Professional Documents

Culture Documents

Stainless Steel Finishes for Industrial Applications

Uploaded by

Anonymous oTrMzaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stainless Steel Finishes for Industrial Applications

Uploaded by

Anonymous oTrMzaCopyright:

Available Formats

Stainless Steel Enclosures and Industrial Applications

Finishes for Stainless Steel

Metals are finished not only for aesthetic purposes, but also to improve their corrosion resistant

properties. The ASTM A480 standard provides a framework for different metal finishes based on

certain criteria. Sheet steel finishes are designated by a system of numbers ranging from a No.

1 finish to a No. 8 finish. Additional global standards that apply to metal finishes include BS EN

10088-2 and ISO 1302.

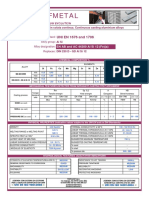

Surface Finish Specifications

ASTM Roughness Roughness BS EN

A480 ASTM A480 Description Ra (in) Ra (m) 10088-2 ISO 1302

- - - - 1U -

- - - - 1C -

No. 1 Hot-rolled, annealed, and de-scaled. 157 to 276 4.0 to 7.0 1E, 1D N8, N9

- - - - 2H -

Mill Finish

- - - - 2C -

- - 16 to 39 0.4 to 1.0 2E N5, N6

No. 2D Cold-rolled, dull finish. 16 to 39 0.4 to 1.0 2D N5, N6

No. 2B Cold-rolled, bright finish. 3.9 to 20 0.1 to 0.5 2B N3 to N5

A bright cold-rolled finish retained by

final annealing in a controlled

No. BA atmosphere furnace. 2.0 to 3.9 0.05 to 0.1 2R N2, N3

- - - - 2Q -

- - 79 to 98 2.0 to 2.5 1G, 2G N7

Intermediate polished finish, one or

No. 3 both sides. 28 to 47 0.7 to 1.2 1J, 2J N6, N7

General purpose polished finish, one

No. 4 or both sides. 12 to 25 0.3 to 0.6 1J, 2J N4, N5

Special Finish

Dull satin finish, Tampico brushed,

No. 6 one or both sides. 10 to 20 0.25 to 0.50 1K, 2K N5

No. 7 Light luster finish. 2.4 to 7.9 0.06 to 0.20 - N3, N4

No. 8 Mirror finish. 0.8 to 3.9 0.02 to 0.10 1P, 2P N1 to N3

- - - - 2F -

- - - - 1M, 2M -

- - - - 2W -

- - - - 2L -

- - - - 1S, 2S -

You might also like

- Naval BrassDocument1 pageNaval BrassAugusto Gabriel Flores ManzanedaNo ratings yet

- t7765x 71131Document12 pagest7765x 71131rimmabrn5No ratings yet

- DZR BrassDocument1 pageDZR BrasssmrdojeNo ratings yet

- TNI2TIDocument2 pagesTNI2TIKureiNo ratings yet

- TCS3200 Color SensorColor Detector Schematics PDFDocument1 pageTCS3200 Color SensorColor Detector Schematics PDFsiogNo ratings yet

- Rcwl-0516 3.2Ghz Motion Detector (U1 Is Rcwl-9196) : 3.3V Out GND Vout 4-28V in C6 C10 R1 C16 C17Document3 pagesRcwl-0516 3.2Ghz Motion Detector (U1 Is Rcwl-9196) : 3.3V Out GND Vout 4-28V in C6 C10 R1 C16 C17ahmadNo ratings yet

- Notes and revision history for wireless power receiver circuitDocument3 pagesNotes and revision history for wireless power receiver circuitJonas Staugaitis100% (2)

- Radar Motion Sensor1Document3 pagesRadar Motion Sensor1Mohammad DaoudNo ratings yet

- Go-Nador: Layout Ready To Transfer Resistors Capacitors Potentiometers Parts ListDocument1 pageGo-Nador: Layout Ready To Transfer Resistors Capacitors Potentiometers Parts ListPaulo MagdalenaNo ratings yet

- Company Name: Design Specifications Nozzles Couplings / SupportsDocument21 pagesCompany Name: Design Specifications Nozzles Couplings / Supportsmohsen ranjbarNo ratings yet

- How To Build 1wamp PDFDocument8 pagesHow To Build 1wamp PDFVíctor FaucheretNo ratings yet

- Ripples, v9.0: SMT PartsDocument6 pagesRipples, v9.0: SMT PartsrubixkubeNo ratings yet

- Non Pre-load Bolt Assemblies BS EN 15048Document5 pagesNon Pre-load Bolt Assemblies BS EN 15048Sakthivel VNo ratings yet

- Fuente alimentación FA5_.1 2018Document1 pageFuente alimentación FA5_.1 2018iago.lorenzoNo ratings yet

- SNS2 - Bare Pump DimensionDocument1 pageSNS2 - Bare Pump DimensionChaiporn LimawararatNo ratings yet

- Pin Function:: Optional CDS PhotoresistorDocument1 pagePin Function:: Optional CDS PhotoresistorRobert BedfordNo ratings yet

- Heladera circuit board diagramDocument1 pageHeladera circuit board diagramedgarbarinasNo ratings yet

- Flender Coupling N-BWNDocument1 pageFlender Coupling N-BWNCharles ChengNo ratings yet

- Leaded Nickel SilverDocument1 pageLeaded Nickel Silvermp87_ingNo ratings yet

- Model Spice - Laborator 1Document97 pagesModel Spice - Laborator 1Fage RaulNo ratings yet

- 2x Gain BTL With 2 Pcs Transistor: Main Supply 1x GAIN R13 18K 2x GAIN R13 4K7Document2 pages2x Gain BTL With 2 Pcs Transistor: Main Supply 1x GAIN R13 18K 2x GAIN R13 4K7mdeky20No ratings yet

- WifiLamp - Hardware - SCHDocument1 pageWifiLamp - Hardware - SCHEmerson TorresNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Jonathan Getial CruzNo ratings yet

- Sirius 3R Schütz 3RT1.2: Contactor ContacteurDocument2 pagesSirius 3R Schütz 3RT1.2: Contactor Contacteurdisanty94No ratings yet

- IzolateDocument7 pagesIzolateGaál Csaba NimródNo ratings yet

- Yarns v0.3: SMT PartsDocument3 pagesYarns v0.3: SMT PartsjbwiltsNo ratings yet

- Illustrated Assembly Manual k8012Document20 pagesIllustrated Assembly Manual k8012War LinuxNo ratings yet

- Coldrolled Steelstrips - . - # B ? (Box Strappings) - Specification .D (Document7 pagesColdrolled Steelstrips - . - # B ? (Box Strappings) - Specification .D (VivekNo ratings yet

- Data Sheet White Metal SelectionDocument2 pagesData Sheet White Metal SelectionmygolNo ratings yet

- Roughness Conversion Chart RampinelliDocument1 pageRoughness Conversion Chart RampinelliServesh KumarNo ratings yet

- Bav23, Bav23a, Bav23c, Bav23s NXPDocument13 pagesBav23, Bav23a, Bav23c, Bav23s NXPdiego hache fernandezNo ratings yet

- SUBBU DAC Power Supply V3 SchematicsDocument1 pageSUBBU DAC Power Supply V3 Schematicscristi289100% (1)

- Key Facts Typical Wire Analysis: - Bossweld 71T-1Document1 pageKey Facts Typical Wire Analysis: - Bossweld 71T-1cj elec techNo ratings yet

- Linear Mode Current Sink Led DriverDocument9 pagesLinear Mode Current Sink Led DriverJosé Ganga BarbosaNo ratings yet

- EMV2 Flanger Circuit DesignDocument10 pagesEMV2 Flanger Circuit DesignBruno VianaNo ratings yet

- C-Pad 02Document1 pageC-Pad 02wotax31173No ratings yet

- Grundfosliterature 6511721Document25 pagesGrundfosliterature 6511721jesusbierzo1961No ratings yet

- Schematics-478020 RouterDocument5 pagesSchematics-478020 RouterALFONZO DANIELNo ratings yet

- Robbin Group: For Approval As Drawing S552 Rev. 14Document1 pageRobbin Group: For Approval As Drawing S552 Rev. 14Marcelo GonzagaNo ratings yet

- 2022 Versiona AFPCatalog May2022 Web-26-27Document2 pages2022 Versiona AFPCatalog May2022 Web-26-27Asa ReidNo ratings yet

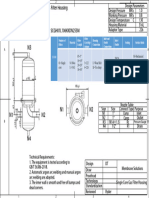

- Single Core Gas Filter Housing-37345Document1 pageSingle Core Gas Filter Housing-37345Вова НазаровNo ratings yet

- Bom - Ups With BmsDocument27 pagesBom - Ups With BmsNuaman SaghirNo ratings yet

- Schematic - Voltage Controlled FM Transmitter Circuit - 2022-12-13 PDFDocument1 pageSchematic - Voltage Controlled FM Transmitter Circuit - 2022-12-13 PDFEvie Anindya PutriNo ratings yet

- Steel Tubes: See Notes !Document5 pagesSteel Tubes: See Notes !amit kumar sarkarNo ratings yet

- CCDC JSDL S20 08 eDocument2 pagesCCDC JSDL S20 08 eLuong LeNo ratings yet

- Wiring DiagramDocument85 pagesWiring DiagramAlfredo Lopez AvellaNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- High Performance 2A Uldo Linear Regulator: ApplicationsDocument11 pagesHigh Performance 2A Uldo Linear Regulator: ApplicationsStuxnetNo ratings yet

- Renk Metal Therm 89Document1 pageRenk Metal Therm 89rajeskumarNo ratings yet

- PROBLEM 7-20: MACHINE DESIGN - An Integrated Approach, 4th Ed. 7-20-1Document2 pagesPROBLEM 7-20: MACHINE DESIGN - An Integrated Approach, 4th Ed. 7-20-1Diana Alejandra Bermudez FajardoNo ratings yet

- B 32 - 00 - QjmylvjfraDocument11 pagesB 32 - 00 - QjmylvjfraAndresNo ratings yet

- MCTC MIB A 小区监控使用指导 (英) V0.0Document5 pagesMCTC MIB A 小区监控使用指导 (英) V0.0Douglas LamNo ratings yet

- 39-p-116-81 (Earth Rod)Document5 pages39-p-116-81 (Earth Rod)RamzanNo ratings yet

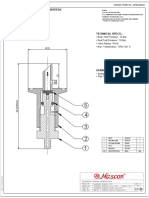

- Drawing Format No. MT/DGN/002-01 Milipore Sampling ValveDocument1 pageDrawing Format No. MT/DGN/002-01 Milipore Sampling ValveGunwant VarmaNo ratings yet

- mBUS Servo Board LS-163m1g3: Doc # 71216301 / Rev A, 06/10/2021Document12 pagesmBUS Servo Board LS-163m1g3: Doc # 71216301 / Rev A, 06/10/2021Ilhami DemirNo ratings yet

- Semiconducting III–V Compounds: International Series of Monographs on SemiconductorsFrom EverandSemiconducting III–V Compounds: International Series of Monographs on SemiconductorsNo ratings yet

- Container Lift and Wheed AddonDocument10 pagesContainer Lift and Wheed AddonAnonymous oTrMzaNo ratings yet

- Design Analysis and Comparison Between The Conventional Materialswith Composite Material of The Leaf Springs Fmoa 1000127Document20 pagesDesign Analysis and Comparison Between The Conventional Materialswith Composite Material of The Leaf Springs Fmoa 1000127Anonymous oTrMzaNo ratings yet

- AOMEI Backupper UserManual PDFDocument64 pagesAOMEI Backupper UserManual PDFAnonymous oTrMzaNo ratings yet

- Rexroth Aventics in Line Flow ValveDocument2 pagesRexroth Aventics in Line Flow ValveAnonymous oTrMza100% (1)

- On Karl Popper's Liberal Principle of Freedom: The Individual and Social AspectsDocument7 pagesOn Karl Popper's Liberal Principle of Freedom: The Individual and Social AspectsAnonymous oTrMzaNo ratings yet

- 2012 Properly Spec MaterialsDocument6 pages2012 Properly Spec MaterialsKurt ZarwellNo ratings yet

- Rexroth Aventics in Line Flow Valve PDFDocument2 pagesRexroth Aventics in Line Flow Valve PDFAnonymous oTrMzaNo ratings yet

- AOMEI Backupper UserManual PDFDocument64 pagesAOMEI Backupper UserManual PDFAnonymous oTrMzaNo ratings yet

- Caase18 Preliminary Agenda Mar20 v1Document277 pagesCaase18 Preliminary Agenda Mar20 v1Anonymous oTrMzaNo ratings yet

- Handbook of Plastic FilmsDocument422 pagesHandbook of Plastic FilmsStefan Boiadjiev100% (18)

- Rexroth Aventics in Line Flow Valve PDFDocument2 pagesRexroth Aventics in Line Flow Valve PDFAnonymous oTrMzaNo ratings yet

- Publications CatalogDocument60 pagesPublications CatalogAnonymous oTrMzaNo ratings yet

- Cross Asset Investment Strategy Special Focus 201103 enDocument5 pagesCross Asset Investment Strategy Special Focus 201103 enAnonymous oTrMzaNo ratings yet

- Cio Parameter REV5 en 02Document280 pagesCio Parameter REV5 en 02Mircea MurarNo ratings yet

- Operator's Manual For Arc Welding: Motoman XRC 2001 ControllerDocument436 pagesOperator's Manual For Arc Welding: Motoman XRC 2001 ControllerAnonymous oTrMzaNo ratings yet

- Yasnac Motoman Robot Manual PDFDocument375 pagesYasnac Motoman Robot Manual PDFchidambaram kasi100% (5)

- Fourie IJ Chapter 2Document30 pagesFourie IJ Chapter 2Anonymous oTrMzaNo ratings yet

- Cross Asset Investment Strategy Special Focus 201103 enDocument5 pagesCross Asset Investment Strategy Special Focus 201103 enAnonymous oTrMzaNo ratings yet

- ECSS-Threaded Fasteners HandbookDocument236 pagesECSS-Threaded Fasteners HandbookmoshiktNo ratings yet

- Design of Shaft PDFDocument5 pagesDesign of Shaft PDFAnonymous oTrMzaNo ratings yet

- Delta VFD WiringDocument6 pagesDelta VFD WiringAnonymous oTrMzaNo ratings yet

- Dsiac Summer 2016 Volume 3 Number 3Document40 pagesDsiac Summer 2016 Volume 3 Number 3Anonymous oTrMzaNo ratings yet

- Solidworks FEM - lm1Document61 pagesSolidworks FEM - lm1Bruno AlvesNo ratings yet

- Design of ShaftDocument5 pagesDesign of ShaftAnonymous oTrMzaNo ratings yet

- 5th Grade Classroom RemindersDocument3 pages5th Grade Classroom RemindersAnonymous oTrMzaNo ratings yet

- Fea LeverDocument174 pagesFea LeverAnonymous oTrMzaNo ratings yet

- DELTA Start UpDocument3 pagesDELTA Start UpAnonymous oTrMzaNo ratings yet

- ASME B1 1 2003 Unified Inch Screwed Threads PDFDocument189 pagesASME B1 1 2003 Unified Inch Screwed Threads PDFAnonymous oTrMzaNo ratings yet

- Achieve RelFlow PG02 FinalDocument20 pagesAchieve RelFlow PG02 FinalAnonymous oTrMzaNo ratings yet

- Mil DTL 45932 - 1DDocument6 pagesMil DTL 45932 - 1DAnonymous oTrMzaNo ratings yet

- Reasons For Hot Dip Galvanizing - Galvanising Process - Wedge GalvanizingDocument2 pagesReasons For Hot Dip Galvanizing - Galvanising Process - Wedge GalvanizingluthfibomentNo ratings yet

- 1.2842 enDocument2 pages1.2842 enCosmin IonutNo ratings yet

- Umesh Vishvakarma Sir Rahul Dev Sahu Nitesh Sahu Monendra SahuDocument10 pagesUmesh Vishvakarma Sir Rahul Dev Sahu Nitesh Sahu Monendra SahuMarina CdfmNo ratings yet

- Advantages and uses of rotational molding, blow molding, and other plastic forming processesDocument2 pagesAdvantages and uses of rotational molding, blow molding, and other plastic forming processesapril_ian02No ratings yet

- HW1 SolDocument4 pagesHW1 Soluzair ahmadNo ratings yet

- Welding Presentation AESDocument31 pagesWelding Presentation AEScharlessimoNo ratings yet

- CarbonitridingDocument2 pagesCarbonitridingSelva KumarNo ratings yet

- 50th SMOC - JSW Bellary - WorkshopDocument28 pages50th SMOC - JSW Bellary - WorkshopPRADEEP_351No ratings yet

- Micron WSeries Filter SpecDocument2 pagesMicron WSeries Filter SpecReach HomeNo ratings yet

- Metal Processing Techniques Presentation SummaryDocument15 pagesMetal Processing Techniques Presentation Summarym.abdullahNo ratings yet

- Essential Variables For All ProcessesDocument4 pagesEssential Variables For All ProcessesRahulNo ratings yet

- Returned Receipt For Equipment: Land Transportation OfficeDocument68 pagesReturned Receipt For Equipment: Land Transportation Officemaricris punayNo ratings yet

- 4 20180 Vj-Type Love-SpecimenDocument13 pages4 20180 Vj-Type Love-SpecimenteraneeNo ratings yet

- Code Requirements: Post Weld Heat Treatment: Asme Sec-Iii: Div.-1Document22 pagesCode Requirements: Post Weld Heat Treatment: Asme Sec-Iii: Div.-1Vinu RaveendranNo ratings yet

- Me9201 Manufacturing TechnologyDocument2 pagesMe9201 Manufacturing TechnologySenthilsuja KumarNo ratings yet

- Danse Macabre For Saxophone QuartetDocument48 pagesDanse Macabre For Saxophone QuartetPancake BombDX52No ratings yet

- NEW SILVER 5.5-10 230-400-50-60 20-07-2017 1127340125 ING PartsDocument15 pagesNEW SILVER 5.5-10 230-400-50-60 20-07-2017 1127340125 ING PartsCarlos Ferreira100% (1)

- What Is EDMDocument2 pagesWhat Is EDMNur' AyuniNo ratings yet

- Unit II PPT MT I Vol 1Document51 pagesUnit II PPT MT I Vol 1loganathanNo ratings yet

- Electro Chemical MachiningDocument10 pagesElectro Chemical Machiningdev2945No ratings yet

- Induction FurnaceDocument4 pagesInduction FurnaceMuhammad Noman100% (1)

- Chemical Pulping ProcessDocument19 pagesChemical Pulping ProcessSyahmi HarizNo ratings yet

- Arc WeldingDocument24 pagesArc Weldingaq lapar100% (5)

- Biaya Perunit Prod.Document69 pagesBiaya Perunit Prod.Alan Limp BizkitNo ratings yet

- General Cutting Data Acquire Sheet Vers 5Document1 pageGeneral Cutting Data Acquire Sheet Vers 5Anonymous VRspXsmNo ratings yet

- Corri DurDocument2 pagesCorri DurStuartNo ratings yet

- Flash AllDocument2 pagesFlash AllJolanta RadzyńskaNo ratings yet

- Resistance WeldingDocument22 pagesResistance WeldingLOKENDRA91100% (2)

- Bearing InterchangeDocument19 pagesBearing InterchangeRay RawlinsonNo ratings yet

- Heat Treatment of Gauge MaterialsDocument16 pagesHeat Treatment of Gauge MaterialsshdblikhnNo ratings yet