0% found this document useful (0 votes)

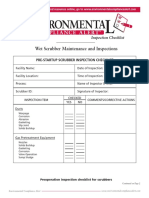

281 views5 pagesWet Scrubber Inspection Checklist

The document provides pre-startup, daily, monthly, and maintenance inspection checklists for wet scrubbers. The pre-startup checklist includes over 30 inspection items for ducts, gas pretreatment equipment, scrubbers, mist eliminators, and liquor treatment systems. The daily checklist includes inspection of gas pretreatment, scrubbers, mist eliminators, pressures, temperatures, and opacity. The monthly checklist includes additional inspection of piping, valves, pumps, fans, ducts, and sensors. A maintenance report form is also included to track maintenance jobs.

Uploaded by

Edmund YoongCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

281 views5 pagesWet Scrubber Inspection Checklist

The document provides pre-startup, daily, monthly, and maintenance inspection checklists for wet scrubbers. The pre-startup checklist includes over 30 inspection items for ducts, gas pretreatment equipment, scrubbers, mist eliminators, and liquor treatment systems. The daily checklist includes inspection of gas pretreatment, scrubbers, mist eliminators, pressures, temperatures, and opacity. The monthly checklist includes additional inspection of piping, valves, pumps, fans, ducts, and sensors. A maintenance report form is also included to track maintenance jobs.

Uploaded by

Edmund YoongCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd