Professional Documents

Culture Documents

Erection Operation & Maintenance Manual For 415V, 3000A NSPBD

Uploaded by

thegemishere100%(1)100% found this document useful (1 vote)

394 views66 pagesThe document provides information on the erection, operation, and maintenance of 415V, 3000A non-segregated phase busducts for a solar power project in Jaisalmer, Rajasthan. It details the salient features of the busducts such as the aluminum alloy enclosures and busbars, FRP supports, inspection openings, and terminations. It also outlines factory assembly and testing, material receipt and handling, storage, pre-erection, erection, pre-commissioning, post-commissioning, operation and maintenance, field testing, dos and don'ts, and maintenance schedule.

Original Description:

C&S NSPBD Manual

Original Title

Erection Operation & Maintenance Manual for 415V, 3000A NSPBD

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides information on the erection, operation, and maintenance of 415V, 3000A non-segregated phase busducts for a solar power project in Jaisalmer, Rajasthan. It details the salient features of the busducts such as the aluminum alloy enclosures and busbars, FRP supports, inspection openings, and terminations. It also outlines factory assembly and testing, material receipt and handling, storage, pre-erection, erection, pre-commissioning, post-commissioning, operation and maintenance, field testing, dos and don'ts, and maintenance schedule.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

394 views66 pagesErection Operation & Maintenance Manual For 415V, 3000A NSPBD

Uploaded by

thegemishereThe document provides information on the erection, operation, and maintenance of 415V, 3000A non-segregated phase busducts for a solar power project in Jaisalmer, Rajasthan. It details the salient features of the busducts such as the aluminum alloy enclosures and busbars, FRP supports, inspection openings, and terminations. It also outlines factory assembly and testing, material receipt and handling, storage, pre-erection, erection, pre-commissioning, post-commissioning, operation and maintenance, field testing, dos and don'ts, and maintenance schedule.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 66

C&SElectricLtd

B-1, Site-IV, Surajpur Industrial Area, Kasna Road, Greater Noida.

Dist :- G.B. Nagar (U.P.)

Ph. No. :- 91-0120-3914500-01 Fax No. 91-0120-2341896

Website : www.cselectric.co.in

APPD CHKD REVISIONS DATE BY

FOR 415V, 3000A

NON- SEGREGETED PHASE BUSDUCT

TI TLE OF THE DOCUMENT

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

2

CONTENTS

PART NO DESCRIPTION PAGE NO.

I SALIENT FEATURES OF BUSDUCTS 3-4

II FACTORY ASSEMBLY AND ROUTINE TESTS 5

III MATERIAL RECEIPT 5

IV STORAGE 6

V PRE-ERECTION 6

VI ERECTION 7-12

VII PRE-COMMISIONING 13

VIII POST COMMISIONING 14-15

IX OPERATION & MAINTENANCE 16

XI FIELD TESTS 17

XII DOS AND DONTs 17

XII MAINTENANCE SCHEDULE 18

XIV APPROVED DRG. MDL 19

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

3

Part-I-SALIENT FEATURES OF BUSDUCTS

The Busducts serve as interconnections between Transformer and LT Panel (Switchgear). These are of Non-

segregated Phase type. The Busducts are natural air cooled for Outdoor and Indoor purpose.

ENCLOSURE:-

The Enclosures are rectangular in cross section and are fabricated out of Al Alloy Sheets. Adjacent sections of

the Busducts are connected by means of Bolts and nuts with gasket in between to render the Busduct dust and

vermin proof.

BUSBAR:-

Al Alloy flats (PVC Sleeved) are used as busbars with Painted Matt black colour except contact surface.

Busbars are designed to meet the thermal and dynamic rating of Busduct. The final temperature of the Busbars

is limited to 95

0

C the specified requirements.

BUSBAR SUPPORTS:-

Bus supports are FRP plate having adequate electrical and mechanical characteristics. The Busbars are

supported on the FRP plate in such a way as to allow free movement of busbars due to thermal variations. FRP

supports are suitably spanned to with stand mechanical forces that are likely to act during short circuit.

BUSBAR RIGID JOINT:-

Bolted overlap type Busbar rigid joints are envisaged for connecting successive Busbars of the same phase. HTS

bolts, nuts and spring steel washers are used to achieve an efficient joint.

INSPECTION OPENING:-

Bolted type inspection openings of sufficient size are provided on the enclosures to facilitate maintenance of

busbar supports and busbar joints.

RUBBER BELLOW:-

EPDM rubber bellows are provided at transformer end terminations. These will provide flexibility in erection

and also take care of settlement of Transformer / Switchgear connections.

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

4

WALL FRAME ASSY:-

Wall frame assembly with FRP sealing pale provided at the location crossing the busduct Transformer yard /

roomto switchgear roomfor prevent of any fire in equipment to other equipment, Sealing plate also stop the air

fromoutdoor to indoor. Silica gel breathers are provided at both side of sealing plate for any absorbing any

moisture.

TERMINATIONS

TRANSFORMER & PANEL END TERMINATION:-

Busducts are terminated on to the Transformer / Switchgear by means of copper laminated Flexibles HTS bolts,

nuts and washers are used to achieve an efficient joint.

SPACE HEATERS:-

Space heaters are provided at regular intervals in the run of the Busduct enclosure for complete run of

Busducts. These can be removed or replaced without disturbing the bus arrangement. All the space heaters are

wired to a common marshalling box provided at suitable locations at Panel side adaptor Box.

MARSHALLING BOX:-

Space heater wiring is envisaged by 2.5 mm

2

copper wires running through PVC conduits. The Marshalling box

is made of Al alloy and space heaters are wired to it.

GROUNDING:-

Al earth bus size-1 Nos 50x10 thk. flats are provided along the entire run of the Busduct at single side of

enclosure bottomedge line. Provision is made for connecting the ground bus at the equipment ends. All ground

bus joints are made with MS electro galvanised bolts and nuts.

PAINTING:-

The exterior of the enclosure is painted Epoxy based (Indoor with RAL 7032 & Outdoor with 631 of IS : 5), for

enclosure interior and busbar painted with Matt black paint.

********

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

5

Part-III-FACTORY ASSEMBLY & ROUTINE TESTS

Before assembly of various Busduct sections detailed study of Layout / Erection & Key diagram and other

contract drawings should be made to ensure no part of Busduct is missed. The Busducts after assembly must be

checked for fouling and clearances. Power frequency high voltage test must be conducted on entire assembly as

routine tests.

After completion of the tests Busducts have to be dismantled and each Busduct sections should be separately

kept in a casing with a packing list. All assemblies must have erection marks clearly marked up.

Part-IV-MATERIAL RECEIPT (UNLOADING, INSPECTION & HANDLING)

1, Proper crane/sufficient manpower shall be employed for unloading the packing from the trucks/wagons.

Under no circumstances should the packing be rolled/ pushed down the wagons/trucks.

2, Make a thorough inspection of the complete consignment for verification of quantity and external damages.

If any damage is found or suspected, report at once with particulars.

3, During unloading and handling operation if loose parts are found in the bottom of equipment, preserve them

for re-assembly or replace themin the respective locations.

4, While uncrating the packages, sufficient care shall be taken to avoid damages due to sharp crowbars or

opening levers.

5, Contents of the case/crate shall be verified with the packing slip kept inside the package.

6, The structures shall be clean, free from sharp edges, bends etc. The external damages to galvanizing due to

rough handling or unusual weather conditions or any other cause shall be verified.

7, All packages shall be handled gently as the busducts may be sent partly assembled with insulators.

8, Entire quantity of enclosures, elements, loose items etc. shall be received as per the packing list.

9, The enclosures shall not have any external damages or deformation. If the flange edges are damaged,

gaskets and the retaining arrangement will not effectively seal the enclosures.

10, The enclosure surface shall be free fromdents, scratches on the painted surface and at welded joints.

11, The Busbars support shall be verified for any cracks, etc.

12, All the inspection covers shall be tightly closed with proper gaskets inside.

13, The enclosures are to be checked for presence of any foreign material inside.

14, Water or any deposits inside the enclosure shall be thoroughly cleaned.

15, The items which are made of Aluminumor soft materials shall be handled very carefully to avoid any

damage at site.

16, Ensure that the assemblies/components are put back in the original packing as in received condition before

sending themfor storage.

********

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

6

Part-V-STORAGE

1, All assemblies/components shall be properly packed in the original packing with suitable polythene

covers.

2, All packages must be kept in well protected areas.

3, All small fragile items must be stored in proper containers at safe locations to avoid any damage.

4, Identification marks or tags shall be kept for easy identification.

5, All the items shall be stored in a systematic way for easy removal and to avoid any damage.

6, The heavy packages shall be stored one above the other.

7, Suitable slings shall be used to avoid impact on the packages while handling.

8, The structure shall not be laid directly on the ground and should be stacked on wooden battens to avoid

direct contact with soil or water.

9, The Hardware such as Bolts, Nuts & Washers shall be stored in indoor and kept size wise in racks

preferably with a coating of oil in separate compartment for easy identification.

10, Enclosure, Busbars & FRP shall be protected carefully.

11, Inspection covers shall be tightly closed to avoid entry of dust and water.

12, Rubber bellows shall be stored in such a way to avoid direct contact with heat and sharp materials, which

will damage the same.

13, Flexibles shall be well protected fromany damage.

Part-VI-PRE ERECTION

1, All documents especially bill of material, layout drawings for busducts and structures shall be kept

readily available.

2. All the tools and tackles shall be made available. All civil details and equipment locations are checked

thoroughly to ensure perfect matching of busduct sections as per field quality assurance manual.

3. The rubber bellows shall be in good condition, and made ready for assembly/erection.

4. The FRP and the busbars shall be thoroughly cleaned with dry air before and after the assembly.

5. The ends of busbars shall be smooth and free fromdust, dents and paint etc.

6. The inside of enclosure shall be cleaned and free of foreign materials.

7. All surfaces that are to be bolted of busbars and earth bus etc. shall be thoroughly cleaned and free of

foreign materials.

********

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

7

Part-VII- ERECTION

GENERAL

Before the erection of busducts at site the Layout / Erection and Key / Assembly Drawings shall be studied in

detail and an easy and better procedure shall be developed. If the materials have been stored properly with

correct inventory, the installation work can proceed without the delay in searching for missing parts.

It is always preferable to begin the work at one end proceed to the other end. At this juncture, check up whether

necessary arrangements are provided at Switchgear / Transformer terminals for terminating Busducts use proper

tools like tirfor, pulley block etc. for lifting the enclosures. Proper selection of pulleys (2 or 3 sheaves) with

good quality manila ropes will improve the mechanical advantage and minimize the strain to erection crew

particularly when busducts are to be installed at high elevations.

Stringing the busducts for lifting and moving shall be done by skilled erectors and it shall be supervised that the

strings are provided properly so that the enclosures are lifted in a balanced manner without giving chance for

slip off. Check for the correctness of erection number on the enclosure before lifting and erecting the same in

the proper location. All enclosures must be in position and alignment should be checked before proceeding with

the bolting of busbars.

After the bus and support housings are in position, the FRP shall be wiped clean and all dust and foreign matter

removed frominside the enclosures. During the assembly, all the open portions of the bus enclosures shall be

protected from the accumulation of dust or dirt. Provision shall be made to prevent the entry of dust into the

portion of the enclosures, which have been erected.

SUPPORT STRUCTURES

1. Check up whether all foundation for steel columns have been cast and fixing plates have been embedded.

2. A thorough study of Layout / Erection & Key diagramis essential before taking up the steel erection. It

shall be ensured that all elevations are as per the drawing and any deviation shall be brought to the notice

of the customer. Under no circumstance the column erection should commence until the elevations match

with the approved drawings.

3. After ascertaining the correct location of embedded plates, weld the studs and fill up the gap between the

plate and floor with lean concrete or plaster such that the surface is in flush with the finished floor with

only studs projecting out.

4. Install supporting members in their respective places.

5. Verify with the drawings frequently to ensure correct installation of structures.

6. Keep the transverse member in position and tighten them after ascertaining the correct location.

7. Avoid using twisted member. This will cause great difficulty while aligning the enclosures.

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

8

8. Ensure all members of structures are properly grounded.

ENCLOSURE

Each standard enclosure is provided with two supports, one at either end. The site assembly work should start

froma fixed position. This may be from either the transformer or switchgear terminals. If there is a wall / floor

crossing, the erection work may also be commenced from this place, after checking thoroughly the correctness

of the position of the wall / floor opening.

BOLTING OF ENCLOSURE:-

The complete busduct is aligned and correct positioning at reference points such as transformer terminals, wall /

floor crossing, Switchgear terminals etc. is ensured. Connections between successive enclosures are done by

bolting with a EPDM gasket in between enclosure flanges. All inspection openings on the enclosures shall be

closed the moment the corresponding busbar joints are completed.

BUSBARS

Before proceeding with the busbar assembly, the FRP shall be thoroughly checked for any mechanical damage

during transit. Further it is desirable to megger the individual busduct sections before joining themtogether. If

poor results are obtained, the FRP are to be checked. Meggering the FRP sheets at the initial stage will avoid

replacement of FRP after the final assembly of busducts, which is laborious and time consuming.

For bolted joints in busducts, the following joining procedure should be adopted.

JOINING PROCEDURE

FOR BOLTED JOINTS:-

1. Apply a thin filmof suitable grease on the joint surfaces busbar and splice plate. Rub with steel wool on

the greased joint surface. Wipe away with a clean cloth.

2. The surface will have a silvery gleam which will contrast with the surface to the aluminumnot cleaned

then apply `Multipurpose grease at once, on the joint surface (any delay should be avoided to prevent re-

oxidization).The coating should be approx. 1mmthick and should cover the entire contact area.

3. Tighten the bolts after keeping the contact surfaces correctly in position. While tightening, ensure a

generous squeeze of the grease fromthe joint. If sufficient grease does not appear, disconnect and apply

additional grease and then tighten.

4. Bolts & nuts which are supplied with spring washers shall be tightened initially with spanners and finally

checked with torque wrench for the recommended values, which are furnished below:

5. Bolt tightness Torque values:

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

9

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

10

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

11

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

12

SPECIFIED INSTRUCTIONS :

1. Proper tools shall be used for transportation of materials.

2. The required assemblies or components alone shall be taken to erection site at each stage of erection.

3. The fragile itemshall be handled carefully.

4. The structures shall be properly tightened after alignment.

5. The lifting slings shall be put properly to avoid any distortion and ensure temporary supports if necessary

are ready before lifting the busducts.

6. The floor frame assembly shall be assembled with gaskets properly before lifting to its position.

7. Enclosure sections and rubber bellows shall be properly placed & busbars shall be checked.

8. Before making the joints the cleanliness of jointing ends of busbars shall be checked.

9. Proper application of contact grease is necessary for busbar ends before jointing.

10. The bolts shall not be hammered but tightened fully to the required torque without over tightening.

11. The clearances between phase and enclosures shall confirmto the design values throughout the busducts.

12. Insulators and seal off bushings shall be checked for any damage.

13. No foreign materials or tools shall be left inside the enclosure.

14. All inspection covers shall be properly tightened with gaskets inside and the rubber bellows shall be

connected properly.

15. The earthing of busducts and structures shall be done properly.

16. If Transformer or switchgear connections are to be done later ensure that the enclosure ends are covered

properly.

17. Painting touch up if required shall be done for entire run of busducts.

********

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

13

PART-VII-PRE COMMISIONING

1. All pre-commissioning tests shall be conducted for busducts as per the field quality assurance.

2. Power frequency withstand tests shall be made in the field at 80% of the values given below:

Nominal Voltage inV(RMS) Power Frequency withstand(1 minute dry) in KV(RMS)

415 2.5

3. All joints have to be made properly tightened with correct bolt and nuts. Ensure that no joints have been

left without bolts.

4. All bolts and nuts have to be properly tightened.

5. There shall not be any bending/buckling of structure members.

6. All the structures shall be properly earthed to the station ground bus.

7. The temporary supports of busbars inside the enclosures if any shall be removed.

8. The Porcelain and FRP shall be verified for breakage etc.

9. The interior of the enclosures, busbars, FRP/sealing shall be cleaned and free from dirt, oil, grease or any

deposits and moisture.

10. Ensure that no flexible laminations have come out protruding and sharp corner is left anywhere.

11. Ensure all bolts and nuts at every flange joints and inspection covers are properly tightened.

12. The gaskets shall be provided at every flange joints and the inspection covers.

13. Proper earthing of busducts and support structures with station earthing systemshall be done.

14. The wiring and terminal clamps in the marshalling boxes and space heater/ thermostat shall be checked for

correctness.

15. The space heaters and thermostat shall be in good working condition.

********

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

14

PART-VIII- POST COMMISIONING

All precautions normally observed for High Tension Apparatus should be taken when inspecting Non

Segregated Phase Busduct and associated equipments. Housing should never be opened unless the entire unit is

shut down and the personnel working on the equipment assure themselves that the busduct is not live.

The only reason for opening the bus housing is to clean the FRP to check the space heaters and to ensure if any

loose contact is there in wiring. The first time the unit is shut down, a set of inspection covers in Indoor area

may be removed to determine the amount of dust collected. If this is appreciable, further inspection should be

made and insulators cleaned. If the insulators are clean the interval of inspection can be lengthened. Normally,

the inspection would have to be made more often than yearly intervals. However, the frequency of inspection

should be based on local conditions. Much longer intervals could safely be expected unless local atmosphere has

a very large amount of suspended dust. Space heater can be removed and replaced by suitably opening the

inspection covers.

It is recommended that during the annual maintenance for the equipments like transformer etc. the busducts

also should be checked for dust collection, insulation resistance values, tightness of all bolts and nuts and spring

washers etc. It is desirable to change the busduct gaskets one in 5 years if they are found hard and brittle.

The tightness of busbar joints should be checked during this period with the help of torque wrench. Sufficient

amount of `Multiple-Purpose grease also should be applied at the joining surfaces. The Flexibles used at

Transformer, Switchgear terminals should also be checked for any abnormal temperature rise.

As already stated, the frequency of inspection should be decided based on the amount of dust collection. Besides

this, there is no need to have quarterly/half yearly maintenance checks. But it is preferable to inspect all joints

and FRP at least once in a year.

Since the busbars are enclosed, no failure is expected. Expected failure, which may occur, is at support FRP,

either due to dust collection and condensation or due to minor cracks. In such events, the FRP must be cleaned

and the busbars to be hipoted before commissioning. If FRP do not withstand the hi-pot, then replace themwith

new ones. If the busducts are inspected and maintained periodically there can be no chance of any failures.

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

15

SPECIFIC INSTRUCTIONS :-

1. Proper tools and plants shall be used for transporting materials.

2. The required assemblies or components alone shall be taken to erection site at each stage of erection.

3. The fragile itemshall be handled carefully.

4. The structures shall properly tightened after alignment.

5. The lifting slings shall be put properly to avoid any distortion and ensure temporary supports if necessary

are ready before lifting the busducts.

6. The floor assembly shall be assembled and gasket properly before lifting to its position.

7. Enclosure sections and rubber bellows shall be properly placed and busbars checked.

8. Before making the joints the cleanness of jointing ends of busbars shall be checked.

9. Proper application of contact grease is necessary for busbar ends before jointing.

10. The bolts shall not be hammered but tightened fully to the required torque without over tightening.

11. The clearances between phase and enclosures shall confirmto the design values throughout the busducts.

12. FRP and sealing shall be checked for any damage.

13. No foreign materials or tools shall be left inside the enclosure.

14. All inspection covers shall be properly tightened with gaskets inside and the rubber bellows shall be

connected properly.

15. The earthing of busducts and structures shall be done properly.

16. If transformer or switchgear connections are to be done later ensure that the enclosure ends are covered

properly.

17. Painting touch up, if required shall be done for entire run of busducts for good physical appearance of the

assembly.

*********

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

16

PART-IX-OPERATION & MAINTENANCE

All precautions normally observed for High Tension Apparatus should be taken when inspecting Non

Segregated Phase Busduct and associated equipments. Housings should never be opened unless the entire unit is

shut down and the personnel working on the equipment assure themselves that the busduct is not live.

The only reason for opening the bus housing is to clean the FRP, sealing plate and to check the space heaters

and to ensure if any loose contact in wiring. The first time the unit is shut down, a set of inspection covers in

Indoor area may be removed to determine the amount of dust collected. If this is appreciable, further

inspection should be made and insulators cleaned. If the insulators are clean, the interval of inspection can be

lengthened. Normally the inspection would have to be made often than yearly intervals. However the frequency

of inspection should be based on local conditions. Much longer intervals could safely be expected unless local

atmosphere has a very large amount of suspended dust. Space heater can be removed and replaced by suitably

opening the inspection covers.

It is recommended that during the annual maintenance for the equipments like transformer etc. the busducts also

should be checked for dust collection, FRP resistance values, tightness of all bolts and nuts and spring washers

etc. It is desirable to change the busduct gaskets once in 5 years if they are found hard and brittle.

The tightness of busbar joints should be checked during this period with the help of torque wrench. Sufficient

amount of `Multi-Purpose grease also should be applied at the joining surfaces. The Flexibles used at

Transformer and Switchgear Terminations should also be checked for any abnormal temperature rise. Replace

if necessary, bimetallic strips, ensure that no flexible connecting bolt is loose due to vibration.

As already stated, the frequency of inspection should be decided based on the amount of dust collection.

Besides this, there is no need to have quarterly / half - yearly maintenance checks. But it is preferable to inspect

all joints and the insulators at least once in a year.

Since the busbars are enclosed, no failure is expected often except failure of insulation. This will occur at

support FRP/ sealing, either due to dust collection and condensation or due to minute cracks. In such events, the

bushings must be cleaned and the busbars to be hi -poted before commissioning. If FRP / sealing plate do not

withstand the Hi- pot, then replace them with new ones. If the busducts are inspected and maintained

periodically there can be no chance of any failures.

********

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

17

Part-XI-FIELD TESTS

The following are the suggested field tests to be conducted on the Busduct:-

Open inspection covers and check bus conductor joint bolts with the help of Torque Wrench. Ensure at least

10% of the joint locations are checked. Check up for any possible gaps between surfaces by using feeler gauge.

Dielectric Tests

Power Frequency withstand tests can be made in the field at 80% of the values given

Nominal Voltage Power Frequency Withstand

(1 Minute Dry)

415 V 2.5 KV

Precautions for Conducting Power Frequency Tests

1) Disconnect termination of enclosure and Bus conductor at Transformer/Generator.

2) Cordon off the entire Segregated Phase Busduct area.

Part-XII-Dos & Donts

D0's

1. Clean the insulators, seal off bushings, drain plugs etc periodically as noted.

2. Check for tightness of busbar joints and grease themsuitably.

3. Ensure the functioning of space heaters and thermostats.

4. Ensure the quality of the EPDM rubber gasket and change the same with a new one at periodic inspection

if found necessary.

5. Check effectiveness of joints at rubber bellows to avoid seepage of water.

6. Check effectiveness of earth continuity.

7. Enclosure exterior painting may be done once in five years.

DON'Ts

1. Do not open any of the inspection opening covers when the unit is live.

2. Do not walk over the busduct.

3. Do not disconnect any of the earth connection during maintenance.

4. Do not open rubber bellow with sharp edged tools.

5. Do not use sharp tools while doing maintenance work at equipment termination to avoid any damages.

*******

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

18

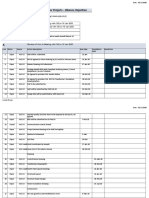

MAINTENANCE SCHEDULE

No. ITEM TO BE

INSPECTED

INSPECTION

NOTES

ACTION REQUIRED IF

INSPECTION SHOWS

UNSATISFACTORY

RESULTS

FREQUENCY

1. Busbar Support

(FRP )

Check for dirt Clean Annual

2. Busbars joints and

terminations.

Check for bolt

tightness.

Tighten the bolts for required

level. Apply grease if required.

Annual

3. Insulation resistance. Check for I.R.

value between

busbar and

enclosure &

between busbars.

If the I.R. value is less than 0. 5

Mega Ohmwhen measured

with a 1000V Mega Ohm

Meter, it is recommended to

take out the FRP and clean the

same and recheck for IR value.

Annual

4. Rubber bellows &

gaskets

Check for

brittleness

If the same is found too brittle

the same needs replacement

Once in 3 years

*******

Project : 1x125 MW Concentrated Solar Thermal Power Project Jaisalmer, Rajasthan

Doc. No.: 5427PN050-DHU-E-MRS-LVS-XXX-XXX Rev 00

C&S Doc.No.: C-1410-0712-16507

Doc Title: - Erection, Operation & Maintainanace Manual for 415V, 3000A Non-Segregated Phase Busduct.

C&SElectric Ltd.

19

AS BUILT/APPROVED DRAWING

SL.

NO.

DRAWING TITLE DRAWING NO. C&S DRG. NO.

15 Erection Kety Diagram for S/S-2 at swbd. OSS (02-PC-302) for 415V, 3000A Non-Segregated Phase Busduct 5427PN050-DHU-E-MRS-LVS-XXX-XXX C-1410-0712-16506D

13 Erection Kety Diagram for S/S-1 at swbd. USS (01-PC-302) for 415V, 3000A Non-Segregated Phase Busduct 5427PN050-DHU-E-MRS-LVS-XXX-XXX C-1410-0712-16506B

14 Erection Kety Diagram for S/S-2 at swbd. OSS (02-PC-301) for 415V, 3000A Non-Segregated Phase Busduct 5427PN050-DHU-E-MRS-LVS-XXX-XXX C-1410-0712-16506C

12 Erection Kety Diagram for S/S-1 at swbd. USS (01-PC-301) for 415V, 3000A Non-Segregated Phase Busduct 5427PN050-DHU-E-MRS-LVS-XXX-XXX C-1410-0712-16506A

10 Supporting structure arrangement for S/S-2 at SWBD. OSS (02-PC-301) for 415V, 3000A NSPBD 5427PN050-DHU-E-MRS-LVS-XXX-XXX C-1410-0712-16504C

11 Supporting structure arrangement for S/S-2 at SWBD. OSS (02-PC-302) for 415V, 3000A NSPBD 5427PN050-DHU-E-MRS-LVS-XXX-XXX C-1410-0712-16504D

8 Supporting structure arrangement for S/S-1 at SWBD. USS (01-PC-301) for 415V, 3000A NSPBD 5427PN050-DHU-E-MRS-LVS-XXX-XXX C-1410-0712-16504A

9 Supporting structure arrangement for S/S-1 at SWBD. USS (01-PC-302) for 415V, 3000A NSPBD 5427PN050-DHU-E-MRS-LVS-XXX-XXX C-1410-0712-16504B

6 Busduct connection at Transformer end for 415V, 3000A NSPB 5427PN050-DHU-E-MRS-LVS-LAY-008 C-1410-0712-16502

7 Busduct connection at Switchgear end for 415V, 3000A NSPB 5427PN050-DHU-E-MRS-LVS-LAY-007 C-1410-0712-16503

4 Layout of S/S-2 at SWBD. OSS (02-PC-301) for 415V, 3000A Non-Segregated Phase Busduct 5427PN050-DHU-E-MRS-LVS-LAY-006A C-1410-0712-16501A

5 Layout of S/S-2 at SWBD. OSS (02-PC-302) for 415V, 3000A Non-Segregated Phase Busduct 5427PN050-DHU-E-MRS-LVS-LAY-006B C-1410-0712-16501B

2 Layout of S/S-1 at SWBD. USS (01-PC-301) for 415V, 3000A Non-Segregated Phase Busduct 5427PN050-DHU-E-MRS-LVS-LAY-005A C-1410-0712-16500A

3 Layout of S/S-1 at SWBD. USS (01-PC-302) for 415V, 3000A Non-Segregated Phase Busduct 5427PN050-DHU-E-MRS-LVS-LAY-005B C-1410-0712-16500B

1 General Arrangement Drawing for 415V, 3000A Non-Segregated Phase Busduct 5427PN050-DHU-E-MRS-LVS-BDU-001 C-1410-0712-16499

Drawing List for 415V 3000A (Non-Segregated Phase Busduct)

Non-Segregated Phase Busduct

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

Y

R

B

R

N

Y

B

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

I

T

E

M

D

E

S

C

R

I

P

T

I

O

N

S

L

.

N

O

.

S

P

E

C

I

F

I

C

A

T

I

O

N

S

Y

M

B

O

L

S

Q

T

Y

.

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

L

E

V

A

T

I

O

N

N

R

Y

B

R

Y

B

2

1

I

N

D

O

O

R

O

U

T

D

O

O

R

S

I

D

E

V

I

E

W

G

R

A

D

E

Q

T

Y

.

M

A

T

E

R

I

A

L

S

L

.

N

O

.

D

E

S

C

R

I

P

T

I

O

N

B

I

L

L

O

F

M

A

T

E

R

I

A

L

S

3

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

1U 1V 1W

2

2

4

.

6

0

0

2

2

7

.

8

0

0

1U 1V 1W

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

2

2

4

.

6

0

0

2

2

7

.

8

0

0

1U 1V 1W

1U 1V 1W

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

1U 1V 1W

2

2

4

.

6

0

0

2

2

7

.

8

0

0

1U 1V 1W

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

1U 1V 1W

1U 1V 1W

2

2

4

.

6

0

0

2

2

7

.

8

0

0

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

1U 1V 1W

2

2

7

.

8

0

0

1U 1V 1W

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

I

T

E

M

N

O

.

D

E

S

C

R

I

P

T

I

O

N

I

S

M

B

-

1

5

0

4

-

I

S

A

-

5

0

X

5

0

X

6

m

m

T

H

K

.

I

N

2

0

0

X

2

0

0

B

O

X

F

O

R

M

A

T

I

O

N

W

E

I

L

D

E

D

W

I

T

H

B

A

T

T

E

N

P

L

A

T

E

C

1

B

1

,

B

2

,

B

3

I

S

A

-

5

0

X

5

0

X

6

m

m

T

H

K

.

S

1

,

S

3

I

S

M

C

-

1

0

0

C

1

I

S

A

-

5

0

X

5

0

X

6

m

m

T

H

K

.

A

1

I

S

A

-

7

5

X

7

5

X

8

m

m

T

H

K

.

S

2

S

A

Y

=

0

.

4

0

T

O

N

N

E

/

B

D

N

O

.

O

F

B

D

:

-

0

2

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

2

.

A

L

L

S

U

P

P

O

R

T

I

N

G

S

T

R

U

C

T

U

R

E

S

H

A

L

L

B

E

M

S

.

H

O

T

D

I

P

G

A

L

V

A

N

I

S

E

D

A

S

P

E

R

I

S

:

4

7

5

9

.

3

.

A

L

L

H

A

R

D

W

A

R

E

S

H

A

L

L

B

E

S

T

A

I

N

L

E

S

S

S

T

E

E

L

.

G

E

N

.

N

O

T

E

S

:

-

1

.

A

L

L

D

I

M

E

N

S

I

O

N

S

A

R

E

I

N

M

M

U

N

L

E

S

S

O

T

H

E

R

W

I

S

E

S

P

E

C

I

F

I

E

D

.

4

.

W

H

E

N

E

V

E

R

T

H

E

R

E

I

S

A

N

Y

M

I

S

M

A

T

C

H

O

F

H

O

L

E

S

D

U

R

I

N

G

J

O

I

N

I

N

G

O

F

S

U

P

P

O

R

T

S

T

R

U

C

T

U

R

E

D

U

E

T

O

C

I

V

I

L

/

O

T

H

E

R

M

I

S

A

L

I

G

N

M

E

N

T

S

,

T

H

E

S

A

M

E

S

H

A

L

L

B

E

W

E

L

D

E

D

A

N

D

A

P

P

L

I

E

D

W

I

T

H

Z

I

N

C

S

P

R

A

Y

.

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

1U 1V 1W

1U 1V 1W

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

I

T

E

M

N

O

.

D

E

S

C

R

I

P

T

I

O

N

I

S

M

B

-

1

5

0

4

-

I

S

A

-

5

0

X

5

0

X

6

m

m

T

H

K

.

I

N

2

0

0

X

2

0

0

B

O

X

F

O

R

M

A

T

I

O

N

W

E

I

L

D

E

D

W

I

T

H

B

A

T

T

E

N

P

L

A

T

E

C

1

B

1

,

B

2

,

B

3

I

S

A

-

5

0

X

5

0

X

6

m

m

T

H

K

.

S

1

,

S

3

I

S

M

C

-

1

0

0

C

1

I

S

A

-

5

0

X

5

0

X

6

m

m

T

H

K

.

A

1

I

S

A

-

7

5

X

7

5

X

8

m

m

T

H

K

.

S

2

S

A

Y

=

0

.

4

0

T

O

N

N

E

/

B

D

N

O

.

O

F

B

D

:

-

0

2

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

2

.

A

L

L

S

U

P

P

O

R

T

I

N

G

S

T

R

U

C

T

U

R

E

S

H

A

L

L

B

E

M

S

.

H

O

T

D

I

P

G

A

L

V

A

N

I

S

E

D

A

S

P

E

R

I

S

:

4

7

5

9

.

3

.

A

L

L

H

A

R

D

W

A

R

E

S

H

A

L

L

B

E

S

T

A

I

N

L

E

S

S

S

T

E

E

L

.

G

E

N

.

N

O

T

E

S

:

-

1

.

A

L

L

D

I

M

E

N

S

I

O

N

S

A

R

E

I

N

M

M

U

N

L

E

S

S

O

T

H

E

R

W

I

S

E

S

P

E

C

I

F

I

E

D

.

4

.

W

H

E

N

E

V

E

R

T

H

E

R

E

I

S

A

N

Y

M

I

S

M

A

T

C

H

O

F

H

O

L

E

S

D

U

R

I

N

G

J

O

I

N

I

N

G

O

F

S

U

P

P

O

R

T

S

T

R

U

C

T

U

R

E

D

U

E

T

O

C

I

V

I

L

/

O

T

H

E

R

M

I

S

A

L

I

G

N

M

E

N

T

S

,

T

H

E

S

A

M

E

S

H

A

L

L

B

E

W

E

L

D

E

D

A

N

D

A

P

P

L

I

E

D

W

I

T

H

Z

I

N

C

S

P

R

A

Y

.

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

1U 1V 1W

2

2

4

.

4

5

0

2

2

7

.

8

0

0

1U 1V 1W

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

I

T

E

M

N

O

.

D

E

S

C

R

I

P

T

I

O

N

I

S

M

B

-

1

5

0

4

-

I

S

A

-

5

0

X

5

0

X

6

m

m

T

H

K

.

I

N

2

0

0

X

2

0

0

B

O

X

F

O

R

M

A

T

I

O

N

W

E

I

L

D

E

D

W

I

T

H

B

A

T

T

E

N

P

L

A

T

E

C

1

B

1

,

B

2

,

B

3

I

S

A

-

5

0

X

5

0

X

6

m

m

T

H

K

.

S

1

,

S

3

I

S

M

C

-

1

0

0

C

1

I

S

A

-

5

0

X

5

0

X

6

m

m

T

H

K

.

A

1

I

S

A

-

7

5

X

7

5

X

8

m

m

T

H

K

.

S

2

S

A

Y

=

0

.

4

0

T

O

N

N

E

/

B

D

N

O

.

O

F

B

D

:

-

0

2

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

2

.

A

L

L

S

U

P

P

O

R

T

I

N

G

S

T

R

U

C

T

U

R

E

S

H

A

L

L

B

E

M

S

.

H

O

T

D

I

P

G

A

L

V

A

N

I

S

E

D

A

S

P

E

R

I

S

:

4

7

5

9

.

3

.

A

L

L

H

A

R

D

W

A

R

E

S

H

A

L

L

B

E

S

T

A

I

N

L

E

S

S

S

T

E

E

L

.

G

E

N

.

N

O

T

E

S

:

-

1

.

A

L

L

D

I

M

E

N

S

I

O

N

S

A

R

E

I

N

M

M

U

N

L

E

S

S

O

T

H

E

R

W

I

S

E

S

P

E

C

I

F

I

E

D

.

4

.

W

H

E

N

E

V

E

R

T

H

E

R

E

I

S

A

N

Y

M

I

S

M

A

T

C

H

O

F

H

O

L

E

S

D

U

R

I

N

G

J

O

I

N

I

N

G

O

F

S

U

P

P

O

R

T

S

T

R

U

C

T

U

R

E

D

U

E

T

O

C

I

V

I

L

/

O

T

H

E

R

M

I

S

A

L

I

G

N

M

E

N

T

S

,

T

H

E

S

A

M

E

S

H

A

L

L

B

E

W

E

L

D

E

D

A

N

D

A

P

P

L

I

E

D

W

I

T

H

Z

I

N

C

S

P

R

A

Y

.

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

1U 1V 1W

1U 1V 1W

2

2

4

.

6

0

0

2

2

7

.

8

0

0

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

I

T

E

M

N

O

.

D

E

S

C

R

I

P

T

I

O

N

I

S

M

B

-

1

5

0

4

-

I

S

A

-

5

0

X

5

0

X

6

m

m

T

H

K

.

I

N

2

0

0

X

2

0

0

B

O

X

F

O

R

M

A

T

I

O

N

W

E

I

L

D

E

D

W

I

T

H

B

A

T

T

E

N

P

L

A

T

E

C

1

B

1

,

B

2

,

B

3

I

S

A

-

5

0

X

5

0

X

6

m

m

T

H

K

.

S

1

,

S

3

I

S

M

C

-

1

0

0

C

1

I

S

A

-

5

0

X

5

0

X

6

m

m

T

H

K

.

A

1

I

S

A

-

7

5

X

7

5

X

8

m

m

T

H

K

.

S

2

S

A

Y

=

0

.

4

0

T

O

N

N

E

/

B

D

N

O

.

O

F

B

D

:

-

0

2

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

2

.

A

L

L

S

U

P

P

O

R

T

I

N

G

S

T

R

U

C

T

U

R

E

S

H

A

L

L

B

E

M

S

.

H

O

T

D

I

P

G

A

L

V

A

N

I

S

E

D

A

S

P

E

R

I

S

:

4

7

5

9

.

3

.

A

L

L

H

A

R

D

W

A

R

E

S

H

A

L

L

B

E

S

T

A

I

N

L

E

S

S

S

T

E

E

L

.

G

E

N

.

N

O

T

E

S

:

-

1

.

A

L

L

D

I

M

E

N

S

I

O

N

S

A

R

E

I

N

M

M

U

N

L

E

S

S

O

T

H

E

R

W

I

S

E

S

P

E

C

I

F

I

E

D

.

4

.

W

H

E

N

E

V

E

R

T

H

E

R

E

I

S

A

N

Y

M

I

S

M

A

T

C

H

O

F

H

O

L

E

S

D

U

R

I

N

G

J

O

I

N

I

N

G

O

F

S

U

P

P

O

R

T

S

T

R

U

C

T

U

R

E

D

U

E

T

O

C

I

V

I

L

/

O

T

H

E

R

M

I

S

A

L

I

G

N

M

E

N

T

S

,

T

H

E

S

A

M

E

S

H

A

L

L

B

E

W

E

L

D

E

D

A

N

D

A

P

P

L

I

E

D

W

I

T

H

Z

I

N

C

S

P

R

A

Y

.

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

1U 1V 1W

2

2

4

.

6

0

0

2

2

7

.

8

0

0

1U 1V 1W

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

2

2

4

.

6

0

0

2

2

7

.

8

0

0

1U 1V 1W

1U 1V 1W

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

1U 1V 1W

2

2

4

.

6

0

0

2

2

7

.

8

0

0

1U 1V 1W

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

E

N

G

I

N

E

E

R

I

N

G

C

O

N

S

U

L

T

A

N

T

:

1U 1V 1W

1U 1V 1W

2

2

4

.

6

0

0

2

2

7

.

8

0

0

You might also like

- 415v Air Circuit Breaker-14Document2 pages415v Air Circuit Breaker-14Subhransu MohapatraNo ratings yet

- Maintenance Procedure For Switchyard Equipment Volume-II (EHDocument39 pagesMaintenance Procedure For Switchyard Equipment Volume-II (EHbisas_rishiNo ratings yet

- HT Switch Gear & Breakers ManualDocument73 pagesHT Switch Gear & Breakers Manualwilliam lobo100% (9)

- HT Cable Termination Kit 14.3.22Document8 pagesHT Cable Termination Kit 14.3.22JIGSNo ratings yet

- Vs1 en 150dpiDocument13 pagesVs1 en 150dpiPatrik PulungNo ratings yet

- On Job Training at Tanjung Bin Power Plant Erick ImmanuelDocument40 pagesOn Job Training at Tanjung Bin Power Plant Erick ImmanuelFabi FahrizalNo ratings yet

- Motor ProtectionDocument50 pagesMotor ProtectionYajidNo ratings yet

- Relay Test Reports - CRP-6071 - 1Document15 pagesRelay Test Reports - CRP-6071 - 1rajesh kannanNo ratings yet

- Odhisha Power Generation Corporation LTD Page 1 of 3 BGR Energy Systems LTD - Power Project DivisionDocument4 pagesOdhisha Power Generation Corporation LTD Page 1 of 3 BGR Energy Systems LTD - Power Project DivisionalagurajNo ratings yet

- 1HYB800001-042A-OM Manual (1-Pole) PDFDocument193 pages1HYB800001-042A-OM Manual (1-Pole) PDFFredy MedranoNo ratings yet

- HT MotorDocument25 pagesHT MotorgaladrialNo ratings yet

- Nit 1467 2Document217 pagesNit 1467 2mohd adilNo ratings yet

- SA-P-050 - Dry Type Power TransformersDocument4 pagesSA-P-050 - Dry Type Power TransformersUET MAINNo ratings yet

- TR-7570 Winding Temperature IndicatorManual PDFDocument30 pagesTR-7570 Winding Temperature IndicatorManual PDFkiran100% (5)

- Motor Check ListDocument7 pagesMotor Check ListPrateek Kumar SinghNo ratings yet

- Electricalnotes Wordpress Com 2011 11 27 What Is Earthing PDFDocument20 pagesElectricalnotes Wordpress Com 2011 11 27 What Is Earthing PDFArie Amri MartaNo ratings yet

- PGCIL GIS Test Reqmts.Document56 pagesPGCIL GIS Test Reqmts.JaiNo ratings yet

- VCBDocument19 pagesVCBmadan_153No ratings yet

- Manual MotorsDocument10 pagesManual Motorst_syamprasadNo ratings yet

- CVT vs EMVT ComparisonDocument1 pageCVT vs EMVT ComparisondseshireddyNo ratings yet

- 1 - Primary Substations Enel - HV-MVDocument29 pages1 - Primary Substations Enel - HV-MVGiovanni Andre Gonzalez FauneNo ratings yet

- Electrical Motor SpecificationDocument6 pagesElectrical Motor SpecificationmishtinilNo ratings yet

- EHV Circuit Breaker Flashover Case StudyDocument29 pagesEHV Circuit Breaker Flashover Case StudymarconchinNo ratings yet

- System Protection Department: Information of TheDocument120 pagesSystem Protection Department: Information of TheSSE BHADANANo ratings yet

- Partial Discharge Diagnostic System PDFDocument2 pagesPartial Discharge Diagnostic System PDFSellappan MuthusamyNo ratings yet

- Maintenance Procedure: Preventive Mantenance of HT MotorDocument5 pagesMaintenance Procedure: Preventive Mantenance of HT Motorsanjay sharmaNo ratings yet

- Transformer BhelDocument17 pagesTransformer BhelAayushiNo ratings yet

- 8BK80 ModifiedDocument57 pages8BK80 Modifiedrohitvdave5250% (2)

- Common Problems Observed and Its RemedyDocument6 pagesCommon Problems Observed and Its RemedyMayank KumarNo ratings yet

- Sop For Esp ChargingDocument3 pagesSop For Esp ChargingrubanprabuNo ratings yet

- Erection Procedure For 415 V LCC, LDBS, LPS, SPDocument40 pagesErection Procedure For 415 V LCC, LDBS, LPS, SPAnmohieyNo ratings yet

- LV SWBDQualityInspectionGuideDocument72 pagesLV SWBDQualityInspectionGuiderajap2737No ratings yet

- Troubleshoot Power Issues & Detect Faults QuicklyDocument10 pagesTroubleshoot Power Issues & Detect Faults QuicklyBala SubramanianNo ratings yet

- Power Supplies PDFDocument292 pagesPower Supplies PDFAsadNo ratings yet

- Electrical Pre-Commissioning ProtocolsDocument85 pagesElectrical Pre-Commissioning ProtocolsAlok NayakNo ratings yet

- Instruction Manual FOR Large Vertical A.C. Motors: Bharat Heavy Electricals Limited, Bhopal (M.P.)Document40 pagesInstruction Manual FOR Large Vertical A.C. Motors: Bharat Heavy Electricals Limited, Bhopal (M.P.)PraveenKvNo ratings yet

- DC Charger (BTL 10)Document16 pagesDC Charger (BTL 10)chdi100% (1)

- 11 KV VCB - BrihoDocument95 pages11 KV VCB - BrihobanuNo ratings yet

- Check List For Testing: Equipment Needed To Be TestedDocument2 pagesCheck List For Testing: Equipment Needed To Be TestedKarthik EvilordNo ratings yet

- List of Aux. Relay and Protection RelayDocument4 pagesList of Aux. Relay and Protection Relaypadmawar100% (2)

- Pantograph Isolator Hot Spot EliminationDocument40 pagesPantograph Isolator Hot Spot Eliminationjilu_siluNo ratings yet

- DGA of CT OilDocument13 pagesDGA of CT Oilraza239No ratings yet

- 220,132,11KV Shutdown Normalization ProcedureDocument2 pages220,132,11KV Shutdown Normalization Procedurearsalanhamid100% (1)

- Condition Monitoring of Instrument Transformers - POWERGRID ExperienceDocument36 pagesCondition Monitoring of Instrument Transformers - POWERGRID ExperiencebcqbaoNo ratings yet

- Soot BlowerDocument29 pagesSoot BlowerPratik JangidNo ratings yet

- DVR STG ProtocolDocument8 pagesDVR STG Protocolprt24No ratings yet

- Ge Make BrekaersDocument16 pagesGe Make Brekaerssuji100% (1)

- Test Report: Measurement of Turns RatioDocument2 pagesTest Report: Measurement of Turns RatioJRC TestingNo ratings yet

- Technical Specification of 630 Kva, 11 - 0.415 KV Dry Type Outdoor Transformers .Document22 pagesTechnical Specification of 630 Kva, 11 - 0.415 KV Dry Type Outdoor Transformers .spidervinoNo ratings yet

- Power TransformerDocument55 pagesPower TransformerPrakash KumarNo ratings yet

- Unit-Ii: Converter and HVDC System Control: Principles of DC Link ControlDocument22 pagesUnit-Ii: Converter and HVDC System Control: Principles of DC Link ControlMr. R. Jagan EEENo ratings yet

- Dry Type Transformer For Mangdechu PDFDocument6 pagesDry Type Transformer For Mangdechu PDFRinzinNo ratings yet

- 6.6kv CB 6Document3 pages6.6kv CB 6vinospaceshuttle100% (1)

- 2.u#1 11KV Switchgear Testing Book-2 PDFDocument219 pages2.u#1 11KV Switchgear Testing Book-2 PDFSabyasachi PatraNo ratings yet

- IPBD MANUAL-Info Catagory PDFDocument26 pagesIPBD MANUAL-Info Catagory PDFTirthankar DattaNo ratings yet

- SECTION - 16465 Bus-Way & Power FeedersDocument7 pagesSECTION - 16465 Bus-Way & Power FeedersWaleed Abd El-HamiedNo ratings yet

- Electrical Plant ChecklistDocument5 pagesElectrical Plant ChecklistAjish Rajan TNo ratings yet

- SECTION - 16465 Bus-Way & Power FeedersDocument7 pagesSECTION - 16465 Bus-Way & Power FeedersWaleed Abd El-HamiedNo ratings yet

- MOSL Global EconomyDocument70 pagesMOSL Global EconomythegemishereNo ratings yet

- Testing of aggregatesDocument2 pagesTesting of aggregatesthegemishereNo ratings yet

- PBC Consultant User Manual - 201902150922143702Document22 pagesPBC Consultant User Manual - 201902150922143702thegemishereNo ratings yet

- Letter To Lab For Testing of 10mm & 20mm Coarse AggregateDocument2 pagesLetter To Lab For Testing of 10mm & 20mm Coarse Aggregatethegemishere67% (6)

- Letter To Lab For Testing Water SampleDocument2 pagesLetter To Lab For Testing Water SamplethegemishereNo ratings yet

- Journal of Electrical Engineering) Impact of The Cooling Equipment On The Key Design Parameters of A Core-Form Power TransformerDocument8 pagesJournal of Electrical Engineering) Impact of The Cooling Equipment On The Key Design Parameters of A Core-Form Power TransformerthegemishereNo ratings yet

- AVAADA ENERGY 7-day concrete cube testingDocument1 pageAVAADA ENERGY 7-day concrete cube testingthegemishere100% (1)

- Corrigendum 3 Dated 4.12.19Document2 pagesCorrigendum 3 Dated 4.12.19thegemishereNo ratings yet

- Pgcil Bikaner-Sbc PDFDocument1 pagePgcil Bikaner-Sbc PDFthegemishereNo ratings yet

- SP-1131 - Handover and As-Built DocumentationDocument47 pagesSP-1131 - Handover and As-Built DocumentationVin Bds80% (5)

- MOM BikanerDocument2 pagesMOM BikanerthegemishereNo ratings yet

- Corrigendum 1 Dated 19.9.19Document1 pageCorrigendum 1 Dated 19.9.19thegemishereNo ratings yet

- TManual Chapter 01 PDFDocument22 pagesTManual Chapter 01 PDFJay Rameshbhai ParikhNo ratings yet

- Gujarat Energy Transmission Corporation Limited Safety ManualDocument82 pagesGujarat Energy Transmission Corporation Limited Safety ManualPiyush BorkarNo ratings yet

- 240 87605434 PDFDocument68 pages240 87605434 PDFthegemishereNo ratings yet

- 6577 TutorialPower JBF 20120911 Web PDFDocument21 pages6577 TutorialPower JBF 20120911 Web PDFsulemankhalidNo ratings yet

- PR-1000 - Operations Handover ProcedureDocument19 pagesPR-1000 - Operations Handover ProcedureParmit Choudhury100% (1)

- Bikener Key Dates 0502Document24 pagesBikener Key Dates 0502thegemishereNo ratings yet

- PR-1000 - Operations Handover ProcedureDocument19 pagesPR-1000 - Operations Handover ProcedureParmit Choudhury100% (1)

- 6577 TutorialPower JBF 20120911 Web PDFDocument21 pages6577 TutorialPower JBF 20120911 Web PDFsulemankhalidNo ratings yet

- 11 Distance ProtectionDocument22 pages11 Distance ProtectionSristick100% (1)

- Technical - Specification - For - Communication - Equipment PDFDocument79 pagesTechnical - Specification - For - Communication - Equipment PDFBinode sarkarNo ratings yet

- 1Document1 page1thegemishereNo ratings yet

- POWERGRID's pre-commissioning procedures for substation equipmentDocument149 pagesPOWERGRID's pre-commissioning procedures for substation equipmentVeeranki Bharath80% (5)

- Precommissioning Procedure PDFDocument201 pagesPrecommissioning Procedure PDFraghavendran raghuNo ratings yet

- POWERGRID's pre-commissioning procedures for substation equipmentDocument149 pagesPOWERGRID's pre-commissioning procedures for substation equipmentVeeranki Bharath80% (5)

- HOTOPlan Checklist MasterDocument52 pagesHOTOPlan Checklist Masterthegemishere100% (3)

- Precommissioning Procedure PDFDocument201 pagesPrecommissioning Procedure PDFraghavendran raghuNo ratings yet

- Technical - Specification - For - Communication - Equipment PDFDocument79 pagesTechnical - Specification - For - Communication - Equipment PDFBinode sarkarNo ratings yet

- Rajasthan Transmission ManualDocument357 pagesRajasthan Transmission Manualzaheeruddin_mohdNo ratings yet

- Summer Training Report at B H E L BhopalDocument66 pagesSummer Training Report at B H E L BhopalshantanuNo ratings yet

- COLORMATCHING GUIDELINES FOR DEMI-PERMANENT HAIR COLORDocument1 pageCOLORMATCHING GUIDELINES FOR DEMI-PERMANENT HAIR COLORss bbNo ratings yet

- Holes Human Anatomy and Physiology 12Th Edition Shier Test Bank Full Chapter PDFDocument53 pagesHoles Human Anatomy and Physiology 12Th Edition Shier Test Bank Full Chapter PDFJakeOwensbnpm100% (9)

- Creative 2nd QuarterDocument6 pagesCreative 2nd QuarterJanice CordovaNo ratings yet

- DBR Gensets DPL120UK Installation, Operation and Maintenance Manual For YN 513510 (MANUAL-I - 2958658 - 1 - A) - 1Document282 pagesDBR Gensets DPL120UK Installation, Operation and Maintenance Manual For YN 513510 (MANUAL-I - 2958658 - 1 - A) - 1RaymondNo ratings yet

- Elementary English Lesson LogsDocument9 pagesElementary English Lesson LogsApril Mendoza-ConradaNo ratings yet

- Orienteering Lesson PlanDocument34 pagesOrienteering Lesson PlanJuan Carlos Guillen BayonNo ratings yet