Professional Documents

Culture Documents

Spec - Iso - Floor

Uploaded by

cokiaaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spec - Iso - Floor

Uploaded by

cokiaaCopyright:

Available Formats

Bergviks Iso Floor Raised Access Floor System

SECTION 09 6900 - Access Flooring

SECTION 10270 RAISED ACCESS FLOORING

PART 1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary

Conditions and Division 1 Specification Sections, apply to this Section.

1.2 SUMMARY

A. Concrete sealer shall be compatible with pedestal adhesive.

B. Electrical contractor shall provide necessary material and labor to electrically connect

the access floor to the building

C. Quantity Allowances: Provide the following as specified in Division 1 Section

"Allowances":

1. Floor panel sizes.

Cut-outs in floor panels.

1.3 UNIT PRICES

A. Unit Prices: The Contract Sum will be adjusted for changes in quantity from that indicated

in allowances for specified panel sizes and cutouts in floor panels based on amounts

stipulated in the Form of Agreement and complying with Division 1 Section "Unit

Prices." Changes to quantities and to the Contract Sum will be made by Change Order.

1.4 DEFINITION

A. ESD: Electrostatic discharge. The transfer of electric charge between bodies at different

potentials, from panel surface to ground.

1.5 SYSTEM DESCRIPTION

A. Raised Access Flooring System: Assemblies composed of modular and self-

supporting floor sub-structure bolted together, having gravity placed floor panels

Page 1 of 11

Bergviks Iso Floor Raised Access Floor System

on top not connected to the pedestal supports. Lateral strength of floor system

shall be independent from all floor panels being in place or fully removed.

1.6 PERFORMANCE REQUIREMENTS

A. Structural Performance: Provide access flooring system capable of withstanding the

following loads and stresses within limits and under conditions indicated, as

determined by testing manufacturer's current standard test procedures:

1. Concentrated Loads: Provide 23.6 x 23.6 inch (600x600 mm) floor panels,

including those with cutouts, capable of withstanding a concentrated

design load of 1100 lbf (5000 N), with a top-surface deflection under load

and a permanent set not to exceed, respectively, 0.13 and 0.008 inch (3.3

mm and 0.2 mm). If custom size floor panels are provided with a span of

less or equal to 31.5 (800 mm) between secondary support beams, they

need to comply with the above deflection and permanent set values as

well, except if located under installed equipment cabinets or racks.

2. Rolling Loads: Provide 23.6 x 23.6 inch (600x600 mm) floor panels, capable

of withstanding a rolling load of 1400 lbf (6350 N), with a top-surface

deflection under load and a permanent set not to exceed, respectively, 0.13

and 0.008 inch (3.3 mm and 0.2 mm).

3. Uniform Distributed Loads: Provide self-supporting floor structure, without

panels in place, capable of withstanding a minimum 204 lbs/sf (10 kN/m2)

uniform distributed load. For heavy equipment, which requires higher

loading in accordance with the engineering drawing, the floor structure

shall provide a uniform distributed loading capable of supporting the

equipment for each individual case to avoid using separate equipment

stands under Server racks or cabinets.

4. Ultimate* Loads: Provide access flooring sub-structure system capable of

withstanding a minimum ultimate concentrated load of 2500 lbf (9070 N)

and a minimum ultimate distributed load of 1500 lbf/ft2 (39 kN/m2)

without failing,

* = max deflection of L/360 of span between beam sections

5. Pedestal Axial Load Test: Provide structure and pedestal assemblies, without

panels in place, capable of withstanding a 7000 lbf (31 136 N) axial load

per pedestal.

Page 2 of 11

Bergviks Iso Floor Raised Access Floor System

6. Recycled Content: Understructure system and Floor panel shall be required to have

a minimum recycled content of 50%.

B. ESD-Control Properties: Provide floor coverings with ESD-control properties

indicated as determined by testing identical products per test method indicated

by an independent testing and inspecting agency.

1. Antistatic Floor Covering Properties:

a. Electrical Resistance: Test per ESD STM 7.1.

1) Average greater than 50,000 ohms and less than 1,000 megohm

when test specimens and installed floor coverings are tested

surface to ground resistivity.

b. Static Generation: Less than 100 V when tested per AATCC-134 at 40

percent relative humidity with conductive footwear.

1.7 SUBMITTALS

A. Product Data: For each type of product indicated.

B. Shop Drawings: Include Auto-CAD layout of access flooring system including

measurements between all support members and indicated panel sizes in

relationship to adjoining Work based on field-verified dimensions.

1. Details and sections with descriptive notes indicating materials, bolted floor

understructure, fasteners, finishes, typical and special edge conditions and

accessories.

2. For installed products indicated to comply with design loads, include

structural data analysis report signed and sealed by a qualified professional

engineer prior to starting installation.

C. Samples for Initial Selection: For each type of flooring material and exposed finish

indicated.

D. Samples for Verification: For each type of flooring material and exposed finish

indicated.

1. One complete full-size floor panel and floor understructure unit for each type

of access flooring system required.

E. Product Certificates: For each type of access flooring system, signed by product

manufacturer.

Page 3 of 11

Bergviks Iso Floor Raised Access Floor System

F. Qualification Data; For Installer: Certified by manufacturer.

G. Product Test Reports: Based on evaluation of comprehensive tests performed by a

qualified testing agency, or performed by access flooring manufacturer and

witnessed by a qualified testing agency, for each type of flooring material and

exposed finish.

1.8 QUALITY ASSURANCE

A. Installer Qualifications: Lead Installer has to be trained and certified by

manufacturer in order for the warranty to be valid.

B. Source Limitations: Obtain access flooring system through one source from a

single manufacturer.

C. Regulatory Requirements: Fabricate and install access flooring to comply with

NFPA 75 requirements for raised flooring.

D. Provide floor panels that are clearly and permanently marked on their underside

with panel type, batch number/date and rolling-load rating.

E. Pre-installation Conference: Conduct conference at Project site to comply with

requirements in Division 1 Section "Project Management and Coordination."

including verification of room dimension(s) and floor height(s).

1. Review connection with mechanical and electrical systems.

2. Review and finalize construction schedule and verify availability of materials,

Installer's personnel, equipment, and facilities needed to make progress

and avoid delays.

1.9 PROJECT CONDITIONS

A. Environmental Limitations: Do not install access flooring until spaces are enclosed,

sub floor sealed, ambient temperature is between 40 and 90 deg F (4 and 32 deg

C), and relative humidity is not more than 70 percent.

1.10 COORDINATION

A. Coordinate location of mechanical and electrical work in under floor cavity to

prevent interference with access flooring pedestals.

Page 4 of 11

Bergviks Iso Floor Raised Access Floor System

B. Mark pedestal locations on sub floor by use of a grid, to enable mechanical and

electrical work to proceed without interfering with access flooring pedestals.

C. Installation shall be performed in two (2) phases, floor sub-structure only in phase I

to enable mechanical and electrical work to be done without removing floor

panels. Once the mechanical and electrical work is completed under the floor,

phase II can commence installing the floor panels on top of the sub-structure.

Proceed with installation only after completion of other construction within

affected spaces receiving access flooring.

1.11 EXTRA MATERIALS

A. Furnish extra materials described in subparagraphs below that match products

installed and that are packaged with protective coverings for storage and

identified with labels describing contents.

1. Flooring Panels: 5 (of each size if applicable)

2. Pedestals including head bracket: 5 (of each height if applicable)

3. 94.5 inch (2400 mm) long 80x40 mm tube steel sections: 5

4. Stepless cable ladder brackets of each width (if applicable)

PART 2 - PRODUCTS

2.1 FLOOR PANELS AND UNDERSTRUCTURE

A. Basis-of-Design Product: Subject to compliance with requirements, provide a

Dynamic raised access floor system or similar by the following:

1. Bergvik Flooring North America, Inc., 2040 Shipley Drive, Building C-3,

Salisbury, Maryland 21801. Phone: (410) 548-1449. Fax: (410) 548-2630

Email: marketing@bergvik.com

2. Alternative floor system shall meet or exceed all requirements as indicated

herein and must receive prior written approval by the architect or designer.

3. Product: Iso Floor, a modular and self supporting bolted floor sub-structure,

having gravity placed wood-core panel system with metal backside on top.

Floor panels shall not be connected to the pedestal supports allowing for lateral

strength of floor system to be independent from all floor panels being in place or

fully removed. The self-supporting floor sub-structure is to be installed only

during phase I, if shown on engineering drawings, in order to furnish all

under floor installations prior to installing the phase II floor panels.

Page 5 of 11

Bergviks Iso Floor Raised Access Floor System

B. Floor Panels, General: Provide modular panels complying with the following

requirements that one person, using a portable lifting device, can interchange

with other field panels without disturbing adjacent panels or understructure:

1. Nominal Panel Size: 23.6 x 23.6 inch (600x600 mm). Custom size panels to

be specified if shown on engineering drawings.

2. Fabrication Tolerances: Fabricate panels to the following tolerances with

square ness tolerances expressed as the difference between diagonal

measurements from corner to corner:

a. Size and Squareness: Plus or minus 0.015 inch (0.38 mm) of required

size, with a squareness tolerance of plus or minus 0.015 inch (0.38

mm), unless tolerances are otherwise indicated for a specific panel

type.

b. Flatness: Plus or minus 0.020 inch (0.50 mm), measured on a diagonal

on top of panel.

3. Panel Attachment to Understructure: By gravity.

C. Wood-Core Panels with metal backside: Fabricate from 1.5 inch (38 mm) thick,

V313 moist resistant and E1 type particleboard core, made with less than 10

ppm urea formaldehyde and be fully recyclable. Manufacturer of particleboard

shall operate its own bio power plant to make sure that the amount of thermal

energy derived from biofuel is atleast 91 percent and shall make sure that the

forests harvested are re-planted with atleast one million seedlings annually.

Manufacturer shall also use the ISO 14001 Environmental Management System

as a tool to continually improve environmental issues.

Laminate bottom aluminum face sheet with a direct laminate process using heat

and pressure, providing a flame-spread index of 25 or less per ASTM E84 or

NFPA 266. Provide tapered core edges including direct laminated surface finish

of M335 Granite dcor. All panel edges should be enclosed with a 0.02-inch

(0.45 mm) glued perimeter ABS edge trim. Edge trim shall be applied so it

covers the tapered panel edges, including surface finish. Provide custom panel

sizes under equipment unless open bottom access is specified using a 1.5

square (38 mm) steel tube under front and back of the equipment if shown on

engineering drawings. Provide custom panels if shown on engineering drawings

to assure all panels in service or cooling aisles are fully removable.

C. D. Perforated Airflow Panels: Perforated Triad steel airflow panels designed

for static loads of 1500 lbs. shall be interchangeable with standard field panels

and shall have 25% to 56% open surface area with the following air distribution

capability:

At 56%, Panel without damper: 2845 cfm at 0.1-inch of H2O (static pressure).

At 56%, Panel with OPD damper at 50% open position: 1400 cfm at 0.1-inch

of H2O (static pressure).

At 56%, Panel with OPD damper at 100% open position: 2805 cfm at 0.1-inch

of H2O (static pressure).

Page 6 of 11

Bergviks Iso Floor Raised Access Floor System

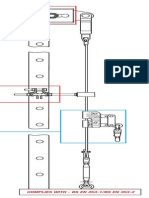

E. Floor understructure: Assembly shall consist of 3 x 1.5 inch (80x40 mm) primary

and secondary layer tube steel beam sections bolted together 90 degrees

perpendicular to each other with angle clips and self tapping screws. Tube steel

sections shall provide a yield and a tensile strength to meet the max allowed

temporary deflection of L/360 of span. Certified structural engineer shall furnish

a distributed and concentrated static load calculation report for approval. All

primary sections shall have a tension screw plate mounted to one side for tension

against the perimeter wall. Provide open bottom access under the equipment

racks using a 1.5 square (38 mm) steel tube under front and back of the

equipment aisle if shown on engineering drawings. Recycled scrap metal content

shall be minimum 50% and steel manufacturer shall use the ISO 14001

Environmental Management System as a tool to continually improve

environmental issues.

F. Pedestals: Assembly consisting of base, 3 x 1.5 inch (80x40 mm) tube column and

head cap including head bracket with provisions for height adjustment, made of

steel.

1. Base: Rectangular base with not less than 11.6 sq. in. (75 sq. cm.) of bearing

area.

2. Column: Of height required to bring finished floor to elevations indicated,

less 8.25 inch (210 mm). Pressed securely into base plate and head cap.

3. Provide vibration-proof leveling mechanism for making and holding fine

adjustments in height over a range of not less than +/- 1 inches (25 mm)

and for locking at a selected height, so deliberate action is required to

change height setting and vibratory displacement is prevented.

4. Head: Designed to support head bracket indicated which is attached to

primary stringer.

G. Rust corrosion, metal components: All parts of the Floor understructure including

Pedestal components shall be hot-dipped galvanized to ensure that no zinc

particles will erode into the atmosphere.

2.2 FLOOR PANEL COVERINGS

A. General: Provide factory-applied direct Laminate by raised access flooring

manufacturer to top surface of floor panels.

B. Standard Direct Laminate:

1. Manufactured from phenolic and melamine resin impregnated papers, using a

high-wear type melamine glass overlay.

a. Wear resistant to >6000 cycles according to EN 438-2:6 1991.

2. Fabricate to cover each panel face prior to applying edge trim.

Page 7 of 11

Bergviks Iso Floor Raised Access Floor System

3. Colors and Dcor(s): M335 Granite // H817 Alder // A287 Oak as shown on

engineering drawings..

C. Basis-of-Design Product: Subject to compliance with requirements, provide the

product, or a comparable product by one of the following:

1. Coveright

2.3 ACCESSORIES

A. Nail plugs: Manufacturer's standard nail plugs for securing pedestals to sub floor if

nothing else is shown on the engineering drawings.

B. Cutouts: Provide cutouts in floor panels for cable grommets and service outlets.

Provide reinforcement or additional support, if needed, to make custom size

panels or cutouts that comply with standard performance requirements.

1. Number, Size, Shape, and Location: Allow for a minimum of //// circular

penetrations for cutouts of //..// inch (minimum) in diameter in the floor as

shown on engineering drawings.

2. Fit cutouts with manufacturer's standard grommets in sizes indicated or, if

size of cutouts exceeds maximum grommet size available, trim edge of

cutouts with manufacturer's standard plastic molding or edgetrim. Furnish

removable covers for grommets if specified.

C. Ramps: Manufacturer's standard ramp construction of width and slope indicated,

but not steeper than 1:12, with non-slip floor covering to match the same

performance and construction requirements as of the access flooring, or as

indicated on engineering drawings.

D. Railings: Standard extruded-aluminum railings, at ramps and open-sided perimeter

of access flooring where indicated. Include handrail, intermediate rails, posts,

brackets, end caps, wall returns, wall and floor flanges, plates, and anchorages

where required, or as indicated on engineering drawings. .

E. Panel Lifting Device: Manufacturer's standard portable lifting device of double type

required for specified panels. Provide one lifting devices per room including

wall mounted panel lifting bracket for each lifting device.

F. Perimeter Support: Where indicated, provide manufacturers standard method for

supporting panel edges and forming transition between access flooring and

adjoining floor coverings. Perimeter support covering shall match floor panel

finish(es) or as indicated on engineering drawings.

.

Page 8 of 11

Bergviks Iso Floor Raised Access Floor System

PART 3 - EXECUTION

3.1 EXAMINATION

A. Examine substrates, with Installer and manufacturer's representative present, for

compliance with requirements for installation tolerances and other conditions

affecting performance of work.

1. Verify that substrates comply with tolerances and other requirements

specified in other Sections and that substrates are free of cracks, ridges,

depressions, scale, foreign deposits, and debris. Verify that concrete slab

sub floor has been sealed.

2. Proceed with installation only after unsatisfactory conditions have been

corrected.

3.2 PREPARATION

A. Lay out floor panel installation to keep the number of cut panels at floor perimeter

to a minimum. Avoid using panels cut to less than 8 inches (200 mm).

B. Complete any necessary sub floor preparation, and vacuum clean sub floor to

remove construction debris before beginning installation.

3.3 INSTALLATION

A. Install access flooring system and accessories under supervision of access flooring

manufacturers authorized and certified representative to produce a rigid, firm

installation that complies with performance requirements and is free of

instability, rocking, rattles, and squeaks.

Installation, phase I

B. Install primary beam sections supported by and mounted to pedestal assemblies so

that no interference with feeder cables to and from equipment racks or cabinets

occurs.

C. Set pedestals with nail plugs as recommended by access flooring manufacturer to

provide full bearing of pedestal base on sub floor.

D. Level sub-structure pedestals to permit panels on top to be level and to proper

height as set out in engineering drawings. Secure the leveling by tightening the

locking nuts on all pedestals.

E. Install secondary beam sections supported by primary beam sections using angle

clips and self-tapping screws so that they line up center to center with all panels

in accordance with the manufacturers floor layout drawings.

Page 9 of 11

Bergviks Iso Floor Raised Access Floor System

Before installation phase II starts, perform cable management, electrical and HVAC

installations under the floor substructure to prevent floor panels to be removed

and reinstalled by subcontractors. By following this procedure, project schedule

can be shortened and damage of floor panels be avoided.

Installation, phase II

F. Install floor panels securely in place on top of secondary beam sections, properly

seated with panel edges flush. Do not force panels into place. Verify if custom

size panels are to be located in rows where equipment racks or cabinets of

different depths are to be installed, to allow for service aisle panels to be fully

removable.

G. Scribe perimeter panels to provide a close fit with adjoining construction using

foam tape between perimeter panel and wall, with no voids greater than 1/4 inch

(6 mm) where panels abut vertical surfaces.

H. Cut and trim access flooring and perform other dirt-or-debris-producing activities

at a remote location or as required to prevent contamination of sub floor under

access flooring already installed.

I. Ground flooring system as recommended by manufacturer and as needed to comply

with performance requirements for electrical resistance of floor system and

coverings.

J. Clean dust, dirt, and construction debris caused by floor installation, and vacuum

sub floor area, as installation of floor panels proceeds.

K. Install access flooring without change in elevation between adjacent panels and

within the following tolerances:

1. Plus or minus 1/16 inch (1.5 mm) in any 10-foot (3 meter) distance.

2. Plus or minus 1/8 inch (3 mm) from a level plane over entire flooring area.

3.4 ADJUSTING, CLEANING, AND PROTECTION

A. Prohibit traffic on access flooring structure unless floor panels have been installed,

or floor structure is covered by secure means to prevent accidents.

B. After completing installation, vacuum clean access flooring and cover with

continuous sheets of reinforced paper or plastic if required. Maintain protective

covering until time of Substantial Completion.

C. Replace access floor panels that are stained, scratched, or otherwise damaged or

that do not comply with specified requirements.

Page 10 of 11

Bergviks Iso Floor Raised Access Floor System

D. After completed installation, inspect completed raised access floor installation

together with customer using manufacturers standard completed inspection

form and sign off for approval. Provide one copy to the customer and return

one copy to manufacturer as a proof of completion and acceptance.

E. After receipt of signed completed inspection form, manufacturer shall provide

customer with a detailed warranty document dated and signed by an authorized

officer of the manufacturer.

END OF SECTION 10270

Page 11 of 11

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- ASM Bolted Stringer SystemDocument6 pagesASM Bolted Stringer SystemNeelima ParanjpeyNo ratings yet

- Raised Access Flooring System SpecificationDocument6 pagesRaised Access Flooring System SpecificationAsad NizamNo ratings yet

- FS300D - Vinyl Tile Panel - Bolted Stringer SystemDocument6 pagesFS300D - Vinyl Tile Panel - Bolted Stringer SystemManuel OrdoñezNo ratings yet

- Concore 1500Document8 pagesConcore 1500jonie609No ratings yet

- Concore 2500Document8 pagesConcore 2500jonie609No ratings yet

- Haworth Wood Flooring System SpecificationDocument8 pagesHaworth Wood Flooring System SpecificationDiaszNo ratings yet

- Key IWS CoatingDocument6 pagesKey IWS Coatingfaisal hanifNo ratings yet

- F - A F Key Quartz B-125 1/8" Epoxy Decorative Quartz Resinous Flooring UV Light Resistant Epoxy Grout/SealerDocument7 pagesF - A F Key Quartz B-125 1/8" Epoxy Decorative Quartz Resinous Flooring UV Light Resistant Epoxy Grout/SealerUmerNo ratings yet

- 1.1 A. 1.2 A. B. C. 1.3 A. B. C. D. E. F. G. H. I.: Click HereDocument5 pages1.1 A. 1.2 A. B. C. 1.3 A. B. C. D. E. F. G. H. I.: Click HereRiksa AsNo ratings yet

- Hill Country StoneDocument3 pagesHill Country StoneAJAYSINGLABTINo ratings yet

- Section 035216 - Lightweight Insulating ConcreteDocument5 pagesSection 035216 - Lightweight Insulating ConcreteWENDING HUNo ratings yet

- Aluco21spec PDFDocument12 pagesAluco21spec PDFRené Galbraith BerraNo ratings yet

- Section 09 Resilient Wood Flooring System Junckers Duobat 110+ SystemDocument3 pagesSection 09 Resilient Wood Flooring System Junckers Duobat 110+ SystemLindbladJunckersNo ratings yet

- Mechanically Stabilized Earth Retaining Walls Effective: February 3, 1999 RevisedDocument8 pagesMechanically Stabilized Earth Retaining Walls Effective: February 3, 1999 RevisedJoseph StalinNo ratings yet

- BUR SpecificationDocument5 pagesBUR SpecificationajuciniNo ratings yet

- Architextures - Barrisol Stretch Ceilings SpecDocument4 pagesArchitextures - Barrisol Stretch Ceilings SpecMohammed Abdul BaseerNo ratings yet

- EWS Series 400 SpecsDocument11 pagesEWS Series 400 Specscancer24No ratings yet

- 09 69 33fazDocument11 pages09 69 33fazbrian walter abarintosNo ratings yet

- Reinforced AAC Panel SpecificationsDocument12 pagesReinforced AAC Panel SpecificationswinsonecNo ratings yet

- Solar Car Park CanopyDocument6 pagesSolar Car Park CanopyAnish BabuNo ratings yet

- Aluminum Composite Pannel LimitsDocument7 pagesAluminum Composite Pannel LimitsRex SirilanNo ratings yet

- Wood Roof Decking Tiles Guide SpecificationDocument7 pagesWood Roof Decking Tiles Guide SpecificationJoyce RobisonNo ratings yet

- CsiDocument9 pagesCsiyamanta_rajNo ratings yet

- 03 48 00clcDocument5 pages03 48 00clcAira LauzonNo ratings yet

- Section 035440 - Cement-Based ScreedDocument11 pagesSection 035440 - Cement-Based ScreedWENDING HUNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07500-1 RoofingDocument8 pagesITCC in Riyadh Residential Complex J10-13300 07500-1 RoofinguddinnadeemNo ratings yet

- Linen Chute Installation GuideDocument4 pagesLinen Chute Installation GuideMoath AlhajiriNo ratings yet

- Acoustical Tile Ceilings (Ms - FL)Document9 pagesAcoustical Tile Ceilings (Ms - FL)walid abou kachfeNo ratings yet

- Light Medium Duty Dumbwaiter Master SpecDocument9 pagesLight Medium Duty Dumbwaiter Master SpecIbnu SyaNo ratings yet

- Specs ColdRoomDocument6 pagesSpecs ColdRoommdalt9180No ratings yet

- SPC Occ 221423 MeDocument4 pagesSPC Occ 221423 Metarekhisham1234No ratings yet

- Technical Specifications: Excavation, Backfilling Site WorksDocument4 pagesTechnical Specifications: Excavation, Backfilling Site WorksHazim AhmadNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 09515 - 1 Cement Board CeilingDocument5 pagesITCC in Riyadh Residential Complex J10-13300 09515 - 1 Cement Board CeilinguddinnadeemNo ratings yet

- Suspended Ceiling Systems-10.24.2012Document30 pagesSuspended Ceiling Systems-10.24.2012Rica Jeremias CamachoNo ratings yet

- Busbar Trunking System (Busways)Document6 pagesBusbar Trunking System (Busways)saravana3kumar3ravic100% (1)

- Specification for Public Health InstallationDocument14 pagesSpecification for Public Health InstallationComofco GibraltarNo ratings yet

- 26 25 00 Busway XJLDocument4 pages26 25 00 Busway XJLuddinnadeemNo ratings yet

- 11.1 Specific Requirements: Table 3 Minimum ClearancesDocument7 pages11.1 Specific Requirements: Table 3 Minimum ClearancesEma WeismanNo ratings yet

- XHC-000-Rev 2.0 T3 Precision Pre-Installation Requiements DocumentDocument13 pagesXHC-000-Rev 2.0 T3 Precision Pre-Installation Requiements DocumentBill MtsyNo ratings yet

- 14 2400 Hydraulic ElevatorsDocument12 pages14 2400 Hydraulic ElevatorsPercy GoitsemangNo ratings yet

- Raised Floor Works-SpecsDocument5 pagesRaised Floor Works-SpecsdenisjayNo ratings yet

- Fs800 HPL Ficha TecnicaDocument7 pagesFs800 HPL Ficha TecnicaBull433No ratings yet

- AcousticDocument10 pagesAcousticKurnianda Dian WulandariNo ratings yet

- 057521Document20 pages057521M.Senthil VelavanNo ratings yet

- Acoustical Ceiling Tile SpecificationDocument5 pagesAcoustical Ceiling Tile SpecificationuddinnadeemNo ratings yet

- #1 Requirement FlooringDocument3 pages#1 Requirement Flooringnatee8632No ratings yet

- Aluminum Composite PanelsDocument4 pagesAluminum Composite PanelsSaurav ChaudharyNo ratings yet

- Joint Sealants - MSTDocument9 pagesJoint Sealants - MSTwafikmh4No ratings yet

- Mozaik Climbing Wall Performance SpecDocument5 pagesMozaik Climbing Wall Performance SpecHarryDammanickNo ratings yet

- Construct Ultrablock Gravity WallDocument11 pagesConstruct Ultrablock Gravity WallFernando LesterNo ratings yet

- Aluminum Cover Spec 50 PSF Surface Mounted (Updated 120115)Document5 pagesAluminum Cover Spec 50 PSF Surface Mounted (Updated 120115)Arturo BarrosNo ratings yet

- TerracottaDocument11 pagesTerracottaDiaszNo ratings yet

- Expansion Joint Cover Assembly SpecificationsDocument5 pagesExpansion Joint Cover Assembly SpecificationsuddinnadeemNo ratings yet

- Grounding and Bonding - Electrical Design GuideDocument2 pagesGrounding and Bonding - Electrical Design GuideJasm MutingNo ratings yet

- Technical ProposalDocument6 pagesTechnical ProposalMark Sinclair100% (1)

- Flat Concrete Floor Work Method - FindotekDocument16 pagesFlat Concrete Floor Work Method - FindotekTAHER AMMARNo ratings yet

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Geo 5 User Guide enDocument1,100 pagesGeo 5 User Guide enElias Matheus OliveiraNo ratings yet

- GEO5 v16 Software ManualDocument1,127 pagesGEO5 v16 Software ManualBza ZaBug100% (1)

- European Structural SectionsDocument32 pagesEuropean Structural Sectionskogi3075100% (3)

- Guitar Maker 0995Document1 pageGuitar Maker 0995cokiaaNo ratings yet

- 15 Ironsteelaccess CoversDocument10 pages15 Ironsteelaccess CoversimadNo ratings yet

- BS EN 353-1/353-2 Safesite Cabloc SpecificationDocument1 pageBS EN 353-1/353-2 Safesite Cabloc SpecificationcokiaaNo ratings yet

- Memorandum: Iso Floor and UBC-97 Zone 4Document1 pageMemorandum: Iso Floor and UBC-97 Zone 4cokiaaNo ratings yet

- Iso Floor BergvikDocument8 pagesIso Floor BergvikcokiaaNo ratings yet

- CablocDocument4 pagesCabloccokiaaNo ratings yet

- Revolutionary Raised Floor System - HiFlex FloorDocument2 pagesRevolutionary Raised Floor System - HiFlex FloorcokiaaNo ratings yet

- BF PTY Airflow Prod SheetDocument2 pagesBF PTY Airflow Prod SheetcokiaaNo ratings yet

- En 362 - 2004Document19 pagesEn 362 - 2004cokiaa67% (3)

- Bergvik Earthquake Bracing Frames PDFDocument2 pagesBergvik Earthquake Bracing Frames PDFcokiaaNo ratings yet

- Raised Floor System For Telecom SwitchesDocument12 pagesRaised Floor System For Telecom SwitchesMustapha OthmanNo ratings yet

- Guard-rail Stress Analysis for StairwayDocument1 pageGuard-rail Stress Analysis for StairwaycokiaaNo ratings yet

- Guard-Rail Stress Analysis: Max 102 MPaDocument1 pageGuard-Rail Stress Analysis: Max 102 MPacokiaaNo ratings yet

- PM 7 GuardrailDocument1 pagePM 7 GuardrailcokiaaNo ratings yet

- Capital ProtectaDocument60 pagesCapital Protectacokiaa0% (1)

- Bergvik Isofloor US WebDocument12 pagesBergvik Isofloor US WebMuhammad Noshad RizviNo ratings yet

- BS EN 353-1/353-2 Safesite Cabloc SpecificationDocument1 pageBS EN 353-1/353-2 Safesite Cabloc SpecificationcokiaaNo ratings yet

- Bergvik Earthquake Bracing Frames PDFDocument2 pagesBergvik Earthquake Bracing Frames PDFcokiaaNo ratings yet

- Kapi TeltDocument9 pagesKapi TeltcokiaaNo ratings yet

- BF PTY Airflow Prod SheetDocument2 pagesBF PTY Airflow Prod SheetcokiaaNo ratings yet

- Accessories: Safety in ActionDocument6 pagesAccessories: Safety in ActioncokiaaNo ratings yet

- SÖLL - A Name That Guarantees Quality: Fall Protection Systems - Hot Dip GalvanizingDocument2 pagesSÖLL - A Name That Guarantees Quality: Fall Protection Systems - Hot Dip GalvanizingcokiaaNo ratings yet

- CablocDocument4 pagesCabloccokiaaNo ratings yet

- Kapi TeleDocument14 pagesKapi TelecokiaaNo ratings yet

- KAPITELGDocument7 pagesKAPITELGcokiaaNo ratings yet

- KAPITELGDocument7 pagesKAPITELGcokiaaNo ratings yet

- NPT ThreadsDocument6 pagesNPT ThreadsmakanbhupindersinghNo ratings yet

- 14 OSID Installation Sheet UL A3 IE LoresDocument2 pages14 OSID Installation Sheet UL A3 IE LoresIzhoneRdrNo ratings yet

- Revised Compendium On IR-DRDO Bio-ToiletDocument195 pagesRevised Compendium On IR-DRDO Bio-ToiletLRC ER-LLHNo ratings yet

- Knauf Cleaneo - 2022 - ENDocument16 pagesKnauf Cleaneo - 2022 - ENAnastasya YusufNo ratings yet

- Machine Design/Shop Practice Trivia: Multiple Choice QuestionsDocument9 pagesMachine Design/Shop Practice Trivia: Multiple Choice QuestionsPaul EdwardNo ratings yet

- 330CLC and 370C Excavator IntroductionDocument5 pages330CLC and 370C Excavator IntroductionJuan FloresNo ratings yet

- Oht - PPT290621Document35 pagesOht - PPT290621Dhruv TrivediNo ratings yet

- Free Hand Skech Book - 579Document22 pagesFree Hand Skech Book - 579mpatilboy25No ratings yet

- Parts Manual Compressor Model Airsource Plus - Ir: SERIAL NUMBER RANGE 349459 To 349464Document53 pagesParts Manual Compressor Model Airsource Plus - Ir: SERIAL NUMBER RANGE 349459 To 349464heruNo ratings yet

- Mini IP Dome Camera User's ManualDocument27 pagesMini IP Dome Camera User's ManualHenrry DiazNo ratings yet

- MJ520 Mobile Scissor Lift Table Instruction ManualDocument5 pagesMJ520 Mobile Scissor Lift Table Instruction Manuallalit PatilNo ratings yet

- Parts Catalog: FY8-31EB-010Document90 pagesParts Catalog: FY8-31EB-010GrayShadow88No ratings yet

- VCA03 FH2 CE Fire HydrantDocument2 pagesVCA03 FH2 CE Fire HydrantSenghy MaoNo ratings yet

- Manual Z-precision Kit GuideDocument18 pagesManual Z-precision Kit Guidetobajej752No ratings yet

- MCMC MTSFB TC G010 - 2017 - RNF Smart Pole PDFDocument33 pagesMCMC MTSFB TC G010 - 2017 - RNF Smart Pole PDFseanNo ratings yet

- LK-1900B P PDFDocument108 pagesLK-1900B P PDFAchmad RezaNo ratings yet

- Catalogo Valvulas de SeguridadDocument66 pagesCatalogo Valvulas de Seguridadhogsp1No ratings yet

- CASE - First Year Exam - 2nd Re-Exam August 2021 - Førsteårsprøven - 2. Re-Eksamen August 2021 (EN-DK)Document31 pagesCASE - First Year Exam - 2nd Re-Exam August 2021 - Førsteårsprøven - 2. Re-Eksamen August 2021 (EN-DK)SafridNo ratings yet

- E GTH-4013 From SN 14518 To 17991Document138 pagesE GTH-4013 From SN 14518 To 17991sixin93551No ratings yet

- Steelwise Strength and EngagementDocument3 pagesSteelwise Strength and EngagementGiri DharanNo ratings yet

- Spare Parts List: Hydraulic BreakerDocument36 pagesSpare Parts List: Hydraulic BreakerOS100% (1)

- Quiz LetDocument25 pagesQuiz LetChristopher Lennon Dela CruzNo ratings yet

- Knauf D12 SystemDocument28 pagesKnauf D12 SystemAmin ChhipaNo ratings yet

- Lo1. Prepare Materials, Tools and Equipment For Installing FormworksDocument7 pagesLo1. Prepare Materials, Tools and Equipment For Installing FormworksmaxmanNo ratings yet

- Standard VCS 5511,: Volvo Car CorporationDocument35 pagesStandard VCS 5511,: Volvo Car CorporationRapegaNo ratings yet

- Reusing Screws and Bolts Is A Safety Risk and Decreases Fan ReliabilityDocument3 pagesReusing Screws and Bolts Is A Safety Risk and Decreases Fan ReliabilityThanaraj SanmughamNo ratings yet

- CTP Special Hardware:: Heavy WashersDocument5 pagesCTP Special Hardware:: Heavy WashersAten HarisNo ratings yet

- Spare Parts Catalogue 2018/19Document96 pagesSpare Parts Catalogue 2018/19vinu_krishnan91No ratings yet

- Lathe 1340 Jet ManualDocument71 pagesLathe 1340 Jet ManualRC VilledaNo ratings yet

- High Tensile Nuts BoltsDocument10 pagesHigh Tensile Nuts BoltssagarhalappaNo ratings yet