Composite Steel Design

Uploaded by

ALABIADESINAComposite Steel Design

Uploaded by

ALABIADESINA- Concrete Filled CHS Composite Column

- Continuous Steel and Concrete Composite Beam

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 1 of 12

Rev:

06

Subject:

Concrete Filled CHS Composite Column

Made by/date:

JM/September 2004

Client:

Checked/date:

GHC/October 2004

Concrete Filled CHS Composite Column

The following Eurocodes and pre-Eurocodes have been used for this worked example:

BS EN 1990, Basis of Structural Design, July 2002, with UK National Annex, March 2004

BS EN 1991-1-1, Eurocode 1 Actions on structures Part 1.1: General actions Densities, self-weight,

imposed loads for buildings, July 2002

prEN 1992-1-1, Eurocode 2 Design of concrete structures Part 1.1: General rules and rules for

buildings, April 2003

prEN 1993-1-1, Eurocode 3 Design of steel structures Part 1.1: General rules and rules for buildings,

December 2003

prEN 1994-1-1, Eurocode 4 Design of composite steel and concrete structures Part 1.1: General rules

and rules for buildings, January 2004

prEN 10025-2, Hot rolled products of non-alloy structural steels Part 2: Technical delivery conditions for

flat products, March 1998

The following design guidance document has been used for this worked example:

T.T.Lie and V.K.R. Kodur (1996), Fire Resistance of Steel Columns Filled with Bar-Reinforced Concrete,

Journal of Structural Engineering, Vol. 122, Jan 1996, ASCE

Notes on European Standards

BS EN denotes a European Standard that has been published by BSi

prEN denotes a draft European standard that is not publicly available

Note on values contained in this worked example

The computer software used to calculate the expressions given in this worked example does not

round the values at intermediate stages during the calculation. Therefore some values given on the

following sheets may appear to be incorrect when determined using rounded input values.

BRE and Buro Happold have made every effort to ensure the accuracy and quality of all the information

in this document when first published. However, they can take no responsibility for the subsequent use

of this information, nor for any errors or omissions it may contain.

Queen's Printer and Controller of Her Majesty's Stationery Office 2005

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 2 of 12

Rev:

06

Subject:

Concrete Filled CHS Composite Column

Made by/date:

JM/September 2004

Client:

Checked/date:

GHC/October 2004

N

G

+N

Q

4

.

5

0

m

M

G

+M

Q

Figure 0: Overview of Composite Column

Design Example of a concrete filled composite column to EN1994-1-1 Tables and clause

numbers relate to

Consider the 4.5m high column shown EN1994-1-1

subject to an axially applied point unless stated

load, and an applied moment. This otherwise

mimics the common situation where a

column is subject to axially applied

load from storeys above and a

moment induced by a floor beam at

the storey considered.

The column section is circular and

therefore doubly symmetric. It is

assumed to be pinned top and

bottom.

It has been designed using the

simplified method of analysis in

accordance with clause 6.7.3

EN1994.

The design is based on first order

analysis with appropriate amplification

to the design moments to account for

second order effects.

The required fire resistance is 60

minutes.

1. Design Data

L = 4.50 m

Effective or buckling length, L

e

= 4.50 m

Note: The Eurocodes do not give any guidance regarding effective or buckling lengths of

members subject to compressive axial load. Reference should be made to textbooks for

this information.

1.1. Loading

1.1.1. Permanent Actions (G)

N

G

= 3000 kN

M

G

= 50.00 kNm

1.1.2. Variable Actions (Q)

N

Q

= 1300 kN

M

Q

= 45.00 kNm

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 3 of 12

Rev:

06

Subject:

Concrete Filled CHS Composite Column

Made by/date:

JM/September 2004

Client:

Checked/date:

GHC/October 2004

1.2. Loading factors

Partial loading factor for permanent actions, !

G

= 1.35 EN 1990 Table

Partial loading factor for variable actions, !

Q

= 1.50 A1.2(B) & N.A

1.3. Materials

1.3.1. Steelwork

Grade S355, nominal yield strength, f

y

= 355 N/mm

2

Partial Safety Factor, !

M0

= 1.00 6.1(1) EN1993-1-1

Note: Recommended value used for !M0. This value may be altered by the UK National

Annex to EN1993-1-1.

Design strength, f

yd

= f

y

/!

M0

= 355 N/mm

2

Modulus of elasticity, E

a

= 210 kN/mm

2

3.2.6(1)

EN1993-1-1

1.3.2. Concrete

Normal Weight concrete strength class C40/50

Characteristic cylinder strength, f

ck

= 40 N/mm

2

Partial Safety Factor, !

c

= 1.5 Table 2.1N

Note: Recommended value for !c, given in Table 2.1N, EN1992-1-1. This value may be EN1992-1-1

altered by the UK National Annex to EN1992-1-1.

Design value of concrete cylinder strength, f

cd

= f

ck

/!

c

= 26.7 N/mm

2

Secant modulus of elasticity, E

cm

= 35.0 kN/mm

2

Table 3.1

Note: alternatively the secant modulus can be calculated from, Ecm = 22[(fcm/10)

0.3

], EN1992-1-1

where fcm is the mean value of concrete cylinder compressive strength and is equal to

fck+8(MPa.)

1.3.3. Reinforcement

Grade S460, yield strength, f

sk

= 460 N/mm

2

Partial Safety Factor, !

s

= 1.15 Table 2.1N

Note: Recommended value for !c, given in Table 2.1N, EN1992-1-1. This value may be EN1992-1-1

altered by the UK National Annex to EN1992-1-1.

Design strength, f

sd

= f

sk

/!

s

= 400.0 N/mm

2

Modulus of elasticity, E

s

= 210 kN/mm

2

Note: for composite structures, the design value of the modulus of elasticity Es may be

taken as equal to the value for structural steel given in EN1993-1-1, 3.2.6 (from clause

3.2(2), EN1994-1-1).

2. Global Analysis

The effects of deformed geometry (second-order effects) must be considered. In

addition, appropriate allowances must be incorporated within the structural analysis

to cover the effects of imperfections, including geometrical imperfections such as

lack of verticality.

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 4 of 12

Rev:

06

Subject:

Concrete Filled CHS Composite Column

Made by/date:

JM/September 2004

Client:

Checked/date:

GHC/October 2004

Second-order effects will be included indirectly by using a first-order analysis 5.2.2(2)

modified with appropriate amplification. The amplification considered in this example

is in accordance with clause 6.7.3.4(5). See section 12 for details.

In accordance with clause 5.3.2.3(1), a design value for initial bow for the composite

column has been taken from Table 6.5. Assuming a reinforcement ratio of less than

3%, the design value of initial bow should be taken as L/300. Therefore, the member

imperfection should be taken as 15.00 mm

The effects of the applied support moment and the moment due to the initial member

imperfection have been combined and the maximum combined moment at either the

support or mid-span has been used as the design bending moment.

2.1. Design Value Actions

N

Ed

= N

G

" !

G

+ N

Q

" !

Q

= 6000 kN

M

Ed

= 0.5"(M

G

" !

G

+ M

Q

" !

Q

) + N

Ed

"0.015 = 158 kNm (at mid height)

V

Ed

= (M

G

" !

G

+ M

Q

" !

Q

)/L = 30 kN

3. Trial Column size

Trial column size assumed considering axial load only, given the required fire

resistance is (from Lie and Kodur (1996)):

Trial diameter = [(t

fire

"(L

e

-1000)) /(0.08"(f

ck

+ 20)) " #(N

Ed

)]

0.4

where: t

fire

= required fire resistance in minutes = 60 minutes

! trial column diameter = 409 mm

Try CHS 406.4 section

determine minimum wall thickness to prevent local buckling:

maximum (d/t) = 90"(#(235/f

y

)) = 73.225 Table 6.3

minimum t = 5.550mm therefore min 6 mm thick wall required

Try CHS 406.4x10.0 section

d = 406.4 mm

t = 10.0 mm A

a

= 124.5 cm

2

I

a

= 24476 cm

4

W

pa

= 1572 cm

3

Assume 1.5% reinforcement, based on concrete area. Approximate reinforcement

required is:

minimum reinforcement = (($"(d-2"t)

2

)/4)"1.5/100 = 1759 mm

2

A minimum of 6 bars should be adopted, therefore try 10 No. 16 dia bar(s)

A

s

= 2010 mm

2

d

rebar

= 16 mm A

bar

= A

s

/10 = 201 mm

2

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 5 of 12

Rev:

06

Subject:

Concrete Filled CHS Composite Column

Made by/date:

JM/September 2004

Client:

Checked/date:

GHC/October 2004

4. Composite Cross Section Properties

A

a

= 124.5 cm

2

A

s

= 20.1 cm

2

A

c

= (($"d

2

)/4)-A

a

-A

s

=1153 cm

2

concrete diameter, d

c

= d - 2"t = 386 mm

Second Moment of Area of Steel Section, I

a

= 24476 cm

4

Second Moment of Area of Reinforcement,

I

s

given by:

Assume 8mm links around main

reinforcement and 50mm cover.

therefore R = d

c

/2-50d

rebar

/2 - 8 = 127 mm

y

1

= 121 mm y

2

= 75 mm

therefore,

I

s

= 4"A

bar

"y

1

2

+ 4"A

bar

"y

2

2

= 1629 cm

4

Second Moment of Concrete, I

c

= ($"(d-2"t)

4

)/64 = 109425 cm

4

4.1. Reinforcement Ratio

The ratio of reinforcement area to concrete area should not exceed 6%. In concrete 6.7.3.1(3)

filled hollow sections no longitudinal reinforcement is normally necessary unless

required for fire resistance.

actual reinforcement ratio = (A

s

/A

c

) = 1.744 %

Therefore reinforcement ratio is less than 6%

5. Simplified Method of Design

A simplified axial load - moment (N-M) interaction curve is produced in order to

determine the resistance of a composite cross-section to combined compression and

bending. The simplified interaction curve is illustrated in Figure 6.19. A modified

version, indicating a CHS column example, has been reproduced below.

R

y

1

y

2

Figure 0: Composite column cross-

section

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 6 of 12

Rev:

06

Subject:

Concrete Filled CHS Composite Column

Made by/date:

JM/September 2004

Client:

Checked/date:

GHC/October 2004

Figure 1: Simplified Interaction Curve and Corresponding Stress Distributions

In order to produce the N-M interaction curve the cross-sectional capacities at points

A to D should be determined assuming the stress distributions indicated.

In addition, it should be noted that the Simplified Method of design is subject to the

following limitations:

The column cross-section must be prismatic and symmetric about both axes

over its whole height

The relative contribution of the steel section to the design resistance of the

composite section must be between 0.2 and 0.9

The relative slenderness of the composite column, %, must not be greater

than 2.0

The limitations noted have been considered at the appropriate location within this

calculation.

The following sections outline the calculation of points A to D on the simplified N-M

interaction curve for the cross-section considered.

5.1. Point A on Simplified N-M Interaction Curve

The plastic resistance to compression N

pl.Rd

of a composite cross-section should be

calculated by adding the plastic resistances of its components: 6.7.3.2

N

pl.Rd

= A

a

"f

yd

+ 0.85"A

c

"f

cd

+ A

s

"f

sd

equation (6.30)

Note: for concrete filled sections the 0.85 factor can increase up to 1.0 (as shown in

Figure3). A further increase in concrete strength may also be taken in accordance with

clause 6.7.3.2(6) with a concrete filled tube of circular cross section if " does not exceed

0.5 and e/d is less than 0.1 (where e is the eccentricity of loading given by MEd/NEd and d

N

M

A

C

D

B

A

B

C

D

f

cd

f

cd

f

cd

f

cd

f

yd

f

yd

f

yd

f

yd

hn

hn

2hn

hn

hn

2hn

f

sd

f

sd

f

sd

f

sd

N

pl.Rd

N

pm.Rd

N

pm.Rd

/2

M

pl.Rd

M

pl.Rd

M

Max.Rd

+

+

+ +

+

+

-

-

-

-

-

- -

- -

-

- -

-

-

-

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 7 of 12

Rev:

06

Subject:

Concrete Filled CHS Composite Column

Made by/date:

JM/September 2004

Client:

Checked/date:

GHC/October 2004

is the external diameter of the column). An iterative process is therefore required to

determine whether this additional increase in concrete strength can be used.

The plastic resistance to axial force, N

pl.Rd

, of a concrete filled section is therefore:

N

pl.Rd

= A

a

"f

yd

+ A

c

"f

cd

+ A

s

"f

sd

= 8298 kN

5.1.1. Check Applicability of Simplified Method

At this point we have sufficient data to check the steel section contribution ratio and

the relative slenderness of the column to confirm that the simplified method is

applicable. In addition, the value of relative slenderness may allow a further increase

in concrete strength to be taken:

The steel section contribution ratio, &, should fufill the following condition: 0.2<&<0.9. 6.7.1(4)

The ratio, &, is defined in clause 6.7.3.3(1), and is given by:

&=(A

a

"f

yd

)/ N

pl.Rd

= 0.533 equation (6.38)

Therefore 0.2 < & < 0.9 limits are satisfied and the use of the simplified method is applicable

as far as the steel section contribution is concerned

The relative slenderness, %, for the plane of bending considered is given by: 6.7.3.3 (2)

%=#( N

pl.Rk

/N

cr

) equation (6.39)

where:

N

pl.Rk

is the characteristic value of plastic resistance to compression using

characteristic values within equation (6.30).

N

cr

is the elastic critical normal force for the relevant buckling mode calculated with

the effective flexural stiffness EI

eff

Therefore N

pl.Rk

= A

a

"f

y

+ A

c

"f

ck

+ A

s

"f

sk

= 9956 kN

For the determination of the relative slenderness and the elastic critical force, the

effective flexural stiffness, EI

eff

, is given by: 6.7.3.3(3)

EI

eff

= E

a

"I

a

+ E

s

"I

s

+ K

e

"E

cm

"I

c

equation (6.40)

where K

e

is a correction factor that should be taken as 0.6 6.7.3.3(3)

In addition, account should be taken of the influence of long-term creep effects on

the effective elastic stiffness, in accordance with clause 6.7.3.3(4). The modulus of

elasticity of the concrete should be reduced to the value E

c.eff

in accordance with

equation (6.41):

E

c.eff

= E

cm

"1/[1+(!

G

"N

G

/N

Ed

)"'

t

]

-

-

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 8 of 12

Rev:

06

Subject:

Concrete Filled CHS Composite Column

Made by/date:

JM/September 2004

Client:

Checked/date:

GHC/October 2004

where '

t

is the creep coefficient according to clause 5.4.2.2(2), taken as 1.5 from

Figure 3.1, prEN 1992-1-1, for loading at 28 days

N

Ed

is the total design normal force

N

G.Ed

is the part of this normal force that is permanent, therefore, N

G.Ed

= !

G

"N

G

! E

c.eff

= 17.4 kN/mm

2

and EI

eff

= E

a

"I

a

+ E

s

"I

s

+ K

e

"E

c.eff

"I

c

= 66239 kNm

2

The elastic critical normal force, N

cr

, for a pin ended column is given by:

N

cr

= $

2

"EI

eff

/L

e

2

= 32284 kN

Therefore the relative slenderness, % is:

%=#( N

pl.Rk

/N

cr

)

%=0.555 < 2.0 therefore it is OK to use simplified method of design

however, as % is now greater than 0.5 no further enhancement of the concrete

strength due to confinement is allowed.

The plastic resistance to axial force, N

pl.Rd

, remains 8298 kN

5.2. Point D on Simplified N-M Interaction Curve

Plastic Bending Capacity, M

maxRd

, is given by:

M

maxRd

=W

pa

"f

yd

+ W

pc

"f

cd

+ W

ps

"f

sd

Plastic modulus of steel section is W

pa

= 1572 cm

3

Plastic modulus of the reinforcement is W

ps

= 4"y

1

"A

bar

+ 4"y

2

" A

bar

= 158 cm

3

Effective plastic modulus of concrete is W

pc

= (d

c

3

)/6 W

ps

= 9458 cm

3

! M

max.Rd

= W

pa

"f

yd

+ 0.5"W

pc

"f

cd

+ W

ps

"f

sd

M

max.Rd

= 747 kNm

The axial load at the point of maximum bending is ! N

pm.Rd

therefore 0.5 " N

pm.Rd

= 1564 kN

5.3. Point C on Simplified N-M Interaction Curve

The plastic resistance moment of the composite section, M

pl.Rd

, is given by:

Determination of position of neutral axis depth, h

n

, when axial load is zero:

h

n

= (N

pm.Rd

A

sn

"(2"f

sd

f

cd

)) /(2"d"f

cd

+ 4"t"(2"f

yd

f

cd

)) = 57.463 mm

-

-

-

-

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 9 of 12

Rev:

06

Subject:

Concrete Filled CHS Composite Column

Made by/date:

JM/September 2004

Client:

Checked/date:

GHC/October 2004

where:

A

sn

is the reinforcement area within h

n

, therefore (initial guess) A

sn

= 2"A

bar

= 402

mm

2

and N

pm.Rd

is the compressive resistance of the whole area of concrete (see below).

Generally, W

psn

= W

ps

but as the worst case is where only two bars occur within h

n

,

and these are on the centre line; W

psn

= 0 cm

3

W

pcn

= (d-2"t)"h

n

2

W

psn

= 1276 cm

3

W

pan

= d"h

n

2

W

pcn

W

psn

= 66 cm

3

Determine the plastic resistance of composite section, M

pl.N.Rd

, taking into account

the compressive normal force:

M

pl.N.Rd

= W

pan

"f

yd

+ 0.5"W

pcn

"f

cd

+ W

psn

"f

sd

M

pl.N.Rd

= 40.456 kNm

M

pl.Rd

= M

max.Rd

M

pl.N.Rd

M

pl.Rd

= 707 kNm

The design value of the resistance of the concrete to compression, N

pm.Rd

, is given

by:

N

pm.Rd

= ($"d

c

2

)/4 " f

cd

= 3127 kN

5.4. Point B on Simplified N-M Interaction Curve

The value of M

pl.Rd

has previously been determined in order to define point C on the

N-M interaction curve.

M

pl.Rd

= 707 kNm

6. Plastic Resistance to Vertical Shear, V

Rd

As a simplification, shear may be assumed to be resisted by the steel section alone. 6.7.3.2(4)

In the absence of torsion, the design plastic shear resistance, V

pl.a.Rd

, is given by: 6.2.6 (2)

V

pl.a.Rd

= A

v

"(f

y

/#(3))/!

M0

EN1993-1-1

where A

v

is the shear area given by:

A

v

= 2"A

a

/$ = 79.28 cm

2

6.2.6(3)

EN1993-1-1

! Design shear resistance of composite section,V

pl.a.Rd

= 1625 kN 6.2.2.2

Therefore as the applied shear is less than half the shear resistance, the effect of shear on

the plastic moment resistance can be ignored 6.2.2.4(1)

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 10 of 12

Rev:

06

Subject:

Concrete Filled CHS Composite Column

Made by/date:

JM/September 2004

Client:

Checked/date:

GHC/October 2004

7. Resistance of Column to Buckling under Axial Loads

For simplification for composite members in axial compression, the design value of

the normal force, N

Ed

, should satisfy the following:

N

Ed

/xN

pl.Rd

!1.0; 6.7.3.5(2)

where:

N

pl.Rd

is the plastic resistance of the composite section determined using the material

factor !

M1

instead of !

M0

to determine the steel strength, f

yd

(Note: in this case !

M1

=

!

M0

therefore there is no change in the value of N

pl.Rd

).

x is the reduction factor for the relevant buckling mode given in clause 6.3.1.2

EN1993-1-1, in terms of the relative slenderness %. The relevant buckling curve for

cross-sections of composite columns are given in Table 6.5, EN1994, where (

s

is the

reinforcement ratio A

s

/A

c

= 1.744% therefore from Table 6.5, buckling curve a

should be used.

For the determination of the internal forces the design value of the effective flexural

stiffness, EI

eff.II

, used to determine the relative slenderness of the member, should be

determined from: 6.7.3.4(2)

EI

eff.II

= K

o

"(E

a

"I

a

+ E

s

"I

s

+ K

e.II

"E

c.eff

"I

c

) equation (6.42)

where K

e.II

is a correction factor which should be taken as 0.5

and K

o

is a calibration factor which should be taken as 0.9

Note: The value Ec.eff has been used in place of Ecm in equation (6.42) in order to allow for

long term effects (in the same way as calculated in section 6.).

therefore EI

eff.II

= 579."10

6

kN/cm

-2

and the elastic critical normal force, N

cr

, for a pin ended column is then given by:

N

cr.II

= $

2

"EI

eff.II

/L

e

2

= 28221 kN

Therefore the relative slenderness, % is:

% = #( N

pl.Rk

/N

cr.II

) = 0.594

The reduction factor x is given by:

x = 1/()+#()

2

-%

2

));

where: ) = 0.5"[1 + *"(%-0.2) + %

2

] where *=0.21 for buckling curve a

!x = 0.89;

and x"N

pl.Rd

= 7404 kN

therefore N

Ed

/(x"N

pl.Rd

) = 0.81 < 1.0 therefore buckling resistance is OK

-

-

-

-

-

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 11 of 12

Rev:

06

Subject:

Concrete Filled CHS Composite Column

Made by/date:

JM/September 2004

Client:

Checked/date:

GHC/October 2004

8. Resistance of Column to Bending Moments

For non-sway columns the use of the 1

st

order moments calculated may be permitted

by multiplying the design bending moment, M

Ed

, by a correction factor, k, given by: 6.7.3.4 (5)

k = +/(1-N

Ed

/N

cr.eff

) ! 1.0 equation (6.43)

where:

N

cr.eff

is the critical normal force for the relevant axis, corresponding to the effective

flexural stiffness given in clause 6.7.3.4 (2), with the effective length taken as the

column length. In this case, N

cr.eff

= N

cr.II

= 28221 kN

+ is an equivalent moment factor given in Table 6.4, which is equal to 0.66, for a

column with a moment diagram corresponding to end moments and 1.0 for moment

diagram produced from lateral load or member imperfection.

Two values of k must therefore be calculated, corresponding to the applied moment

and the moment due to member imperfections. The design moment, M

Ed

, should

then be modified if appropriate.

when considering the applied end moment, k

1

= +

1

/(1-N

Ed

/N

cr.eff

) = 0.838 < 1.0

therefore k

1

= 1.0

for the moment due to member imperfection, k

2

= +

2

/(1-N

Ed

/N

cr.eff

) = 1.270

!the design moment at mid-height, M

Ed

= 0.5"k

1

"(M

G

" !

G

+ M

Q

" !

Q

) +

k

2

"(N

Ed

"0.015) = 181.80 kNm

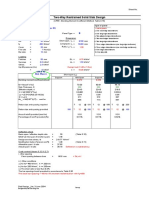

9. Plot Simplified Interaction Curve (Figure 6.19 EN1994).

The points A-D, calculated above should now be plotted to produce the simplified N-

M interaction curve (Figure 6.19, EN1994):

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 12 of 12

Rev:

06

Subject:

Concrete Filled CHS Composite Column

Made by/date:

JM/September 2004

Client:

Checked/date:

GHC/October 2004

Figure 2: Simplified N-M Interaction Curve.

Using this simplified N-M interaction curve, the design value of the plastic moment of

the composite member taking into account the relevant compression normal force,

termed M

pl.N.Rd

, can be determined. The value of M

pl.N.Rd

, is defined as: 6.7.3.6(1)

M

pl.N.Rd

=

d

"M

pl.Rd

and the following inequality should be satisfied:

M

Ed

/M

pl.N.Rd

= M

Ed

/

d

"M

pl.Rd

! *

M

where the coefficient *

M

is taken as 0.9 for steel grades between S235 and S355

and 0.8 for steel grades between S420 and S460.

when N

Ed

= 6000 kN,

d

is:

d

= (N

pl.Rd

N

Ed

)/(N

pl.Rd

N

pm.Rd

) = 0.444

!M

Ed

/(

d

"M

pl.Rd

)= 0.579 < 0.9 therefore the bending resistance taking into account the

normal force NEd is OK

A

C

D

B

d

"M

pl.Rd

N

pl.Rd

=8298kN

xN

pl.Rd

=7404kN

M

Max.Rd

= 747kNm

N

M

N

pm.Rd

=3127kN

!N

pm.Rd

=1564kN

M

pl.Rd

= 707kNm

N

Ed

=6000kN

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 1 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

Continuous Steel and Concrete Composite Beam

The following Eurocodes and pre-Eurocodes have been used for this worked example:

BS EN 1990, Basis of Structural Design, July 2002, with UK National Annex, March 2004

BS EN 1991-1-1, Eurocode 1 Actions on structures Part 1.1: General actions Densities, self-weight,

imposed loads for buildings, July 2002

prEN 1992-1-1, Eurocode 2 Design of concrete structures Part 1.1: General rules and rules for

buildings, April 2003

prEN 1993-1-1, Eurocode 3 Design of steel structures Part 1.1: General rules and rules for buildings,

December 2003

prEN 1994-1-1, Eurocode 4 Design of composite steel and concrete structures Part 1.1: General rules

and rules for buildings, January 2004

prEN 10025-2, Hot rolled products of non-alloy structural steels Part 2: Technical delivery conditions for

flat products, March 1998

Notes on European Standards

BS EN denotes a European Standard that has been published by BSi

prEN denotes a draft European standard that is not publicly available

Note on values contained in this worked example

The computer software used to calculate the expressions given in this worked example does not

round the values at intermediate stages during the calculation. Therefore some values given on the

following sheets may appear to be incorrect when determined using rounded input values.

BRE and Buro Happold have made every effort to ensure the accuracy and quality of all the information

in this document when first published. However, they can take no responsibility for the subsequent use

of this information, nor for any errors or omissions it may contain.

Queen's Printer and Controller of Her Majesty's Stationery Office 2005

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 2 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

Design Example of a 20m span continuous composite beam to EN1994-1-1. Table and clause

Consider the internal composite beam A-A between edge columns and a numbers relate to

central support. Beam is subject to uniform floor loading and is assumed to EN1994-1-1

be fully continuous. unless stated

otherwise

Figure 1: Floor Layout

b = 3.00m b = 3.00m b = 3.00m b = 3.00m

L = 10.00m

Composite Beam

Composite

Deck Span

L = 10.00m

A

A

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 4 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

where fcm is the mean value of concrete cylinder compressive strength and is equal to

fck+8(MPa.)

Dry Density = 24.0 + 1.0 kN/m

3

(for normal percentage reinforcement) Table A.1 Annex A

Wet Density = 24.0 + 1.0 + 1.0 kN/m

3

(for normal percentage reinforcement) EN 1991-1-1

1.2.3. Shear Connectors

19mm diameter stud, d

stud

= 19.00 mm

Note: EN1994-1-1 uses d to denote the clear depth of the web of the structural section,

the overall diameter of a circular hollow section and the minimum transverse dimension of

a column, in addition to the diameter of a stud connector. The variable dstud has been used

in this example to differentiate between these various definitions.

95mm length after welding h

sc

= 95mm

Ultimate tensile strength of stud, f

u

= 450.00 N/mm

2

Partial Safety Factor, !

V

= 1.25 2.4.1.2(5) and

Note: Recommended value used for !V. This value may be altered by the UK National 6.6.3.1(1)

Annex to EN1994-1-1.

1.2.4. Reinforcement

Grade S460, yield strength, f

sk

= 460 N/mm

2

Partial Safety Factor, !

s

= 1.15 Table 2.1N

Note: Recommended value for !c, given in Table 2.1N, EN1992-1-1. This value may be EN1992-1-1

altered by the UK National Annex to EN1992-1-1.

Modulus of elasticity, E

s

= 210 kN/mm

2

Note: for composite structures, the design

value of the modulus of elasticity Es may be

taken as equal to the value for structural steel

given in EN1993-1-1, 3.2.6 (from clause

3.2(2), EN1994-1-1).

2. Selection of Trial Beam Size

An approximate span to depth ratio for

the steel section for a continuous

composite secondary beam is 25.

Therefore given a 10.0 m span, try at

least a 400 mm deep beam.

Try UB 457x191x89

h

a

= 463.4 mm b = 191.9 mm

d = 407.6 mm t

w

= 10.5 mm

t

f

= 17.7 mm r = 10.2 mm

A

a

= 114 cm

2

I

yy

= 41015 cm

4

W

el.y

= 1770 cm

3

W

pl.y

= 2014 cm

3

i

z

= 4.29 cm

z

z

y y

t

w

t

f

b

h

d

r

Figure 2: Steel Beam Cross-section

a

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 5 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

3. Section Classification

For t

f

= 17.700 mm

Yield strength, f

y

= 275.0 N/mm

2

EN 10025

" = #((235)/ f

y

) = 0.924 7.3 & Table 4

During the execution stage the neutral axis will be at mid depth of the steel section

and classification of the section is based on sheet 1 of Table 5.2, EN1993-1-1:

c = (bt

w

2$r)/2 = 80.50 mm

Flange: c/t

f

= 4.55 < 9$" = 8.32 Therefore flange is class 1 EN1993-1-1

Web: d/t

w

= 38.82 < 72$" = 66.56 Therefore web is class 1 Table 5.2

Therefore section is class 1 during execution

In the composite stage it is possible for a distance c of the web to be in

compression over the central support. Assuming the neutral axis is at least 100mm

below the top surface of the upper flange of the beam, c = d-100 = 307.60 mm

Web: c/t

w

= 29.30 < 33$" = 30.51 Therefore web is class 1 EN1993-1-1

Table 5.2

Therefore the web of section is class 1 during the composite stage

Note: This classification assumes a neutral axis depth. A more detailed check should be

carried out once the depth of the web in compression is calculated (see section 6.3.3).

4. Actions

4.1. Execution Stage

4.1.1. Permanent Actions, g

k

Concrete Slab area (per m width) A

c

= [(h-h

p

)$1000 + (140$h

p

$(1000/153))]

A

c

=145667 mm

2

Weight of Wet Concrete slab = 3.79 kN/m

2

Weight of Steel deck (allow) 0.17 kN/m

2

Weight of Reinforcement (allow) 0.04 kN/m

2

Weight of Steel beam (allow) 0.25 kN/m

2

Therefore, g

exe

= 4.25 kN/m

2

4.1.2. Variable Actions, q

k

Execution loading = 0.50 kN/m

2

Therefore, q

exe

= 0.50 kN/m

2

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 6 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

4.2. Composite Stage

4.2.1. Permanent Actions, g

k

Weight of Cast Concrete slab = 3.64 kN/m

2

Weight of Steel deck (allow) 0.17 kN/m

2

Weight of Reinforcement (allow) 0.04 kN/m

2

Weight of Steel beam (allow) 0.25 kN/m

2

Services and Ceilings = 0.50 kN/m

2

Therefore, g

comp

= 4.60 kN/m

2

4.2.2. Variable Actions, q

k

Occupancy, (for category C2 ocupancy) = 4.00 kN/m

2

Table 6.1

EN1991-1-1

Moveable Partitions = 0.5 kN/m

2

6.3.1.2(8)

Note: Variable actions are not independent of each other. EN1991-1-1

Therefore, q

comp

= 4.50 kN/m

2

4.3. Partial factors for Actions

Partial factor for permanent actions (where unfavourable), !

G.sup

= 1.35 Table A1.2(B)

Partial factor for permanent actions (where favourable), !

G.inf

= 1.00 EN 1990-1-1

Partial factor for variable actions (where unfavourable), !

Q

= 1.50

Partial factor for variable actions (where favourable), !

Qi

= 0.00

Note: As the variable actions considered in this example are not independent " factors

need not be considered.

5. Execution Stage Design

5.1. Global Analysis

The moments and forces within the section are determined using elastic analysis

methods.

It has been assumed that the rotational stiffness and moment resistance of the

beam/column connection will provide full continuity.

The resistance of the steel beam is determined using plastic section analysis.

Maximum uniformly distributed design load per span

F

exe.max

= 3$(!

G.sup

$g

exe

+ !

Q

$q

exe

) = 19.45 kN/m

Minimum uniformly distributed design load per span, F

exe.min

= 0.00 kN/m

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 7 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

5.1.1. Load Case 1 Maximum Design Load on both spans

Figure 3: Design loading

Figure 4: Bending Moments with full design load on both spans.

5.1.2. Load Case 2 Maximum Design Load on one span only

Figure 5: Design loading

Figure 6: Design Bending Moments with maximum load on one span only.

Considering both loadcases, the maximum design moments on the steel section

during the execution stage are:

Design negative moment, M

a.Ed.negative

= 243.28 kNm

Design positive moment, M

a.Ed.positive

= 186.26 kNm

19.45 kN/m

10.00 m 10.00 m

-243.28 kNm

136.85 kNm

10.00 m 10.00 m

19.45 kN/m

-121.64 kNm

186.26 kNm

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 8 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

In addition, the maximum shear force on the steel section is:

Design shear, V

a.Ed

= 121.64 kN

5.2. Plastic Resistance to Vertical Shear, V

Rd

6.2.2.2

The design plastic shear resistance of the structural steel section, V

pl.a.Rd

, in the

absence of torsion is given by: 6.2.6 (2)

V

pl.a.Rd

= A

v

$(f

y

/#(3))/!

M0

EN1993-1-1

Where A

v

is the shear area given by:

A

v

= A

a

(2 $ b $ t

f

) + ((t

w

+ (2 $ r)) $ t

f

) = 5130 mm

2

6.2.6(3)

But not less than % $ h

w

$ t

w

= 4494 mm

2

EN1993-1-1

where h

w

is the clear web depth between flanges h

w

= h

a

- (2 $ t

f

) = 428 mm

and % is conservatively taken as 1.0. 6.2.6(3)

EN1993-1-1

A

v

= 5130 mm

2

! Design shear resistance V

pl.a.Rd

= 814.53 kN 6.2.2.2

Therefore as the applied shear is less than half the shear resistance, the effect of shear on

plastic moment resistance can be ignored 6.2.2.4(1)

5.3. Plastic Moment Resistance of Steel Section

It is assumed that the beam is fully restrained against lateral torsional buckling

under positive moments, since the decking spans perpendicular to the beam and is

directly attached to the top flange.

!Positive moment Resistance of steel section, M

pl.a.Rd

= W

pl.y

$f

yd

= 553.75 kNm

Beam is Satisfactory for positive moment resistance during execution of the

Structure

5.4. Lateral Torsional Buckling resistance of the Steel Beam 6.3.2.1

Considering the negative design moment, the design buckling resistance of a

laterally unrestrained beam is taken as: EN1993

M

b.Rd

= &

LT

$ W

pl.y

$f

y

/!

M1

equation (6.55)

where:

W

y

= W

pl.y

for a class 1 section

&

LT

is the reduction factor for lateral torsional buckling, which for a rolled section, is

given by:

&

LT

= 1/('

LT

+#('

LT

2

-($)

LT

2

)) 6.3.2.3(1)

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 9 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

where:

!

LT

= 0.5"[1+#

LT

"( $

LT

$

LT.0

)+ %"$

LT

2

]

the parameters $

LT.0

and % may be given in the National Annex. Recommended

values of, $

LT.0

= 0.4 and % = 0.75 are given in EN1993-1-1.

#

LT

is given in Table 6.3, EN1993 using the appropriate buckling curve, determined

using Table 6.5, EN1993. For h

a

/b = 2.415, use buckling curve c and #

LT

= 0.49

The non-dimensional slenderness, $

LT

, is defined as &(W

pl

.

y

"f

y

/M

cr

) where M

cr

is the

elastic critical moment for lateral torsional buckling. Unfortunately EN1993-1-1 does

not give expressions for calculating M

cr

and therefore designers must use textbooks

to obtain the most appropriate equation for M

cr

. However, the non-dimensional

slenderness, $

LT

, can more conveniently be found using the following relationship:

$

LT

= [$

LT

/$

1

]"%

0.5

where $

1

= '"[E

a

/f

y

]

0.5

Note: This is equation (F.12) in Appendix F.2 of the draft Eurocode DD ENV1993-1-1,

published in 1992. This information has been removed from the latest draft EN1993-1-1,

presumably as it is considered to be textbook information.

For a beam with uniform doubly symmetric cross-sections $

LT

can be obtained from:

$

LT

= 0.9"(L/i

z

)/[C

1

0.5

"[1+0.05"[(L/i

z

)/(h

a

/t

f

)]

2

]

0.25

] = 124.067

where C

1

= 1.285 (corresponding to the shape of the bending moment diagram with

load on both spans)

Note: This is equation (F.20) in Appendix F.2 of the draft Eurocode DD ENV1993-1-1,

published in 1992. This information has been removed from the latest draft EN1993-1-1,

presumably as it is considered to be textbook information.

Therefore, $

LT

= 1.238

and !

LT

= 1.280

which gives (

LT

= 0.505

!M

b.Rd

= 279.86 kNm > Ma.Ed.negative therefore OK

Beam is stable without further restraint during the execution stage

6. Composite Stage Design

6.1. Global Analysis

The moments and forces within the section are determined using linear elastic

global analysis methods. Moment redistribution, in accordance with clause 5.4.4

has been carried out.

The cross section over the support is class 1, and therefore the support moments

(determined for the uncracked section) have been reduced by 40%, the maximum

permitted for this class in Table 5.1.

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 10 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

The resistance of the steel beam and composite section are determined using

plastic section analysis.

Maximum uniformly distributed design load on beam, F

comp.max

= 3$(!

G.sup

$g

comp

+

!

Q

$q

comp

) = 38.89 kN/m

Minimum uniformly distributed design load on beam, F

comp.min

= 3$!

G.inf

$g

comp

=

13.80 kN/m

6.1.1. Load Case 1 Maximum Design Load on both spans

Figure 7: Design loading

Figure 8: Design Bending Moments with full design load on both spans (with no

moment redistribution)

6.1.2. Load Case 2 Maximum Design Load on one span only

Figure 9: Design loading

38.89 kN/m

10.00 m 10.00 m

-486.00 kNm

273.38 kNm

13.80 kN/m

10.00 m 10.00 m

38.89 kN/m

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 11 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

Figure 10: Design Bending Moments with load on one span only (with no moment

redistribution)

Therefore considering both loadcases and adopting the maximum 40% reduction in

support moment permitted, the maximum moments on the composite section are:

Design hogging moment, M

Ed.negative

= 486.00$0.6 = 291.600 kNm (loadcase 1)

Design sagging moment, M

Ed.positive

= 335.32+0.5$(0.4$329.25) = 401.170 kNm

(loadcase 2)

Note: This redistributed design positive moment is an approximate value, assuming the

positive moment at mid-span increases by approximately ! the decrease in negative

moment over the support.

The maximum elastic shear force on the section is 242.00kN. The redistributed

shear force is given by:

V

Ed

= F

comp.max

$ L/2 + M

Ed.negative

/L = 223.594 kN

!Design shear, V

Ed

= 223.59 kN

6.2. Plastic Resistance to Vertical Shear, V

Rd

6.2.2.2

In this example, because the contribution of the reinforced concrete part of the

beam has not been established, the design plastic shear resistance of the

composite section, V

Rd

, is conservatively taken as that for the structural steel

section alone, V

pl.a.Rd

, in accordance with clause 6.2.6, EN1993-1-1.

!Design shear resistance (as previously calculated in section 5.2), V

Rd

= V

pl.a.Rd

=

814.53 kN 6.2.2.2

Therefore as the applied shear is less than half the shear resistance, the effect of shear on

plastic moment resistance can be ignored 6.2.2.4(1)

6.3. Moment Resistance with full Shear Interaction, M

pl.Rd

6.2.1.2

6.3.1. Effective Widths of Compression Flange, b

eff

5.4.1.2

Effective length of beam span between supports, L

e.1

=0.85$L = 8500 mm Figure 5.1

-329.25 kNm

335.32 kNm

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 12 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

Effective length of beam over support, L

e.2

= 0.25$(2$L) = 5000 mm Figure 5.1

Midspan effective breadth, b

eff.1

= 2$ L

e.1

/8 = 2125 mm < beam spacing

and support effective breadth, b

eff.2

= 2$ L

e.2

/8 = 1250 mm < beam spacing

6.3.2. Midspan Moment Resistance

In the midspan region of the beam, the moment resistance of the composite section

is calculated in the same way as for a simply-supported composite beam.

Compressive Resistance of Slab, N

c.f

, neglecting the contribution of any

reinforcement in compression in accordance with clause 6.2.1.2(1)c, is:

N

c.f

= 0.85$f

ck

$b

eff.1

$h

c

/!

c

= 4768.50 kN

Tensile Resistance of Steel Section, N

pl.a

, is:

N

pl.a

= f

yd

$A

a

= 3128.56 kN

Since N

pl.a

<N

c.f

the plastic neutral axis (pna) lies within the concrete flange,

therefore the moment resistance of the composite beam assuming full shear

interaction is given by:

M

pl.Rd.positive

= N

pl.a

$[(h

a

/2)+h

c

+h

p

- (N

pl.a

$h

c

)/ (N

c.f

$2)]

M

pl.Rd.positive

= 1092.57 kNm > MEd.positive therefore OK

6.3.3. Support Moment Resistance

At the internal support the negative (hogging) moment resistance is obtained by

considering the tensile resistance of the reinforcement within the slab.

Assume T16 bars at 200mm centres (1005mm

2

/m) with 25mm cover to the top of

the slab.

d

bar

= 16mm A

bar

= +$d

bar

2

/4 = 201 mm

2

A

s

= b

eff.2

$ 1005 = 1256 mm

2

Axial capacity of the steel section, N

pl.a

, is:

N

pl.a

= f

yd

$A

a

= 3128.56 kN

Axial capacity of the slab reinforcement, N

s

, is:

N

s

= f

sk

$A

s

/!

s

= 502.50 kN

Depth of the neutral axis below the top surface of upper flange , z

cw

, is given by:

z

cw

= h

a

/2 - N

s

/(2$t

w

$f

yd

) = 145 mm

therefore, M

pl.Rd.negative

is given by:

M

pl.Rd.negative

= M

pl.a.Rd

+ N

s

$(h

a

/2 + z) N

s

2

/(4$t

w

$f

yd

)

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 13 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

where z is the distance from the top of the steelwork to the centreline of the slab

reinforcement, z = 117 mm

Therefore M

pl.Rd.negative

= 707.11 kNm > MEd.negative, therefore OK

6.3.4. Lateral Torsional Buckling of Composite Section

In accordance with guidance outlined in clause 6.4.3, the lateral torsional buckling

resistance of this continuous beam (within a building structure), has not been

checked. This is because the relevant conditions outlined in clause 6.4.3(1) have

been satisfied.

6.4. Moment Resistance with Actual Shear Interaction

6.4.1. Shear Connector Resistance 6.6.3.1

The design shear resistance of a single shear connector welded in accordance with

EN14555 is given by:

P

Rd

= [0.8$f

u

$(+$d

stud

2

)/4]/!

V

equation (6.18)

or

P

Rd

= [0.29$*$d

stud

2

$#(f

ck

$E

cm

)]/!

V

equation (6.19)

whichever is the smaller, with:

*=0.2$(h

sc

/d

stud

+ 1) if 3 < h

sc

/ d

stud

< 4 equation (6.20)

or

*=1 if h

sc

/ d

stud

> 4 equation (6.21)

h

sc

/d

stud

= 5.00 therefore *=1

therefore:

P

Rd

= [0.8$f

u

$(+$d

stud

2

)/4]/!

V

= 81.66 kN equation (6.18)

or

P

Rd

= [0.29$*$d

stud

2

$#(f

ck

$E

cm

)]/!

V

= 99.10 kN equation (6.19)

The deck spans perpendicular to the beam and is therefore transverse. The effect

of a reduction factor, k

t

, on the shear connector resistance should be checked. 6.6.4.2

There is one stud per trough of the deck, therefore n

r

= 1

k

t

= (0.7$b

o

)/(#(n

r

)$h

p

)$(h

sc

/h

p

1) = 1.66 equation (6.23)

> 1.0 therefore no reduction in the shear connector resistance

therefore P

Rd

= 81.66 kN

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 14 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

6.4.2. Shear Stud Layout Loadcase 1

Figure 12: Shear Stud Layout corresponding to loadcase 1

The maximum positive moment is at a point approximately 3.75m away from the far

left hand support. Therefore, 24 troughs are available for the positioning of the

shear stud connectors between this support and the point of maximum negative

moment. Between the internal support and the point of maximum negative moment,

there are 41 shear stud positions.

6.4.3. Shear Stud Layout Loadcase 2

Figure 13: Shear Stud Layout corresponding to loadcase 2

The point of maximum sagging moment is approximately 4.0m away from the far

left hand support. Therefore 26 troughs are available for the positioning of the shear

stud connectors. There are 39 shear stud positions between the internal support

and the point of maximum sagging moment.

6.4.4. Degree of Shear Connection, 6.6.1

The longitudinal shear force transfer, R

q

, between the left hand support and the

point of maximum positive moment, is:

R

q.positive

= 24$P

Rd

= 1959.84 kN (loadcase 1)

24 studs at 153mm centres

10.0 m

Column C

L

250 41 studs at 153mm centres

Column C

L

26 studs at 153mm centres

10.0 m

Column C

L

250 39 studs at 153mm centres

Column C

L

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 15 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

R

q.positive

= 26$P

Rd

= 2123.16 kN (loadcase 2)

Note: It has been assumed that the area between the left hand support and the point of

maximum positive moment is critical as there are significantly more shear studs between

the point of maximum positive moment and the internal support, even if those within the

hogging region of the beam are ignored. This should be checked when the number of

shear studs required to yield the slab reinforcement in the hogging region of the beam is

determined (see section 6.4.5).

Minimum degree of shear connection, %

min

, for beam of length less than 25.00m is

given by:

%

min

= 1-[(355/f

y

)$(0.75-0.03$L)] = 0.419 or 0.4 (whichever is greater) 6.6.1.2

actual degree of shear interaction, %, is given by:

%

positive

= N

c

/N

c.f

= R

q.positive

/N

pl.a

= 0.626 (loadcase 1)

%

positive

= N

c

/N

c.f

= R

q.positive

/N

pl.a

= 0.679 (loadcase 2)

both of which are greater than %

min

and are therefore OK

6.4.5. Moment Resistance, M

Rd

6.2.1.3

The negative plastic moment resistance in hogging bending should be determined

in accordance with clause 6.2.1.2, assuming there is full interaction between the

structural steel, reinforcement and concrete. Appropriate shear connection should

be provided to ensure yielding of the reinforcement in tension.

In other words, sufficient shear studs should be provided in the hogging region of

the beam to yield the reinforcement in tension prior to failure of the shear

connectors.

The number of studs required to yield the reinforcement, N

s

/P

Rd

= 6

There are therefore sufficient shear studs in the hogging region of the beam to yield

the reinforcement in tension. Therefore, M

Rd.negative

is given by:

M

Rd.negative

= M

pl.Rd.negative

= 707.11 kNm > MEd.negative, therefore OK

Beam is satisfactory for negative moment resistance in service

The positive moment resistance of the composite beam is obtained using the linear

interaction method in accordance with clause 6.2.1.3(5) as follows:

M

Rd

= M

pl.a.Rd

+ (N

c

/N

c.f

)$(M

pl.Rd

-M

pl.a.Rd

) equation (6.1)

where:

N

c

is the compressive normal force in the concrete flange

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 16 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

N

c.f

is the compressive normal force in the concrete flange if full shear interaction is

provided, where the ratio % = N

c

/N

c.f

is the degree of shear interaction.

The degree of shear interaction varies between loadcase 1 and loadcase 2, as the

number of shear studs between the supports and the point of maximum positive

bending moment varies between the two loadcases. The separate values of

positive moment resistance corresponding to the two loadcases should,

theoretically, be considered.

In practice, however, it would normally be acceptable to conservatively calculate the

positive moment resistance of the composite section using the minimum shear

interaction (corresponding to loadcase 1) and compare this with the maximum

positive design moment (corresponding to loadcase 2 in this example). This

approach has been adopted.

Therefore the moment resistance with partial shear interaction, for the sagging

regions of the composite beam (using the minimum shear interaction) is:

M

Rd.positive

= M

pl.a.Rd

+ %

positive

$(M

pl.Rd.positive

M

pl.a.Rd

) = 891.28 kNm > MEd.positive,

therefore OK

Beam is satisfactory for positive moment resistance in service

6.5. Transverse Reinforcement and Longitudinal Shear Resistance Check

Check resistance of the concrete flange to splitting. To prevent concrete failure the

longitudinal shear stress should satisfy the following inequality:

v

Ed

< ,$(f

ck/

!

c

)$sin(-

f

)$cos(-

f

) equation (6.22)

EN1992-1-1

where:

, = 0.6$(1-f

ck

/250) 6.2.3(3) & 6.2.2(6)

-

f

is the angle between the diagonal strut assumed in the Eurocode 2 model and

the longitudinal axis of the slab, which is chosen (within limits) by the designer.

Note: the recommended range of #f may be found within the National Annex to EN1992,

but in the absence of more rigourous calculation, the limits are 45

o

>#f >26.5

o

, for 6.2.4(4)

compression flanges or 45

o

>#f >38.6

o

for tension flanges. EN1992-1-1

The design shear stress, v

Ed

, for one stud per trough, is given by:

v

Ed

= P

Rd

/(2$0.153$h

f

) = 2.70 N/mm

2

6.6.6.1(5)

using h

f

= h

c

= 99 mm 6.6.6.4(1)

If we choose the angle, -

f

= 26.5 (which leads to a lower bound)

,$(f

ck

/!

c

)$sin(-

f

)$cos(-

f

) = 5.37 N/mm

2

therefore v

Ed

< ,$(f

ck/

!

c

)$sin(-

f

)$cos(-

f

)is satisfied

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 17 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

In addition, the area of transverse reinforcement within the slab, A

sf

, should satisfy

the following:

A

sf

$(f

sk

/!

s

)/s

f

> v

Ed

$h

f

/cot(-

f

) equation (6.21)

EN1992-1-1

where:

A

sf

is the area of the transverse reinforcing bars at spacing s

f

Note: in this example the contribution of the profiled metal sheeting has been

conservatively neglected, although clause 6.6.6.4(4) allows the contribution of sheeting

with ribs transverse to the beam and continuous over it to be taken.

The minimum slab reinforcement, A

s.min

= k

s

$k

c

$k$f

ct.eff

$A

ct

/.

s

7.4.2(1)

where:

f

ct.eff

is the mean value of tensile strength which can be taken as f

ctm

= 2.60 N/mm

2

k is a coefficient which allows for the effect of non-uniform self-equilibriating

stresses and is equal to 0.8

k

s

is a coefficient which allows for the effect of the reduction of the normal force of

the concrete slab due to initial cracking or local slip and is taken as 0.9

kc is a coefficient which takes account of the stress distribution within the section

immediately prior to cracking and is given by:

k

c

=1/(1+h

c

/(2$z

o

)) + 0.3; <1.0

where z

o

is the vertical distance between the centroids of the un-cracked concrete

flange and the un-cracked composite section, calculated using the modular ratio n

0

.

n

0

= E

a

/E

cm

where E

cm

is the secant modulus of elasticity for short term loading

therefore; n

0

= 6

The depth from the bottom of the steel section to the centroid of the un-cracked

section, y

na

, is:

y

na

= [(h

a

/2)$A

a

$n

0

+ h

c

$b

eff.2

$((h

c

/2)+h

a

+h

p

)]/(A

a

$n

0

+ h

c

$b

eff.2

) = 446 mm

Therefore the distance between the centroid of the un-cracked composite section

and the centroid of the un-cracked concrete flange, z

o

, is:

z

o

= h

a

+h

p

+h

c

/2 y

na

= 118 mm

.

s

is the maximum stress permitted in the reinforcement after cracking. This may be

taken as the characteristic yield strength, f

sk

Act is the area of the tensile zone immediately prior to cracking. For simplicity the

area of concrete section within the effective width may be used.;

therefore; k

c

= 1.005

and A

s.min

= 506 mm

2

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 18 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

Try T12-200 reinforcement to the top face of the slab, so A

sf

= 113.1 mm

2

and s

f

=

200mm

Hence, A

sf

$(f

sk

/!

s

)/s

f

= 226 N/mm

and v

Ed

$h

f

/cot(-

f

) = 133 N/mm

therefore A

sf

$(f

sk

/!

s

)/s

f

> v

Ed

$h

f

/cot(-

f

) is satisfied and no additional reinforcement is

required.

7. Serviceability Limit States

7.1. Elastic Stress Check

No stress checks are required for normal conditions and consequently no limits are

outlined in EN1994. 7.2.2(1)

7.2. Deflections

7.2.1. Execution Stage Deflections

Deflection of the bare steel beam during execution is given by:

Second moment or area of the steel section, I

yy

= 41015 cm

4

The deflection due to variable actions, w

var.exe

, during execution is given by:

Unfactored variable action on beam, F

var.exe

= 15.00 kN

The critical loadcase for deflection is where only one span is fully loaded, the

deflection (determined using a commercial software package) is:

w

var.exe

= 1.63 mm <L/360 therefore OK Draft UK National

Annex EN1993-1-1

Note: The limit above has been taken from the Draft UK National Annex for EN 1993-1-1,

it may change during the development of the National Annex.

The deflection due to both permanent and variable actions, w

tot.exe

, during execution

is given by:

Total unfactored design action on beam, F

tot.exe

= 142.42 kN

The deflection (determined using software package) is:

w

tot.exe

= 15.50 mm < L/250 therefore OK

Note: The above limit corresponds with current British practice, it may change during the

development of the National Annex. It should also be noted that the SCI publication P300

suggests an absolute limit of 25mm in the non-composite stage to limit ponding of the wet

concrete.

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 19 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

7.2.2. Composite Stage Deflections

The deflection of the composite section due to variable and total actions has been

determined using commercially available software, using the second moment of

area of the composite section based on elastic (uncracked) properties to the

sagging regions of the beam. Appropriate allowance must be made for the effects

of cracking of concrete and in accordance with clause 5.4.2.3(3), a reduced flexural

stiffness has been used over 15% of the span on each side of the internal support.

Second moment of area of the composite section based on elastic (uncracked )

properties, I

c

, is given, from first principles, by:

I

c

= [A

a

$(h

a

+2$h

p

+h

c

)

2

]/[4$(1+n

L

$R)] + (b

eff.1

$h

c

3

)/(12$n

L

) + I

yy

where:

R = A

a

/(b

eff.1

$h

c

) = 0.054

The effects of creep may be taken into account by using a modular ratio, n

L

, given 5.4.2.2(2)

by:

n

L

= n

0

$(1+/

L

$0

t

) = 15.90

where:

n

0

= E

a

/E

cm

where E

cm

is the secant modulus of elasticity for short term loading

0

t

is the creep coefficient taken as 1.5 from Figure 3.1, EN 1992-1-1, for loading at

28 days

/

L

is a creep multiplier depending upon the type of loading, taken as 1.1 for

permanent loads.

Note: For simplification in building structures, the effects of creep may alternatively be 5.4.2.2(11)

taken into account by replacing the concrete area, Ac, by effective steel areas Ac/n for

both short and long term loading, where n is the nominal modular ratio corresponding to

an effective modulus of elasticity for concrete of Ec,eff taken as Ecm/2.

Appropriate allowance should also be made for the effects of concrete shrinkage in 7.3.1(8)

accordance with clause 5.4.2.2(1), but, unless specifically required by the client, the

effect of curvature due to the shrinkage of normal weight concrete need not be

included when the ratio of span to overall depth of composite beam is not greater

than 20.

The overall depth of composite beam is 613 mm and the ratio of span to overall

depth is therefore 16.303 and the effect can be ignored.

In addition, the effects of incomplete interaction may be ignored for most cases, 7.3.1(4)

provided that the shear interaction is greater than 0.50.

Therefore I

c

= 109601 cm

4

Over the central support a reduced flexural stiffness, E

a

I

2

, is used, where E

a

is the

Youngs modulus of steel and I

2

is the second moment of area of the effective steel 1.5.2.12

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 20 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

section calculated neglecting concrete in tension but including reinforcement.

Over the support the concrete is within the tensile zone of the composite section

and I

2

is therefore the second moment of area of the steel section and slab

reinforcement, given by:

The depth from the bottom of the steel section to the neutral axis, y

na1

= [(h

a

/2)$A

a

+

(h

a

+h-25-d

bar

/2)$A

s

]/(A

a

+A

s

) = 266 mm

Therefore the distance between the neutral axis and the centroid of the steel

section, y

a

= y

na1

- (h

a

/2) = 35 mm and to the centroid of the reinforcement, y

s

=

(h

a

+h-25-d

bar

/2) y

na

= 135 mm

Number of reinforcing bars in the effective width of slab = A

s

/A

bar

= 6 (approx) and

the second moment of area of the reinforcement, I

s

= 6$+$d

bar

4

/64 = 1.930 cm

4

Therefore, I

2

= A

a

$y

a

2

+I

yy

+ A

s

$y

s

2

+I

s

= 44661 cm

4

Therefore the deflection due to variable actions, w

var.comp

, is given by:

Unfactored variable action on beam, F

var.comp

= 135.00 kN

The critical loadcase for deflection is where only one span is fully loaded, the

deflection (determined using a commercial software package) is:

w

var.comp

= 5.95 mm < L/360 therefore OK Draft UK National

Annex EN1993-1-1

Note: The limit above has been taken from the Draft UK National Annex for EN 1993-1-1,

it may change during the development of the National Annex.

Therefore the deflection due to both permanent and variable actions, w

tot.comp

, is

given by:

Total unfactored load on beam, F

tot.comp

= 273.05 kN

The critical loadcase for deflection is where only one span is fully loaded, the

deflection (determined using a commercial software package) is:

w

tot.comp

= 10.02 mm< L/250 therefore OK

Note: The above limit corresponds with current British practice, it may change during the

development of the National Annex.

7.2.3. Composite stage vibration check

The dynamic property of the floor beam should satisfy criteria outlined in clause

A1.4.4, EN1990-1-1. This clause states that the natural frequency of vibrations of

the structure or structural member should be kept above appropriate values which

depend upon the function of the building and the source of the vibration. It does not

Project Title:

EC3 & EC4 Worked Examples

Project Number:

Sheet 21 of 21

Rev:

07

Subject:

Continuous steel and concrete composite beam

Made by/date:

CGR/September 2004

Client:

Checked/date:

GHC/October 2004

provide any guidance regarding the magnitude of this value, but does suggest that

the value be agreed with the client and/or the relevant authority.

A natural frequency limit of 4Hz has been used in this example, assuming that

walking is the main source of the vibration.

Consider the weight of the floor in the dynamic calculations to include the self

weight of the slab and beam, 10% of the imposed load (excluding partitions) and

ceilings and services.

therefore, F

vib

= 150.05 kN

It is necessary to consider the mode shape of vibration when calculating the natural

frequency of a continuous beam. Due to the influence of the asymmetric inertial

forces, the natural frequency is approximately the same as that of a simply-

supported beam.

!The deflection of the composite beam subject to instantaneously applied self

weight is:

w

vib

= (5$F

vib

$L

3

)/(384$E

a

$I

c

) = 8.49 mm

and the natural frequency of the beam, f, (subject to uniformly distributed loading) is

given by:

f = 18/#(w

vib

) = 6.178 Hz > 4.0Hz therefore OK

Note: Whilst the 4Hz natural frequency limit is an almost universally accepted industry

standard for vibrations, satisfying the limit will not guarantee that the element or structure

as a whole will perform adequately.

You might also like

- Design Detail Report for Structural ElementsNo ratings yetDesign Detail Report for Structural Elements18 pages

- Response Spectrum Analysis in Seismic DesignNo ratings yetResponse Spectrum Analysis in Seismic Design19 pages

- Anup KR Guru - AFCON - Construction Method For - (10!11!2017)No ratings yetAnup KR Guru - AFCON - Construction Method For - (10!11!2017)11 pages

- Pinned Base Plate Connection UB305X165X40No ratings yetPinned Base Plate Connection UB305X165X403 pages

- Design of Compression Members: As Per IS 800: 2007No ratings yetDesign of Compression Members: As Per IS 800: 2007119 pages

- Ilide - Info Bridge Abutment Pier Design As Per Irc PRNo ratings yetIlide - Info Bridge Abutment Pier Design As Per Irc PR112 pages

- Joint Design Calculation for Beams and ColumnsNo ratings yetJoint Design Calculation for Beams and Columns8 pages