Professional Documents

Culture Documents

Electrical Motor Specification

Uploaded by

mishtinilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical Motor Specification

Uploaded by

mishtinilCopyright:

Available Formats

Issued Date:

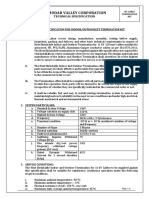

E & I TECHNICAL SPECIFICATION

5/1/2020

Document Number: Rev. Page Number:

0037-E-PRO-PRO-NI-T-I-002 00 Page 73 of 196

3.6. INDUCTION MOTOR FOR CONTINUOUS RATING & HEAVY DUTY TYPE VOLTAGE,

415V & 6.6KV

3.6.1. Scope

This specification covers the requirements for three phase foot/flange mounted continuous

rating and duty type induction motors.

Higher efficiency motors shall comply with the latest version of IS 325, IS12615 & IEC 60034-1

except where modified or extended by this specification and with the relevant parts of standards

mentioned in para 3.6.2.

Squirrel Cage Motors shall be suitable for direct on line starting. Motors shall be capable of

continuously delivering their full rated output at the rated speed under site conditions without

any adverse effects. Motors up to and including 160 kW rating shall operate on 415V power

supply, shall be premium efficiency class IE3 and motors above 160 kW shall operate on 6.6 kV

power supply.

Motors shall be suitable for the application and shall have characteristics required for the duty

of the driven equipment.

Motor operating through variable frequency drives shall be suitable for invertor duty.

Vibration monitoring system shall be provided for HT motors as well as motor rated above 160kW

driven through VFD at 415V/690V. All such motors shall be provided with vibration pads for

mounting vibration detectors in X & Y direction for both DE & NDE side. Vibration reading of

motors shall be made available in control room for monitoring and alarm purpose. 4-20 mA loop

powered vibration sensors with SS case material and integral cable shall be considered.

Protection class shall be IP66 or better. Frequency range and type shall be selected based on the

application. Necessary mounting pads/studs on the motor /pump shall be provided. Necessary

junction box for field termination shall be of IP65 protection class. Sensor cable shall be laid in

flexible steel conduit.

The equipment shall operate in a highly polluted environment.

Whenever the basis for motor ratings are not specified in the corresponding mechanical

specification, maximum continuous motor ratings shall be at least 10% above the maximum load

demand of the driven equipment under entire operating range including voltage and frequency

variations.

3.6.2. Other Relevant Standards

IS: 900 Code of practice for installation and maintenance of induction motors

Dimensions and output ratings for foot mounted electrical machines with

IS: 8223 frame number 355 to 1080

IS: 1231 Dimension of three phase foot mounted induction motors

IS: 2223 Dimension of flange mounted induction motors

IS: 210 Frames for rotating electrical machines

Classification of insulating materials for electrical machinery and

IS: 1271 apparatus in relation to their thermal stability in service

Designation for type of construction and mounting arrangement for

IS: 2253 electrical machines

© Copyright Adani Enterprises Limited 2016. All rights reserved.

Contains confidential information proprietary to Adani not to be disclosed to third parties without Adani's prior written

permission.

Issued Date:

E & I TECHNICAL SPECIFICATION

5/1/2020

Document Number: Rev. Page Number:

0037-E-PRO-PRO-NI-T-I-002 00 Page 74 of 196

IS: 3043 Code of practice for earthing

IS: 4029 Guide for testing three phase induction motors

IS: 4691 Degree of protection provided by enclosures for electrical machinery

IS: 4722 Rotating electrical machinery

IS: 6362 Designation of methods of cooling for rotating electrical machinery

IS: 7816 Guide for testing insulation resistance of rotating machinery

IS: 12065 Permissible limits of noise level for rotating electrical machines

IS: 12075 Mechanical vibrations of rotating electrical machines

IS: 2147 Degree of protection provided by industrial enclosures

IS: 4729 Measurement and evaluation of vibration of rotating electrical machines

IS: 4889 Method of determination of efficiency of rotating electrical machines

IS: 8789 Values of performance characteristic for three phase induction motors

IS: 12824 Type of duty and classes of rating for rotating electrical machines

IS: 12802 Temperature rise measurement of rotating electrical machines

IS: 3003 Carbon Brushes for electrical machines

IS: 5 Colours for ready mixed paints and enamels

3.6.3. Design

Electrical

a) The motors shall be of continuous duty (S1) and rating type in accordance with relevant

code.

b) The motor shall be designed to deliver rated output with the terminal voltage differing

from its rated value by not more than ± 10%, frequency differing from its rated value by

not more than -5% to + 5% and any combination of these limited to 10%.

c) The motors shall be capable of withstanding the forces associated with the maximum in

rush current, the locked rotor torque and the pull out torque at the highest system

voltage and at the upper limit of supply frequency during starting.

d) The motors shall be capable of starting and accelerating to the rated speed along-with

the fully loaded driven equipment without exceeding the acceptable winding temperature

even when the supply voltage is 80% of rated voltage.

e) Motor shall be suitable for 3 nos. consecutive cold starts up and 2 nos. consecutive hot

starts up. Motors shall be suitable for four equally spread starts per hour when the motor

is under normal service condition

f) The motors shall withstand for the time as per motor manufacturer (approved make)

recommendation without stalling or abrupt change in speed under gradual increase of

torque, its rated value, the voltage and frequency being maintained at their rated value.

g) The accelerating torque at any speed with the lowest starting voltages shall be at least

10% of rated full load torque.

h) The starting torque and pull out torque of the squirrel cage motors shall match the load

requirement.

i) Motors shall be rated for continuous operation in an ambient temperature of 50°C with

temperature rise limited to permissible temperature rise limits.

© Copyright Adani Enterprises Limited 2016. All rights reserved.

Contains confidential information proprietary to Adani not to be disclosed to third parties without Adani's prior written

permission.

Issued Date:

E & I TECHNICAL SPECIFICATION

5/1/2020

Document Number: Rev. Page Number:

0037-E-PRO-PRO-NI-T-I-002 00 Page 75 of 196

j) The starting current of the LV motors shall be as per IS-12615.

k) The starting current of the HV motors shall be as per IS-325.

l) The motors shall be designed to withstand 120 % of rated speed for 2 minutes without

mechanical damage.

m) During detail engineering following minimum motor characteristic curves shall be

provided along with motor datasheet

- Speed vs torque curve (at 80%,100%V) with load torque superimposed,

- Efficiency/ power factor vs load

- Speed vs current

- Time vs current

- Thermal withstand curve

Mechanical

a) The method of cooling for LT/HT motors shall depend upon the system requirement.

b) The enclosures for motor shall have IP55 protection in accordance with ARE: 4961.

c) All Squirrel cage induction motor shall have Insulation Class F with Minimum Permissible

temperature rise Limited to class 'B'.

d) All VVFD driven Squirrel cage induction motor shall have Insulation Class H with Minimum

Permissible temperature rise Limited to class 'F'.

e) The motor vibration shall confirm to the requirements in accordance with relevant code.

f) The motor noise level shall confirm to the requirements in accordance with relevant code.

3.6.4. Construction Details

3.6.4.1. General

The motor and its components such as stator, rotor end shield, terminal boxes and the bearings

shall be designed to be readily inter-changeable as integral units for the same design and rating.

All non-metallic components used shall be resistant to flame propagation

All heavy parts of the motors shall be provided with necessary lifting arrangements

3.6.4.2. Stator Frame and Shield

The stator frames and end shields shall be rugged and made of cast iron conforming to relevant

code.

The frame holding the stator core and windings must be strong and rigid to withstand short

circuit force and unbalanced magnetic pull and minimize vibrations.

3.6.4.3. Cooling Arrangement

HT and LT Squirrel cage motors shall be Totally Enclosed, Fan Cooled, (TEFC) by a light weight

cast aluminum fan of bi-directional design and very low inertia. The fan shall be keyed to the

shaft.

The cooling fans for each motor shall be of such design that the motors can turn in any direction

with/without minor modification at site.

© Copyright Adani Enterprises Limited 2016. All rights reserved.

Contains confidential information proprietary to Adani not to be disclosed to third parties without Adani's prior written

permission.

Issued Date:

E & I TECHNICAL SPECIFICATION

5/1/2020

Document Number: Rev. Page Number:

0037-E-PRO-PRO-NI-T-I-002 00 Page 76 of 196

3.6.4.4. Enclosure

The enclosure shall be totally enclosed fan cooled with suitable means for breathing and

drainage. The drain hole diameter shall not exceed 6 mm.

3.6.4.5. Stator

The stator core shall be built up of low loss high permeability steel laminations.

The winding shall be two-layer type consisting of synthetic enameled copper conductors in Semi

closed slots.

Winding shall be vacuum impregnated to make them non- hygroscopic and oil resistant and shall

be suitable for continuous and satisfactory operation under conditions of high temperature and

high humidity.

All motors shall have fungus protection including special treatment of insulation and metal

against fungus, insects and corrosion. Motors are to be installed in tropical atmosphere.

Motors shall have class F insulation with permissible temperature rise limited to class B (at rated

KW rating) over 50 deg.C by resistance at rated output.

All winding overhangs and leads shall be adequately supported braced and blocked.

All motors shall be equipped with suitable lifting arrangements or lugs.

3.6.4.6. Rotor

The rotor core shall be of similar construction to that of the stator

The cage bars for cage motors shall be of die cast aluminium.

The complete rotor shall be dynamically balanced with the fan on the shaft for TEFC motors and

with integral heat exchangers for CACA motors ensuring vibration free smooth running.

3.6.4.7. Shaft

The shaft shall be manufactured from high grade steel, preferably C-40. The sustained deflection

of the shaft shall well below 10% of the air gap.

3.6.4.8. Bearing

The bearings shall be ball / roller type for HT and 415 V motors

The bearings shall be self-lubricated. Motors with higher kW rating shall be non- self-lubricating

type and shall have online greasing arrangement.

All motors used for VVVF drives should have insulated bearings on NDE side. Additional shaft

brush shall also be given to restrict circulating current towards load side bearings as well.

In HT Motors Bearings shall be insulated as required to prevent shaft current and resultant

bearing damage.

Each bearing of HT motor shall be provided with dial type thermometer with adjustable alarm

contract and the same signal shall be configured in PLC.

The bearings shall be in accordance with the relevant codes. Bearing life should be minimum

60000Hrs for all the motors.

All motors shall be grease/oil lubricants as per IS.

© Copyright Adani Enterprises Limited 2016. All rights reserved.

Contains confidential information proprietary to Adani not to be disclosed to third parties without Adani's prior written

permission.

Issued Date:

E & I TECHNICAL SPECIFICATION

5/1/2020

Document Number: Rev. Page Number:

0037-E-PRO-PRO-NI-T-I-002 00 Page 77 of 196

3.6.4.9. Terminal Box

Terminal boxes integral with the stator frame shall be provided with terminals for stator leads.

Additional terminal box shall be provided for slip ring motors.

Terminals shall be suitable for receiving single layer armoured Aluminium / copper conductor

PVC/XLPE insulated cables.

Terminal boxes shall be suitable for top/ side/ bottom entry of cable, depending on mounting,

application and space availability at site.

All motors shall be provided with cable termination boxes with removable undrilled gland plates

suitable for terminating cables and required quantity of double compression glands.

Terminal box shall be suitable to withstand short circuit current of 50kA for 0.25 sec.

Each terminal box shall be fitted with earthing screw of suitable size at both end.

Unless otherwise approved, the terminal boxes shall be capable of being turned through 360

degrees in steps of 90 degrees.

Separate terminal boxes shall be provided for space heaters, thermistor and RTD.

All Terminal box shall have IP55 Degree of protection.

An additional adopter box to the motor terminal box shall be provided if required to facilitate

cable terminations. The size of the adopter box shall be decided based on cable size and number

of cables to be terminated. The box shall be good quality and fabricated out of 2 mm thick MS

Sheet, properly painted and gasketed.

3.6.4.10. Earthing Terminal

Two independent earthing terminals shall be provided in accordance with I.E Rules on diagonally

opposite corners of the motor for bolted connection.

3.6.4.11. Mounting

As per requirement of equipment

3.6.4.12. Auxiliary Devices

The motor shall be suitable for the auxiliary devices mentioned below:

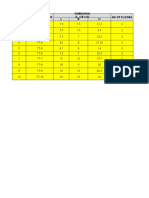

Type of Load Aux Devices

HT Motor Embedded Resistance Temperature Detectors

(RTD PT 100-Duplex) 6 nos. for windings with

additional 2 nos. for bearings for HT motors and

LV Motor rated above 160kW driven with VFD.

Space Heater Space Heaters suitable for 230V, 50 Hz, single

phase supply system shall be provided for

motors above 30 kW capacity. For motors below

© Copyright Adani Enterprises Limited 2016. All rights reserved.

Contains confidential information proprietary to Adani not to be disclosed to third parties without Adani's prior written

permission.

Issued Date:

E & I TECHNICAL SPECIFICATION

5/1/2020

Document Number: Rev. Page Number:

0037-E-PRO-PRO-NI-T-I-002 00 Page 78 of 196

30 kW, space heaters shall be provided if it is

meant for specific use in damp areas.

Thermistor Motors rated 75 kW and above shall be fitted

with thermistors for winding protection and

their control units shall be installed in MCC.

Vibration sensor HT motors as well as motor rated above 160kW

driven through VFD at 415V/690V shall be

provided with vibration pads for mounting

vibration detectors in X & Y direction for both DE

& NDE side

3.6.4.13. Noise & Vibration

Motors shall be selected with low noise levels in accordance with IS 12065.

The peak amplitude of the vibration shall also be within the specified limits of IS: 12075.

Maximum noise level measured at a distance of 1.5 meter from the outer surface of the motor

shall not exceed 85 db (A).

3.6.4.14. Performance

The values of minimum full load speed, maximum full load current, minimum pull out torque and

minimum locked motor torque as percentage of full load torque at rated voltage and frequency

for duty type S1 shall be in accordance with relevant code.

3.6.4.15. Rating Plate

A rating plate stating the following information shall be supplied with each motor:

a) Reference standard

b) Name of manufacturer

c) Manufacturer's number and frame reference

d) Type of duty

e) Class of insulation

f) Frequency in Hz

g) Number of phases

h) Rated output in kW

i) Rated voltage and winding connections

j) Current, approximate in amperes at rated output

k) Speeds in revolutions per minute, at rated output

l) Rotor (Secondary) voltage and winding connections

m) Rotor (Secondary) current in amperes at rated output

n) Ambient temperature

o) Enclosure Type

p) Bearing detail

q) Lubrication detail with Relubrication Hrs details

© Copyright Adani Enterprises Limited 2016. All rights reserved.

Contains confidential information proprietary to Adani not to be disclosed to third parties without Adani's prior written

permission.

You might also like

- 1986-0040-EL-SPE01-0001 RA Specification For Induction MotorsDocument14 pages1986-0040-EL-SPE01-0001 RA Specification For Induction MotorsjmohammadrezaNo ratings yet

- MV Panel Earth Switch Contact Resistance Test ReportDocument1 pageMV Panel Earth Switch Contact Resistance Test ReportGajendran SriramNo ratings yet

- Battery Capacity TestDocument3 pagesBattery Capacity TestL AdlyNo ratings yet

- Solid q50 Denind 1808 V11webDocument2 pagesSolid q50 Denind 1808 V11webNinditya NugrohoNo ratings yet

- Transformer BhelDocument17 pagesTransformer BhelAayushiNo ratings yet

- Instruction Manual FOR Large Vertical A.C. Motors: Bharat Heavy Electricals Limited, Bhopal (M.P.)Document40 pagesInstruction Manual FOR Large Vertical A.C. Motors: Bharat Heavy Electricals Limited, Bhopal (M.P.)PraveenKvNo ratings yet

- Dry Type Transformer For Mangdechu PDFDocument6 pagesDry Type Transformer For Mangdechu PDFRinzinNo ratings yet

- 10P01 1a e 604 R00 - HCSD - Pump - MotorDocument17 pages10P01 1a e 604 R00 - HCSD - Pump - Motorsuleman247No ratings yet

- Charging Method and EquipmentDocument16 pagesCharging Method and EquipmentlrpatraNo ratings yet

- Odhisha Power Generation Corporation LTD Page 1 of 3 BGR Energy Systems LTD - Power Project DivisionDocument4 pagesOdhisha Power Generation Corporation LTD Page 1 of 3 BGR Energy Systems LTD - Power Project DivisionalagurajNo ratings yet

- 9.MLDB CTDocument3 pages9.MLDB CTalagurajNo ratings yet

- VCBDocument19 pagesVCBmadan_153No ratings yet

- Iocl City Gas Distribution Project For GADocument4 pagesIocl City Gas Distribution Project For GAsubudhiprasannaNo ratings yet

- Maintenance Procedure: Preventive Mantenance of HT MotorDocument5 pagesMaintenance Procedure: Preventive Mantenance of HT Motorsanjay sharmaNo ratings yet

- Motor Thermal ModelDocument15 pagesMotor Thermal ModelnagarajasarmaNo ratings yet

- Motor Protection Relay Test ReportDocument5 pagesMotor Protection Relay Test ReportSiva NandhamNo ratings yet

- I6s UPS Catalogue (Domestic)Document8 pagesI6s UPS Catalogue (Domestic)SagarNo ratings yet

- HT MotorDocument25 pagesHT MotorgaladrialNo ratings yet

- ABB AC - Motor 500KW - Final Service ReportDocument4 pagesABB AC - Motor 500KW - Final Service ReportZi MingNo ratings yet

- FCMA Soft Starters for MotorsDocument4 pagesFCMA Soft Starters for Motors4usangeetNo ratings yet

- FGD - Technical DiaryDocument61 pagesFGD - Technical DiaryanmohieyNo ratings yet

- L86-051 Test ReportDocument6 pagesL86-051 Test ReportAMIT BISWASNo ratings yet

- Voltage Drop Calculation of 11kV H.V. Motor at Starting: ST STDocument2 pagesVoltage Drop Calculation of 11kV H.V. Motor at Starting: ST STdpkfatnani05No ratings yet

- 13.8 KV 111-05-SG-0-301 - 1 of 2 - Sel 751a, Sel710 & Sel451Document8 pages13.8 KV 111-05-SG-0-301 - 1 of 2 - Sel 751a, Sel710 & Sel451Jayabal GnanaprakasamNo ratings yet

- Case StudiesDocument32 pagesCase StudiesSE Electrical100% (1)

- Bearing HeaterDocument5 pagesBearing HeaterAnand KatariyaNo ratings yet

- Upgrading The ProtectionDocument4 pagesUpgrading The ProtectionMukesh KumarNo ratings yet

- 11 KV Power Cable Site Test Report: (NMGR105 To NMGR106)Document3 pages11 KV Power Cable Site Test Report: (NMGR105 To NMGR106)Gajendran Sriram100% (1)

- Multi-turn actuators and controls guideDocument80 pagesMulti-turn actuators and controls guideMotorola AndroidNo ratings yet

- PDFDocument15 pagesPDFNilesh KhareNo ratings yet

- Slip Ring Motor Liquid Resistor Soft Starting System (HV-LRS) PDFDocument4 pagesSlip Ring Motor Liquid Resistor Soft Starting System (HV-LRS) PDFLouie FernandezNo ratings yet

- Operacion Recloser RoclwillDocument54 pagesOperacion Recloser RoclwillChristian Vasquez MedranoNo ratings yet

- Alternator TestingDocument40 pagesAlternator TestingAmit BiswasNo ratings yet

- 0260 573 PVE Y 233 03 Guaranteed Technical Particulars For GISDocument36 pages0260 573 PVE Y 233 03 Guaranteed Technical Particulars For GISBebilson MansinghNo ratings yet

- Smart Solutions. Strong Relationship. Apex Series IE2 MotorsDocument20 pagesSmart Solutions. Strong Relationship. Apex Series IE2 Motorsvipulpanchotiya100% (1)

- Drop Voltage Calculation For MotorsDocument8 pagesDrop Voltage Calculation For MotorsSESA43142No ratings yet

- Testing of Turbo GeneratorsDocument4 pagesTesting of Turbo Generatorsemmanuel akaNo ratings yet

- HT Cable Termination Kit 14.3.22Document8 pagesHT Cable Termination Kit 14.3.22JIGSNo ratings yet

- Bearing Mounting - SKF Drive Up MethodDocument5 pagesBearing Mounting - SKF Drive Up Methodkuruvillaj2217No ratings yet

- Manufacturing and Testing of Turbo GeneratorsDocument84 pagesManufacturing and Testing of Turbo Generatorsgnikhilreddy2No ratings yet

- CGL Flame - Proof - MotorsDocument15 pagesCGL Flame - Proof - MotorspriteshNo ratings yet

- Instantaneous Relay PQ8nCH2JSDocument8 pagesInstantaneous Relay PQ8nCH2JSVijayaganthaan Visvanatthan100% (1)

- Erection Procedure For 415 V LCC, LDBS, LPS, SPDocument40 pagesErection Procedure For 415 V LCC, LDBS, LPS, SPAnmohieyNo ratings yet

- A Generator - Our Experience 23042016Document10 pagesA Generator - Our Experience 23042016Chilamkurti Siva Sankara RaoNo ratings yet

- 220V DC System Battery Charger DescriptionDocument6 pages220V DC System Battery Charger DescriptionTaraknath MukherjeeNo ratings yet

- Commissioning of DAVRDocument70 pagesCommissioning of DAVRPMG Bhuswal Project100% (1)

- Sizing Calculation For Equipment Earthing: 2x330MW TPP, Mundra SEZ Attachment-2 To Doc - No.6785-EL-DSN-633-001Document2 pagesSizing Calculation For Equipment Earthing: 2x330MW TPP, Mundra SEZ Attachment-2 To Doc - No.6785-EL-DSN-633-001Harveen SinghNo ratings yet

- Vacuum Circuit BreakerDocument6 pagesVacuum Circuit BreakerMd Rodi BidinNo ratings yet

- DVR STG ProtocolDocument8 pagesDVR STG Protocolprt24No ratings yet

- BO EP Generator TestingDocument31 pagesBO EP Generator TestingCandiano PopescuNo ratings yet

- Ge Make BrekaersDocument16 pagesGe Make Brekaerssuji100% (1)

- Manual MotorsDocument10 pagesManual Motorst_syamprasadNo ratings yet

- Gen Write UpDocument11 pagesGen Write Upsarirag100% (1)

- DG SET-Technical Specs PDFDocument26 pagesDG SET-Technical Specs PDFankur yadavNo ratings yet

- 120MW Generator Static & Dynamic Testing FormatDocument25 pages120MW Generator Static & Dynamic Testing FormatnadeshenNo ratings yet

- 44AD0600-00-E.02-001A-A4 - Rev 0 - Standard Specification For LV Induction MotorDocument8 pages44AD0600-00-E.02-001A-A4 - Rev 0 - Standard Specification For LV Induction MotorAvinash ShuklaNo ratings yet

- 3.HT Motor SpecificationDocument18 pages3.HT Motor SpecificationsidearthmanNo ratings yet

- 4.3 - APPENDIX-3C - Motor RequirementDocument5 pages4.3 - APPENDIX-3C - Motor RequirementSubrata DasNo ratings yet

- FS For Medium Voltage Motor PDFDocument8 pagesFS For Medium Voltage Motor PDFMd SajjadNo ratings yet

- BasicsofACHEBrochure WebDocument33 pagesBasicsofACHEBrochure WebTrần Tuấn VũNo ratings yet

- Technical Specification of DamperDocument2 pagesTechnical Specification of DampermishtinilNo ratings yet

- Technical Specification of GrillsDocument1 pageTechnical Specification of GrillsmishtinilNo ratings yet

- Adjustable Louver Grill Volume ControlDocument1 pageAdjustable Louver Grill Volume ControlmishtinilNo ratings yet

- Chemical Storage Tanks Specifications Rev. 8-24-04Document13 pagesChemical Storage Tanks Specifications Rev. 8-24-04Rahmi ArslanNo ratings yet

- Maximizing Energy Efficiency Through Utilization of By-Product GasesDocument9 pagesMaximizing Energy Efficiency Through Utilization of By-Product GasesbalusmeNo ratings yet

- Motor technical specificationsDocument2 pagesMotor technical specificationsmishtinilNo ratings yet

- Mechanical Spec - Plain Water DSSDocument9 pagesMechanical Spec - Plain Water DSSmishtinilNo ratings yet

- Specification ChillerDocument28 pagesSpecification Chillermishtinil100% (1)

- TT Details - AdaniDocument4 pagesTT Details - AdanimishtinilNo ratings yet

- Plate With Surface Crack: BITS PilaniDocument4 pagesPlate With Surface Crack: BITS Pilaniraaspoy2007No ratings yet

- Essential PDMS Commands for Piping, Equipment & StructuresDocument12 pagesEssential PDMS Commands for Piping, Equipment & StructuresmishtinilNo ratings yet

- Utility Write UpDocument15 pagesUtility Write UpmishtinilNo ratings yet

- Tech Spec For Misc. PumpsDocument6 pagesTech Spec For Misc. PumpsmishtinilNo ratings yet

- Pipe Estimation ps-1Document9 pagesPipe Estimation ps-1mishtinilNo ratings yet

- Feeder List - R0 - CHPDocument42 pagesFeeder List - R0 - CHPmishtinilNo ratings yet

- A8ga 45240 65 DW 5039 - R3Document1 pageA8ga 45240 65 DW 5039 - R3mishtinilNo ratings yet

- Franc3D - Onramp 1: BITS PilaniDocument21 pagesFranc3D - Onramp 1: BITS Pilaniraaspoy2007No ratings yet

- Different Type Air DryerDocument9 pagesDifferent Type Air DryermishtinilNo ratings yet

- Accumulator Sizing For Water SystemDocument5 pagesAccumulator Sizing For Water SystemmishtinilNo ratings yet

- Clarifications & DeliverablesDocument4 pagesClarifications & DeliverablesmishtinilNo ratings yet

- Storage Type Water-Cooler & Water Purifier Storage Type Water CoolerDocument2 pagesStorage Type Water-Cooler & Water Purifier Storage Type Water CoolermishtinilNo ratings yet

- Altroz India 01Document1 pageAltroz India 01KarniNo ratings yet

- Arvind Corotech BrochureDocument11 pagesArvind Corotech BrochuremishtinilNo ratings yet

- Garden City of IndiaDocument20 pagesGarden City of IndiamishtinilNo ratings yet

- Assignment Seventh SemDocument10 pagesAssignment Seventh SemmishtinilNo ratings yet

- Revised - 02 Dry - Vent - Capacity - Selection - 10.05.10Document34 pagesRevised - 02 Dry - Vent - Capacity - Selection - 10.05.10mishtinilNo ratings yet

- Lab Manual: Control Systems Design and Analysis: Using The Quanser Controls Board For NI ELVIS IIIDocument12 pagesLab Manual: Control Systems Design and Analysis: Using The Quanser Controls Board For NI ELVIS IIImishtinilNo ratings yet

- Full Page PhotoDocument1 pageFull Page PhotomishtinilNo ratings yet

- Current TransfDocument8 pagesCurrent Transfraj961100% (1)

- Aegis SGR BrochureDocument2 pagesAegis SGR BrochureAmazonas ManutençãoNo ratings yet

- Electrical Engineer CV RafeequeDocument4 pagesElectrical Engineer CV Rafeequerafeequepk12150% (2)

- Screw Air Compressor Electrical Tank MountedDocument12 pagesScrew Air Compressor Electrical Tank MountedK B TempNo ratings yet

- Compas 3000 SFA6127 SD102402 SA eDocument99 pagesCompas 3000 SFA6127 SD102402 SA eEliane MasonNo ratings yet

- 113Document26 pages113Zubair Irshad0% (1)

- All Motor DetailsDocument45 pagesAll Motor DetailsValipireddy NagarjunNo ratings yet

- Learn About Vibration: Volume 1: Basic Understanding of Machinery VibrationDocument55 pagesLearn About Vibration: Volume 1: Basic Understanding of Machinery VibrationamekhzoumiNo ratings yet

- Catalogo Delta Ms300bDocument40 pagesCatalogo Delta Ms300bEduardo CamNo ratings yet

- Leading in the World of BIMDocument35 pagesLeading in the World of BIMRobby Renz100% (1)

- Induction Motor ModelDocument31 pagesInduction Motor ModelMohammedHaythamNo ratings yet

- 9.all, More Electric Aircraft Engine & Airframe Systems Implementation, Bedek Aviation Group, Aircraft Programs Division, Israel Aerospace Industries, IsraelDocument48 pages9.all, More Electric Aircraft Engine & Airframe Systems Implementation, Bedek Aviation Group, Aircraft Programs Division, Israel Aerospace Industries, Israelfinock100% (1)

- How To Read A PLC Wiring Diagram (Control Panel Wiring Diagram) - UpmationDocument35 pagesHow To Read A PLC Wiring Diagram (Control Panel Wiring Diagram) - UpmationwebsterchikambaNo ratings yet

- BMS IO SummaryDocument1 pageBMS IO SummaryRoyal AirconNo ratings yet

- ABB Energy Efficiency For Power Plant Auxiliaries V2 0Document362 pagesABB Energy Efficiency For Power Plant Auxiliaries V2 0Stratford StrativariousNo ratings yet

- Asses Form-Elevators and Escalators-Technician - TYPE ADocument15 pagesAsses Form-Elevators and Escalators-Technician - TYPE ASUNDAR TNo ratings yet

- VFD Paper - NTPC-PMIDocument9 pagesVFD Paper - NTPC-PMIamulya1981No ratings yet

- TT100 User Manual 2012 ENGL PDFDocument90 pagesTT100 User Manual 2012 ENGL PDFErika Sears100% (1)

- Centrifugal Chiller - Fundamentals - Energy-ModelsDocument30 pagesCentrifugal Chiller - Fundamentals - Energy-ModelsPrashant100% (1)

- Iec 61800 5 1Document12 pagesIec 61800 5 1jose girotNo ratings yet

- US100 Standard Stock Catalog Complete PDFDocument505 pagesUS100 Standard Stock Catalog Complete PDFJoel C. VegaNo ratings yet

- Lift MLC 8000Document202 pagesLift MLC 8000Phạm MạnhNo ratings yet

- Intake, Raw Water Pump Station, and Transmission Mains: 1.1 ScopeDocument27 pagesIntake, Raw Water Pump Station, and Transmission Mains: 1.1 ScopeAmos MutoroNo ratings yet

- Substation 631: Distribution Transformers (Oil Filled Outdoor)Document40 pagesSubstation 631: Distribution Transformers (Oil Filled Outdoor)PrasadNo ratings yet

- Types of Starters: It'S Features and Advantages& DisadvantagesDocument30 pagesTypes of Starters: It'S Features and Advantages& DisadvantagesGrace ZuluetaNo ratings yet

- Eaton 186094 DC1 S2011FB A20CE1 en - GBDocument7 pagesEaton 186094 DC1 S2011FB A20CE1 en - GBLucian LupuNo ratings yet

- Miller Water Cooled Oil Free Centrifugal Chiller Installation Opration Maintenance Manual PDFDocument74 pagesMiller Water Cooled Oil Free Centrifugal Chiller Installation Opration Maintenance Manual PDFjunaidNo ratings yet

- Delta VFD-VEDocument316 pagesDelta VFD-VEJoao Stuard Herrera QuerevalúNo ratings yet

- Variable voltage variable frequency drive with fault protectionDocument25 pagesVariable voltage variable frequency drive with fault protectionsyed42210No ratings yet