Professional Documents

Culture Documents

Robocasting: Additive Manufacturing Technique

Uploaded by

Ionuț StănculeaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Robocasting: Additive Manufacturing Technique

Uploaded by

Ionuț StănculeaCopyright:

Available Formats

Robocasting

Robocasting or Direct Ink Writing (DIW) is an

additive manufacturing technique in which a lament of

'ink' is extruded from a nozzle, forming an object layer

by layer. The technique was rst developed in the United

States in 1996 as a method to allow geometrically complex ceramic green bodies to be produced by additive

manufacturing.[1] In robocasting, a 3D CAD model is divided up into layers in a similar manner to other additive

manufacturing techniques. A uid (typically a ceramic

slurry), referred to as an 'ink', is then extruded through a

small nozzle as the nozzles position is controlled, drawing

out the shape of each layer of the CAD model. The ink

exits the nozzle in a liquid-like state but retains its shape

immediately, exploiting the rheological property of shear

thinning. It is distinct from fused deposition modelling

as it does not rely on the solidication or drying to retain

its shape after extrusion.

orientation.

2 Applications

The technique can produce non-dense ceramic bodies

which are very fragile and must be sintered before they

can be used for most applications, analogous to a wet

clay ceramic pot before being red. A wide variety

of dierent geometries can be formed from the technique, from solid bars of material to intricate microscale

scaolds.[4] To date the most researched application for

robocasting is in the production of biologically compatible tissue implants. Woodpile stacked lattice structures

can be formed quite easily which allow bone and other tissues in the human body to grow and eventually replace the

transplant. With various medical scanning techniques the

precise shape of the missing tissue was be established and

input into 3d modelling software and printed. Calcium

phosphate glasses and hydroxyapetite have been extensively explored as candidate materials due to their biocompatibility and structural similarity to bone.[5] Other

potential applications include the production of specic

high surface area structures, such as catalyst beds or fuel

cell electrolytes.[6] Advanced metal matrix- and ceramic

matrix- load bearing composites can be formed by inltrating woodpile bodies with molten glasses, alloys or

slurries.

Process

Robocasting begins with a software process which slices

an STL le (stereolithography le format) into layers of

similar thickness to the nozzle diameter. The part is produced by extruding a continuous lament of ink material

in the shape required to ll the rst layer. Next, either

the stage is moved down or the nozzle is moved up and

the next layer is deposited in the required pattern. This is

repeated until the 3d part is complete. Numerically controlled mechanisms are typically used to move the nozzle Robocasting has also been used to deposit polymer and

diameters (<2m)

in a calculated tool-path generated by a computer-aided sol-gel inks through much ner nozzle

[2]

than

is

possible

with

ceramic

inks.

manufacturing (CAM) software package. Stepper motors

or servo motors are usually employed to move the nozzle

with precision as ne as nanometers.[2]

3 References

The part is typically very fragile and soft at this point.

Drying, debinding and sintering usually follow to give the

part the desired mechanical properties.

[1] Stuecker, J (2004). Advanced Support Structures for

Enhanced Catalytic Activity. Industrial & Engineering

Chemistry Research 43 (1). doi:10.1021/ie030291v.

Depending on the ink composition, printing speed and

printing environment, robocasting can typically deal with

moderate overhangs and large spanning regions many

times the lament diameter in length, where the structure

is unsupported from below.[3] This allows intricate periodic 3D scaolds to be printed with ease, a capability

which is not possessed by other additive manufacturing

techniques. These parts have shown extensive promise in

elds of photonic crystals, bone transplants, catalyst supports and lters. Furthermore supporting structures can

also be printed from a fugitive ink which is easily removed. This allows almost any shape to be printed in any

[2] Xu, Mingjie; Gratson, Gregory M.; Duoss, Eric B.; Shepherd, Robert F.; Lewis, Jennifer A. (2006). Biomimetic

silicication of 3D polyamine-rich scaolds assembled

by direct ink writing.

Soft Matter 2 (3): 205.

doi:10.1039/b517278k. ISSN 1744-683X.

[3] Smay, James E.; Cesarano, Joseph; Lewis, Jennifer A.

(2002). Colloidal Inks for Directed Assembly of 3-D

Periodic Structures. Langmuir 18 (14): 54295437.

doi:10.1021/la0257135. ISSN 0743-7463.

[4] Lewis, Jennifer (2006). Direct Ink Writing of 3D Functional Materials. Advanced Functional Materials 16 (17):

21932204. doi:10.1002/adfm.200600434.

[5] Miranda, P (2008). Mechanical properties of calcium phosphate scaolds fabricated by robocasting..

Journal of Biomedical Materials 85 (1): 218227.

doi:10.1002/jbm.a.31587.

[6] Kuhn, M.; Napporn, T.; Meunier, M.; Vengallatore, S.;

Therriault, D. (2008). Direct-write microfabrication of

single-chamber micro solid oxide fuel cells. Journal

of Micromechanics and Microengineering 18: 015005.

doi:10.1088/0960-1317/18/1/015005.

External links

Robocasting, MIT Technology Review

EXTERNAL LINKS

Text and image sources, contributors, and licenses

5.1

Text

Robocasting Source: http://en.wikipedia.org/wiki/Robocasting?oldid=652935653 Contributors: Ezrado, ImageRemovalBot, De728631,

Ronhjones, Yobot, Buster Hateld and Claudio.cantone

5.2

Images

File:Folder_Hexagonal_Icon.svg Source: http://upload.wikimedia.org/wikipedia/en/4/48/Folder_Hexagonal_Icon.svg License: Cc-bysa-3.0 Contributors: ? Original artist: ?

File:Symbol_list_class.svg Source: http://upload.wikimedia.org/wikipedia/en/d/db/Symbol_list_class.svg License: Public domain Contributors: ? Original artist: ?

5.3

Content license

Creative Commons Attribution-Share Alike 3.0

You might also like

- Top Romanian Inventors and DiscoverersDocument8 pagesTop Romanian Inventors and DiscoverersIonuț StănculeaNo ratings yet

- 3D Printing: Additive Manufacturing GuideDocument10 pages3D Printing: Additive Manufacturing GuideKelvin Dale YubidiNo ratings yet

- Ce 3010 Honors Project 3d Printing and Construction IndustryDocument18 pagesCe 3010 Honors Project 3d Printing and Construction Industryapi-297914209No ratings yet

- A Review of Laminated Object Manufacturing (LOM) Aspects and Various Processes Used in ItDocument9 pagesA Review of Laminated Object Manufacturing (LOM) Aspects and Various Processes Used in ItIJAERS JOURNALNo ratings yet

- Processes and Printers 3DDocument6 pagesProcesses and Printers 3DFresnel FisicoNo ratings yet

- RAPID PROTOTYPING TECHNOLOGIESDocument11 pagesRAPID PROTOTYPING TECHNOLOGIESAbhishek TuliNo ratings yet

- Sinhgad College of Engineering, Pune - 41Document11 pagesSinhgad College of Engineering, Pune - 41NikNo ratings yet

- Powder Bed and Inkjet HeadDocument3 pagesPowder Bed and Inkjet HeadIonuț StănculeaNo ratings yet

- 3D Printing and NanotechnologyDocument18 pages3D Printing and NanotechnologyJoyitaNo ratings yet

- Fused Deposition Modelling of Synthetic FibersDocument15 pagesFused Deposition Modelling of Synthetic Fibersaariyaraj.pNo ratings yet

- Introduction To 3D PrinterDocument11 pagesIntroduction To 3D PrinterNilanka HarshaniNo ratings yet

- Prototyping, Are Being Developed As An Alternative To Subtractive Processes. TheseDocument19 pagesPrototyping, Are Being Developed As An Alternative To Subtractive Processes. TheseBalasivarama ReddyNo ratings yet

- Design and 3D Printing of Scaffolds and Tissues 2015 EngineeringDocument8 pagesDesign and 3D Printing of Scaffolds and Tissues 2015 EngineeringSambit Kumar GhoshNo ratings yet

- Manufacturing Process-Ii: Lab Manual 01Document8 pagesManufacturing Process-Ii: Lab Manual 01Abdul Rehman FaisalNo ratings yet

- Manufacturing Process-Ii: Lab Manual 01Document8 pagesManufacturing Process-Ii: Lab Manual 01Abdul Rehman FaisalNo ratings yet

- Rapid Prototyping: Create Something QuicklyDocument8 pagesRapid Prototyping: Create Something QuicklyAnonymous ecgeyhVNo ratings yet

- 3D Printing The Dawn of A New Era in ManufacturingDocument4 pages3D Printing The Dawn of A New Era in ManufacturingEditor IJRITCCNo ratings yet

- Jasveer and Jianbin - 2018 - Comparison of Different Types of 3D Printing TechnDocument9 pagesJasveer and Jianbin - 2018 - Comparison of Different Types of 3D Printing Technkkl12No ratings yet

- Case Study On Rapid PrototypingDocument7 pagesCase Study On Rapid PrototypingSachin KumbharNo ratings yet

- A Review On 3d PrinterDocument5 pagesA Review On 3d PrinterFiona TranNo ratings yet

- Additive Manufacture of Ceramics Components byDocument11 pagesAdditive Manufacture of Ceramics Components byاقْرَأْ وَرَبُّكَ الْأَكْرَمُNo ratings yet

- Kaushalendra PDFDocument24 pagesKaushalendra PDFharshNo ratings yet

- Ceramic Materials Unit 5,6Document32 pagesCeramic Materials Unit 5,6Akhil BaaNo ratings yet

- IEEE Paper On 3d PrintingDocument4 pagesIEEE Paper On 3d PrintingSumit Rai91% (11)

- "3D Printing: An Emerging Era of Future Printing": Mr. Pravin AhirwarDocument25 pages"3D Printing: An Emerging Era of Future Printing": Mr. Pravin AhirwarSudipta NathNo ratings yet

- Laminated Object Manufacturing (LOM) Is A RP Process That Was Developed andDocument6 pagesLaminated Object Manufacturing (LOM) Is A RP Process That Was Developed andJeyaram kumarNo ratings yet

- 3D Printing: A 40-Character IntroductionDocument29 pages3D Printing: A 40-Character IntroductionAbdul QualeqNo ratings yet

- 3d PrintingDocument8 pages3d PrintingMuhammed BasheerNo ratings yet

- Additive ManufacturingDocument4 pagesAdditive ManufacturingUttam AnimireddyNo ratings yet

- Binder JettingDocument6 pagesBinder JettingDaniel Felipe Garzon CuervoNo ratings yet

- From Biochips To Laboratory-On-A-Chip System: Lei Wang, Hongying Yin, and Jing ChengDocument38 pagesFrom Biochips To Laboratory-On-A-Chip System: Lei Wang, Hongying Yin, and Jing ChengAditi SinhaNo ratings yet

- Tihomir Grishiv-WPS OfficeDocument5 pagesTihomir Grishiv-WPS OfficeAbhilash KNo ratings yet

- 3d PrintingDocument54 pages3d PrintingCrazy Khan BolteNo ratings yet

- FIBERSIM Software Streamlines Composite DesignDocument9 pagesFIBERSIM Software Streamlines Composite DesignTakis PlimirasNo ratings yet

- Rapid Prototyping: Ashish Menon-13Bme0317 Sumit Sankhyan - 13bme0051 Siddhartha SARKAR - 13BME0281Document19 pagesRapid Prototyping: Ashish Menon-13Bme0317 Sumit Sankhyan - 13bme0051 Siddhartha SARKAR - 13BME0281AshishMenonNo ratings yet

- 3D Printing TechnologyDocument27 pages3D Printing TechnologyRuquiyaNo ratings yet

- Additive Manufacturing Notes Unit II Solid Based RPSDocument10 pagesAdditive Manufacturing Notes Unit II Solid Based RPSVenkata Naveen MaddaliNo ratings yet

- Seminar ReportDocument29 pagesSeminar Reportavish747No ratings yet

- Simulation Investment CastingDocument19 pagesSimulation Investment CastingtwanNo ratings yet

- ADDITIVE MANUFACTURING On 18.5.20Document10 pagesADDITIVE MANUFACTURING On 18.5.20aravindNo ratings yet

- 3D PrintingDocument27 pages3D Printingnaveen_kumar29173017No ratings yet

- 3dprintingpracticelab 230710091102 b46f4fddDocument36 pages3dprintingpracticelab 230710091102 b46f4fddchantiNo ratings yet

- Stereolithography: 3D Printing Layer by LayerDocument3 pagesStereolithography: 3D Printing Layer by LayerIonuț StănculeaNo ratings yet

- 3D Printer InformationDocument16 pages3D Printer Informationmahesh mulikNo ratings yet

- Binder Jetting of A Complex-Shaped Metal Partial Denture FrameworkDocument17 pagesBinder Jetting of A Complex-Shaped Metal Partial Denture FrameworkVasanth BhaskarNo ratings yet

- Rapid PrototypeDocument5 pagesRapid PrototypeŘíź'vé ŔahmæñNo ratings yet

- History and Applications of 3D Printing TechnologyDocument15 pagesHistory and Applications of 3D Printing TechnologyVikram Shenoy HandiruNo ratings yet

- 65 Course Project ReportDocument8 pages65 Course Project ReportAditya SonkusareNo ratings yet

- Additive Manufacturing PDFDocument3 pagesAdditive Manufacturing PDFKannan கண்ணன்No ratings yet

- Report Assignment 1 - 3D Printing - FINALDocument10 pagesReport Assignment 1 - 3D Printing - FINALAmirAfizJimNo ratings yet

- 1 s2.0 S2095809916300716 Main 3Document8 pages1 s2.0 S2095809916300716 Main 3Lê Bảo NgọcNo ratings yet

- Elastomeros Impresion 3DDocument15 pagesElastomeros Impresion 3DSofía BárcenasNo ratings yet

- Comparison of RP Techniques PDFDocument31 pagesComparison of RP Techniques PDFSantoshNo ratings yet

- 3D Printing: A New Era in Manufacturing TechnologiesDocument7 pages3D Printing: A New Era in Manufacturing TechnologiesashishNo ratings yet

- Special Report CHINA FOUNDRY The Role AnDocument12 pagesSpecial Report CHINA FOUNDRY The Role AnSUNDRAMNAGANo ratings yet

- Visualizing Potential Sink MarksDocument10 pagesVisualizing Potential Sink MarksSusil KumarNo ratings yet

- On 3D PrinterDocument21 pagesOn 3D PrinterAshish KumarNo ratings yet

- Presented By: Kalpesh Shah M.E. (Design)Document40 pagesPresented By: Kalpesh Shah M.E. (Design)Terminator941988No ratings yet

- Newly Developed Automatic Lay-Up Process For Manufacturing of FRP SheetsDocument6 pagesNewly Developed Automatic Lay-Up Process For Manufacturing of FRP SheetsInternational Journal of computational Engineering research (IJCER)No ratings yet

- Stereolithography: 3D Printing Layer by LayerDocument3 pagesStereolithography: 3D Printing Layer by LayerIonuț StănculeaNo ratings yet

- Abecedar UbuntuDocument194 pagesAbecedar UbuntuTudor Mihai Grigoropol100% (2)

- Lecture 51 ChallengeDocument1 pageLecture 51 ChallengeIonuț StănculeaNo ratings yet

- Ccna R&s at A GlanceDocument2 pagesCcna R&s at A Glanceadryano85No ratings yet

- Assembly The Lego Man Using CATIA v5Document3 pagesAssembly The Lego Man Using CATIA v5ionut76733No ratings yet

- Bioprinting 3d PDFDocument2 pagesBioprinting 3d PDFIonuț Stănculea100% (1)

- Solid Ground Curing 3d PrintingDocument3 pagesSolid Ground Curing 3d PrintingIonuț Stănculea0% (1)

- Powder Bed and Inkjet HeadDocument3 pagesPowder Bed and Inkjet HeadIonuț StănculeaNo ratings yet

- Selective Laser 3d PRTGDocument3 pagesSelective Laser 3d PRTGIonuț StănculeaNo ratings yet

- Scut SuportDocument1 pageScut SuportIonuț StănculeaNo ratings yet

- Laser Engineered 3d Printing NowDocument2 pagesLaser Engineered 3d Printing NowIonuț StănculeaNo ratings yet

- Continuous Liquid 3d PrintingDocument3 pagesContinuous Liquid 3d PrintingIonuț StănculeaNo ratings yet

- 3D Printed Homes in Under a DayDocument2 pages3D Printed Homes in Under a DayIonuț StănculeaNo ratings yet

- Assembly Design To The Next Level Advanced TopicDocument12 pagesAssembly Design To The Next Level Advanced TopicIonuț StănculeaNo ratings yet

- Sheet Metal in Solid EdgeDocument51 pagesSheet Metal in Solid EdgeIonuț StănculeaNo ratings yet

- Assembly in Solid Eg deDocument59 pagesAssembly in Solid Eg deIonuț StănculeaNo ratings yet

- Solidegeindrumar 2Document63 pagesSolidegeindrumar 2Ionuț StănculeaNo ratings yet

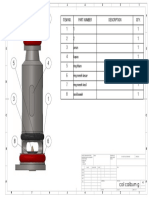

- AutoDesk educational product data fileDocument1 pageAutoDesk educational product data fileIonuț StănculeaNo ratings yet

- Speeds&Feeds Machinery'sHandbook 29editionDocument324 pagesSpeeds&Feeds Machinery'sHandbook 29editionmihailfelixdumitrescNo ratings yet

- An A-Z Index of the Windows CMD command referenceDocument7 pagesAn A-Z Index of the Windows CMD command referenceSahirNo ratings yet

- Etalonare Traductor 04 Apr.2014Document1 pageEtalonare Traductor 04 Apr.2014Ionuț StănculeaNo ratings yet

- 3D Printed Homes in Under a DayDocument2 pages3D Printed Homes in Under a DayIonuț StănculeaNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductIonuț StănculeaNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductIonuț StănculeaNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductIonuț StănculeaNo ratings yet

- Technical drawing measurements listDocument1 pageTechnical drawing measurements listIonuț StănculeaNo ratings yet

- User Guide EnglishDocument115 pagesUser Guide EnglishIonuț StănculeaNo ratings yet

- PoemsDocument1 pagePoemsIonuț StănculeaNo ratings yet

- Torsion of SectionsDocument3 pagesTorsion of SectionsanilmaviNo ratings yet

- Quartz Analogue Watches User Manual: Display and FunctionsDocument3 pagesQuartz Analogue Watches User Manual: Display and FunctionsFlorin MihaiNo ratings yet

- Conexion de M800 PDFDocument16 pagesConexion de M800 PDFChemikal EngineerNo ratings yet

- Name of Work: Estimation For Proposed Construction of Tara Ramesh, Tangali, Kadur Taluk, Chikkamagalur DistrictDocument25 pagesName of Work: Estimation For Proposed Construction of Tara Ramesh, Tangali, Kadur Taluk, Chikkamagalur DistrictDEEPIKANo ratings yet

- Marketing DB ModelDocument2 pagesMarketing DB Modeld j goraNo ratings yet

- The Effect of Inrush Current On Transformer ProtectionDocument9 pagesThe Effect of Inrush Current On Transformer Protectionbigsteve9088No ratings yet

- Sage X3 - User Guide - HTG-Printing CLOB Comments PDFDocument8 pagesSage X3 - User Guide - HTG-Printing CLOB Comments PDFcaplusinc100% (1)

- Discrepancy Switches - Control Discrepancy Switches Standard Electrical DiagramsDocument20 pagesDiscrepancy Switches - Control Discrepancy Switches Standard Electrical DiagramsAnonymous XS9jAhY1pENo ratings yet

- Technical Solutions For The Installation of High Voltage CablesDocument13 pagesTechnical Solutions For The Installation of High Voltage Cablesrrazak63No ratings yet

- GID-253-CV-GTPP-SITE-016, Rev - 1 Ironite IPS FlooringDocument6 pagesGID-253-CV-GTPP-SITE-016, Rev - 1 Ironite IPS FlooringAkash SharmaNo ratings yet

- AMI Pen TestingDocument10 pagesAMI Pen TestingcutenemesisNo ratings yet

- Axisym TutorialDocument13 pagesAxisym TutorialFredNo ratings yet

- Pneumatic Control SystemfinalDocument6 pagesPneumatic Control SystemfinalneoNo ratings yet

- Aa 02 Short-Circuit Iec StandardDocument58 pagesAa 02 Short-Circuit Iec StandardSupriyanto SuhonoNo ratings yet

- EXPERIMENT No 5 - MuX and DeMuxDocument6 pagesEXPERIMENT No 5 - MuX and DeMuxSaksham DhawanNo ratings yet

- Heat Transfer Characteristics of Thermal Energy Storage System Using PCM Capsules - A Review - 2008Document21 pagesHeat Transfer Characteristics of Thermal Energy Storage System Using PCM Capsules - A Review - 2008navidelecNo ratings yet

- Coil Caliburn GDocument1 pageCoil Caliburn GLukman Arsyanto WibowoNo ratings yet

- Catalogo Honeywell - CodigosDocument2 pagesCatalogo Honeywell - CodigosCésar GuzmánNo ratings yet

- Thyrodur 2210Document1 pageThyrodur 2210Grafički RadoviNo ratings yet

- Maytag Cycle GuideDocument9 pagesMaytag Cycle GuideReggieNo ratings yet

- Chapter 10Document9 pagesChapter 10J.K HomerNo ratings yet

- Shotcrete Slope StabilizationDocument7 pagesShotcrete Slope StabilizationJ. Kumar Infraprojects Ltd100% (1)

- 3Document2 pages3Marketing ResearchNo ratings yet

- AN2085Document9 pagesAN2085ahseerhsgNo ratings yet

- Study pointers in C with examplesDocument6 pagesStudy pointers in C with examplespremsagarNo ratings yet

- Determination of HCV of Solid or Liquid Fuel Using Bomb CalorimeterDocument11 pagesDetermination of HCV of Solid or Liquid Fuel Using Bomb CalorimeterRavi PatilNo ratings yet

- All 31 9amDocument134 pagesAll 31 9amSikha KaushikNo ratings yet

- Calculating masonry costs for a residential structureDocument7 pagesCalculating masonry costs for a residential structureSean Franz VilardoNo ratings yet

- Training Manual-Piping: Piping Study Underground PipingDocument30 pagesTraining Manual-Piping: Piping Study Underground Pipingrams789100% (2)

- Integration of SAP Into The Laboratory WorkflowDocument5 pagesIntegration of SAP Into The Laboratory WorkflowgvlaxmipathiNo ratings yet