Professional Documents

Culture Documents

Wet Scrubber Maintenance and Inspections: Pre-Startup Scrubber Inspection Checklist

Uploaded by

vanyoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wet Scrubber Maintenance and Inspections: Pre-Startup Scrubber Inspection Checklist

Uploaded by

vanyoCopyright:

Available Formats

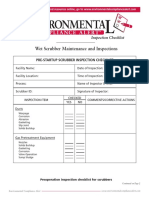

For other compliance tools and resources online, go to www.environmentalcompliancealert.

com

Wet Scrubber Maintenance and Inspections

PRE-STARTUP SCRUBBER INSPECTION CHECKLIST

Facility Name: Date of Inspection:

Facility Location: Time of Inspection:

Process: Name of Inspector (Print):

Scrubber ID: Signature of Inspector:

CHECKED

INSPECTION ITEM COMMENTS/CORRECTIVE ACTIONS

YES NO

Ducts

Warpage

Corrosion

Abrasion

Gasketing

Slip Joint

Solids Buildup

Gas Pretreatment Equipment

Nozzles

Solids Buildup

Gasketing

Corrosion

Valve Operation

Sump Sludge

Preoperation inspection checklist for scrubbers

Continued on Page 2

Environmental Compliance Alert www.environmentalcompliancealert.com

Page 2

CHECKED

INSPECTION ITEM COMMENTS/CORRECTIVE ACTIONS

YES NO

Scrubber

Nozzles

Clogging

Wearing

Abrasion

Abrasion

Buildup

Corrosion

Piping

Scaling

Rusting

Riggings

Leakage

Sump Sludge

Mist Eliminator

Nozzles

Clogging

Wearing

Abrasion

Piping

Rusting

Pitting

Leakage

Valve Operation

Corrosion

Mist Eliminator Media

Buildup

Cleaned

Replaced

Liquor Treatment

pH Control

Calibration Check

Probe Buildup

Caustic Hold Tank

Sludge Buildup

Valve Operation

Piping Leakage

Preoperation inspection checklist for scrubbers (continued)

Continued on Page 3

Environmental Compliance Alert www.environmentalcompliancealert.com

Page 3

DAILY SCRUBBER INSPECTION FORM

Facility Name: Date of Inspection:

Facility Location: Time of Inspection:

Process: Name of Inspector (Print):

Scrubber 10: Signature of Inspector:

INSPECTION ITEM COMMENTS/CORRECTIVE ACTIONS

1) Gas pretreatment equipment

(if applicable)

- Leaks

- Abnormal sounds

- Pressure drop normal?

2) Scrubber and mist eliminator

- Leaks

- Abnormal sounds

- Pressure drop normal?

3) Liquor treatment

- Leaks

- Abnormal sounds

Pressures:

Pressure drop across scrubber _____ in. WG

Scrubbing liquid pressure _____ psi

Scrubber liquid flow _____ gpm Quench liquid flow _____ gpm

(if applicable)

Temperatures:

Gas into system _____ ˚F

Gas into scrubber _____ ˚F

Gas from scrubber _____ ˚F

Liquid from scrubber _____ ˚F

Fan amps _____ Pump amps _____

Opacity _____ %

Daily inspection form example

Continued on Page 4

Environmental Compliance Alert www.environmentalcompliancealert.com

Page 4

MONTHLY SCRUBBER INSPECTION FORM

Facility Name: Date of Inspection:

Facility Location: Time of Inspection:

Process: Name of Inspector (Print):

Scrubber ID: Signature of Inspector:

INSPECTION ITEM COMMENTS/CORRECTIVE ACTIONS

1) Gas pretreatment equipment

Piping Leakage

Valve Operation

Pump/Lub.

2) Scrubber

Piping Leakage

Valve Operation

Level Control

Pump/Lub.

3) Mist Eliminator

Piping Leakage

Valve Operation

Pump/Lub.

4) Liquor Treatment

Piping Leakage

Valve Operation

Level Control

Pump/Lub.

5) Fans. Ducts, Pipes

- Abrasion

- Corrosion

- Solids Buildup

6) Check sensors, alarm systems, and

bypass devices for proper operation

Monthly inspection form example

Continued on Page 5

Environmental Compliance Alert www.environmentalcompliancealert.com

Page 5

MAINTENANCE REPORT FORM

Department Unit System Subsystem Component Subcomponent

Originator: Date: Time:

Assigned to: 1 Mechanical Priority: 1 Emergency Unit Status: 1 Normal

2 Electrical 2 Same Day 2 Derated

3 Instrumentation 3 Routine 3 Down

Problem Description:

Foreman: Date: Job Status: 1 Repairable

2 Hold for:

Cause of Problem: Tools

3 Parts

4 Outage

Work Done:

Supervisor: Completion Date:

Materials Used:

Labor Requirements:

Maintenance report form example

Environmental Compliance Alert www.environmentalcompliancealert.com

You might also like

- Analysis of High Contact Resistance in SIG ContactsDocument9 pagesAnalysis of High Contact Resistance in SIG ContactsA.K.SINGHNo ratings yet

- Range Shift Troubleshooting Procedures T300 Series MackDocument22 pagesRange Shift Troubleshooting Procedures T300 Series MackHamilton Miranda100% (1)

- Daily Equipment Safety ChecklistDocument5 pagesDaily Equipment Safety ChecklistArturo Ramos AlvezoNo ratings yet

- Inspection Checklist - Batching Plant: Form Ref.: Project: Sub-Contractor: Structure Element: DateDocument4 pagesInspection Checklist - Batching Plant: Form Ref.: Project: Sub-Contractor: Structure Element: Datedana setiawan100% (1)

- Chemical Dosing Pump SATRDocument2 pagesChemical Dosing Pump SATRDeshan Sing100% (1)

- Bit Wear PatternDocument11 pagesBit Wear PatternRezaNo ratings yet

- Brief Information: Innovative and Highly Functional Surface DesignsDocument52 pagesBrief Information: Innovative and Highly Functional Surface DesignsSon NguyenNo ratings yet

- Wet Scrubber Maintenance and Inspections: Pre-Startup Scrubber Inspection ChecklistDocument5 pagesWet Scrubber Maintenance and Inspections: Pre-Startup Scrubber Inspection ChecklistEdmund YoongNo ratings yet

- Cleaning Validation Protocol TemplateDocument3 pagesCleaning Validation Protocol Templatemuhammad asifNo ratings yet

- S Inspect ProcDocument11 pagesS Inspect ProcDi Quan Di QuanNo ratings yet

- Cleaning ValidationDocument16 pagesCleaning ValidationBabu JadhavNo ratings yet

- Maintenance ApproachDocument4 pagesMaintenance ApproachBarathNo ratings yet

- Facility Inspection Checklist - UpdatedDocument1 pageFacility Inspection Checklist - UpdatedFaith Joy BolivarNo ratings yet

- Decontamination of Lab Equipment SOPDocument7 pagesDecontamination of Lab Equipment SOPElizabeth ForresterNo ratings yet

- MS-FIRE-001 - Automatic Sprinkler Circuit TestingDocument8 pagesMS-FIRE-001 - Automatic Sprinkler Circuit TestingKo KoNo ratings yet

- Module 4 Inspection Methods PDFDocument86 pagesModule 4 Inspection Methods PDFElias Jurado TeixeiraNo ratings yet

- Ffe - Weekly - Monthly Maintenance & Inspection PG.1Document2 pagesFfe - Weekly - Monthly Maintenance & Inspection PG.1Gerome Eugenio100% (1)

- Fire Pump Test Meter Instructions - Wiratama Mitra Abadi - Industrial EquipmentDocument6 pagesFire Pump Test Meter Instructions - Wiratama Mitra Abadi - Industrial EquipmentLuigi CasamassimaNo ratings yet

- 01 Vol2part2 - Plant InspectionDocument37 pages01 Vol2part2 - Plant Inspectionsreekumar.chandran100% (1)

- Aim of Procedure: Daily Operations Checks - Franna CranesDocument5 pagesAim of Procedure: Daily Operations Checks - Franna CranesakhmadbayNo ratings yet

- Commissioning Methodologies (CM) - MUS-01 Pipework Flushing and Cleaning Method StatementDocument3 pagesCommissioning Methodologies (CM) - MUS-01 Pipework Flushing and Cleaning Method StatementMohammad OsmanNo ratings yet

- JH FRM Pae 001 15 Drum Roller Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 15 Drum Roller Plant Pre Acceptance ChecklistStansilous Tatenda NyagomoNo ratings yet

- Template of Cleaning Validation ProtocolDocument7 pagesTemplate of Cleaning Validation Protocol王仁宏No ratings yet

- Integrity SOPs For VeinDocument3 pagesIntegrity SOPs For VeinziadddNo ratings yet

- Cleaning Validation Protocol TEMPLATEDocument9 pagesCleaning Validation Protocol TEMPLATEnatavceNo ratings yet

- Into Plane Fuel ChecklistDocument5 pagesInto Plane Fuel ChecklistHusam FNo ratings yet

- WW Flyer WELLSHARP Oil Gas Operator Representative OGORDocument3 pagesWW Flyer WELLSHARP Oil Gas Operator Representative OGORNeemias TavaresNo ratings yet

- Maintenance Course WorkDocument4 pagesMaintenance Course WorkGodfrey OdieroNo ratings yet

- CLEANING VALIDATION PROTOCOLDocument7 pagesCLEANING VALIDATION PROTOCOLArieTamaNo ratings yet

- JRPACKING Valve Sealing Device and Weigher SpecsDocument24 pagesJRPACKING Valve Sealing Device and Weigher SpecsSansan DianoNo ratings yet

- Liquid Penetrant ExaminationDocument5 pagesLiquid Penetrant ExaminationKevin ThomasNo ratings yet

- TE CONNECTIVITY MANUFACTURING PHILIPPINES INC. TESTING AND COMMISSIONING REPORTDocument36 pagesTE CONNECTIVITY MANUFACTURING PHILIPPINES INC. TESTING AND COMMISSIONING REPORTNorman CanlasNo ratings yet

- Dry Test 1907Document10 pagesDry Test 1907talhaNo ratings yet

- PM ProgramDocument29 pagesPM Programemad youssefNo ratings yet

- Designing effective medical device cleaning procedures through lab studiesDocument37 pagesDesigning effective medical device cleaning procedures through lab studiesOrielson CruzNo ratings yet

- Gestion Mantenimiento Puente GruaDocument11 pagesGestion Mantenimiento Puente GruaBryan Esteban Casas ZapataNo ratings yet

- SPM Kapasitas 50.000 DWT Inspeksi UmumDocument1 pageSPM Kapasitas 50.000 DWT Inspeksi UmumBilly KurniawanNo ratings yet

- Measurement of Residual Particulate Contamination On ComponentsDocument20 pagesMeasurement of Residual Particulate Contamination On Componentsdivyesh khuntNo ratings yet

- Form - 1 Soil Handling EquipmentDocument3 pagesForm - 1 Soil Handling EquipmentFauzan Setya MulyaNo ratings yet

- Field Inspection Manual-Volumetric Measuring Devices-: Standard Test Procedure - Table of ContentsDocument4 pagesField Inspection Manual-Volumetric Measuring Devices-: Standard Test Procedure - Table of ContentsSumanth ReddyNo ratings yet

- Cleaning Validation Cleaning Validation Is A Validation Program To VerifyDocument27 pagesCleaning Validation Cleaning Validation Is A Validation Program To Verify董彬彬100% (2)

- Excitation System Commissioning ProcedureDocument7 pagesExcitation System Commissioning ProcedurehardaniNo ratings yet

- Storage of Raw Materials Category Checklist ItemsDocument6 pagesStorage of Raw Materials Category Checklist Itemsashumishra007No ratings yet

- NCC-IMS-FM-05-02 - OPRP Control Chart Is7.0Document9 pagesNCC-IMS-FM-05-02 - OPRP Control Chart Is7.0baseimNo ratings yet

- Concrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistDocument2 pagesConcrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistTFattahNo ratings yet

- 0.SOP - Environment Monitoring Program SOP SAMBADocument6 pages0.SOP - Environment Monitoring Program SOP SAMBAAyush BhatNo ratings yet

- Job DescriptionDocument6 pagesJob DescriptionNishit SuvaNo ratings yet

- MAS Kit Instruction ManualDocument6 pagesMAS Kit Instruction Manualfionafong0402No ratings yet

- Daily Preventive Mantainence SheetDocument4 pagesDaily Preventive Mantainence Sheetcer.qualityNo ratings yet

- JH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistFeroz Gull100% (1)

- Optimize Boiler Uptime with Proper MaintenanceDocument88 pagesOptimize Boiler Uptime with Proper MaintenanceMansuri atikNo ratings yet

- 02961E00 - Eni Guidelines On Risk-Based InspectionsDocument54 pages02961E00 - Eni Guidelines On Risk-Based InspectionsMauro MLR100% (3)

- Maintenance Prevention Information: Document No: Equipment: Lavadora Tacome Page No: 1 of 6Document6 pagesMaintenance Prevention Information: Document No: Equipment: Lavadora Tacome Page No: 1 of 6efgartellNo ratings yet

- Ees - Preventive Maintenance ChecklistDocument3 pagesEes - Preventive Maintenance ChecklistEkdant Enviro Services ekdant labNo ratings yet

- Capsule Process Validation ProtocolDocument28 pagesCapsule Process Validation ProtocolNavdeep ChaudharyNo ratings yet

- Hydraulic System Inspection SOPDocument6 pagesHydraulic System Inspection SOPZev ZekNo ratings yet

- SOP: Optimize Hydraulic System PerformanceDocument6 pagesSOP: Optimize Hydraulic System PerformanceGovinda RaiNo ratings yet

- 40 - Suncombe CIP Overview PresentationDocument46 pages40 - Suncombe CIP Overview PresentationSantiago AguayoNo ratings yet

- Jumbo Drilling Rig Plant Pre Acceptance ChecklistDocument3 pagesJumbo Drilling Rig Plant Pre Acceptance ChecklistRubén López LemaNo ratings yet

- Maintenance of Absorption Column and Stripping ColumnsDocument2 pagesMaintenance of Absorption Column and Stripping ColumnsJoseph OrjiNo ratings yet

- Anjali Pathak SRM College of PharmacyDocument28 pagesAnjali Pathak SRM College of PharmacyAshok LenkaNo ratings yet

- Anjali Pathak SRM College of PharmacyDocument28 pagesAnjali Pathak SRM College of PharmacyAshok LenkaNo ratings yet

- Caterpillar Contamination Control Neng7004Document132 pagesCaterpillar Contamination Control Neng7004Сергей КурильчикNo ratings yet

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- Little Glee Monster-My Best FriendDocument2 pagesLittle Glee Monster-My Best FriendvanyoNo ratings yet

- Ryu Ji Hyun Night Is Gone, Again LyricDocument1 pageRyu Ji Hyun Night Is Gone, Again LyricvanyoNo ratings yet

- Little Glee Monster - Kimi ni Todoku made (39Document1 pageLittle Glee Monster - Kimi ni Todoku made (39vanyoNo ratings yet

- FlameDocument1 pageFlamevanyoNo ratings yet

- Perhap Love GugudanDocument1 pagePerhap Love GugudanvanyoNo ratings yet

- CNBLUE Strumming Pattern Love LightDocument1 pageCNBLUE Strumming Pattern Love LightvanyoNo ratings yet

- Because of You-Introvert Boss-Ez Kim LyricDocument1 pageBecause of You-Introvert Boss-Ez Kim LyricvanyoNo ratings yet

- K-ON My Love is a Stapler (Capo 5Document2 pagesK-ON My Love is a Stapler (Capo 5vanyoNo ratings yet

- You Belong With MeDocument2 pagesYou Belong With MevanyoNo ratings yet

- Sumika EqualDocument1 pageSumika EqualvanyoNo ratings yet

- Avril LavigneDocument3 pagesAvril LavignevanyoNo ratings yet

- Beautiful Chords by Wanna OneDocument5 pagesBeautiful Chords by Wanna OnevanyoNo ratings yet

- Beautiful Chords by Wanna OneDocument5 pagesBeautiful Chords by Wanna OnevanyoNo ratings yet

- A love story retold - Taylor Swift's "Love StoryDocument2 pagesA love story retold - Taylor Swift's "Love Storyvanyo0% (1)

- Experiment 1 1Document8 pagesExperiment 1 1Walt MensNo ratings yet

- Davichi – Nostalgia Romanization LyricsDocument2 pagesDavichi – Nostalgia Romanization LyricsvanyoNo ratings yet

- Canon in D Classical Guitar Version: Capo 2Document5 pagesCanon in D Classical Guitar Version: Capo 2vanyoNo ratings yet

- Calibration of Glassware 2009Document5 pagesCalibration of Glassware 2009Imad AghilaNo ratings yet

- Performance Monitoring of Air Poolution Control SystemsDocument30 pagesPerformance Monitoring of Air Poolution Control SystemsFauzan HardiNo ratings yet

- Baby Steps Ending LyricDocument4 pagesBaby Steps Ending LyricvanyoNo ratings yet

- Wet Scrubber: We Make Air Work For YouDocument14 pagesWet Scrubber: We Make Air Work For YouvanyoNo ratings yet

- Local Exhaust Ventilation (LEV) (PDF 110KB) PDFDocument8 pagesLocal Exhaust Ventilation (LEV) (PDF 110KB) PDFvanyoNo ratings yet

- Local Exhaust Ventilation (LEV) GuidanceDocument72 pagesLocal Exhaust Ventilation (LEV) Guidancelhphong021191No ratings yet

- NaOh and Na2CO3 Purity TitrateDocument3 pagesNaOh and Na2CO3 Purity TitratevanyoNo ratings yet

- NaOh and Na2CO3 Purity TitrateDocument3 pagesNaOh and Na2CO3 Purity TitratevanyoNo ratings yet

- Use Windows Media Creation Tool To Upgrade Your PCDocument27 pagesUse Windows Media Creation Tool To Upgrade Your PCvanyoNo ratings yet

- Wet Scrubbers For Gaseous ControlDocument39 pagesWet Scrubbers For Gaseous ControlJess GohNo ratings yet

- Ion AnalysisDocument65 pagesIon AnalysisvanyoNo ratings yet

- Baby Steps Ending LyricDocument4 pagesBaby Steps Ending LyricvanyoNo ratings yet

- Goulds Vertical ReaderDocument20 pagesGoulds Vertical ReaderSonthi MooljindaNo ratings yet

- The Turbine Lubricating Oil System: ObjectivesDocument23 pagesThe Turbine Lubricating Oil System: Objectivesefmaggio100% (2)

- Erosion CorrosionDocument26 pagesErosion CorrosionElma MhjNo ratings yet

- Schenckprocessminingna BrochureDocument8 pagesSchenckprocessminingna Brochurehalder_kalyan9216No ratings yet

- Wear-Resistant Fused Alloy Steel Plate Maximizes UptimeDocument4 pagesWear-Resistant Fused Alloy Steel Plate Maximizes Uptimevampiry1972No ratings yet

- Friction Behavior of Lubricated Zinc Phosphate CoatingsDocument5 pagesFriction Behavior of Lubricated Zinc Phosphate CoatingsRestu SihotangNo ratings yet

- Flush Gearboxes and Bearing Housings EffectivelyDocument6 pagesFlush Gearboxes and Bearing Housings EffectivelyiagoramonNo ratings yet

- Belt Failure Analysis GuideDocument8 pagesBelt Failure Analysis Guidetropical0007No ratings yet

- Slide Ways of Machine ToolsDocument42 pagesSlide Ways of Machine ToolsTousif RezaNo ratings yet

- Stellite 21Document2 pagesStellite 21Mohsen ParpinchiNo ratings yet

- Catalogue Bron Plastic PDFDocument54 pagesCatalogue Bron Plastic PDFpsorpNo ratings yet

- Xaloy Barrel BR Russian Rev1Document4 pagesXaloy Barrel BR Russian Rev1matic91No ratings yet

- 2014 SD Mechanical Contact Best PracticesDocument94 pages2014 SD Mechanical Contact Best PracticesAmit Patil0% (1)

- Cottrell, David, Factors Affecting The Accommodation of Thermal Movement in Halter Based Aluminium Standing Seam Systems (2014)Document271 pagesCottrell, David, Factors Affecting The Accommodation of Thermal Movement in Halter Based Aluminium Standing Seam Systems (2014)aaNo ratings yet

- B.Tech. (5 Semester Mechanical) TRIBOLOGY (MEPE-17)Document5 pagesB.Tech. (5 Semester Mechanical) TRIBOLOGY (MEPE-17)varunNo ratings yet

- Roller Chain MaintenanceDocument8 pagesRoller Chain MaintenanceRodrigo SenedezeNo ratings yet

- Infinity Belt Cleaners2docxDocument14 pagesInfinity Belt Cleaners2docxKumar JbsNo ratings yet

- Meritor Parts Failure AnalysisDocument115 pagesMeritor Parts Failure AnalysiskkmechNo ratings yet

- Effects of Tungsten Carbide Thermal Spray CoatingDocument13 pagesEffects of Tungsten Carbide Thermal Spray CoatingDAIANE CRISTINE CAVALLARINo ratings yet

- West-Trak's No.1 Product Guide for Ground Engaging Tools & Undercarriage PartsDocument180 pagesWest-Trak's No.1 Product Guide for Ground Engaging Tools & Undercarriage Partsmarcusdba100% (1)

- Chute Design and Problems-Causes and SolutionDocument19 pagesChute Design and Problems-Causes and SolutionThakaneNo ratings yet

- SKF Industrial Shaft Seals (5300 EN) - CATALOGUE PDFDocument379 pagesSKF Industrial Shaft Seals (5300 EN) - CATALOGUE PDFLily VyNo ratings yet

- Bearing Fault Detection Techniques - A Review: January 2015Document19 pagesBearing Fault Detection Techniques - A Review: January 2015Anang Prase TyoNo ratings yet

- Design of Plastic Cutting ToolsDocument3 pagesDesign of Plastic Cutting Toolsmuhammad imam100% (1)

- Beam Strenght of Spur Gear Tooth-Lewis EqnDocument3 pagesBeam Strenght of Spur Gear Tooth-Lewis EqnavenashaNo ratings yet