Tolerancing PDF

Uploaded by

86satheshTolerancing PDF

Uploaded by

86sathesh- Framework

- Sensitivity Analysis

A quality measure for comparing different feature

deviations to perform sensitivity analysis in tolerancing

Philipp Ziegler, Sandro Wartzack

Chair of Engineering Design

Friedrich-Alexander-Universitt Erlangen-Nrnberg

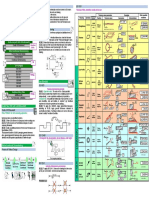

Framework 4. Tolerance Analysis Simulation Model t A

t/2

y

The proposed simulation model bases on Homogenous Trans-

1. Tolerances in mechanical engineering design formations T SE(2)/SE(3). The simulation model consists of: l

t/l

Axiom of manufacturing imprecision: All Model Input Tolerances: Manufacturing deviations are

Figure 4: Pin with coaxiality tolerance (l), deviating front cylinder (m)

manufacturing and assembly processes are represented by transformations Td which are restricted and associated parameters: the deviation domain for Td (r) [4]

y

inherently imprecise and produce parts and by tolerances (figure 4).

y

products that vary. [1]

x

Assembly Operation: Assemble the components is T(x,y,)

x

Nominal drill hole size deviation geometric deviations

represented by transformations T which are guided by

Figure 5: Pin-hole assembly with contact control points (l),

control points to avoid collisions (figure 5). represented by T (r)

y

Figure 1: Different deviating drill holes Clearance Deviations: Assembled features have

Tolerances restrict the geometric variations of position deviations Tc inside the clearance domain which

parts with respect to the nominal geometry.

Figure 2: Cylindricity tolerance and the

associated tolerance zone [2]

also are restricted by control points (figure 6). x

Figure 6: Possible positions of the pin with control points (l) and

associated parameters: the clearance domain for T c (r) [4]

Tolerance analysis explores the relations between the assigned part-tolerances Model Output: The resulting relative position of two tf A

features or a resulting assembly clearance. Functional

and the products assemblability and functionality. tf/const

requirements often are formulated as geometric

tf/2

tolerance with associated functional domain [4] (figure 7).

x

2. Tolerance analysis in early design stages Characteristic: In the proposed model, several A

To shorten the product design process, product analyses have to be performed parameters are restricted together by tolerances the Figure 7: Important here is the relative position of the two axes.

as early as possible to avoid late product modifications, which are cost- and time- parameters are dependent (figure 4, 6 and 7 (r)). The functional requirement is formulated as coaxiality tolerance

(l), with associated functional domain (r)

consuming. A simulation model for early design stages

should have a high performance

could handle partially incomplete geometry

doesnt has to recognize detailed manufacturing information 5. Sensitivity Analysis in Tolerancing

Commonly one-dimensional sensitivity analysis considering size deviation is performed. The methods are

restricted to independent input parameters as well as independent model outputs. r = (t+)/2 y r = t/2

3. Features

Features are generic shapes with which engineers Problems in sensitivity analysis of geometric tolerances B

x

associate certain properties or attributes and knowledge The deviation quality is for general deviation domains trivially

r = (t-)/2

useful in reasoning about the product. [3] not clear A t A B

Figure 3: The feature drill hole Only the deviation domain size of a geometric tolerance can Figure 8: Position tolerance of a drill hole: The tolerance

A feature can be a flange, a drill hole, a ball bearing, be changed, not the form (figure 8) quantity t only restricts the radius of the tolerance zone, the

angular position of a deviation is not controlled [5]

a screw, etc.. A feature usually is defined by multiple conditions and parameters!

Sensitivity Analysis of Geometric Tolerances

y

6. Deviation quality measure t/2

8. Application Example: Tolerance Scaling of Pin-Hole- F6/2 A

For the deviation domain D t/l Connection h6/2 A

D={(x,) 6 | for all u f: ||Td(x,)u - u||2 t/2} l

t

Two-dimensional simulation-model

dF7

dh7

of a feature f with tolerance value t, the quality of a

Deviating pin and hole with clearance fit (figure 13)

deviation (x,) is defined as

d/2h7

Geometric tolerances: Coaxiality (figure 12, figure 4)

={ 0 | maxu ||Td(x,)u - u||2 = t/2}. y d d

Size tolerances: diameters of pin & hole (figure 12)

d/2F7

t/2

A A

d d

Model output: size of the deviation domain of the pin,

For the fast calculation of the quality measure, the t/l

approximated by a monte-carlo sampling (200 samples) Figure 12: Dimensions and tolerances of pin & hole

t

l

domain D should be convex. This is ensured, if

Sensitivity analysis: 5000 samples

the function ||T(x,)u - u||2 is quasi-convex, what

Relative difference of

Figure 9: Quality evaluation of a the total effects

for the here considered tolerances is the case. deviating line with quality = t/t. 0,3

Question: How scale the sensitivity values with the 0,2

international fit system? 0,1

International fit system 10-20 20-30 30-40 40-50

7. Sensitivity Analysis based on deviation quality The tolerance zone t is defined by a letter and a

#-difference

Figure 13: Exemplary clearance fit Figure 14: Relative difference

measure number (figure 12), dependent on the nominal of pin & hole of the total effects sum

Quality value SA algorithm Tensor sampling dimension N (figure 11 and table below).

Sampling Scaling of total effects

IT7

f ( x)

y 0,6

EI

f

[ x1 ; x2 ]

Var ( f )[ x1 ; x2 ]

Scaling of d in mm: 0,5

10, 20, 30, 40, 50 pin_left

x1 x2 0,4

Tolerancing System: pin_right

IT7

0,3

N

Basic shaft system (DIN 7157) hole_left

0,2 hole_right

Sampling: The input parameters of the Clearance fit:

Quality of Output Simulation 0,1 coax_pin

sensitivity analysis are the quality values model Pin tolerance: h7 coax_hole

y Figure 11: Tolerance zone IT 7 0

for deviating features with Monte-Carlo =0.4 for pin (red) and hole (blue) for Hole tolerance: F7 10 20 30 40 50

the same nominal dimension N d

Methods.

Sensitivity Analysis (SA) algorithm: d d/2 IT7(d) IT7(d/2) IT6/2(d/2) F: EI(d) F: EI(d/2) Figure 15: Scaling of the total effects values dependent on d

mm mm m m m m m

variance-based SA, based on Jansens

Figure 10: SA with quality value tensor inferface 10 5 15 12 4 13 10 Interpretation: The relative difference is for

formula. 20 10 21 15 4,5 20 13

Interface SA Simulation model: The simulation model has to translate the 10-20 and 30-40 very high (figure 14). There,

30 15 21 18 5,5 20 16

quality values from the SA algorithm into matching deviation parameters (x,). 40 20 25 21 6,5 25 20

the main contribution of pin/hole_right

50 25 25 21 6,5 25 20 increases significantly (figure 15).

[1] V. Srinivasan, Role of Statistics in Achieving Global Consistency of Tolerances, Proceedings of the 6th CIRP International Seminar on Computer-Aided Tolerancing, University of Twente, Netherlands, 1999.

[2] W. Jorden, W. Schtte, Form- und Lagetoleranzen Handbuch fr Studium und Praxis, 7th edition, Carl Hanser Verlag, Mnchen, 2012.

[3] J. Shah, Conceptual development of form features and feature models, Research in Engineering Design, 2: 93-108, 1991.

[4] G. Ameta, S. Serge and M. Giordano, Comparison of Spatial Math Models for Tolerance Analysis: Tolerance-Maps, Deviation Domain, and TTRS, Jour. of Comp. and Inf. Sc. in Eng., 11(2): 021004, pp. 8, 2011.

[5] Z. Wu, Sensitive Factor for Position Tolerance, Research in Engineering Design, 9: 228-234, 1997.

Lehrstuhl fr Konstruktionstechnik Prof. Dr.-Ing. Sandro Wartzack

You might also like

- Understanding Roundness Measurement TechniquesNo ratings yetUnderstanding Roundness Measurement Techniques7 pages

- Dimensional Management Tolerances GuideNo ratings yetDimensional Management Tolerances Guide27 pages

- Dr. Greg Hetland - Profile Tolerancing Proof of Compliance - Vs - Process FeedbackNo ratings yetDr. Greg Hetland - Profile Tolerancing Proof of Compliance - Vs - Process Feedback38 pages

- Jambeswar's Machining & Metrology GuideNo ratings yetJambeswar's Machining & Metrology Guide119 pages

- Measuring Principles For Geometrical Tolerances: Standard STD 112-0004ENo ratings yetMeasuring Principles For Geometrical Tolerances: Standard STD 112-0004E38 pages

- 22 Geometrical Tolerancing and Datums 2020 Manual of Engineering DrawingNo ratings yet22 Geometrical Tolerancing and Datums 2020 Manual of Engineering Drawing21 pages

- Geometrical Tolerancing in Practice en 10037113No ratings yetGeometrical Tolerancing in Practice en 1003711310 pages

- Interpret The Flatness Control. - Interpret The Straightness Control. - Interpret The Circularity Control. - Interpret The Cylindricity ControlNo ratings yetInterpret The Flatness Control. - Interpret The Straightness Control. - Interpret The Circularity Control. - Interpret The Cylindricity Control23 pages

- ASME Y14.5M-1994: Dimensioning & Tolerancing100% (1)ASME Y14.5M-1994: Dimensioning & Tolerancing56 pages

- CMMs: Essential for Precision IndustriesNo ratings yetCMMs: Essential for Precision Industries35 pages

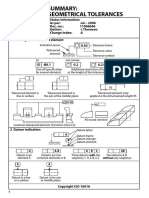

- Summary-Geometrical Tolerance - I - 07-2006 - Rev ANo ratings yetSummary-Geometrical Tolerance - I - 07-2006 - Rev A10 pages

- Design Issues in Mechanical Tolerance AnalysisNo ratings yetDesign Issues in Mechanical Tolerance Analysis22 pages

- Application Monte Carlo Tolerance Stdy 1No ratings yetApplication Monte Carlo Tolerance Stdy 15 pages

- System of Limits, Fits, Tolerance and Gauging PDFNo ratings yetSystem of Limits, Fits, Tolerance and Gauging PDF32 pages

- Mechanical Tolerances in Engineering DrawingsNo ratings yetMechanical Tolerances in Engineering Drawings31 pages

- Geometric Tolerance Analysis: Abstract This Chapter Focuses On Five Main Literature Models of Geometric TolerNo ratings yetGeometric Tolerance Analysis: Abstract This Chapter Focuses On Five Main Literature Models of Geometric Toler31 pages

- Tolerance Analysis in Compressor AssemblyNo ratings yetTolerance Analysis in Compressor Assembly6 pages

- Islamic University of Science and Technology: Calendar 2021No ratings yetIslamic University of Science and Technology: Calendar 202114 pages

- Assessment of The Termination of Construction Contracts in India100% (1)Assessment of The Termination of Construction Contracts in India6 pages

- EVOLIS Twin Plus User Manual EN (English)No ratings yetEVOLIS Twin Plus User Manual EN (English)88 pages

- Vasicoselective Anticholinergics OverviewNo ratings yetVasicoselective Anticholinergics Overview13 pages

- Gte-I Course File III Btech Civil - 173No ratings yetGte-I Course File III Btech Civil - 17348 pages

- Catheter Ablation for Ventricular FibrillationNo ratings yetCatheter Ablation for Ventricular Fibrillation13 pages

- John Deere - Parts Catalog: Printer Friendly PageNo ratings yetJohn Deere - Parts Catalog: Printer Friendly Page60 pages

- Pipeline Integrity Management Training PDFNo ratings yetPipeline Integrity Management Training PDF4 pages

- Class 150 & 300 Ball Valve SpecificationsNo ratings yetClass 150 & 300 Ball Valve Specifications1 page

- Air-Standard Cycle Analysis and ComparisonsNo ratings yetAir-Standard Cycle Analysis and Comparisons28 pages