Professional Documents

Culture Documents

Multicriteria Inventory Model For Spare Parts: Mladen Bošnjaković

Multicriteria Inventory Model For Spare Parts: Mladen Bošnjaković

Uploaded by

lfa2011Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multicriteria Inventory Model For Spare Parts: Mladen Bošnjaković

Multicriteria Inventory Model For Spare Parts: Mladen Bošnjaković

Uploaded by

lfa2011Copyright:

Available Formats

Viekriterijski model skladitenja rezervnih dijelova

M. Bonjakovi

ISSN 1330-3651

UDC/UDK 658.786/.787.011.8

MULTICRITERIA INVENTORY MODEL FOR SPARE PARTS

Mladen Bonjakovi

Preliminary notes

Inventory control of spare parts is essential to many organizations. Excess inventory leads to high holding costs and a large commitment of funds. In the other

hand stock outs can have a great impact on production or service. The paper proposes a methodology for spare parts inventory control applying multicriteria

inventory model. It is based on ranking and classifying the spare parts in groups according to similar attributes. Each group of spares, depending on attributes of

the spares that belong to it, joins the appropriate inventory policy model and forecasting demand model.

Keywords: inventory control, multicriteria inventory model, spare part

Viekriterijski model skladitenja rezervnih dijelova

Prethodno priopenje

Upravljanje skladitem rezervnih dijelova bitno je za mnoge tvrtke. Prevelika koliina na zalihi vodi do velikih trokova skladitenja i velikog angamana

novanih sredstava, a s druge strane nedostatak rezervnih dijelova na zalihi u vrijeme njihove potranje moe imati velike posljedice na proizvodnju ili usluge.

Ovaj lanak predlae metodologiju upravljanja skladitem rezervnih dijelova primjenjujui viekriterijski model skladitenja. On se zasniva na rangiranju i

svrstavanju rezervnih dijelova u skupine prema slinim svojstvima. Svakoj skupini rezervnih dijelova, ovisno o karakteristikama dijelova koji joj pripadaju,

pridruuje se odgovarajua politika skladitenja te odgovarajui model predvianja potranje.

Kljune rijei: rezervni dio, upravljanje skladitem, viekriterijski model skladitenja

1

Introduction

Uvod

Efficient management of spare parts inventory is

essential to many companies, those manufacturing ones

(automotive, food processing, petrochemical industry, etc.)

as well as those in the service sector (telecommunications,

electricity, water supply, etc.). Spare parts are kept in

storage to facilitate execution of maintenance functions in

the event of equipment breakdowns. Although this function

is well understood to maintenance managers, many

companies are faced with the problem of keeping large

quantities of spare parts in stock that are often outdated,

resulting in unreasonably high costs of storage.

Unfortunately, most maintenance managers are not

interested in this issue, but are guided by the principle:

"How much volume is taken from the warehouse was so

ordered".

In the analysis of storage of spare parts an objective

problem is in their specific, often unpredictable, nature of

demand. Some spare parts have great demand, some very

small (one to several years), which significantly

complicates predicting the need for replacement parts.

In the management of spare parts inventory there is a

need to answer the following questions:

a) Keep each spare part in stock or not?

Generally, a part will be stored if the benefit of current

availability is greater than the cost of holding

inventories. This is especially important for spares with

low demand. Comparing the storage costs and the costs

related to stock out at the time of the spare needs, gives

the answer to this question.

b) How many to order at once?

When the decision has been made to stock an item, the

next question to answer is how many to order at once.

To determine an optimal order quantity, a well-known

classical economic order quantity (EOQ) formula can

be used.

Technical Gazette 17, 4(2010), 499-504

c) How many pieces to keep in stock?

For decisions information is required on the annual

demand, ordering costs and holding costs of inventory.

d) When to release a new order?

The moment to release a new order is usually named the

re-order point. Having too many items on stock can

result in high holding costs. On the other hand, having

too few items on stock can result in high penalty costs.

The minimum stock will be determined considering the

consumption during the lead time. The user or the

supplier gives the lead time, and demand is calculated

based on data from the previous periods and on the basis

of the known (planned) needs for spare parts.

This article tries to answer the above questions.

In the literature different approaches are given to the

problem of spare parts inventory.

Agrell [1] presented an interactive multicriteria

framework for an inventory control decision support

system. The article Multi-attribute classification method for

spare parts inventory management by Braglia [2] presents a

model for inventory management. Spare parts classification

is defined with respect to multiple attributes (inventory

constraints, costs of lost production, safety and

environmental objectives, strategies of maintenance

adopted). The decision diagram is integrated with a set of

analytic hierarchy process models used to solve the various

multi-attribute decision sub-problems.

De Almeida [3] presents multicriteria decision models

for two maintenance problems: repair contract selection and

spares provisioning. Two criteria (risk and cost) are

combined through a multi attribute utility function in the

spares provisioning decision model. Ching [4] proposed an

inventory control approach called ABC-fuzzy

classification, which can handle variables with either

nominal or non-nominal attribute, incorporate manager's

experience and judgment into inventory classification.

Dekker [5] investigated demand types of spare parts and

consequences of a stock out. Also, he analysed the decision

499

M. Bonjakovi

Multicriteria inventory model for spare parts

rules for selection of spare parts to stock.

2

Inventory model

Model zaliha

Analyzing individual spare parts and components we

may conclude that they do not have the same importance for

the insurance operation of production without downtimes,

for the safety of work equipment, and not even for the same

amount of funds that need to be extracted for their

procurement. Therefore, it is not a good solution to

implement the same inventory management policy on all

items in stock. Thereby, the inventory management policy

means the way to determine the necessary inventory level,

ordering quantity and the time of purchase. The paper

proposes multicriteria inventory model which is based on

ranking and classifying the spare parts in groups according

to similar attributes. Each item in stock is analyzed

according to certain criteria and it joins the corresponding

storage policy. The criteria are:

spare parts value-usage (affiliation withA, B, C group),

!

criticality (affiliation with V, E, D group),

!

frequency of demand (affiliation F, S, N group).

!

group A. For these items should be used the strict control

system, which implies constant reviewing of stock levels, a

small backup supply, and ordering just in time. On the other

hand, for items that make up the group C should be used

mild control, which allows a greater security storage and

periodic review.

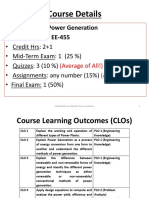

The concept dialog for a computer program to solve this

issue is shown in Fig. 1.

2.2

Ranking by a criticality

Poredak po kritinosti

According to this criterion spare parts and components

are generally classified into three categories: Vital (group

V), essential (Group E) and desirable (D group).

Parameters on the basis of which could be evaluated the

criticality of spare parts are different for different activities,

and the proposed mechanical parameters are shown in Fig.

2.

2.1

Ranking by value-usage

Poredak po godinjem troku

Every spare part in stock has a value. At the time of

taking from the warehouse it becomes a cost. Value-usage is

defined as a product of:

cost of an item x annual inventory demand

By analyzing the annual costs of spare parts (another

time period can be taken for analysis) it may be noted that a

few spare parts usually carry most of the costs.

Items are usually classified into three groups: A, B and

C. Group A consists of approximately 20 % of items with

80% value-usage. It therefore represents the most

significant items from the value-usage. On the other hand,

group C comprises 50 % of items with only a 5 % valueusage. Group B is in the middle with 30 % items and 15 % of

value-usage.

Figure 1 Ranking by value-usage

Slika 1. Poredak po vrijednosti koritenja

Labelling and determination of these three groups is

arbitrary, it can be any number of groups. Likewise, the

exact percentage of items in each group will vary from

inventory to inventory. Important factors are the two

extremes: a few items with a significant proportion of the

value-usage and a large number with relatively small valueusage. The largest part of financial value stocks (80 %) can

be controlled by the careful monitoring of the items of

500

Figure 2 Spare parts criticality

Slika 2. Kritinost rezervnih dijelova

The sub-criticality of spares regarding production,

supply and safety could be described by corresponding

criticality coefficients K1, K2 and K3. Thereby, they can

assign value 1 (for non-critical spares), 2 (for secondary

critical spares) and 3 (for critical spares). Criticality

regarding the storage will be explained later.

a) The criticality regarding the production

The basic goal of maintenance is to ensure availability

and reliability of equipment to the process of production so

that it could proceed continuously without delays in

implementation during the planned amount of products

defined by quality. All the equipment does not have the

same importance for achieving this target. For example,

functional failure of a specific machine will cause

interruption of operation of the overall production, while

the functional failure of some other machine will not

significantly affect the flow of the production. For repairing

one and other machine the same spare part may be needed,

but the fact whether it is or is not on the stock does not have

the same importance. Thus, criticality of spare part is

primarily conditioned by criticality of equipment in which

the spare part is used.

Some parts are installed in just one machine, and some in

more machines and their criticality on this basis increased

(Kranenburg [7]).

Tehniki vjesnik 17, 4(2010), 499-504

M. Bonjakovi

In the single part production, there is an additional

problem. Depending on the type of contract, certain

machine can be critical for the production, but need not be.

In a certain period of time a machine can be a bottleneck of

production, and therefore critical for the production, while

in another period of time it may not be critical.

Consequently the spares for ensuring its functionality gain

or lose importance or criticality.

Equipment can be classified into three groups

according to the criticality of the production: vital, essential,

desirable.

Vital equipment are machines, if termination of their

functions cause:

!

immediate and expensive downtime,

an unacceptable decrease in the efficiency of the entire

!

process of production,

an unacceptable decrease in quality of products.

!

Essential equipment are machines, if the interruption of

their function leads to a significant loss of production, but

not stopping of the entire process of production.

Desirable equipment consists of machines whose

function does not have a significant impact on the quantity

or quality of manufactured products. Therefore, it can allow

the equipment to be some time outside the facility.

In accordance with the previously explained, the

criticality of group to which the individual spare part

belongs depends primarily on the criticality of the group to

which the equipment belongs. As some spares can be more

or less critical for the work of a specific machine their

criticality level may be equal to or less than the criticality

level of the machine. However, the question is in what group

we should classify the spare part, if it is used in the machines

that belong to different criticality groups.

For this complicated model, a possible solution is to

leave management of the company the possibility to analyze

such spare parts and decide on their storage policy.

For practical determination of criticality Labib [4]

suggests joining criticality coefficient ranging from one to

ten for the part and the machine. Common criticality of

spare and the machine can be computed as

Viekriterijski model skladitenja rezervnih dijelova

only the stop of functioning of the machine with little danger

to the operator, spares are essential (K3 = 2). Otherwise

spares are desirable (K3 = 1).

d) Criticality regarding inventory

Some spares eventually lose their quality or usability,

and may be critical for storage from this point of view (in

this case parameter K4=2). If spares have large dimensions

and weight they could be a problem from the viewpoint of

space and transport (parameter K4=3). In this respect if the

spare is more critical it is less desirable to keep in stock.

Therefore, this parameter acts contrary to the previous three

regarding the level of stock. In this case the management of

company has to decide on the storage policy for each such

spare part.

Logical process of classifying spares in group V, E or D

is displayed in Fig. 3.

machine criticality spare crit icality

The resulting value can be used for determining the

criticality coefficient K1:

!

for the values 1 to 3 K1 = 1

!

for the values 4 to 7 K1 = 2

!

for the values 8 to 10 K1 = 3.

b) Criticality regarding availability of purchasing

This classification is carried out based on the lead time

(LT) required to procure the spare part. For example:

K2 =3 Long lead time (more than 4 months)

K2 =2 Difficult available spares (more than 2 weeks but

less than 4 months LT)

K2 =1 Easily available spares (less than a 2 weeks' LT).

c) Criticality regarding safety

Equipment working safety is on a high place regarding

its work. If lack of spares could cause ecological disaster,

danger to any people or danger to their health or the impact

on the safe operation of other machines, spares are assigned

the highest level of criticality (K3 = 3). If their lack causes

Technical Gazette 17, 4(2010), 499-504

Figure 3 Procedure for items classifying acc. criticality

Slika 3. Postupak za razvrstavanje stavki prema kritinosti

Coefficient of spare criticality (KR) is the maximum

value of (K1, K2, K3). If the coefficient KR is assigned the

value 3, the spare is ranked in the V group; the value 2 spare

501

Multicriteria inventory model for spare parts

M. Bonjakovi

is ranked in the E group; the value 1 spare is ranked in the D

group.

The concept dialog for a computer program that solves

this issue is shown in Fig. 4.

(A,V,F)

(A,V,S)

(A,V,N)

(A,E,F)

(A,E,S)

(A,E,N)

(A,D,F)

(A,D,S)

(A,D,N)

(B,V,F)

(B,V,S)

(B,V,N)

(B,E,F)

(B,E,S)

(B,E,N)

(B,D,F)

(B,D,S)

(B,D,N)

(C,V,F)

(C,V,S)

(C,V,N)

(C,E,F)

(C,E,S)

(C,E,N)

(C,D,F)

(C,D,S)

(C,D,N)

Visually it can be displayed as three-dimensional model

of cubes Fig. 6.

Figure 4 Ranking by criticality

Slika 4. Poredak po kritinosti

2.3

Ranking by frequency of demand

Poredak po uestalosti potranje

As already stated earlier the frequency of demand plays

a significant role in the selection of inventory model. As the

frequency is very different, the management of spare parts

will have to use different mathematical inventory models.

For this purpose it is necessary to place spare parts with a

similar frequency of demand in the same group. Number of

groups can be arbitrary, and classification is usually

performed in three groups.

The first group consists of spares which are frequently

used (F-group), the second group consists of spares which

are less used (S-group), and the third group consists of

spares which are very rarely used (N-group). Demand for

spares in this group is one piece in a few years.

Criteria for classification into these groups may be a

number of spares during a certain period as recommended

by Muhammad Razi [9] or the average demand during the

lead time as recommended by Mukhopadhyay [10].

The concept dialog for a computer program that solves

this issue is shown in Fig. 5.

Figure 6 Possible combinations of parameters

Slika 6. Mogue kombinacije parametara

Inventory model needed for each item, which means for

each of the possible combinations of parameters:

!

define management policy

choose an appropriate method for prediction of demand

!

predict the demand of individual items for specific

!

periods

predict the total demand of all items for the year and the

!

total required funds for this demand.

!

!

Figure 5 Ranking by frequency of demand

Slika 5. Poredak po uestalosti potranje

3

Associating parameters to particular spare

Pridruivanje parametara pojedinim rezervnim dijelovima

Each spare can be defined with three parameters:

(value-usage, frequency of demand, criticality)

Parameters can have three values, so the total number of

possible combinations is 27:

502

!

!

!

!

!

!

!

!

!

!

!

!

Data necessary to be known:

item's name and label

the inventory numbers of machines, where some spares

are used

label and name of supplier

lead time for each supplier

ordering cost

inventory cost coefficient

the cost of lack of spare in inventory

purchase value

pieces in stock

tag of the physical places in the warehouse where the

spare is

desired level of service

dates each spare is taken from the warehouse

quantity of taking

quantity in one packaging.

First, it is necessary to clarify the policy management of

spare parts and components. There are three basic policies

of managing spare parts and components. Those are:

without keeping spares in stock

!

one piece in stock

!

Tehniki vjesnik 17, 4(2010), 499-504

M. Bonjakovi

Viekriterijski model skladitenja rezervnih dijelova

more pieces in stock.

Q =

a) Policy management without keeping spares in stock

This policy includes the purchase of spares just in time

of demand. This is the most preferable approach

because it employs a minimum of capital and a

minimum of space for storage. In order to apply this

approach, it is necessary to have reliable suppliers.

!

The policy can be applied:

If the cost of stock out is less than the holding cost for

the mean time between demand

CPJ LT < SVRK h C

2 D Cn

(units)

hC

(2)

where is

D annual demand, units

Cn fixed costs per order

C billing price of spare

Q the number of ordered spares, lot size (units)

h coefficient of the holding cost.

(1)

where is

CPJ value penalty

LT average lead time

SVRK mean time work to failure

h cost coefficient of keeping item on stock

C item unit value.

!

!

!

To items of high value-usage, if the frequency of

demand is not high

To medium value-usage items, if the frequency of

demand is not high and if they are not vital spare,

To small value-usage items, the frequency of small

demand and small criticality.

b) One piece in stock

This management policy implies ordering just in time

when spare is taken from stock.

!

!

!

!

This policy can be applied on:

Critical spares medium frequency of demand,

Mean value-usage items and medium frequency

demand,

Small value-usage items, mid-frequency demand and

low importance,

Small value-usage items, the frequency of low demand

and high and medium criticality.

c) More pieces in stock

In all the cases that were not previously mentioned, it is

possible to implement this policy. It implies stocking

more than one piece of a particular item. Inventory

level, safety stock, the type of inventory control, and the

order replenishment are determined by the item

membership to particular group in decision matrix.

To clarify joining of the management policy to

particular items, the three-dimensional model is separated

into three two-dimensional decision matrices as shown in

Fig. 7.

According to Fig. 7 policy of keeping several pieces in

stock joining EOQ model storage (economic order quantity)

or one of the dynamic models of storage.

Therefore, it is necessary to analyze the demand in the

previous period and to establish whether this is a nearly

constant demand or request of occasional character. If it is

an occasional character demand, recommendation is to use

dynamic order replenishment models (e.g., WagnerWhitinov or Silver-Meal model), and if it is a nearly

constant demand, recommendation is to use EOQ

expression:

Technical Gazette 17, 4(2010), 499-504

Figure 7 Joining of the management policy to particular items

Slika 7. Spajanje politike upravljanja na pojedine stavke

Figure 8 Concept dialog for joining of the management policy

to particular items

Slika 8. Koncept dijalog za spajanje politike upravljanja

na pojedine stavke

Re-order point can be calculated on the basis of the

level of service or according to the method of minimizing

the total cost. In cases of EOQ model a periodic review or

continuous review model can be selected.

For the policy "without keeping inventories" as well as

by keeping only one piece in stock, ordering is done just in

time of demand.

The concept dialog for a computer program that solves

this issue is shown in Fig. 8.

503

Multicriteria inventory model for spare parts

M. Bonjakovi

4

Conclusion

Zakljuak

The management of spare parts is very important for

every manufacturer.

This article proposes the use of the multicriteria

inventory model for optimizing costs related to spare parts.

The proposed criteria for optimization are: value-usage,

criticality and frequency of demand. Mathematical model

for joining management policy to each inventory item

would be too complicated for practical use. Therefore a

model is proposed based on the classification of spares in

similarity groups using classical ABC analysis. Each group

is joining adequate management policy. The concept dialog

for a computer program is given for easy model

implementation in practice. The inventory model is simple

and clear for implementation in everyday practice and

enough efficiency for inventory cost reduction.

5

References

Literatura

[1] Agrell, P. J.Amulticriteria framework for inventory control. //

International Journal of Production Economics, 41, 13(1995), pp 59-70.

[2] Braglia, M.; Grassi, A.; Montanari, R. Multi-attribute

classification method for spare parts inventory management.

// Journal of Quality in Maintenance Engineering, 10,

1(2004), pp 55-65

[3] de Almeida, A. T. Multicriteria decision making on

maintenance: spares and contracts planning. // European

Journal of Operational Research, 129, 2(2001), pp 235-241.

[4] Ching, W. C.; Gin-Shuh Liang; Chien-Tseng Liao Controlling

inventory by combing abc analysis and fuzzy classification.

//Computers & Industrial Engineering, 55, 4(2008), pp 841851.

[5] Dekker, R., et. al. Optimize initial spare parts inventories: an

analysis and improvement of an electronic decision tool,

Report Econometric Institute EI 2004-52, Erasmus

University Rotterdam, 2004.

<URL:http://publishing.eur.nl/ir/repub/asset/1830/ei200452

.pdf> (06.08.10.)

[6] Lenard, J. D.; Roy, B. Multi item inventory control:

multicriteria view. //European Journal of Operational

Research, 87, 3(1995), pp 685692.

[7] Kranenburg, A. A.; Van Houtum, G. J. Effect of commonality

on spare parts provisioning costs for capital goods. //

International Journal of Production Economics, 108, 1-2(July

2007), pp 221-227.

[8] Labib, W. A.; Exton, T. Spare parts decision analysis - The

missing link in CMMs. // Maintenance & Asset

Management, 16, 3(2001), pp 10-17 and 17, 1(2002), pp 1421.

[9] Muhammad, A.; Razi, J.; Tarn, M. An applied model for

improving inventory management in ERP systems. //

Logistics Information Management, 16, 2(2003), pp 114-124.

[10] Mukhopadhyay, S. K.; Pathak, K. Development of Decision

Support System for Stock Control at Area Level in Mines,

IE(I) Journal-MN, 84,August 2003., str. 11-16

[11] Sani, B.; Kingsman, B.G. Selecting the best intervalic

inventory control and demand forecasting methods for low

demand items. // Journal of the Operational Research Society,

48, 7(1997), pp 700-13.

[12] Vereecke, A.; Verstraeten, P. An inventory management

model for an inventory consisting of lumpy items, slow

movers, and fast movers. // International Journal of

Production Economics, 35, 1-3(1994), pp 379-389.

504

Author's address

Adresa autora

Mladen Bonjakovi, MSc

University of applied science Slavonski Brod

Dr. Mile Budaka 1, 35000 Slavonski Brod, Croatia

e-mail: mladbos@gmail.com

Tehniki vjesnik 17, 4(2010), 499-504

You might also like

- Astm D2095 PDFDocument3 pagesAstm D2095 PDFTaher Hama AmeenNo ratings yet

- PM - Maintenance, Repair and Operations (MRO) PDFDocument2 pagesPM - Maintenance, Repair and Operations (MRO) PDFGuillermo SierraltaNo ratings yet

- Ts-020 Cutover StrategyDocument8 pagesTs-020 Cutover Strategymohamed-mofNo ratings yet

- G. Spare Parts ManagementDocument12 pagesG. Spare Parts ManagementVipul TikekarNo ratings yet

- Spare Parts ManagementDocument16 pagesSpare Parts ManagementAlae LmimouniNo ratings yet

- KB61 - Repost Line Items: Cost Center Accounting Cost Center AccountingDocument7 pagesKB61 - Repost Line Items: Cost Center Accounting Cost Center AccountingZakir ChowdhuryNo ratings yet

- Sap User Manual For Preventive Maintenance PDFDocument214 pagesSap User Manual For Preventive Maintenance PDFJose CordobesNo ratings yet

- KCH5N Maintain Profit Center HierarchyDocument6 pagesKCH5N Maintain Profit Center HierarchyAnandNo ratings yet

- KSS4 Execute - Plan - Cost - Splitting PDFDocument9 pagesKSS4 Execute - Plan - Cost - Splitting PDFsawantamit777No ratings yet

- 10.SAP MM - Purchase Info RecordDocument4 pages10.SAP MM - Purchase Info RecordNiranjan NaiduNo ratings yet

- Cost To CompanyDocument13 pagesCost To CompanySahilSankhlaNo ratings yet

- 01 Registration BFR V6.0 09july2021Document103 pages01 Registration BFR V6.0 09july2021Birtukan AberaNo ratings yet

- Blueprint Doc For Sales: Sales of FG From Mother WarehouseDocument8 pagesBlueprint Doc For Sales: Sales of FG From Mother WarehouseSarfraz MohammedNo ratings yet

- Compliance Risk Management BFR V6.0-18July2021Document29 pagesCompliance Risk Management BFR V6.0-18July2021Birtukan AberaNo ratings yet

- FBL3N Account Line Item AnalysisDocument5 pagesFBL3N Account Line Item AnalysisDinesh KumarNo ratings yet

- Tax Litigation BFR V6.0-12July2021Document38 pagesTax Litigation BFR V6.0-12July2021Birtukan AberaNo ratings yet

- 02 Filing BFR V5.0 19july2021Document47 pages02 Filing BFR V5.0 19july2021Birtukan AberaNo ratings yet

- 03-Payment and Revenue Account Reconciliation-V6.0-16July2021Document31 pages03-Payment and Revenue Account Reconciliation-V6.0-16July2021Birtukan AberaNo ratings yet

- Tax Audit BFR V6.0-16July2021Document48 pagesTax Audit BFR V6.0-16July2021Birtukan AberaNo ratings yet

- FI11 - 03 - Part B - Vendor Master CreationDocument34 pagesFI11 - 03 - Part B - Vendor Master Creationiiftgscm batch2No ratings yet

- SAP 002212 - General-maintenance-V1Document37 pagesSAP 002212 - General-maintenance-V1Top NgôNo ratings yet

- FI04 - 01 AP Outgoing PaymentsDocument35 pagesFI04 - 01 AP Outgoing PaymentspramodNo ratings yet

- User Training Manual - FI - Z Developments V 1 1Document20 pagesUser Training Manual - FI - Z Developments V 1 1iiftgscm batch2No ratings yet

- H2.8.1 User Documentation ARDocument119 pagesH2.8.1 User Documentation ARcybervistaNo ratings yet

- Purchase Info Record Using ME11Document6 pagesPurchase Info Record Using ME11morya19No ratings yet

- Esm570 05Document72 pagesEsm570 05abdalrahim mattarNo ratings yet

- Procurement Types:: MM FlowDocument11 pagesProcurement Types:: MM FlowKote RaviNo ratings yet

- Assign Business Area To Consolidation Business Area in SapDocument5 pagesAssign Business Area To Consolidation Business Area in SaparavindNo ratings yet

- S - ALR - 87013181 Material Ledger Data Over Several Periods PDFDocument7 pagesS - ALR - 87013181 Material Ledger Data Over Several Periods PDFSurabhi ChaurasiaNo ratings yet

- MM Harmonization DocumentDocument59 pagesMM Harmonization DocumentRajesh Kumar100% (1)

- P6V7-Case Study ProjectDocument43 pagesP6V7-Case Study Projectabhinay02meNo ratings yet

- Customer Project Settlement 10Document10 pagesCustomer Project Settlement 10Abdelhamid HarakatNo ratings yet

- FSD Ats Custom Form v1.0Document17 pagesFSD Ats Custom Form v1.0Vinay ChughNo ratings yet

- CO03 Display PP Production OrderDocument20 pagesCO03 Display PP Production OrderAshu KumarNo ratings yet

- True/False: List of Attempted Questions and AnswersDocument38 pagesTrue/False: List of Attempted Questions and Answersapi-3745584No ratings yet

- Purchasing Information RecordDocument17 pagesPurchasing Information RecordHoang NguyenNo ratings yet

- Umoja - Job Aid - Inventory MAP Valuation Adjustments (MR21)Document17 pagesUmoja - Job Aid - Inventory MAP Valuation Adjustments (MR21)Mus ChrifiNo ratings yet

- Financial Accounting: Important Tables in SAPDocument5 pagesFinancial Accounting: Important Tables in SAPMohamed GoudahNo ratings yet

- SAP FI Tables ListDocument19 pagesSAP FI Tables ListAjinkya MohadkarNo ratings yet

- Complete ALE WorkingDocument23 pagesComplete ALE WorkingjeetchauhanNo ratings yet

- User Manual FI03: Title: Module NameDocument35 pagesUser Manual FI03: Title: Module NameAbdelhamid HarakatNo ratings yet

- EASA TCDS IM A 085 Hawker Series Issue 5Document73 pagesEASA TCDS IM A 085 Hawker Series Issue 5Sorina CtinNo ratings yet

- AAC-018 The Problem of Bogus PartsDocument7 pagesAAC-018 The Problem of Bogus PartsIsrael UgaldeNo ratings yet

- SAP TablesDocument13 pagesSAP TablesLu VanderhöffNo ratings yet

- FD10N Customer Account Balance DisplayDocument6 pagesFD10N Customer Account Balance Displayhypnoticalstar8120No ratings yet

- MEFCO - L3 - Training - Part 2 - Corrective MaintenanceDocument19 pagesMEFCO - L3 - Training - Part 2 - Corrective MaintenanceSrinivas N GowdaNo ratings yet

- Allocation: Posted Amounts Fixed Amount Fixed RateDocument8 pagesAllocation: Posted Amounts Fixed Amount Fixed RatefharooksNo ratings yet

- Level 2 - Training Manual: Project SystemDocument26 pagesLevel 2 - Training Manual: Project SystemFakhar AbbasNo ratings yet

- T Code Description: Maintenance PlanningDocument5 pagesT Code Description: Maintenance PlanningVjoy Raju NagalapatiNo ratings yet

- PL Stock in TransitDocument1 pagePL Stock in Transitbeema1977No ratings yet

- Design Document: Functional Specification Document FPP InvoicingDocument33 pagesDesign Document: Functional Specification Document FPP InvoicingM AshokNo ratings yet

- CK40N Edit Costing RunDocument39 pagesCK40N Edit Costing RunDurga Prasad TripathyNo ratings yet

- Some of The Most Commonly Used SAPDocument5 pagesSome of The Most Commonly Used SAPnaveenraj111No ratings yet

- Business Process Master List: Level 1 Level 2Document34 pagesBusiness Process Master List: Level 1 Level 2Meghana VastNo ratings yet

- TA040 Application ArchitectureDocument11 pagesTA040 Application ArchitectureAvijit BanerjeeNo ratings yet

- SAP MM Course Sap MM: How To Create SAP RFQ?Document9 pagesSAP MM Course Sap MM: How To Create SAP RFQ?MohammadNo ratings yet

- Pool Asset Management - End-To-End Cycle - SAP BlogsDocument17 pagesPool Asset Management - End-To-End Cycle - SAP BlogsPrasad ShanwareNo ratings yet

- SAP - T - Codes For PM ModuleDocument8 pagesSAP - T - Codes For PM Modulerhys_gauravNo ratings yet

- Multicriteria Inventory Model For Spare Parts: Mladen BošnjakovićDocument6 pagesMulticriteria Inventory Model For Spare Parts: Mladen Bošnjakovićanon_636436248No ratings yet

- Multicriteria Inventory Model For Spare PartsDocument6 pagesMulticriteria Inventory Model For Spare PartsFernando GómezNo ratings yet

- LSCM Project Mp16009Document11 pagesLSCM Project Mp16009Ankit KumarNo ratings yet

- Newsvendor Problems: 1 The Basic ModelDocument6 pagesNewsvendor Problems: 1 The Basic ModelsaeedalemveNo ratings yet

- BMW CaseDocument16 pagesBMW Casesaeedalemve67% (3)

- Pipeline InspectionDocument19 pagesPipeline InspectionsaeedalemveNo ratings yet

- Inventory Management of Spare Parts in An Energy Company PDFDocument32 pagesInventory Management of Spare Parts in An Energy Company PDFsaeedalemveNo ratings yet

- Implications For Service Parts Management PDFDocument7 pagesImplications For Service Parts Management PDFsaeedalemveNo ratings yet

- Maintenance Spares Inventory Management PDFDocument7 pagesMaintenance Spares Inventory Management PDFsaeedalemveNo ratings yet

- A Case Study Based Analysis of Spare Parts Management in The Engineering Industry PDFDocument11 pagesA Case Study Based Analysis of Spare Parts Management in The Engineering Industry PDFsaeedalemveNo ratings yet

- Simple Annuities FinalDocument95 pagesSimple Annuities FinalMae Ann KongNo ratings yet

- Gallium Arsenide Gaas MsdsDocument4 pagesGallium Arsenide Gaas MsdsEunice PunzalanNo ratings yet

- Cadôr - Books About Nothing PDFDocument4 pagesCadôr - Books About Nothing PDFFelipeCussen100% (1)

- Using The BIMCO Shipping KPI Database To IdentifyDocument9 pagesUsing The BIMCO Shipping KPI Database To IdentifydevivovincenzoNo ratings yet

- Group 4: Diet For Healthy Teath BonesDocument26 pagesGroup 4: Diet For Healthy Teath Bonesknowledge chanall chanallNo ratings yet

- Case of Paper BoatDocument11 pagesCase of Paper BoatAshiqnavaz ShaikhNo ratings yet

- P.E Reviewer Module 002Document7 pagesP.E Reviewer Module 002Nhick vincentNo ratings yet

- GlucomaDocument14 pagesGlucomametalheavy9993No ratings yet

- v3PL SAP IntegrationDocument6 pagesv3PL SAP IntegrationShaik Khwaja Nawaz SharifNo ratings yet

- Lecture-1 Introduction To Power Generation and Electrical Power SystemsDocument30 pagesLecture-1 Introduction To Power Generation and Electrical Power SystemsArishaNo ratings yet

- 6 Storm Water Master SpreadsheetDocument16 pages6 Storm Water Master Spreadsheetscelo butheleziNo ratings yet

- Pemeriksaan Colok DuburDocument9 pagesPemeriksaan Colok DuburRidwan Hadinata SalimNo ratings yet

- PDF A Gentle Course in Local Class Field Theory Local Number Fields Brauer Groups Galois Cohomology 1St Edition Pierre Guillot Ebook Full ChapterDocument54 pagesPDF A Gentle Course in Local Class Field Theory Local Number Fields Brauer Groups Galois Cohomology 1St Edition Pierre Guillot Ebook Full Chapterdaphne.szymanski787100% (6)

- Mba Group ActivityDocument14 pagesMba Group ActivitySHERYL SHEKINAH E ARCH-2019 BATCHNo ratings yet

- Use of Nonaqueous Solvents in Parenteral ProductsDocument11 pagesUse of Nonaqueous Solvents in Parenteral ProductsMustafa ShahinNo ratings yet

- 中國成語Document19 pages中國成語Nguyễn HiềnNo ratings yet

- Oxygen Concentrator 7F-5 User's ManualDocument9 pagesOxygen Concentrator 7F-5 User's ManualJunx TripoliNo ratings yet

- Body MechanicsDocument26 pagesBody MechanicsSandeepNo ratings yet

- ETICS Fixings / E.W.IDocument54 pagesETICS Fixings / E.W.INarendra Reddy BhumaNo ratings yet

- Instruction Manual AVTM246100B For Battery Ground Fault TracerDocument44 pagesInstruction Manual AVTM246100B For Battery Ground Fault TracerRovi ElecNo ratings yet

- Decision Area/s (Barangay) Hazards/Problems Technical Findings Impacts/Implications Policy InterventionsDocument2 pagesDecision Area/s (Barangay) Hazards/Problems Technical Findings Impacts/Implications Policy InterventionsCHICKYNo ratings yet

- Phil Precolonial ArtDocument23 pagesPhil Precolonial ArtMonnette Ann Banzuela100% (2)

- Methane Recovery Project - Final PDFDocument18 pagesMethane Recovery Project - Final PDFZayin ValerieNo ratings yet

- Rayo X Protable XFM ITALRAYDocument18 pagesRayo X Protable XFM ITALRAYaplicacionista.imagenesNo ratings yet

- Stinger 3470Document8 pagesStinger 3470allen_renziNo ratings yet

- Ermias TamiruDocument119 pagesErmias TamiruAli HassenNo ratings yet

- Gospel of The SaviorDocument10 pagesGospel of The SaviorDanielNo ratings yet

- Super Duplex Steel s32750 Flanges SuppliersDocument3 pagesSuper Duplex Steel s32750 Flanges SuppliersRajtilak MetalNo ratings yet

- Hydraulic ValvesDocument19 pagesHydraulic ValvesRahul SinghNo ratings yet