucks

Injuries such as fractures or, at worst, fatalities can be caused as a result of: the vehicle crashing into other vehicles and/or other objects; staff and visitors being hit by lift trucks; objects falling from lift trucks onto staff and visitors; lift trucks toppling over; people falling from the vehicle or parts of the vehicle; and being crushed by the mast.

Supervisor to ensure truck drivers check trucks each day before starting. Separate pedestrian entrance(s) with protective barrier rail to be provided next to roller-shutter doors. Housekeeping standards and floor condition to be covered by a monthly inspection by manager and brief record kept. Strict requirement that only competent drivers may operate lift trucks to be explained to all staff. Disciplinary action to be taken against anyone involved in breaking this rule.

JB RB SP SP

10/1/06 20/6/06 27/1/06 23/1/06

10/1/06

27/1/06 23/1/06

Example risk assessment: A warehouse

3 of 6 pages

Health and Safety Executive

What are the hazards? Who might be harmed and how? Traffic movements (deliveries etc) Injuries such as fractures or, at worst, fatalities can be caused by: staff and visitors being hit by vehicle; people falling from a vehicle or parts of a vehicle; and objects falling from vehicle onto staff and visitors.

What are you already doing? Floor and traffic routes suitable for the vehicles using them. Vehicle routes kept free of obstructions (with spillages being cleaned up promptly). Parking of cars and vans only allowed in marked spaces well away from external delivery/dispatch area. Outside area gritted when frosty, snow cleared. Sensible speed limits imposed and adhered to. Adequate signage to warn of hazards. Reversing of delivery vehicles should be avoided unless absolutely necessary. Any reversing that is necessary should be overseen by a trained reversing assistant (banksman). Only standard palletised loads wrapped. Machine is relatively new and instructions show it meets the relevant guarding standard. Emergency stop button provided. Fixed guards on moving parts. Mechanical parts maintained regularly. Staff trained to use correctly.

What further action is necessary? Anyone working in the vicinity of moving vehicles should be given training and highvisibility clothing.

Action by who? SP

Action by Done when? 20/1/06 20/1/06

Machinery Stretch-wrap machine

All staff using the machine. Moving parts can trap parts of the body (eg fingers/hand/ arm) causing crush injuries. The whole body may also get trapped between moving pallet load and fixed structure. Staff can also cut themselves on sharp edges or scald themselves on hot parts.

Area around machine to be kept unobstructed at all times. Area around machine to be indicated by use of markings in fluorescent orange-red. Weekly check on guarding and condition of machine.

JB RB JB

18/1/06 28/4/06 18/1/06

18/1/06

18/1/06

Conveyor belt for unloading from lorries

As above, particularly where the belt meets rollers.

Guards provided for moving parts. Conveyor instructions show it meets guarding standards. Emergency stop button provided. Regular maintenance. Fixed electrical installations are maintained to a suitable standard and inspected every five years.

Weekly check on guarding and condition of conveyor.

JB

18/1/06

18/1/06

Portable electrical equipment Mess room: industrial cleaner, kettle and heater

All staff could receive potentially fatal electrical shocks or burns if they use faulty electrical equipment.

Manager to arrange and record the sixmonthly inspection and testing of portable equipment. Instruct staff to report faults immediately.

SP JB

1/5/06 13/1/06 13/1/06

4 of 6 pages

Example risk assessment: A warehouse

Health and Safety Executive

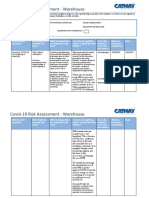

What are the hazards? Who might be harmed and how? Fire Bulk storage of easily burnt materials Ignited through electrical fault, smoking materials, battery recharging etc If trapped in the warehouse, all staff and visitors could suffer from smoke inhalation or burns which could potentially kill.

What are you already doing? Building designed with fire-resisting materials. Exits and fire exits marked and kept clear. Fire extinguishers located throughout warehouse. Access to all exits and fire extinguishers kept clear at all times. Fire detection and alarm system in place. Fire evacuation procedures displayed at each fire alarm point. Maintenance contracts for extinguishers and detection/alarm system. Fire drill and training in use of extinguishers held once a year. Smoking prohibited in the warehouse. Cleaner ensures no debris left around warehouse. All staff trained in good housekeeping during induction. Number of vehicles delivering materials is relatively low and exposure very limited; this prevents build-up of fumes. Drivers not allowed to leave vehicles engines running in warehouse. Roller shutter doors and warehouse windows open, where practicable, to assist ventilation. Cleaner made aware of safe procedures. Rubber gloves used. First-aid facilities (including eye wash) are readily available.

What further action is necessary? Discussions with insurer on the provision of automatic closing of roller-shutter doors linked to fire alarm to be decided upon.

Action by who? SP

Action by Done when? 25/8/06

Hazardous substances Vehicle exhaust fumes

The fumes may cause staff eye irritation and respiratory irritation.

No further action required.

Bleach and cleaning fluids

Direct skin contact could lead to the cleaner getting skin irritation. The vapour may cause the cleaner to have eye irritation or breathing difficulties. Burns or fractures from material ejected could affect any worker nearby at the time.

Investigate availability of safer alternatives for cleaner.

RB

17/2/06

28/2/06

Recharging of forklift truck batteries potential explosion by release of hydrogen, spillage of acid

Batteries charged in designated bay that is well ventilated. Safe system of work used which includes provision and use of goggles and gloves. Potential sources of ignition controlled.

Supervisor to monitor and ensure protective equipment is being worn.

JB

13/1/06

13/1/06

Example risk assessment: A warehouse

5 of 6 pages

Health and Safety Executive

What are the hazards? Who might be harmed and how? Lighting Poor lighting is likely to result in higher levels of work error and accidents.

What are you already doing? Good quality lighting provided throughout the warehouse. Stacking of materials in warehouse on top of racking is restricted in order to avoid blocking light and creating shadows. Cleaner checks that light units are operating and are replaced by electrician when necessary. Floodlighting in the external area.

What further action is necessary? No further action required.

Action by who?

Action by Done when?

Hygiene/comfort

All staff could suffer varied discomfort, eg being too hot/ cold.

Heated mess room provided with hot and cold water and water for beverages. Area kept clean.Lockers available for staff members belongings. Toilets a short walk away, cleaned daily.

No further action required.

Assessment review date: 26/2/07

Example risk assessment: A warehouse Published by the Health and Safety Executive 10/08

6 of 6 pages

You might also like

- Risk Assessment WarehouseDocument12 pagesRisk Assessment WarehouseGul Muhammad Khan100% (3)

- Risk Assessment Example - Warehouse PDFDocument5 pagesRisk Assessment Example - Warehouse PDFPredrag Gligoric60% (5)

- Risk Assessment For Cold Storage WarehousingDocument6 pagesRisk Assessment For Cold Storage WarehousingJohn Kurong100% (3)

- Warehouse Risk AssessmentsDocument4 pagesWarehouse Risk AssessmentsHilario AlinabonNo ratings yet

- Risk Assessment WarehouseDocument34 pagesRisk Assessment WarehouseFadil WimalaNo ratings yet

- Warehouse Risk AssessmentDocument8 pagesWarehouse Risk AssessmentBISHAL ROY100% (2)

- Example Risk Assessment For Contract Bricklayers: How Was The Site-Specific Risk Assessment Done? Setting The SceneDocument16 pagesExample Risk Assessment For Contract Bricklayers: How Was The Site-Specific Risk Assessment Done? Setting The SceneWeei Zhee70No ratings yet

- Mustafa Adnan - Risk Assessment Project PDFDocument2 pagesMustafa Adnan - Risk Assessment Project PDFMustafaAdnanNo ratings yet

- A002 C NightclubDocument6 pagesA002 C NightclubBlas de LezoNo ratings yet

- Manual Handling Risk AssessmentDocument4 pagesManual Handling Risk Assessmentnelson100% (1)

- Example Risk Assessment For A WarehouseDocument8 pagesExample Risk Assessment For A WarehouseNii AshiiiNo ratings yet

- Example Risk Assessment For A WarehouseDocument3 pagesExample Risk Assessment For A Warehousekhalid najjarNo ratings yet

- Abdullah Hashim Industrial Gases and Equipment Co - LTDDocument4 pagesAbdullah Hashim Industrial Gases and Equipment Co - LTDYawar QureshiNo ratings yet

- Model of Risk AssessmentDocument12 pagesModel of Risk AssessmentTony Gallacher60% (5)

- Manufacturing Risk AssessmentDocument4 pagesManufacturing Risk AssessmentVijayakumar Karunanidhi100% (1)

- Risk AssesmentDocument3 pagesRisk Assesmentmrogers72100% (4)

- Warehouse SafetyDocument16 pagesWarehouse SafetyAbhinit SinhaNo ratings yet

- ConfinedSpace RiskAssessmentDocument9 pagesConfinedSpace RiskAssessmentrashid zaman100% (5)

- Forklift Risk AssessmentDocument5 pagesForklift Risk AssessmentPajserchina100% (4)

- 2 - Risk AssessmentDocument4 pages2 - Risk AssessmentNangyal KhanNo ratings yet

- 3-REV.1 - Hot Work - Risk Assessment JHADocument16 pages3-REV.1 - Hot Work - Risk Assessment JHAnaiyar100% (1)

- Pregnancy Risk AssessmentDocument6 pagesPregnancy Risk AssessmentSTEVEN DELAHUNTYNo ratings yet

- Example Risk Assessment For A Warehouse PDFDocument8 pagesExample Risk Assessment For A Warehouse PDFrediet dinoNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatePanchdev KumarNo ratings yet

- Warehouse Risk AssessmentDocument5 pagesWarehouse Risk AssessmentYounis Khan50% (2)

- COVID 19 Risk Assessment High PeakDocument4 pagesCOVID 19 Risk Assessment High PeakShayan KhanNo ratings yet

- Working at Height Risk AssessmentDocument7 pagesWorking at Height Risk AssessmentAshish100% (3)

- Risk Assessment For Tank BaseDocument5 pagesRisk Assessment For Tank Baseramod100% (2)

- Risk Assessment Form-2Document2 pagesRisk Assessment Form-2Badar AlsiyabiNo ratings yet

- 4.2 - Risk Assessment Project - SAMPLEDocument3 pages4.2 - Risk Assessment Project - SAMPLEDhana Sekar71% (21)

- Ng2 Guidance v1 FinalDocument19 pagesNg2 Guidance v1 Finals kumar100% (2)

- Risk Assessment SAMPLEDocument11 pagesRisk Assessment SAMPLERubén Montes100% (1)

- Control of Substances Hazardous To Health and Safety Risk Assessment FormDocument3 pagesControl of Substances Hazardous To Health and Safety Risk Assessment Formhemanth_chaturvedulaNo ratings yet

- Covid-19 RiskAssessmentWarehouseDocument11 pagesCovid-19 RiskAssessmentWarehouseBalgo BalgobinNo ratings yet

- 002 Working at Height Risk AssessmentDocument4 pages002 Working at Height Risk Assessmentgangadharan000100% (14)

- 3 Work Place Risk Assessment 12Document49 pages3 Work Place Risk Assessment 12IgorToporskyNo ratings yet

- Mustafa Adnan - Risk Assessment ProjectDocument2 pagesMustafa Adnan - Risk Assessment ProjectMustafaAdnanNo ratings yet

- Risk Assessment Excavation For Trenches, Duct Bank, Pole Foundations and Back-FillingDocument3 pagesRisk Assessment Excavation For Trenches, Duct Bank, Pole Foundations and Back-FillingSafety Professional0% (1)

- MS 5.0 (1) Risk Assessment ProjectDocument2 pagesMS 5.0 (1) Risk Assessment ProjectAhmed Alrashid100% (1)

- Risk AssessmentDocument10 pagesRisk AssessmentKyaw Kyaw Aung89% (9)

- Forklift Truck Risk AssessmentDocument2 pagesForklift Truck Risk AssessmentAshis Das100% (1)

- JHA Example Installation of Underfloor Plumbing and DrainsDocument15 pagesJHA Example Installation of Underfloor Plumbing and DrainsShamel Jen FacundoNo ratings yet

- Hazard Identification and Risk Assessment Form: Location Activities Hazard ControlsDocument6 pagesHazard Identification and Risk Assessment Form: Location Activities Hazard ControlsVikas SinghNo ratings yet

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Document13 pagesRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul WasayNo ratings yet

- Hot Work Risk Assessment and PermitDocument3 pagesHot Work Risk Assessment and Permitstitchvn75% (12)

- Risk Assessment Project - 3Document3 pagesRisk Assessment Project - 3Syed Amair67% (15)

- Sample Risk AssessmentDocument12 pagesSample Risk Assessmentpaansaeng82% (17)

- Risk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATIONDocument6 pagesRisk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATIONnsadnanNo ratings yet

- Work at HeightDocument22 pagesWork at HeightSayed Darwish75% (4)

- 6-Steel Work Risk Assessment ReportDocument7 pages6-Steel Work Risk Assessment ReportSyed Ali Hassan67% (3)

- Risk Assesment-Rebar Loading & UnloadingDocument1 pageRisk Assesment-Rebar Loading & Unloadingmainraj rajNo ratings yet

- Risk Assessment Steel FixingDocument1 pageRisk Assessment Steel Fixingmohamed ghalyNo ratings yet

- Working at Height: Activity-Based Risk Assessment FormDocument7 pagesWorking at Height: Activity-Based Risk Assessment Formfredo100% (4)

- HIRAC - Work - at - Height - Template PDFDocument8 pagesHIRAC - Work - at - Height - Template PDFRohma Desi ThirtasariNo ratings yet

- Unit IG2: Risk AssessmentDocument13 pagesUnit IG2: Risk AssessmentNauman Qureshi89% (9)

- Iosh Risk AssessmentDocument3 pagesIosh Risk Assessmentmilan shrestha80% (25)

- Risk Assessment For Road HaulageDocument4 pagesRisk Assessment For Road Haulagenkem_sundayNo ratings yet

- Example Risk Assessment For Cold Storage Warehousing: Setting The SceneDocument6 pagesExample Risk Assessment For Cold Storage Warehousing: Setting The Sceneʞǝǝs Uǝ ƎpıɥNo ratings yet

- Example Risk Assessment For A Butcher's Shop: Setting The SceneDocument4 pagesExample Risk Assessment For A Butcher's Shop: Setting The SceneSrikanth BammhideNo ratings yet

- Example Risk Assessment For A Pub: Setting The Scene How Was The Risk Assessment Done?Document6 pagesExample Risk Assessment For A Pub: Setting The Scene How Was The Risk Assessment Done?Blas de LezoNo ratings yet

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptFrom EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptRating: 5 out of 5 stars5/5 (1)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksFrom EverandArizona, Utah & New Mexico: A Guide to the State & National ParksRating: 4 out of 5 stars4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksFrom EverandNew York & New Jersey: A Guide to the State & National ParksNo ratings yet

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoFrom EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoRating: 5 out of 5 stars5/5 (1)

- The Bahamas a Taste of the Islands ExcerptFrom EverandThe Bahamas a Taste of the Islands ExcerptRating: 4 out of 5 stars4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensFrom EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNo ratings yet