Professional Documents

Culture Documents

Sampling of The IDG Oil For Analysis PDF

Uploaded by

tanliankiatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sampling of The IDG Oil For Analysis PDF

Uploaded by

tanliankiatCopyright:

Available Formats

Customer : JST Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 427-427

Rev. Date : May 01, 2017

12-32-24-281-001-A - Sampling of the IDG Oil for Analysis

** ON A/C ALL

TASK 12-32-24-281-001-A

Sampling of the IDG Oil for Analysis

WARNING: BE CAREFUL WHEN YOU WORK ON THE ENGINE COMPONENTS IMMEDIATELY AFTER

THE ENGINE IS SHUTDOWN. THE ENGINE COMPONENTS CAN STAY HOT FOR UP TO ONE

HOUR.

WARNING: WEAR GOGGLES, INSULATED GLOVES AND OTHER PROTECTIVE CLOTHES.

HOT OIL CAN BURN YOUR EYES AND SKIN.

IF OIL TOUCHES YOUR EYES OR SKIN, GET MEDICAL AID.

WARNING: REFER TO THE MSDS FOR ALL MATERIAL USED AND THE MANUFACTURER'S SAFETY IN-

STRUCTIONS FOR ALL EQUIPMENT USED. IF YOU DO NOT OBEY THIS WARNING, INJURY

CAN OCCUR.

CAUTION: DO NOT USE SOLVENTS THAT CONTAIN CHLORINE TO CLEAN THE EQUIPMENT (PUMP,

HOSES, TANK AND FUNNEL) USED TO FILL THE IDG WITH OIL.

CHLORINE CONTAMINATION OF THE OIL CAN CAUSE FAST DETERIORATION OF THE OIL

AND WILL DECREASE THE LIFE OF THE IDG.

1. Reason for the Job

To find the cause of the oil contamination (Skydrol, fuel, water, chlorine, oil degradation and other causes).

NOTE: The best location and time to get an oil sample is at the case drain after operation of the engine, when

the IDG oil is at the operating temperature (80 deg.C (176 deg.F)).

2 Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific AR BOTTLE 1L (0,26 USGAL) - TRANSPARENT

No specific AR CONTAINER 10 L(2 1/2 USGAL)

No specific 1 FILLING EQUIPMENT - TANK OIL, DH13PM TYP

No specific AR WARNING NOTICE(S)

No specific Torque wrench: range

to between 55 and 75 lbf.in (0.62 and 0.85 m.daN)

B. Consumable Materials

REFERENCE DESIGNATION

(Material No. 03ABA1) Synthetic base Lubricating Oil-Turbine Engine - -

** ON A/C 001-001, 004-004, 006-006, 008-011, 014-017, 019-150, 201-202, 204-204, 206-602, 604-650

(Material No. 14QFB1) Wire-Locking Dia: 0.8 mm CRES Nickel Alloy -

** ON A/C ALL

C. Work Zones and Access Panels

Print Date: June 29, 2017 Page 1 of 6

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : JST Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 427-427

Rev. Date : May 01, 2017

12-32-24-281-001-A - Sampling of the IDG Oil for Analysis

ZONE/ACCESS ZONE DESCRIPTION

** ON A/C 001-001, 004-004, 006-006, 008-011, 014-017, 019-150, 201-202, 204-204, 206-602, 604-650

FOR 1000EM1 (ENGINE-1)

437AL, 438AR

FOR 1000EM2 (ENGINE-2)

447AL, 448AR

** ON A/C ALL

D. Expendable Parts

FIG.ITEM DESIGNATION IPC-CSN

** ON A/C 001-001, 004-004, 006-006, 008-011, 014-017, 019-150, 201-202, 204-204, 206-602, 604-650

3 O-ring 24-21-51-02-020

** ON A/C ALL

E. Referenced Information

REFERENCE DESIGNATION

** ON A/C 001-001, 004-004, 006-006, 008-011, 014-017, 019-150, 201-202, 204-204, 206-602, 604-650

(Ref. 12-13-24-612-011-A). IDG Servicing - Filling of the IDG with Oil or Addition of Oil after a

Level Check

(Ref. 24-21-00-612-044-A). Servicing of the IDG after Oil Chemical Contamination

(Ref. 24-21-00-612-044-A-01). Servicing of the IDG after Oil Chemical Contamination and Extension

of the Oil-Filter Differential-Pressure Indicator (DPI)

** ON A/C ALL

(Ref. 24-42-00-861-001-A). Energize the Ground Service Network from the External Power

(Ref. 24-42-00-862-001-A). De-energize the Ground Service Network Supplied from the External

Power

** ON A/C 001-001, 004-004, 006-006, 008-011, 014-017, 019-150, 201-202, 204-204, 206-602, 604-650

(Ref. 71-13-00-010-010-A). Opening of the Fan Cowls 437AL(447AL),438AR(448AR)

(Ref. 71-13-00-410-010-A). Closing of the Fan Cowls 437AL(447AL),438AR(448AR)

(Ref. 78-30-00-040-012-A). Deactivation of the Thrust Reverser Hydraulic Control Unit (HCU) for

Ground Maintenance

(Ref. 78-30-00-440-012-A). Re-activation of the Thrust Reverser Hydraulic Control Unit (HCU) after

Ground Maintenance

** ON A/C ALL

** ON A/C 001-001, 004-004, 006-006, 008-011, 014-017, 019-100, 201-202, 204-204, 206-300, 351-602,

604-650

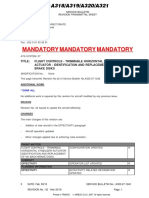

IDG Oil Sampling for Analysis SHEET 1

Print Date: June 29, 2017 Page 2 of 6

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : JST Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 427-427

Rev. Date : May 01, 2017

12-32-24-281-001-A - Sampling of the IDG Oil for Analysis

ENGINE

GEARBOX

6

OVER FLOW

DRAIN HOSE

10ml 4

CONTAINER

0ml

N_MM_123224_3_XAN0_01_00

Figure 12-32-24-991-00100-00-D / SHEET 1/1 - IDG Oil Sampling for Analysis

** ON A/C 001-001, 004-004, 006-006, 008-011, 014-

017, 019-100, 201-202, 204-204, 206-300, 351-602, 604-650

Print Date: June 29, 2017 Page 3 of 6

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : JST Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 427-427

Rev. Date : May 01, 2017

12-32-24-281-001-A - Sampling of the IDG Oil for Analysis

3. Job Set-up

Subtask 12-32-24-861-051-A

A. Energize the ground service network

(Ref. AMM TASK 24-42-00-861-001) .

Subtask 12-32-24-941-050-A

B. Safety Precautions

(1) On the center pedestal, on ENG panel 115VU:

(a) Make sure that the ENG/MODE selector switch is in the NORM position.

(b) Make sure that the ENG/MASTER 1(2) control switch was in the OFF position not less than five

minutes before you do this procedure.

(c) Put WARNING NOTICE(S) in position to tell persons not to operate the ENG/MODE selector

switch and the ENG/MASTER 1(2) control switch.

(2) On the ENG section of maintenance panel 50VU:

(a) Make sure that the ON legend of the FADEC GND PWR/1(2) pushbutton switch is off.

(b) Put WARNING NOTICE(S) in position to tell persons not to energize FADEC 1(2).

** ON A/C 001-001, 004-004, 006-006, 008-011, 014-017, 019-150, 201-202, 204-204, 206-602, 604-650

Subtask 12-32-24-010-050-B

C. Open the fan cowls (Ref. AMM TASK 71-13-00-010-010) :

(1) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

(2) FOR 1000EM2 (ENGINE-2)

447AL, 448AR.

Subtask 12-32-24-481-050-B

D. Deactivate the thrust reverser system (Ref. AMM TASK 78-30-00-040-012) .

** ON A/C ALL

4. Procedure

** ON A/C 001-001, 004-004, 006-006, 008-011, 014-017, 019-100, 201-202, 204-204, 206-300, 351-602, 604-650

(Ref. Fig. IDG Oil Sampling for Analysis SHEET 1)

** ON A/C 001-001, 004-004, 006-006, 008-011, 014-017, 019-150, 201-202, 204-204, 206-602, 604-650

Subtask 12-32-24-864-050-A

A. Depressurization of the IDG Case

WARNING: POINT THE OVERFLOW DRAIN HOSE INTO A CONTAINER WHEN YOU CONNECT

THE HOSE TO THE OVERFLOW DRAIN HALF-COUPLING. THIS WILL PREVENT

BURNS FROM THE HOT OIL SPRAY. HOT OIL CAN CAUSE BURNS TO EYES AND

SKIN.

CAUTION: DO NOT USE DEVICES OTHER THAN THE APPROVED OVERFLOW DRAIN-HOSE FIT-

TING. HARD METAL OBJECTS SUCH AS SCREWDRIVERS CAN CAUSE DAMAGE TO

THE OVERFLOW DRAIN HALF-COUPLING SEAT.

(1) Put a CONTAINER 10 L(2 1/2 USGAL) below the IDG.

Print Date: June 29, 2017 Page 4 of 6

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : JST Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 427-427

Rev. Date : May 01, 2017

12-32-24-281-001-A - Sampling of the IDG Oil for Analysis

(2) Remove the dust cap (5) from the overflow drain half-coupling (6).

(3) Put the end of the drain hose of the FILLING EQUIPMENT - TANK OIL, DH13PM TYP in the

CONTAINER 10 L(2 1/2 USGAL).

(4) Do this step to depressurize the IDG case:

(a) Connect the overflow drain hose of the FILLING EQUIPMENT - TANK OIL, DH13PM TYP to the

overflow drain half-coupling (6).

NOTE: Some oil can come out of the overflow drain hose of the FILLING EQUIPMENT - TANK

OIL, DH13PM TYP when you connect it.

Subtask 12-32-24-281-050-B

WARNING: USE GOGGLES WHEN YOU REMOVE OR INSTALL LOCKWIRE. EACH TIME YOU CUT

LOCKWIRE, REMOVE AND DISCARD IT IMMEDIATELY. LOOSE LOCKWIRE CAN CUT

YOU OR MAKE YOU BLIND, AND/OR CAN CAUSE DAMAGE.

B. Oil Sampling

NOTE: Make sure that the oil is not too hot.

(1) Cut and remove the lockwire from the case drain plug (2).

(2) Loosen the case drain plug (2).

(3) Put a BOTTLE 1L (0,26 USGAL) - TRANSPARENT below the case drain port (1).

NOTE: The transparent bottle (4) must be cleaned and sterilized.

(4) Slowly remove the case drain plug (2) until oil flows out of the case drain port (1).

(5) Fill the transparent bottle (4) with approximately 20 ml (0.053 USgal) of oil.

(6) Seal the case drain port (1).

(7) Remove the O-ring (3) from the case drain plug (2) and discard it.

Subtask 12-32-24-640-050-B

C. Lubricate the new IPC -CSN (24-21-51-02-020) O-ring (3) with Synthetic base Lubricating Oil-Turbine

Engine - - (Material No. 03ABA1).

Subtask 12-32-24-420-050-B

D. Installation of the Case Drain Plug

(1) Install the new O-ring (3) on the case drain plug (2).

(2) Install the case drain plug (2) in the case drain port (1).

(3) TORQUE the case drain plug (2) to between 55 and 75 lbf.in (0.62 and 0.85 m.daN).

(4) Safety the case drain plug with the Wire-Locking Dia: 0.8 mm CRES Nickel Alloy

- (Material No. 14QFB1).

Subtask 12-32-24-281-051-F

E. IDG Oil-Sample Analysis

(1) Send the oil sample bottle to laboratory immediately with these data:

(a) Oil sampling date

(b) Type and brand of oil used

Print Date: June 29, 2017 Page 5 of 6

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : JST Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 427-427

Rev. Date : May 01, 2017

12-32-24-281-001-A - Sampling of the IDG Oil for Analysis

(c) Operating time since last oil sampling

(d) IDG total operating-time

(e) Identification of the IDG (Serial Number).

NOTE: If you do not do the analysis immediately, seal the bottle.

(2) When you get the results of the IDG oil-sample analysis, compare them with the IDG "Oil

Contamination Limits" values (maximum values) given in the Standard Practices Manual (SPM)

(V99167) 24-10-00 chapter "TESTING", paragraph "Oil Condition":

(a) If the results of the IDG oil-sample analysis are less than or equal to the IDG "Oil Contamination

Limits" (maximum values):

No more maintenance is necessary.

(b) If one of the results of the IDG oil-sample analysis is more than the IDG "Oil Contamination

Limits" (maximum values):

Do the servicing of the IDG after oil chemical contamination (Ref. AMM TASK 24-21-00-612-

044) .

Subtask 12-32-24-080-050-A

F. Remove the Overflow Drain Hose

(1) Disconnect the overflow drain hose of the FILLING EQUIPMENT - TANK OIL, DH13PM TYP from the

overflow drain half-coupling (6).

(2) Install the dust cap (5) on the overflow drain half-coupling (6).

Subtask 12-32-24-612-050-B

G. Fill the IDG with oil or add oil to the IDG after a level check (Ref. AMM TASK 12-13-24-612-011) .

** ON A/C ALL

5. Close-up

** ON A/C 001-001, 004-004, 006-006, 008-011, 014-017, 019-150, 201-202, 204-204, 206-602, 604-650

Subtask 12-32-24-410-050-B

A. Close Access

(1) Make sure that the work area is clean and clear of tools and other items.

(2) Activate the thrust reverser system (Ref. AMM TASK 78-30-00-440-012) .

(3) Close the fan cowls (Ref. AMM TASK 71-13-00-410-010) :

(a) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

(b) FOR 1000EM2 (ENGINE-2)

447AL, 448AR.

(4) Remove the warning notice(s).

** ON A/C ALL

Subtask 12-32-24-862-051-A

B. De-energize the ground service network

(Ref. AMM TASK 24-42-00-862-001) .

End of document

Print Date: June 29, 2017 Page 6 of 6

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

You might also like

- Golden Dawn 2 9 The Moon BreathDocument4 pagesGolden Dawn 2 9 The Moon BreathF_RCNo ratings yet

- Shuttle Crew Operations Manual PDFDocument1,161 pagesShuttle Crew Operations Manual PDFNenadSpasovicNo ratings yet

- Lightning and Lightning ProtectionDocument5 pagesLightning and Lightning ProtectionrojofreNo ratings yet

- Change Idg Oil FilterDocument5 pagesChange Idg Oil FilterRindang Sitanggang100% (1)

- FE-V2500-1IA - Glossary of TermsDocument19 pagesFE-V2500-1IA - Glossary of TermsnegrotettNo ratings yet

- Assignment 12Document7 pagesAssignment 12Anonymous mqIqN5zNo ratings yet

- Captured Ammunition Bulletin No 1Document34 pagesCaptured Ammunition Bulletin No 1roberto porto100% (1)

- Sampling of The IDG Oil For Analysis PDFDocument6 pagesSampling of The IDG Oil For Analysis PDFtanliankiatNo ratings yet

- Sampling of The IDG Oil For Analysis PDFDocument6 pagesSampling of The IDG Oil For Analysis PDFtanliankiatNo ratings yet

- Idioms and Phrases MCQs - English Grammar For Competitive ExamsDocument6 pagesIdioms and Phrases MCQs - English Grammar For Competitive ExamsgeologistlakhanNo ratings yet

- Bonding, Grounding or EarthingDocument9 pagesBonding, Grounding or EarthingpannNo ratings yet

- On A/C All: Reference Qty DesignationDocument6 pagesOn A/C All: Reference Qty DesignationMak OrNo ratings yet

- Amm - 12 14 32 614 001 ADocument3 pagesAmm - 12 14 32 614 001 Araiday84No ratings yet

- A318/A319/A320/A321: Service BulletinDocument17 pagesA318/A319/A320/A321: Service BulletinPradeep K s100% (1)

- Uncommanded Ram Air Turbine (RAT) ExtDocument16 pagesUncommanded Ram Air Turbine (RAT) Extpann100% (1)

- CFM Doc Leap 1B Cid Eng Eb 3 V1Document41 pagesCFM Doc Leap 1B Cid Eng Eb 3 V1Paulo SanzNo ratings yet

- Pre-Flight / Transit Check: AIRBUS A320-214 & A320-232 Maintenance Check ListDocument5 pagesPre-Flight / Transit Check: AIRBUS A320-214 & A320-232 Maintenance Check ListrameshneupaneNo ratings yet

- AMM 10-30-00-554-804-A - Return To Operation After A Parking PeriodDocument9 pagesAMM 10-30-00-554-804-A - Return To Operation After A Parking PeriodAndres MendezNo ratings yet

- ATR72 Maintenance Manual Zones & FramesDocument10 pagesATR72 Maintenance Manual Zones & FramesRonald OngNo ratings yet

- Biologic License ApplicationDocument16 pagesBiologic License ApplicationJean Sandra PintoNo ratings yet

- 32-41!11!400-801-A - Installation of The MLG WheelDocument10 pages32-41!11!400-801-A - Installation of The MLG Wheelrüşdi işlerNo ratings yet

- Iodine Summaryupdate 2016Document26 pagesIodine Summaryupdate 2016FrankNo ratings yet

- Apu Load Control Valve R IDocument7 pagesApu Load Control Valve R IBoeing MaxNo ratings yet

- Water Spray Nozzle: Fire Fighting Equipment Data SheetDocument7 pagesWater Spray Nozzle: Fire Fighting Equipment Data SheetJosef MadronaNo ratings yet

- Exterior Inspection B737-800Document14 pagesExterior Inspection B737-800Me KeenNo ratings yet

- 4Document17 pages4Jai DeepNo ratings yet

- B737 Ch70 STD PracticesDocument21 pagesB737 Ch70 STD PracticesAhmed Abdoul ZaherNo ratings yet

- Jetstar Sharklets - PowerPointDocument53 pagesJetstar Sharklets - PowerPointtanliankiatNo ratings yet

- ETOPS Qualified Course Jan 14 PDFDocument44 pagesETOPS Qualified Course Jan 14 PDFtanliankiatNo ratings yet

- Reference: Issue Date: Last Check Date: Status: A/C Type/serie: Ata: Engine Manufacturer: Supplier: Purpose / Reason For Revision: StatusDocument11 pagesReference: Issue Date: Last Check Date: Status: A/C Type/serie: Ata: Engine Manufacturer: Supplier: Purpose / Reason For Revision: StatusNimesh Delan100% (1)

- 29.00.00004 28-JUN-2019 21-JAN-2021 Open A318, A319, A320, A321 29-00 UpdateDocument26 pages29.00.00004 28-JUN-2019 21-JAN-2021 Open A318, A319, A320, A321 29-00 Updatesaid PalaoNo ratings yet

- Dy CHK - 400 2015 New 737 BOOK NG 00 103Document23 pagesDy CHK - 400 2015 New 737 BOOK NG 00 103Syed Salman UddinNo ratings yet

- General Practices Manual Maintenance Procedures Aircraft Wheel BearingsDocument26 pagesGeneral Practices Manual Maintenance Procedures Aircraft Wheel Bearingskien Duy PhanNo ratings yet

- EfcsDocument4 pagesEfcsJai DeepNo ratings yet

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Document6 pagesAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanNo ratings yet

- Job Card: 21-26-00-040-002-A - Deactivation of The Skin Air Outlet Valve in The Closed Position With The Inter..Document10 pagesJob Card: 21-26-00-040-002-A - Deactivation of The Skin Air Outlet Valve in The Closed Position With The Inter..billyNo ratings yet

- A320 STD 1.6.0 Service Bulletin (D00621300)Document11 pagesA320 STD 1.6.0 Service Bulletin (D00621300)Bambi513No ratings yet

- SB 27-1242 r02Document62 pagesSB 27-1242 r02ame7871No ratings yet

- Leap Eng Oil ServicingDocument6 pagesLeap Eng Oil ServicingRameswar PradhanNo ratings yet

- Aircraft Maintenance Manual: TASK 12 13 24 610 801 Servicing of The IDGDocument12 pagesAircraft Maintenance Manual: TASK 12 13 24 610 801 Servicing of The IDGCHIMONo ratings yet

- Service Letter Atr72: TITLE: Air Conditioning - General Guidelines For Transporting Dry IceDocument12 pagesService Letter Atr72: TITLE: Air Conditioning - General Guidelines For Transporting Dry IcePradeep K sNo ratings yet

- 29-11-000-2 Hydraulic System A - Maintenance PracticesDocument13 pages29-11-000-2 Hydraulic System A - Maintenance PracticesJoel CordovaNo ratings yet

- Airbus: AdvanceDocument29 pagesAirbus: AdvanceLeonid Gurulev100% (1)

- ATR FAMILY Septembre2014Document122 pagesATR FAMILY Septembre2014Anonymous gMgeQl1SndNo ratings yet

- DGAC-INDONESIA List of Airworthiness Directives 2010Document63 pagesDGAC-INDONESIA List of Airworthiness Directives 2010Estevam Gomes de AzevedoNo ratings yet

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Document5 pagesAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanNo ratings yet

- FOIM 2019 03 Engine-Cool-down-time Issue 2Document8 pagesFOIM 2019 03 Engine-Cool-down-time Issue 2ralfair16No ratings yet

- A320 Pressurization Test of FuselageDocument1 pageA320 Pressurization Test of FuselageAhmed Abdoul ZaherNo ratings yet

- Apu Oil Filter ReplacementDocument9 pagesApu Oil Filter ReplacementRameswar PradhanNo ratings yet

- Aircraft Anti-Icing SystemDocument3 pagesAircraft Anti-Icing SystemVejay RamNo ratings yet

- A320 AC SystemDocument41 pagesA320 AC SystemCaio MourãoNo ratings yet

- Aircraft Maintenance ManualDocument10 pagesAircraft Maintenance ManualPPC LINE9No ratings yet

- IAD - A318 - A319 - A320 - A321 - AMM - 01-Aug-2021 - 29-00-00-790-001-A - Check of The External Leaks of The Hydraulic ComponentsDocument12 pagesIAD - A318 - A319 - A320 - A321 - AMM - 01-Aug-2021 - 29-00-00-790-001-A - Check of The External Leaks of The Hydraulic ComponentsMONOJ ANo ratings yet

- HAECO Job Applicant Declaration Form - FORM0W00086R01 - 202305 (AGUNG.P)Document2 pagesHAECO Job Applicant Declaration Form - FORM0W00086R01 - 202305 (AGUNG.P)tenhero92No ratings yet

- JCP TitleDocument14 pagesJCP Titlebilly100% (1)

- Square Gasket PDFDocument2 pagesSquare Gasket PDFGoutam SahaNo ratings yet

- Differences Between MRB, MPD and Aircraft Weight RequirementsDocument2 pagesDifferences Between MRB, MPD and Aircraft Weight RequirementsKelik ArifNo ratings yet

- Service Bulletin Atr72: Transmittal Sheet Revision No. 12Document16 pagesService Bulletin Atr72: Transmittal Sheet Revision No. 12Pradeep K sNo ratings yet

- Electropump Removal: Job Card Package Title: IW7 - ATR72 Tail Number - MSN ALLDocument6 pagesElectropump Removal: Job Card Package Title: IW7 - ATR72 Tail Number - MSN ALLJakaria TariganNo ratings yet

- A320-Mel-Cdl-Cdd StatusDocument18 pagesA320-Mel-Cdl-Cdd StatusvproNo ratings yet

- 00 Ground Handling PDFDocument6 pages00 Ground Handling PDFlsthanhlsthanhNo ratings yet

- Cosmetic Condition of Fan Exit Guide VanesDocument1 pageCosmetic Condition of Fan Exit Guide VanesRanjit ShawNo ratings yet

- Product Overview: Naples, May 25th 2011Document39 pagesProduct Overview: Naples, May 25th 2011Mohd Shahril Abd LatiffNo ratings yet

- A320-27-1247 R0 - Config 001Document85 pagesA320-27-1247 R0 - Config 001Edson Carvalho100% (1)

- Technical Procedures Manual Part 2 - : Aircraft Arrival ProcedureDocument4 pagesTechnical Procedures Manual Part 2 - : Aircraft Arrival ProcedureMichael EnriquezNo ratings yet

- Sanitation of The Water Tank and Distribution System: Mech. InspDocument8 pagesSanitation of The Water Tank and Distribution System: Mech. Inspaashishpatel_avdvaNo ratings yet

- Task Card JT8D (Install Fan Blade)Document3 pagesTask Card JT8D (Install Fan Blade)Raden BurhanNo ratings yet

- Difference between Airbus and Boeing auto thrust systemsDocument2 pagesDifference between Airbus and Boeing auto thrust systemsŞevval Yalın100% (1)

- Iran Aseman Airlines Flight 3704Document4 pagesIran Aseman Airlines Flight 3704Yair FernanNo ratings yet

- PMDG 737NGX Paint Kit PDFDocument10 pagesPMDG 737NGX Paint Kit PDFjjgpNo ratings yet

- Oil FilterDocument4 pagesOil FilterRameswar PradhanNo ratings yet

- VQW RTN Sample #3 PDFDocument3 pagesVQW RTN Sample #3 PDFtanliankiatNo ratings yet

- 我愛他Document2 pages我愛他tanliankiatNo ratings yet

- Shi Nian ChordsDocument1 pageShi Nian ChordsVo Haianh0% (1)

- Module 1Document30 pagesModule 1versineNo ratings yet

- Cloud ChartDocument1 pageCloud CharttanliankiatNo ratings yet

- Accepted Manuscript: Process Safety and Environment ProtectionDocument51 pagesAccepted Manuscript: Process Safety and Environment Protectionimran shaukatNo ratings yet

- TCB E-F 015cukDocument2 pagesTCB E-F 015cukTempcoNo ratings yet

- Magellans of The Sky - Prologue - Summer 2010Document12 pagesMagellans of The Sky - Prologue - Summer 2010Prologue MagazineNo ratings yet

- Catalog INSIZE - Instrumente de MasuraDocument32 pagesCatalog INSIZE - Instrumente de MasuraSculegero0% (1)

- Image Processing Based Leaf Rot Disease, Detection of Betel Vine (Piper Betlel.)Document7 pagesImage Processing Based Leaf Rot Disease, Detection of Betel Vine (Piper Betlel.)ManiNo ratings yet

- Changing Landscape and Ecotourism Development in A Large Dam SiteDocument16 pagesChanging Landscape and Ecotourism Development in A Large Dam Siteವಿನಯ್ ಎಮ್. ಆರ್No ratings yet

- Physical Activity Guidelines Advisory Committee ReportDocument683 pagesPhysical Activity Guidelines Advisory Committee Reportyitz22100% (1)

- Alaina W - Food Project ReflectionDocument1 pageAlaina W - Food Project Reflectionapi-438601399No ratings yet

- Chapter 16 - Gripping IFRS ICAP 2008 (Solution of Graded Questions)Document33 pagesChapter 16 - Gripping IFRS ICAP 2008 (Solution of Graded Questions)Falah Ud Din SheryarNo ratings yet

- Eliminating False Detection: Sensing Guide Pulse Level SensorDocument16 pagesEliminating False Detection: Sensing Guide Pulse Level SensorRafael MirandaNo ratings yet

- Financing of New EnterpriseDocument8 pagesFinancing of New EnterpriseSunil BhamuNo ratings yet

- Bs. in P&O India. Syllabus 2010Document58 pagesBs. in P&O India. Syllabus 2010Priscila Arriagada PulgarNo ratings yet

- A Study On Renewable Energy Resources in IndiaDocument39 pagesA Study On Renewable Energy Resources in IndiaDevendra SharmaNo ratings yet

- Aula 4 - Wooten - Organizational FieldsDocument28 pagesAula 4 - Wooten - Organizational FieldsferreiraccarolinaNo ratings yet

- Guide 111: International Electrotechnical CommissionDocument7 pagesGuide 111: International Electrotechnical CommissionSayyid JifriNo ratings yet

- Flow Forming PresentatiionDocument24 pagesFlow Forming PresentatiionSrinivas Ds100% (1)

- Fire Crunch. M 08 Bushfire Attack Level BAL FZ TestedDocument3 pagesFire Crunch. M 08 Bushfire Attack Level BAL FZ TestedTimaiagNo ratings yet

- 60d068822a861e19f4179ec9 - 11. Consensus - Local Cerberus - CompressedDocument1 page60d068822a861e19f4179ec9 - 11. Consensus - Local Cerberus - Compressedhombre pocilgaNo ratings yet

- Instapdf - in Bangalore Tourist Places List 674Document31 pagesInstapdf - in Bangalore Tourist Places List 674R K PathamNo ratings yet

- MODULE-2-VETTECH325 (2)Document31 pagesMODULE-2-VETTECH325 (2)cejproiloNo ratings yet

- Practical 7 - Angiosperms Marking Guide Exercise 1: Class DicotyledonsDocument3 pagesPractical 7 - Angiosperms Marking Guide Exercise 1: Class DicotyledonsDitiro Maletsanake50% (2)

- 16 Balance TestDocument15 pages16 Balance Testelga saniNo ratings yet