Professional Documents

Culture Documents

Safety Instruction Sheets For Plant Piping and Cross-Country Pipelines PDF

Safety Instruction Sheets For Plant Piping and Cross-Country Pipelines PDF

Uploaded by

bainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Instruction Sheets For Plant Piping and Cross-Country Pipelines PDF

Safety Instruction Sheets For Plant Piping and Cross-Country Pipelines PDF

Uploaded by

bainCopyright:

Available Formats

Engineering Encyclopedia

Saudi Aramco DeskTop Standards

SAFETY INSTRUCTION SHEETS FOR PLANT

PIPING AND CROSS-COUNTRY PIPELINES

Note: The source of the technical material in this volume is the Professional

Engineering Development Program (PEDP) of Engineering Services.

Warning: The material contained in this document was developed for Saudi

Aramco and is intended for the exclusive use of Saudi Aramcos employees.

Any material contained in this document which is not already in the public

domain may not be copied, reproduced, sold, given, or disclosed to third

parties, or otherwise used in whole, or in part, without the written permission

of the Vice President, Engineering Services, Saudi Aramco.

Chapter : Mechanical

File Reference: MEX-101.10

For additional information on this subject, contact

PEDD Coordinator on 874-6556

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

MODULE COMPONENT

PAGE

INTRODUCTION .................................................................................................2

DETERMINING THE INFORMATION REQUIRED FOR PLANT PIPING............4

Critical Plant Piping Systems ....................................................................4

Information Contained in Saudi Aramco Form 2821 .................................5

DETERMINING THE INFORMATION REQUIRED FOR CROSS-COUNTRY

PIPELINES ..........................................................................................................7

Information Contained in Saudi Aramco Form 5645-1 ..............................7

Information Contained in Form 5645-1, Cont'd .........................................8

Information Contained in Saudi Aramco Form 5645-2 ..............................9

SUMMARY ........................................................................................................10

Line Identification (Entries 1-6)................................................................11

Equipment Data (Entries 7-16)................................................................11

Operating Limits (Entries 17-28) .............................................................13

Miscellaneous Information (Entries 29-35) ..............................................16

Work Aid 2A: Saudi Aramco Form 5645-1............................................18

Pipeline Identification (Entries 1-12)........................................................18

Equipment Data (Entries 13-24)..............................................................20

Operating Limits (Entries 25-40) .............................................................22

Miscellaneous Information (Entries 41-48) ..............................................25

Work Aid 2B - Saudi Aramco Form 5645-2 .............................................27

Pipeline Identification (Entries 1-9)..........................................................27

Equipment Data (Entries 10-20)..............................................................28

Operating Limits (Entries 21-37) .............................................................29

Operating Limits (Entries 21-37), Cont'd .................................................29

Operating Limits (Entries 21-37), Cont'd .................................................31

Miscellaneous Information (Entries 38-45) ..............................................31

GLOSSARY .......................................................................................................34

Saudi Aramco DeskTop Standards

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

INTRODUCTION

Safety Instruction Sheets are used to ensure that

operations, maintenance, and inspection personnel will

have adequate information that concerns safe operating

limits, protective devices, any special safety precautions

for specified piping system or pipelines, and other

equipment items in a consistent format. The Saudi

Aramco engineer must know how to complete all the

items on the applicable Safety Instruction Sheet,

including Maximum Allowable Operating Pressure

(MAOP), pipewall thickness, pressure test requirements,

and numerous other items that were previously

discussed in this course. The Saudi Aramco engineer is

responsible for the completion of the form, the audit of

the contents of the form, and ensuring that it is included

in the design package.

The Safety Instruction Sheets applicable to piping

systems are as follows:

Saudi Aramco Form 2821.

Saudi Aramco Forms 5645-1 and 5645-2.

Saudi Aramco Form 2821 is used for plant piping

systems, and Forms 5645-1 and 5645-2 are used for

cross-country pipelines. The extent of their use for these

systems will be discussed in later sections. These forms

provide a permanent record of critical data with regard to

the piping system. In particular, pipe material, design

conditions, thicknesses, MAOP, and safety-valve set

pressures are specified on these sheets. By the time

these forms are completed, the piping system design has

been done, and all the information that is necessary to

complete these forms is readily available. Thus, no

additional engineering is required to complete these

forms.

An engineer can obtain a fairly complete picture of the

design of the piping system from the Safety Instruction

Sheets. The Safety Instruction Sheets are part of the

permanent records for the system and are a critical

Saudi Aramco DeskTop Standards

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

resource when changes or maintenance are required on

the piping system. These forms must be completed

before the system is put into operation. They are

completed throughout the design of the piping system,

and they are referred to during inspection and testing.

Saudi Aramco Engineering Standard SAES-A-005,

Safety Instruction Sheet, provides requirements and

instructions for the completion of the appropriate form for

a particular situation. SAES-A-005 should be referred to

when a Safety Instruction Sheet is being completed.

Saudi Aramco DeskTop Standards

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

DETERMINING THE INFORMATION REQUIRED FOR PLANT PIPING

Critical Plant Piping Systems

SAES-A-005 requires that Safety Instruction Sheet,

Saudi Aramco Form 2821, be completed for critical plant

piping. A piping system is determined to be critical based

on operational considerations, design conditions that

make it more difficult to design and/or prone to failure, or

safety considerations. A plant piping system is critical if it

meets at least one of the following criteria:

The failure of the system would lead to a major

shutdown of the plant, or shutdown of a major unit

of the plant.

The design temperature is 340C (650F) or higher.

The design pressure is 3,450 kPa (500 psig) or

higher.

The fluid that is contained in the pipe is toxic or very

corrosive.

There is some other specific operating hazard

associated with the system that is not normally

experienced with the usual plant or process lines.

Saudi Aramco Form 2821 is normally not completed for

piping systems that are covered by Piping Material

Specification Classes D, E, F, G, or H of SAES-L-005.

These Specification Classes are relatively mild in nature,

as follows:

Class D Low-Pressure Utilities, Noncorrosive

Class E Low-Pressure Utilities, Corrosive

Class F Nonpressure Sewers

Class G Small Diameter Piping Around Pumps

and Compressors

Class H Low-Pressure Hydrocarbon Service

Refer to SAES-L-005 for the specific service limitations of

these Classes.

Saudi Aramco DeskTop Standards

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

Information Contained in Saudi Aramco Form 2821

Saudi Aramco Form 2821 identifies system design

information for plant piping systems. The design

information that is identified on Saudi Aramco Form 2821

must be determined in order to complete the form. Work

Aid 1 contains a copy of Form 2821 (Figure 1) with each

entry area numbered. Work Aid 1 also contains a

procedure that may be used to complete the form and is

keyed to the numbered areas. Form 2821 identifies four

primary categories of information as follows:

Line Identification Information. These items

identify the line with respect to line number, end

points, fluid service, other reference drawings, and

the industry code that was used for its design.

Equipment Data. These items define the primary

physical design information for the system, such as

diameter, nominal wall thickness, material, and

flange rating. This information helps personnel

define many of the physical characteristics of the

system without the need to locate the detailed

engineering drawings. Additional needed

information can be found as required because the

design drawings are also referenced. All of this

information was determined during the system

design and most was discussed in earlier modules

of MEX 101.

Saudi Aramco DeskTop Standards

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

Operating Limits. These items define the primary

operating limits for the system, such as design

pressure and temperature, MAOP, test pressure,

and the component(s) that limit the system

operation. This information permits personnel to

perform an initial evaluation of the system to

determine its limitations. This may be required if a

rerate is being considered, or if corrosion has

occurred. All of this information was determined

during the system design and most was discussed

in earlier modules of MEX 101.

Miscellaneous Information. This section contains

additional information regarding location,

identification, and locations for the necessary

approvals.

Refer to Work Aid 1 and Figure 1 for the specific

information that is contained in each of these categories

and for a procedure for completing this form.

Saudi Aramco DeskTop Standards

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

DETERMINING THE INFORMATION REQUIRED FOR CROSS-COUNTRY

PIPELINES

In general, Safety Instruction Sheets are prepared for all

flowlines, trunklines, and cross- country pipelines that

carry any fluid. Saudi Aramco Form 5645-1 shall be

completed for all major pipelines. In addition, Saudi

Aramco Form 5645-2 shall be filled out for the same

pipelines to cover tie-in piping, scraper traps and their

appurtenances, jumpovers, flanges, fittings, any special

components, road crossings, and sun pressure relief

valves. Form 5645-2 shall also be prepared for flowlines,

trunklines, testlines, and submarine pipelines. Both

Forms 5645-1 and 5645-2 are to retain the same Saudi

Aramco drawing number when they are used for different

portions of the same general pipeline, but with different

sheet numbers.

When calculations are required to complete the form, the

issuer of the forms must attach a calculation sheet with

each form to help with any later review that might be

required. The calculation sheet shall show the method

that was used to achieve calculated values, such as

formulas, individual variables that are in the formulas with

their units, specific requirements from the relevant

standards, etc.

Information Contained in Saudi Aramco Form 5645-1

Saudi Aramco Form 5645-1 identifies system design

information for cross-country pipelines. The design

information that is identified on Saudi Aramco Form

5645-1 must be determined in order to complete the

form. Work Aid 2A contains a copy of Form 5645-1

(Figure 2) with each entry area numbered. Work Aid 2A

also contains a procedure that may be used to complete

the form and is keyed to the numbered areas. Form

5645-1 identifies four primary categories of information

as follows:

Pipeline Identification Information. This includes

items such as the pipeline's official designation, end

points, fluid service, the year it was built, valve

Saudi Aramco DeskTop Standards

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

operating diagram reference, the number of sheets

that describe the entire pipeline, reference to the

Forms 5645-2 that are also used for the pipeline,

and the pipeline segment numbers that are covered

by the sheet.

Equipment Data. These items define the primary

physical design information for the pipeline

segments that are covered by a particular sheet.

This includes items such as diameter, nominal wall

thickness, material, flange rating, and whether the

pipeline is buried or aboveground. This information

helps personnel define many of the physical

characteristics of pipelines without the need to

locate the detailed engineering drawings or go into

the field. All of this information was determined

during the pipeline design, and most was discussed

in earlier modules of MEX 101.

Information Contained in Form 5645-1, Cont'd

Operating Limits. These items define the primary

operating limits for the pipeline. This includes items

such as the MAOP of each segment and the overall

system (and the component[s] that limit them), the

Design Factor of each segment, maximum design

temperature, minimum tie-in temperature, minimum

required thickness, and test pressure. This

information permits personnel to perform an initial

evaluation of the pipeline to determine its limitations.

This evaluation may be required if an alternate

operation is being considered, or if corrosion has

occurred. All of this information was determined

during the system design, and most was discussed

in earlier modules of MEX 101.

Saudi Aramco DeskTop Standards

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

Miscellaneous Information. This area contains

additional information regarding location,

identification, and locations for the necessary

approvals.

Refer to Work Aid 2A and Figure 2 for the specific

information that is contained in each of these categories,

and for a procedure for completing this form.

Information Contained in Saudi Aramco Form 5645-2

Saudi Aramco Form 5645-2 identifies system design

information for flowlines, trunklines, testlines, submarine

pipelines, tie-in piping, scraper traps and their

appurtenances, special components, and the other items

that were noted previously. Work Aid 2B contains a copy

of Form 5645-2 (Figure 3) with each entry area

numbered. The design information that is identified on

Saudi Aramco Form 5645-2 must be determined in order

to complete the form. Work Aid 2B also contains a

procedure that may be used to complete the form and is

keyed to the numbered areas.

Saudi Aramco Form 5645-2 identifies the same four

primary categories of information that were discussed for

Saudi Aramco Form 5645-1. However, the specific data

items that are included in the "Equipment Data" and

"Operating Limits" categories are more similar to the

items that are in Form 2821 for plant piping rather than in

Saudi Aramco Form 5645-1; the similarity exists because

the particular pipeline system items for which Saudi

Aramco Form 5645-2 is used are more similar to plant

piping than to cross-country pipelines.

Refer to Work Aid 2B and Figure 3 for the specific

information that is contained in each of these categories

and a procedure for completing this form.

Saudi Aramco DeskTop Standards

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

SUMMARY

Safety Instruction Sheets must be completed before a

piping system can go into operation. For critical plant

piping systems, Form 2821 must be completed. For

cross-country pipelines, Saudi Aramco Forms 5645-1

and 5645-2 must be completed. The completion of these

forms requires the engineer to collect information

regarding system design and operating limits that has

already been determined during detailed engineering.

The collection of data in this manner ensures that

operations, maintenance and inspection personnel have

adequate information in a consistent format.

The next module discusses how to maintain piping and

repair defects after the piping system has been placed in

operation.

Saudi Aramco DeskTop Standards

10

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

WORK AID 1:

PROCEDURES FOR DETERMINING THE INFORMATION TO

COMPLETE A SAFETY INSTRUCTION SHEET FOR PLANT

PIPING

Use the following procedure, in conjunction with Figure 1,

to determine the information that is necessary to

complete Safety Instruction Sheet, Form 2821, for critical

plant piping. The identification numbers that are shown in

the following procedure correspond to those shown in

Figure 1. Reference SAES-A-005, Safety Instruction

Sheet, for additional information. Note that by the time it

is necessary to complete Form 2821, engineering has

been completed, all the required information is readily

available, and no new calculations or selections are

needed.

Line Identification (Entries 1-6)

1.

Show the line identification number, such as P28-3A1.

2. & 3.

Indicate where the line starts and ends, such

as Furnace F-201 to Column C-221, Acid

Pumps G-21A/B to Reactor D-21.

4.

Give specific data on the fluid service, such as

reduced crude with acid, vapor, etc.

5.

Indicate the pertinent pipe isometrics, P & ID's,

or other reference drawings that apply to the

particular line.

6.

Show the applicable industry code and year

that was used in the pipe design, such as ANSI

B31.3, 1990.

Equipment Data (Entries 7-16)

Note that there are three columns within the Equipment

Data area. This permits providing information about

three separate pipe sizes or materials that may be within

Saudi Aramco DeskTop Standards

11

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

the same piping system.

7.

Nominal pipe size (NPS).

8.

Pipewall thickness in inches or millimeters.

Note that this is the nominal pipe thickness,

which was discussed in MEX 101.03.

9.

Pipe material specification and grade, such as

A-106, Gr. B, API 5L, Gr. X-42. Material

selection was discussed in MEX 101.02 and

MEX 101.08.

Equipment Data (Entries 7-16), Cont'd

10.

Indicate whether the pipe has a welded

longitudinal seam (such as SAW, ERW), or is

seamless (SMLS).

11.

Flange rating according to ASME/ANSI B16.5.

Selection of the required flange rating was

discussed in MEX 101.04.

12.

Type of flange face, such as raised face (RF),

ring joint (RTJ), or flat face (FF). Flange face

requirements were discussed in MEX 101.04.

13.

Flange material specification and grade, such

as A-105; A-350, Grade LF-2. Flange material

selection was discussed in MEX 101.04 and

MEX 101.08.

14.

Fitting rating, such as Sch. 40 for butt-weldtype fittings, or 3,000 lb. for threaded- or

socket-welded-type fittings. The rating of pipe

fittings was discussed in MEX 101.04 and MEX

101.08.

15.

Fitting material specification and grade, such

as A-105; A-234, Gr. WPB. Fitting material

specification was discussed in MEX 101.04

and MEX 101.08.

16.

Any specific remarks with regard to material,

Saudi Aramco DeskTop Standards

12

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

components, system limitations. Include items

such as the following:

Precautions that are necessary during

operation or tests. For example, the need

to blind-off expansion joints during

hydrostatic tests because they will not

withstand the test pressure, or the need to

add temporary supports during hydrotest.

Special piping components that may be in

the system, such as soft-seat ball valves.

Operating Limits (Entries 17-28)

17. & 18. Indicate the MAOP and temperature for the

lines as one system based on its weakest

point, such as the corrosion condition of the

line, pressure vessels, flanges, etc. MAOP

was discussed in MEX 101.03 and MEX

101.04.

19.

Saudi Aramco DeskTop Standards

Enter the actual new test pressure. The test

pressure should be consistent with the

hydrostatic test diagram and SAES-A-004.

Test pressure requirements were discussed in

MEX 101.09.

13

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

Operating Limits, (Entries 17-28), Cont'd

20.

Show the limiting item for the test pressure,

such as flanges, pipewall thickness, pressure

vessel, heat exchanger.

21.

Enter the design pressure, which should be

consistent with SAES-L-002.

22.

Enter the design temperature, which should be

consistent with SAES-L-002.

23.

Indicate the limiting item for the design

pressure, such as pipewall thickness, flanges,

process limitations, or any other limiting item.

24.

Enter the equipment safety valve set pressure,

not greater than that shown under Key Number

21.

25.

Nominal Pipe Size (NPS). Note that there are

three columns for size and for Key Numbers 26

and 27. This permits providing information

about three separate pipe sizes that may be

within the same piping system.

26.

Required minimum wall thickness, tm, for the

pipe. Refer to ASME/ANSI B31.3 and MEX

101.03 for method of calculation.

Note that tm is the retirement wall

thickness, and shall also not be less than

the required wall thickness for mechanical

strength. Refer to Saudi Aramco

Inspection Procedure 01-AIP-02-0, SAESL-006, or the piping specialist in the

Consulting Services Department, for

further explanation. When tm is for

mechanical strength, indicate this in the

remarks section.

27.

Saudi Aramco DeskTop Standards

This is calculated based on the nominal wall

thickness of the pipe, minus manufacturing

undertolerance for thickness, and minus the

14

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

value that was determined for Key Number 26.

Note that the corrosion allowance, c, as

determined here, is the remaining pipewall thickness that is above the required

tm. 'c' is not the required corrosion

allowance that was specified as part of

the initial design conditions for the piping

system. If a corrosion allowance is

required, it must be stated in the remarks

area under Key Number 28.

28.

Saudi Aramco DeskTop Standards

Add any remarks that pertain to any item or

calculation above. Indicate any items or

hazards which require consideration by

operations, inspection or maintenance

personnel.

15

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

Miscellaneous Information (Entries 29-35)

29.

District and location.

30.

Plant number.

31.

Follow the usual procedure to obtain drawing

numbers.

32.

Include BI and JO under which the equipment

was installed.

33.

Complete this section showing date and name

of originator.

34.

Engineering concurrence as indicated in

Section 4 of this standard plus project manager

or plant manager's approval, as required.

35.

Signature of Facility Engineering Division head.

Saudi Aramco DeskTop Standards

16

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

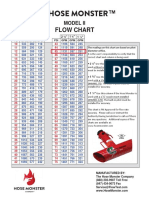

FORM 2821

FIGURE 1

Saudi Aramco DeskTop Standards

17

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

WORK AID 2:

PROCEDURES FOR DETERMINING THE INFORMATION TO

COMPLETE A SAFETY INSTRUCTION SHEET FOR CROSSCOUNTRY PIPELINES

Work Aid 2A:

Saudi Aramco Form 5645-1

Use the following procedure in conjunction with Figure 2

to determine the information that is necessary to

complete Safety Instruction Sheet, Form 5645-1, for

pipelines. The identification numbers that are shown in

the following procedure correspond to those shown in

Figure 2. Reference SAES-A-005, Safety Instruction

Sheet, for additional information. Note that by the time it

is necessary to complete Form 5645-1, engineering has

been completed, all of the required information is readily

available, and no new calculations or selections are

needed.

Pipeline Identification (Entries 1-12)

1.

Give the official designation of the pipeline,

e.g., "Qatif-Ras Tanura Pipeline Number 6"

(QRT-6) and indicate the fluid that is being

handled, such as "stabilized Arabian Light

Crude," "fuel gas," or "water."

2.

Show the name of the pipeline origin, such as

"Qatif Junction."

3.

Show the name of the pipeline termination

point, such as "Ras Tanura."

4.

Indicate the type of fluid that is being handled,

such as Arab Light.

5.

Show the name of the valve operating diagram

of this line, such as "NACRUDE." If not

available, give the P & ID Drawing Number.

6.

Indicate the year in which the line was built.

Saudi Aramco DeskTop Standards

18

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

7.

Give the Kilometer Number where the pipeline

begins.

8.

Give the Kilometer Number of the pipeline

where this particular sheet begins. A pipeline

will typically require several Forms 5645-1 to

cover its entire length. This entry defines

where this particular sheet starts.

9.

Show the number of sheets which cover all

major segments of the pipeline to be covered

by Form 5645-1. This entry defines how many

sheets are used for the entire pipeline.

Pipeline Identification (Entries 1-12), Cont'd

10. & 11. Enter the number of the sheet(s) that cover

items which will be covered by Form 5645-2,

as identified above.

12.

Segments of the pipeline are to be numbered

sequentially, i.e., Sheet 1 will show Segments

1-5, Sheet 2 will show Segments 6-10, and so

on. A single pipeline will have multiple

segments.

Note that each segment shall have the same

diameter, wall thickness, material grade,

hydrostatic test pressure, MAOP, Area

Classification, and type of construction. If any

of these characteristics change, a new

Segment Number is to be used. Also, the

portion of the pipeline that is located between

any two major facilities (such as a scraper trap,

pump station, or a junction point) shall be

considered as a separate segment even if it

has the same characteristics as an adjacent

segment.

Saudi Aramco DeskTop Standards

19

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

Equipment Data (Entries 13-24)

13.

Nominal or outside diameter.

14.

Nominal wall thickness, with fractions shown in

decimals.

15.

Show the grade of pipe material, such as API

5L, GR. X50. SAMSSs references are not

acceptable.

16.

Enter the starting kilometer location of the

segment.

17.

Enter the ending kilometer of the segment.

18.

Indicate the length of the segment, in feet, as

shown on the layout drawing. Since the actual

routing of the pipe will not necessarily be

straight between kilometer stations, the length

of the pipeline segment is not simply the

difference between the two kilometer markers.

19.

Indicate the length of the segment in

kilometers.

Saudi Aramco DeskTop Standards

20

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

Equipment Data (Entries 13-24), Cont'd

20.

Show the process of manufacture for the pipe

(see the mill inspection report).

Seamless (S).

Longitudinally (straight seam) welded submerged-arc (Electricfusion welded) by U-ing, O-ing, Expanding (UOE-EFW).

Longitudinally (straight seam) welded submerged-arc (Electricfusion welded) by Cage Forming (CF-EFW).

Longitudinally (straight seam) welded electric-resistancewelded

(UOE-ERW), (CF-ERW).

Special-welded, submerged-arc (Spiral-EFW).

21.

Indicate the Specified Minimum Yield Strength

in psi, as shown on the mill certificates, for

each item of the purchase order. For example,

41,000 psi.

22.

Indicate the flange rating per ASME/ANSI

B16.5. Selection of the flange rating was

discussed in MEX 101.04.

23.

Show the type of construction for the pipeline

segment as follows:

24.

Saudi Aramco DeskTop Standards

B:

Buried

AGR: Restrained Aboveground.

AGN: Nonrestrained Aboveground.

Include any remarks that are related to pipe

material, such as "X65 pipe in Segment 3 is

installed on an experimental basis to check

weldability".

21

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

Operating Limits (Entries 25-40)

25.

Calculate the internal pressure that is required

to develop a hoop stress that is equal to the

Design Factor (DF) multiplied by the Specified

Minimum Yield Strength (SMYS) of the pipe

based on the pipe outside diameter (OD) and

nominal wall thickness (Tn).

MAOP = (DF)(SMYS)(2Tn)/(OD)

If other factors are limiting (such as flange

rating), indicate the lower MAOP and annotate

accordingly. MAOP of a pipe section was

discussed in MEX 101.03.

26.

Indicate the limiting factor of the MAOP, and

whether it is the pipewall thickness or any other

factor, such as flange rating.

27.

Show the Design Factor of the segment, such

as 0.5, 0.6, or 0.72. Design Factor was

discussed in MEX 101.03.

28.

Show the maximum design temperature.

29.

Indicate minimum design tie-in temperatures

specified in the project specification or "scope

of work".

30.

Indicate the allowable bending stress, Sb, per

SAES-L-051 and SADP-L-051. Allowable

bending stress was discussed in MEX 101.07.

31.

Calculate the required minimum wall thickness

of the pipe, Tm, based on the segment MAOP

and the Design Factor, DF. The required

minimum wall thickness of the pipe was

discussed in MEX 101.03.

Tm = (MAOP)(OD) / [2(DF)(SMYS)]

Note that Tm is the retirement wall thickness,

and shall not be less than the required wall

Saudi Aramco DeskTop Standards

22

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

thickness for mechanical strength. Refer to

Saudi Aramco Inspection Procedure 01-AIP02-0, SAES-L-006, or to the piping specialist in

the Consulting Services Department for further

explanation.

32.

Show the actual hydrostatic test pressure of

the particular segment of pipeline that is

performed immediately after construction. The

test pressure must be calculated in accordance

with SAES-A-004, Pressure Testing. Test

pressure requirements were discussed in MEX

101.09.

Operating Limits (Entries 25-40), Cont'd

33.

Show the test date.

34.

Indicate the factor that limits the test pressure,

such as pipewall thickness, flange rating,

branch connection, etc.

Note that entries for revalidation hydrostatic

tests (entries 35-37) are to be completed when

the information is known. The Safety

Instruction Sheet (SIS) is to be updated after

every revalidation test by the responsible

Operations Engineering unit.

35.

Indicate the actual test pressure for the

revalidation test. The test pressure shall be in

accordance with SAES-A-004 and approved by

the responsible Saudi Aramco Engineering

unit.

36.

Show the test date.

37.

Indicate the factor that limits the test pressure.

Note that this does not necessarily have to be

the same item that limited the initial hydrotest

pressure. For example, the original hydrotest

pressure might have been limited by the

flanges. However, corrosion which may have

occurred in the pipe, itself, could make it the

Saudi Aramco DeskTop Standards

23

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

limiting component for a revalidation test.

38.

Indicate the Maximum Allowable Operating

Pressure (MAOP) of the entire pipeline as if

one system, if applicable. This MAOP will be

dictated by the lowest of the MAOP's across

the entire pipeline, or the maximum pressure

that is achievable upstream due to, for

instance, well head or pump shutoff pressure.

If the pipeline does not have one MAOP for the

system, indicate this by "N/A" and give a clear

explanation in the remarks area, such as "the

line is telescoped."

39.

Show the limiting factor that dictates the

system MAOP.

40.

Include any pertinent remarks that will assist

operations, inspection or maintenance

personnel. Any safety hazards for the pipeline

or fluid that is transported should be

mentioned. If the pipeline is constructed such

that the pipe, flanges, valves, or fittings will not

withstand the shutoff pressure of the pump

plus the static head pressure when a

downstream valve is closed, then this hazard

must be clearly highlighted.

Indicate if surge protection system(s) have

been provided. Make reference to any special

operating instructions.

Saudi Aramco DeskTop Standards

24

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

Miscellaneous Information (Entries 41-48)

41.

Include the drawing numbers of schematic

layout, P & I diagram, process flow diagram,

hydrostatic test diagram, and hydraulic profile

drawing.

42.

District and/or location and the official pipeline

name, as in Item #1.

43.

Show the Plant No.

44.

Follow the usual procedure to obtain a drawing

number.

45.

Include BI and JO under which the pipeline

was installed.

46.

Complete this section showing the date

prepared and the name of the originator.

47.

Engineering concurrence as indicated in

Section 4 plus Project Manager or Plant

Manager's approval, as required.

48.

Signature of Facility Engineering Division head.

Saudi Aramco DeskTop Standards

25

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

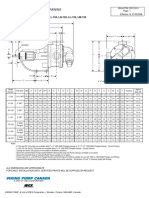

FORM 5645-1

FIGURE 2

Saudi Aramco DeskTop Standards

26

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

Work Aid 2B - Saudi Aramco Form 5645-2

Use the following procedure in conjunction with Figure 3

to determine the information that is necessary to

complete Safety Instruction Sheet, Form 5645-2, for

pipeline tie-in piping, scraper traps and their

appurtenances, jumpovers, as well as flanges, fittings,

any special components, road crossings, sun-pressure

relief valves, flowlines, trunklines, testlines, and

submarine pipelines. The identification numbers that are

shown in the following procedure correspond to those

shown in Figure 3. Reference SAES-A-005, Safety

Instruction Sheet, for additional information. Note that by

the time it is necessary to complete Form 5645-2,

engineering has been completed, all the required

information is readily available, and no new calculations

or selections are needed.

Pipeline Identification (Entries 1-9)

1.-6.

Same as corresponding Key Numbers 1-6 on

Form 5645-1.

7.

Provide adequate information to clearly identify

the equipment; for example, scraper trap, block

valve MOV-123, etc.

8.

Show the location of the equipment by name

and kilometer, such as Qatif Junction, km. 0.0.

In the case of flowlines, testlines, or trunklines,

show the GOSP name at which these lines

terminate.

9.

This section number corresponds to a

numbering system that is adopted in the

pipeline data book. Therefore, this information

must be coordinated with the proponent.

Saudi Aramco DeskTop Standards

27

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

Equipment Data (Entries 10-20)

10.

Show the nominal or outside pipe diameter.

List each kind (one diameter, wall thickness

and steel grade) of pipe or fitting once in

separate columns.

11.

Show the nominal wall thickness of pipe,

fractions in decimals.

12.

Show the material, such as carbon steel, alloy,

etc.

13.

Indicate the process of manufacture for the

pipe, such as seamless (S) or EFW, ERW, or

spiral.

14.

Show the pipe material specification and grade,

such as API 5L, Gr. B. SAMSSs references

are not acceptable.

Equipment Data (Entries 10-20), Cont'd

15.

Show the nominal size of flanges and fittings.

16.

Enter the rating per ASME/ANSI B16.5 for

flanges and valves. Selection of the flange

rating was discussed in MEX 101.04.

17.

Enter the type of flange face, such as raised

face (RF) or ring joint (RTJ). Flange facing

was discussed in MEX 101.04.

18.

Enter whether carbon steel or alloy is used for

flanges or fittings.

19.

Specify the ASTM or other specification and

grade of the material used for flanges or

fittings.

20.

List any special piping components that are not

otherwise covered, and include any other

pertinent remarks.

Saudi Aramco DeskTop Standards

28

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

Operating Limits (Entries 21-37)

21.

Calculate the Maximum Allowable Operating

Pressure (MAOP) in accordance with the

applicable code, as limited by flanges or by the

nominal pipewall thickness, for materials that

are listed under Key Numbers 10 through 20.

MAOP was discussed in MEX 101.03 and MEX

101.04 for pipe and flanges, respectively.

22.

Show the item that is limiting the MAOP in Key

Number 21.

23.

Show the Design Factor, and give the basis of

the Design Factor in the remarks area in Key

Number 37. The Design Factor was discussed

in MEX 101.03.

24.

Show the design temperature.

25.

Show the actual hydrostatic test pressure of

this particular equipment item that was

performed immediately after construction. The

test pressure must be calculated in accordance

with SAES-A-004, Pressure Testing. Test

pressure requirements were discussed in MEX

101.09. The test pressure of this equipment

item must be equal to or greater than the test

pressure in Key Number 32, Form 5645-1, for

the pipeline segment to which this equipment is

connected.

26.

Show the test date.

Operating Limits (Entries 21-37), Cont'd

27.

Indicate the item (pipeline segment, flange or

special fitting) which limits the test pressure.

Note that entries for revalidation of hydrostatic

tests (entries 28-30) are to be completed when

the information is known. The Safety

Instruction Sheet (SIS) is to be updated after

every revalidation test by the responsible

Saudi Aramco DeskTop Standards

29

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

Operations Engineering unit.

28.

Indicate the actual test pressure for the

revalidation test, which must be in accordance

with SAES-A-004 and approved by the

responsible Saudi Aramco Operations

Engineering unit. The test pressure of this

equipment must be equal to or greater than the

test pressure in Key Number 35, on Form

5645-1, for the segment to which this

equipment is connected.

29.

Show the test date.

30.

Indicate the factor that limits the test pressure.

Note that this does not necessarily have to be

the same item that limited the initial hydrotest

pressure. For example, the original hydrotest

pressure might have been limited by the

flanges. However, corrosion which may have

occurred in the pipe, itself, could make it the

limiting component for a revalidation test.

31.

Indicate the Maximum Allowable Operating

Pressure (MAOP) of the entire pipeline as if

one system. This MAOP is the same as that in

Key Number 38 on Form 5645-1.

In case of flowlines, testlines, or trunklines,

refer to SADP-L-022 for further information.

32.

Show the limiting item for the system MAOP.

In the case where a Saudi Aramco standard

governs, indicate which standard it is and its

date, such as SADP-L-022, 30 August 1985.

33.

Show the set pressure of the safety valve, sunpressure relief valve, pressure switch, or other

safety device if one is included, and if it is

required for routine operation. Confirm this

information with the P & ID.

34.

Enter the nominal size or outside diameter.

Saudi Aramco DeskTop Standards

30

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

Operating Limits (Entries 21-37), Cont'd

35.

Calculate Tm based on the system MAOP that

is shown in Key Number 31. If not applicable,

use the MAOP in Key Number 21.

Note that Tm is the retirement wall thickness,

and shall not be less than the required wall

thickness for mechanical strength. Refer to

Saudi Aramco Inspection Procedures 01-AIP02-0, SAES-L-006, or to the piping specialist in

the Consulting Services Department, for further

explanation.

36.

Calculate the corrosion allowance (Tca) which

equals the nominal wall thickness of the pipe

minus Tm that is shown in Key Number 35.

Note that the corrosion allowance, Tca, is the

remaining pipewall thickness that is above the

required Tm. This is not a required corrosion

allowance. If a corrosion allowance is required,

it must be stated (including the referenced

standard) in the remarks area under Key

Number 37.

37.

Include any special remarks regarding safety

hazards in connection with items on the subject

sheet. See the remarks for the main line pipe,

Form 5645-1, Key Number 40.

Miscellaneous Information (Entries 38-45)

38.

Indicate specific drawings for the manifolds,

crossovers, branches, scraper traps, road

crossings, and any items that are covered by

this sheet.

39.

Show the district, area or location, and the

official pipeline, or the equipment name, as

shown in Key Number 1.

40.

Enter the plant number.

Saudi Aramco DeskTop Standards

31

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

41.

Follow the usual procedure to obtain a drawing

number.

42.

Include the BI and JO under which the

pipeline/equipment was installed or revised.

43.

Complete this section showing the date

prepared and name of the originator.

44.

Engineering concurrence as indicated in

Section 4, plus Project Manager or Plant

Manager's approval, as required.

45.

Signature of the Facility Engineering Division

head.

Saudi Aramco DeskTop Standards

32

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

FORM 5645-2

FIGURE 3

Saudi Aramco DeskTop Standards

33

Engineering Encyclopedia

Piping, Pipelines & Valves

Safety Instruction Sheets for Plant

Piping and Cross-Country Pipelines

GLOSSARY

AGN

Nonrestrained Aboveground

AGR

Restrained Aboveground

CF

Cage Forming

EFW

Electric-Fusion Welded

FF

Flat-Face Flange

NPS

Nominal Pipe Size

RF

Raised-Face Flange

RTJ

Ring-Joint Flange

Saudi Aramco

Form 2821

A Safety Instruction Sheet for Plant Piping

Saudi Aramco

Form 5645-1

A Safety Instruction Sheet for Cross-Country

Pipelines

Saudi Aramco

test Form 5645-2

and

A Safety Instruction Sheet for flowlines, trunk lines,

lines, submarine pipelines, tie-in piping, scraper traps

their appurtenances, and special components.

SMYS

Specified Minimum Yield Strength

UOE

U-ing, O-ing, Expanding

Saudi Aramco DeskTop Standards

34

You might also like

- Plastic Pipe Fittings DC-DWVDocument68 pagesPlastic Pipe Fittings DC-DWVAdi KurniaNo ratings yet

- 175 320300Document1 page175 320300sridhar100% (1)

- Valve Selection Types and ClassesDocument71 pagesValve Selection Types and ClassesRaj Bindas100% (2)

- Valve Selection Types and ClassesDocument71 pagesValve Selection Types and ClassesRaj Bindas100% (2)

- Pipe Wall Thickness CalculationDocument79 pagesPipe Wall Thickness CalculationRaj Bindas100% (1)

- Pipe Wall Thickness CalculationDocument79 pagesPipe Wall Thickness CalculationRaj Bindas100% (1)

- 01 Samss 044 PDFDocument11 pages01 Samss 044 PDFAbdul Rahim ShaikhNo ratings yet

- 04-Samss-35 ValvesDocument28 pages04-Samss-35 ValvesNabeel AKNo ratings yet

- 2019 - Saep-1160Document24 pages2019 - Saep-1160smdriyazbashaNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- 00 SAIP 80 Process Equipment Insp GuideDocument90 pages00 SAIP 80 Process Equipment Insp GuideRaj BindasNo ratings yet

- 00 SAIP 80 Process Equipment Insp GuideDocument90 pages00 SAIP 80 Process Equipment Insp GuideRaj BindasNo ratings yet

- SAES-L-150 PDF Download - Pressure Testing of Plant Pipelines - PDFYARDocument7 pagesSAES-L-150 PDF Download - Pressure Testing of Plant Pipelines - PDFYARZahidRafiqueNo ratings yet

- Flanges Types, Classes and AssemblyDocument65 pagesFlanges Types, Classes and AssemblyRaj Bindas100% (8)

- Gap Control For Socket Weld Back Welded Threaded FittingsDocument12 pagesGap Control For Socket Weld Back Welded Threaded Fittingslaz_k100% (1)

- SAES-L-110 PDF Download - Limitations On Pipe Joints and Components - PDFYARDocument9 pagesSAES-L-110 PDF Download - Limitations On Pipe Joints and Components - PDFYARZahidRafiqueNo ratings yet

- Material SelectionDocument99 pagesMaterial SelectionRaj Bindas100% (8)

- Material SelectionDocument99 pagesMaterial SelectionRaj Bindas100% (8)

- Saep 351Document19 pagesSaep 351QA QC100% (1)

- SAES-L-133 PDF Download - Corrosion Protection Requirements - PDFYARDocument6 pagesSAES-L-133 PDF Download - Corrosion Protection Requirements - PDFYARZahidRafique100% (1)

- API 682 GuidelinesDocument28 pagesAPI 682 GuidelinesSergio Solano100% (3)

- Materials System SpecificationDocument21 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- AE-036411-001 INDEX For Drawing and EquipmentDocument1 pageAE-036411-001 INDEX For Drawing and Equipmentnarutothunderjet216No ratings yet

- Saep 324 PDFDocument13 pagesSaep 324 PDFArvind ShakyaNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- 01 Samss 034Document18 pages01 Samss 034aamirtec301100% (1)

- Saep 347 PDFDocument21 pagesSaep 347 PDFRami ElloumiNo ratings yet

- 1000 Questions and Answers 10Document21 pages1000 Questions and Answers 10Mehboob HassanNo ratings yet

- Saes B 064Document14 pagesSaes B 064Engr HafeezullahNo ratings yet

- ASME B36.10 Ed.2018Document36 pagesASME B36.10 Ed.2018Yasser Abd El FattahNo ratings yet

- 34 Samss 611Document8 pages34 Samss 611naruto256No ratings yet

- Saep 27Document14 pagesSaep 27Abdul Ahad LoneNo ratings yet

- 34 Samss 611Document8 pages34 Samss 611shrikantbelekarNo ratings yet

- Quick Guide For P&ID ReviewDocument7 pagesQuick Guide For P&ID ReviewfloredaNo ratings yet

- 12 Samss 008Document4 pages12 Samss 008Moustafa BayoumiNo ratings yet

- 01-SAMSS-049 Reinforced Thermoset Resin (RTR) Pipe, Fittings and Adhesive Packing, Handling, Transportation and Storage 21-FEB-2012 PDFDocument8 pages01-SAMSS-049 Reinforced Thermoset Resin (RTR) Pipe, Fittings and Adhesive Packing, Handling, Transportation and Storage 21-FEB-2012 PDFasiqnaNo ratings yet

- Saudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalDocument12 pagesSaudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalAhdal NoushadNo ratings yet

- 00 Saip 12Document8 pages00 Saip 12aamirtec301No ratings yet

- Safety Instruction SheetDocument32 pagesSafety Instruction SheetAdamuNo ratings yet

- Penstock CaalculationDocument3 pagesPenstock CaalculationGertjan DuniceriNo ratings yet

- Saep 322Document18 pagesSaep 322brecht1980100% (1)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerZhiguo YangNo ratings yet

- Pew-105.03 (P)Document88 pagesPew-105.03 (P)Raj BindasNo ratings yet

- Pew-105.03 (P)Document88 pagesPew-105.03 (P)Raj BindasNo ratings yet

- 34-Samss-010 2018Document9 pages34-Samss-010 2018asimazami69No ratings yet

- 01-SAMSS-333-HF Welded Line Pipe PDFDocument35 pages01-SAMSS-333-HF Welded Line Pipe PDFmunnaNo ratings yet

- Pipewall Thickness CalculationDocument30 pagesPipewall Thickness CalculationTiu TonNo ratings yet

- SAES-L-310 (Design of Plant Piping)Document30 pagesSAES-L-310 (Design of Plant Piping)Cherukunnon Jubu100% (5)

- Materials System SpecificationDocument9 pagesMaterials System SpecificationFAPM1285No ratings yet

- Engineering Procedure: SAEP-310 13 January 2008 Piping and Pipeline Repair Piping Standards Committee MembersDocument39 pagesEngineering Procedure: SAEP-310 13 January 2008 Piping and Pipeline Repair Piping Standards Committee Membersbrecht1980100% (4)

- Iii. Applicable Codes & Standards For Aramco ProjectsDocument5 pagesIii. Applicable Codes & Standards For Aramco ProjectsZain Ali KidwaiNo ratings yet

- GA DrawingDocument4 pagesGA DrawingGalih PrianggodoNo ratings yet

- 04 Samss 048Document11 pages04 Samss 048Sami100% (1)

- 175 043000Document1 page175 043000Fahad AhmadNo ratings yet

- RBI A Quantitative Soulution Made Practical Lynne KaleyDocument80 pagesRBI A Quantitative Soulution Made Practical Lynne KaleyRaj BindasNo ratings yet

- Pavientadora CAT AP500E and BG500EDocument10 pagesPavientadora CAT AP500E and BG500Ealexander_1985100% (1)

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- Gate Ece by RK - KanodiaDocument440 pagesGate Ece by RK - KanodiaParitam Soni100% (1)

- Saes L 130Document5 pagesSaes L 130Ahmed Kabel100% (1)

- Saes W 016 PDFDocument10 pagesSaes W 016 PDFRaj AryanNo ratings yet

- Saep 43Document29 pagesSaep 43QcNo ratings yet

- Saep 321Document25 pagesSaep 321AbdullahNo ratings yet

- E PR 250 PDFDocument30 pagesE PR 250 PDFAmirhosein605334No ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistphilipyapNo ratings yet

- Chapter 4Document28 pagesChapter 4kuma alemayehuNo ratings yet

- Saudi Aramco Inspection ChecklistDocument23 pagesSaudi Aramco Inspection ChecklistjahaanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Thickness CalculationDocument6 pagesThickness CalculationBuddy EkoNo ratings yet

- Saep 347Document27 pagesSaep 347Qaiser Mahmood100% (2)

- SAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageDocument8 pagesSAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageMuhammad Farukh Manzoor0% (1)

- SAER1972Document9 pagesSAER1972zamil2008No ratings yet

- E PR 230 PDFDocument87 pagesE PR 230 PDFAmirhosein605334No ratings yet

- Sa 1141 PDFDocument66 pagesSa 1141 PDFAwais Tariq100% (2)

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- 01 Samss 029Document15 pages01 Samss 029Cherukunnon Jubu100% (1)

- 175 325100Document2 pages175 325100sridhar100% (1)

- Saep 35Document6 pagesSaep 35hendraox3996No ratings yet

- 01 Samss 010Document11 pages01 Samss 010doyenofcastleNo ratings yet

- 175 012000Document2 pages175 012000Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Test Report Temperature Tie-In Welding ReportDocument2 pagesSaudi Aramco Test Report Temperature Tie-In Welding ReportManoj Kumar100% (2)

- Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument5 pagesSaudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliShahbaz AhmadNo ratings yet

- What Is The Difference Between MIG and MAGDocument1 pageWhat Is The Difference Between MIG and MAGRaj BindasNo ratings yet

- Appendix KDocument26 pagesAppendix KRaj BindasNo ratings yet

- Pew 105.04 (P)Document174 pagesPew 105.04 (P)Raj BindasNo ratings yet

- What Is The Difference Between MIG and MAGDocument1 pageWhat Is The Difference Between MIG and MAGRaj BindasNo ratings yet

- API570 - Printable Flash CardsDocument45 pagesAPI570 - Printable Flash Cardstipu321100% (2)

- Equipment For SubmergedDocument4 pagesEquipment For SubmergedRaj BindasNo ratings yet

- Pew 209 .02Document59 pagesPew 209 .02Raj BindasNo ratings yet

- TIG Welding: Process CharacteristicsDocument3 pagesTIG Welding: Process CharacteristicsRaj BindasNo ratings yet

- Asme Ix Presentation Summary Oct 2007Document34 pagesAsme Ix Presentation Summary Oct 2007Antonio GraterolNo ratings yet

- MDR CemDocument30 pagesMDR Cemhafizszul AmirushamNo ratings yet

- Air Cooled CondenserDocument7 pagesAir Cooled CondenserSaravanan RagupathyNo ratings yet

- Bulkline 650-1000 IOM ENDocument24 pagesBulkline 650-1000 IOM ENRobert SerafinNo ratings yet

- Rcug-Ahyz1 TC1Document38 pagesRcug-Ahyz1 TC1Site EngineeringtiaNo ratings yet

- Design Standard Gas Piping For Laboratory Facilities: Revisions LogDocument3 pagesDesign Standard Gas Piping For Laboratory Facilities: Revisions LogZineddine ALICHENo ratings yet

- r200 CatalogoDocument2 pagesr200 CatalogoEu_einNo ratings yet

- 1e V09 MPGB 00043Document10 pages1e V09 MPGB 00043mohamed abouraya100% (1)

- Regulador EQA-99-17Document2 pagesRegulador EQA-99-17Ronan CristhiamNo ratings yet

- HM2H Flow Chart GPMDocument1 pageHM2H Flow Chart GPMJishnu MedhiNo ratings yet

- Valvulas de Seguridad Hansen PDFDocument4 pagesValvulas de Seguridad Hansen PDFLuis ReinoNo ratings yet

- Alltech Pump ManualDocument1 pageAlltech Pump ManualGAUTHAMSANo ratings yet

- Valvepedia FEB-2017Document8 pagesValvepedia FEB-2017aliNo ratings yet

- Maintenance Hydraulics QuizDocument11 pagesMaintenance Hydraulics QuizArshad MullaNo ratings yet

- KA Series PDFDocument8 pagesKA Series PDFsancsa_74No ratings yet

- SpesifikasiDocument3 pagesSpesifikasiIhsannrNo ratings yet

- Mac 2009Document60 pagesMac 2009Ridwan Pramudya100% (1)

- 1.EPV NORTH SEA Exploded PartviewDocument45 pages1.EPV NORTH SEA Exploded PartviewPSC RFQNo ratings yet

- Prosintech CatalogDocument6 pagesProsintech CatalogDeepak PatelNo ratings yet

- FNDWRRDocument3 pagesFNDWRRsranjeitNo ratings yet

- Tecnidro - FirefightingDocument4 pagesTecnidro - FirefightinggtecnidroNo ratings yet

- MVAC Duct Pressure Drop (Reference Summary)Document19 pagesMVAC Duct Pressure Drop (Reference Summary)Cheng Chun TingNo ratings yet

- Larossa: Company Date Philippines 1773 Tunasan Muntinlupa City FAPI Compound E Rodriguez AveDocument1 pageLarossa: Company Date Philippines 1773 Tunasan Muntinlupa City FAPI Compound E Rodriguez AveasdzxcNo ratings yet

- Dimensiones de Bomba Viking L124Document1 pageDimensiones de Bomba Viking L124nerio gerardinoNo ratings yet