Professional Documents

Culture Documents

Responsibilities Legend SITE TEST REPORT

Uploaded by

Abdul RahmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Responsibilities Legend SITE TEST REPORT

Uploaded by

Abdul RahmanCopyright:

Available Formats

Respon

sibilities

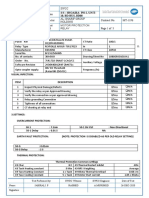

Legend SITE TEST REPORT DATE : 3/08/2017

CSD

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 1 of 18

T12

GENERAL INFORMATION.

TRANSFORMER NAME PLATE DETAILS:

Serial No : 024041501

Make : ELSEWEDY TRAFO Rating Power : 20 MVA

Rated Voltage : 33/13.8 KV Rated Current : 349.91/836.74 A

Number of Phases : 3 Standard : IEC 60076

Rated Frequency : 60 Hz Type of Cooling : ONAF

Vector Group : YN yn0 Oil Temperature Rise : 45C

Winding Temp Rise : 50 C Design Ambient Temp : 55 C

Total Mass : 37500 Kg Total Mass : 137500 Kg

Transport mass with Oil : 32100 Kg Mass of Oil : 9000 kg

TAP CHANGER POSITION 5

SHORT CIRCUIT IMPEDANCE 7.95 %

REFERENCE POWER 20 MVA

TAPPING RANGE 33 KV (33(+4&-7)X1.43%)/13.8KV

HV LV

TAPPING VOLTAGE CURRENT(A) VOLTAGE CURRENT(A)

POSIION V V

20MVA 20MVA

1 34888 330.98

2 34416 335.52

3 33944 340.18

4 33472 344.97

5 33000 349.91

6 32528 354.98 13800 836.74

7 32056 360.21

8 31584 365.69

9 31112 371.14

10 30640 376.85

11 30169 382.75

12 29697 388.83

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 2 of 18

T12

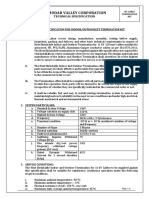

INSULATION LEVEL

1 H.V LINE TERMINAL L1/AC KV 170/70

2 H.V NEUTRAL TERMINAL L1/AC KV 170/38

3 L.V LINE TERMINAL L1/AC KV 95/38

4 L.V NEUTRAL TERMINAL L1/AC KV 95/38

MECHANICAL CHECK AND VISUAL INSPECTION.

ITEM DESCRIPTION DONE REMARKS

1 Check the impact Recorder for any abnormal impact during transit. OK

2 Check all components are installed. OK

Check quality of paint, lifting lugs, quality of weld areas rust spots and wheel OK

3

stoppers.

4 Check nameplates information ( visible place )as per contract specifications OK

5 Check tightness of all bolts (torque wrench method). OK

Check that all groundings are securely connected. OK

6 (at least two grounding points to main tank are available)

7 Check that the piping to Buchholz relay has proper slop. OK

8 Check that the tank pressure is positive.( if applicable ) OK

9 Check the valves between the tank and radiator (To be open). OK

Check the HV LV and Tertiary (if applicable) bushing for any damage and OK

10

completeness.

11 Check the color (to be blue) and quantity of silica gel in breather and oil pot level. OK

12 Check heaters and humidity meters in local panel at correct setting. OK

13 Check phase marking in cable box and it should match with GIS and cables. OK

14 Check all pipes hoses and fan protection (not rubber or plastic). OK

Check the vertical horizontal clearances of live parts to adjacent grounded point to OK

15

conform standard.

16 Check integrity of diaphragm / air bag in the conservator. OK

17 Perform all of the manufacturer specific checks. OK

18 Check labeling of all auxiliary devices as per approved drawing. OK

19 Check proper operation of all auxiliary devices as follows :

a. Tap changer ( upper lower out of step and interlock)

b. Oil level gauges.

c. Top oil temperature gauges.

d. Winding temperature gauge

e. OLTC Oil / Gas surge (pressure) relay.

f. Pressure relief device.

g. Push buttons and indicators.

h. Oil sampling port (main tank & OLTC).

i. Upper and lower main tank valves.

j. Tap changer diverter switch compartment, oil filtering pumps and filter in

good condition (if available).

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 3 of 18

T12

k. Cooling fans / pumps (for all settings).

l. Buchholz relay

20 Check Oil leakage by applying 0.35kpa over pressure for 24 hrs. OK

21 Check that the sampling devices are reachable. OK

Check oil level in main tank, conservator, tap changer tank and bushing etc. test the OK

22

oil level gauges and their alarms.

23 Bleed trapped air at the bushing turrets and tank top. OK

24 Check flow of oil in flow meter in correct direction and proper rate (if applicable ) OK

25 Check all external wiring for correctness and tightness. OK

Check on line insulating oil dissolved gas and ,moisture monitoring system OK

26

(if installed )

27 Check pocket of temperature sensors have oil inside OK

ELECTRICAL TESTS:

ITEM DESCRIPTION DONE REMARKS

1. Core insulation resistance test. OK

2. Winding insulation resistance test and Polarization Index test at 5 kV DC. OK

3. Winding resistance test (all taps). OK

4. Excitation current measurements test at 10 KV. OK

5. Insulation power factor and bushing test at 10 kV AC. OK

6. Vector relationship test. OK

Winding temperature device test by heating the sensor in oil bath . Also check OK

7.

by current injection. Setting as per approved drawing to be applied and tested.

Oil temperature device to be calibrated by heating in oil bath. Setting as per OK

8.

approved drawing to be applied and tested.

9. Percentage Impedance test (at Low, Normal and High taps.) OK

10. Turns Ratio Test.(all taps). OK

11. Magnetic Balance Test. (at Low, Normal and High taps.) OK

On load tapchanger tests : OK

a. Check current and voltage ratings of Tap changer motor.

b. Raise/Lower control (Local remote) and indication , and perform

adjustment as required.

c. End of tap travel control.

d. End of winding travel control (both ends).

e. AVR setting of bandwidth, mid point, time delay , etc., and adjust as per

approved setting.

12.

f. Master/ Slave check out of step blocking alarm.

g. Master/ Slave control check either transformer as master.

h. Parallel operation Disturbed check alarm.

i. Check that the windings are not open circuited during tap changing.

This should be done during the winding resistance test.

13. Cooling System Check. OK

Check for current and voltage ratings of all motors for tap changer and fans OK

14. match to SEC standard supply. Check that MCBs for protection are set at proper

overload settings.

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 4 of 18

T12

Fan motor currents shall be measured and checked against rating. Check wiring OK

15.

size is adequate to carry the current.

Check that the phase sequence of supply voltage to fan motors is correct. Check OK

16. fan rotation direction and confirm and air flow is towards Radiator.

MCBs in cooler control cubicle to be checked by current injection for alarm and OK

17.

trip.

Bushing current transformer tests : OK

a. Polarity.

b. Insulation resistance.

c. Secondary winding resistance (all windings and all taps).

d. Current Ratio (inject current).

18. e. Magnetization Characteristics (Minimum five points below and two points

above the knee point).

f. Verify secondary circuits, terminal to terminal.

g. Burden test.

Demagnetize CT cores after all tests. Ensure no open circuit on CT

secondary side.

Functional checks for the following : OK

a. Liquid level (alarm and trip).

b. Top oil temperature device: fans/ (stop, start alarm and trip).

19. c. Winding temperature Device.

d. Buchholz Relay (alarm and trip).

e. Oil/ Gas surge (pressure) relay (alarm and trip).

f. Pressure relief device (alarm and trip).

Insulating Oil Tests : OK

Prior to energization , the contractor shall submit insulating oil test reports

tested at an independent laboratory , for the following :

a. Dielectric strength

1. ASTM D 877 (2.5 mm gap) for unprocessed oil and for OLTC oil.

2. ASTM D 1816 (1.0 mm gap) for oil in Main tank.

b. Acid Neutralization Number (ASTM D 974).

c. Interfacial Tension (ASTM D 971).

20. d. Color (ASTM D 1500).

e. Moisture content (ASTM D 1533).

f. Power Factor Test (ASTM D 924).

g. Dissolved gas in oil Analysis (ASTM D3 612).

H. Dielectric dissipation factor, resistivity, sediment and /or perceptible

sludge.

Another Oil sample shall be given to SEC transmission for their own

analysis and comparison purposes. Asyringe oil sample shall be taken by

contractor.

A Main tank insulation Oil sample for dissolved gas analysis shall be taken OK

immediately prior to first energizing

21.

a power transformer and another sample three days after continuous

energization.

ELECTRICAL TEST:

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 5 of 18

T12

1. CORE INSULATION RESISTANCE MEASUREMENT

Oil Temperature:- 25

Amb. Temp. : 25

Voltage applied : 1000 V DC Acceptable Value: - 200 M OR Above

CORE TO EARTH FRAME TO EARTH CORE TO FRAME

2. WINDING INSULATION RESISTANCE MEASUREMENT:

Oil Temp : 25 C

Amb. Temp : 25 C

Voltage Applied : 5000 V Acceptable Value: - > 200 M

MEASURED INSULATION RESISTANCE (G)

TIME

HV EARTH( LV GROUND) LV EARTH (HV GROUND) HV LV

1 Minute

10Minute

PI=10min:

1 min:

Acceptable Value for Polarization Index = Not less than 1.25

Equipment Used : Insulation Resistance Tester

Make :

Model No. / Sl. No. :

Calibration Date :

Next Calibration Date :

3. VECTOR RELATIONSHIP TEST.

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 6 of 18

T12

Vector Group of Transformer : YNyn0 Oil Temp. : 21

Amb. Temp. : 25

Transformer was excited from H.V. winding with a suitable Low three phase power supply and Vector Group checked.

VECTOR RELATIONSHIP TEST.

Vector Group of Transformer : YNyn0

Transformer was excited from H.V. winding with a suitable Low three phase power supply and Vector Group checked.

Short 1U and 2U in transformer.

VECTOR DIAGRAM PLOT 1U,2U

2N

2W 2V

1N

1W 1V

MEASUREMENT: TAP NO: 1

1U-1N 1V-1N 1W-1N 1U-1V 1V-1W 1W-1U 2U-2N 2V-2N 2W-2N

1U-2U 1V-2U 1W-2U 1N-2U 2U-2V

1U-2V 1V-2V 1W-2V 1N-2V 2V-2W

1U-2W 1V-2W 1W-2W 1N-2W 2W-2U

1U-2N 1V-2N 1W-2N 1N-2N

Relationship required

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 7 of 18

T12

MEASUREMENT: TAP NO: 5

1U-1N 1V-1N 1W-1N 1U-1V 1V-1W 1W-1U 2U-2N 2V-2N 2W-2N

123.6 124.3 124.6 213.8 215.3 214.5 51.53 51.74 51.87

1U-2U 1V-2U 1W-2U 1N-2U 2U-2V

1U-2V 1V-2V 1W-2V 1N-2V 2V-2W

1U-2W 1V-2W 1W-2W 1N-2W 2W-2U

1U-2N 1V-2N 1W-2N 1N-2N

Relationship required

MEASUREMENT: TAP NO: 12

1U-1N 1V-1N 1W-1N 1U-1V 1V-1W 1W-1U 2U-2N 2V-2N 2W-2N

1U-2U 1V-2U 1W-2U 1N-2U 2U-2V

1U-2V 1V-2V 1W-2V 1N-2V 2V-2W

1U-2W 1V-2W 1W-2W 1N-2W 2W-2U

1U-2N 1V-2N 1W-2N 1N-2N

Relationship required

Equipment Used : Multimeter

Make : Fluke

Model No. / Sl. No. : 179/ 23350081

Calibration Date : 25/03/2016

Next Calibration Date : 24/03/2017

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 8 of 18

T12

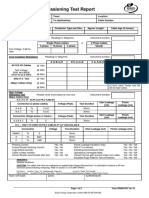

1. WINDING TEMPERATURE INDICATOR TEST

A. CALIBRATION BY CURRENT INJECTION (THERMAL IMAGE TEST)

METHOD:

1. Connect the current injection source on the heater element of winding temperature.

2. Note the initial temperature of winding temperature indicator before any injection.

3. Inject the full load current (secondary value) in the heater element of winding temperature indicator.

4. Keep on injecting the full load current for 40 minutes and observe the increase in temperature at regular intervals (5

minutes).

5. Note the value of temperature after 40 minutes.

6. Calculate the temperature increment by subtracting the initial temperature value from the 40 minute reading.

7. Compare this temperature increment value from the manufacturer data.

DIAGRAM:

Built in Variable Resistor

Current Injection

Source

Heater Element

Winding Temperature Indicator

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 9 of 18

T12

WTI H.V TYPE OF TEMPRATURE GAUGE: AKM-35

Instrument : SINGLE PHASE RELAY KIT

Make : MEGGER

Model No/ Sr. No : SVERKER 780/ 1301356

Calibration Date : 25/11/2016

Calibration Due Date : 24/11/2016

CT RATIO:

Full Load Secondary Current, I1= 2 A

HEATER TEST

Heater Current, I2 = 2 A

INJECTED FULL LOAD CURRENT 2A

I2 / I1 = 450/ 2A

INITIAL TEMPRETURE READING 25 C

STEADY TEMP. AFTER 40 MINS 50 C

TEMPERATURE INCREMENT 25 C

CT RATIO:

WTI L.V

HEATER TEST

Full Load Secondary Current, I1=2 A

INJECTED FULL LOAD CURRENT 2 Amp

Heater Current, I2 = 2 A

INITIAL TEMPRETURE READING 25 c

I2 / I1 = 900/ 2A

STEADY TEMP. AFTER 40 MINS 50 c

TEMPERATURE INCREMENT 22 c

B. CALIBRATION OF SENSORS BY HEATING TYPE OF TEMPRATURE GAUGE: AKM-35

Instrument : Drywell

Make : Fuke

Model No : 9140

Calibration Date : 05-09-2015

Calibration Due Date : 04-09-2016

S. No. : B39281

Each sensor will be heated in the heating calibrator and compare and recorded with the instrument reading.

REF. TEMP. C

WTI H2

WTI X2

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 10 of 18

T12

FUNCTIONAL TEST

OPERATION

DEVICE FUNCTION SETTING REMARKS

PICK UP DROP OUT

Start Air Fan OK

WTI(HV) Alarm OK

Tripping OK

OPERATION

DEVICE FUNCTION SETTING REMARKS

PICK UP DROP OUT

Start Air Fan OK

WTI(LV) Alarm OK

Tripping OK

Criteria : Pickup value shall be within 1%

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 11 of 18

T12

2. - OIL TEMPERATURE INDICATOR TEST

B. CALIBRATION OF SENSORS BY HEATING TYPE OF TEMPRATURE GAUGE: AKM-34

Instrument : Drywell

Make : Fluke

Model No : 9140

Calibration Date : 05-09-2015

Calibration Due Date : 04-09-2016

S. No. : B39281

Each sensor will be heated in the heating calibrator and compare and recorded with the instrument reading.

REF. TEMP. C

OTI

FUNCTIONAL TEST

OPERATION

DEVICE FUNCTION SETTING REMARKS

PICK UP DROP OUT

Start Air Fan OK

OTI Alarm OK

Tripping OK

Criteria : Pickup value shall be within 1%

3. COOLING FAN FUNCTION CHECK

Meter used : Leakage Tester

Make : Fluke

Sl.No : 3325010

Calibration Due Date : 3/03/2016

Fan Motor Rating : 0.75kw

Current ( A ) Direction of

Fan No. Serial no Time to Trip with 1 Phase remove out

Starting Running (Amp/Sec) Rotation

1 W0281490/023 OK

2 W0281490/016 OK

3 W0281490/020 OK

4 W0281490/022 OK

5 W0281490/015 OK

Over Load Current setting: 1A Total Current (All Fans Operating) : 6.1 A

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 12 of 18

T12

6.PERCENTAGE IMPEDANCE TEST:

Oil Temp. : 23

Amb. Temp. : 25

Measured Short circuit current in Primary Measured Short circuit current

Applied voltage (volt)

(Ampere) in secondary (Ampere)

Tap

position

Avg.

1U-1N 1V-1N 1W-1N Avg. Volt. 1U 1V 1W 1N Current 2U 2V 2W 2N

12

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 13 of 18

T12

7.OLTC FUNCTION CHECK.

NAME PLATE DETAILS:

Make : MR Type :

No of Taps : 12 Year :

Sl.No. :

ITEM DESCRIPTION REMARKS

1 Perform adjustment of OLTC as per manufacturer's Instruction below. OK

In every operating position the position indicator of motor drive and tap changer read the same OK

I

position.

Ii Check that both end position the electrical and mechanical limits functions automatically. OK

Iii Check oil level in tap changer diverter conservator. OK

V Check condition of silica gel in tap changer breather. OK

Vi Check tightness of ground connection of the tap changer. OK

Vii Check tightness of ground connection for motor drive housing. OK

2 Check stop valves between oil conservator and tap changer are open. OK

Check manual crank position. Check that insertion of crank interlocks prevents electrical OK

3

operation.

4 Ensure heater is connected. OK

5 Check that drive mechanism and tap changer turn in the same direction. OK

Using crank carry out a few steps in one direction till the diverter switch operation takes place OK

6

(a distinct sound is heard). Note the number of crank turns.

7 Check supply voltage for motor, control and auxiliary circuit. OK

Check phase sequence of motor supply voltage and conformed the direction of rotation is OK

8

correct.

With selector in 'LOCAL ' operate 'LOWER' push button and keep it in pushed condition till the OK

motor stops. Make sure that driving motor is automatically switched off when the tap changer

9

has performed one switching operation.

Check operation counter.

10 Repeat the item 9 with push button 'RAISE' kept in pushed condition. OK

11 Check operation counter. OK

Operate to the end position and check that the operation of push button in the same direction OK

12 does not function any more. Ensure that while hand cranking the termination gear will get

blocked after 2-3 revolution of the crank.

OK

13 Put the selector in REMOTE and conformed NO OPERATION from local control.

Check the running current of drive motor. OK

14

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 14 of 18

T12

8.MAGNETIC BALANCE TEST:

Apply Voltage between two phases of H.V. side. Oil Temp : 23 C

Measure the Voltage at H.V. Amb. Temp.: 25 C

TAP NO: 01

ENERGIZED

HV 1U-1N 1V-1N 1W-1N 2U-2N 2V-2N 2W-2N

TERMINALS

1U-1N

1V-1N

1W-1N

TAP NO: 05 Normal

ENERGIZED

HV 1U-1N 1V-1N 1W-1N 2U-2N 2V-2N 2W-2N

TERMINALS

1U-1N

1V-1N

1W-1N

TAP NO: 17

ENERGIZED

HV 1U-1N 1V-1N 1W-1N 2U-2N 2V-2N 2W-2N

TERMINALS

1U-1N

1V-1N

1W-1N

Equipment Used : Multimeter

Make :

Model No. / Sl. No. : 179/ 23350081

Calibration Date : 25/03/2016

Next Calibration Date : 24/03/2

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 15 of 18

T12

9.FUNCTIONAL CHECK OF AUXILIARY EQUIPMENTS

DESCRIPTION TERMINALS FUNCTION

Alarm Low

1.Oil Level Indicator for Tap changer ( +F65 ) X1-10,11 OK

MAN-MR

TYPE:MTO-ST160G/2C0 High Trip

SERIAL NO:1504257 X1-12,13 OK

Alarm Low

2. Oil Level Indicator for Transformer (+F64) X1-6,7 OK

MAN- MR

TYPE-MTO-ST160G/2C0 High Trip

SERIAL NO:150454 X1-8,9 OK

3. Bucholz Relay (F61) Alarm

OK

X1-4,5

MAN- CEDASPE

MODEL- EB079A27N Trip

SERIAL NO-TH0903 X2-1,2 OK

4. Pressure Relief Device Transformer(+F62) Alarm

OK

MAN-CEDASPE X2-3,4

Trip

MODEL: CPR3-MT

X2-5,6 OK

SERIAL NO.TH0903

Alarm

5.OLTC Pressure relief Device(+F63) X2-7,8 OK

MAN-MR

MODEL: 0,65-CD Trip

SERIAL NO.1496307 X2-79,89 OK

6. OIL SURGER (+F66)

MAN- CEDASPE TRIP

OK

MODEL:900-014-02

SERIAL NO.50219000-1-3

Alarm

7.RUBBER BAG LEAKAGE

X1-129,139 OK

MAN- MR

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 16 of 18

T12

Alarm

8.WTI(HV) ( F71 ) X1-14,15

OK

MAN MR

CODE:MT-ST/60SK/TT/4/10M Trip

SERIAL NO.1504252 X2-11,12 OK

Alarm

9 WTI (LV) ( F72 ) X1-16,17 OK

MAN - MR

CODE MT-ST/60SK/TT/4/10M Trip

SERIAL NO.1504251 OK

X2-13,14

Alarm

10.OTI(HV) (F73 ) X1-18,19 OK

MAN MR

CODE: MT-ST/60SK/TT/4/10M Trip

SERIAL NO.1504248 X2-15,16 OK

10.MAGNETIZING CURRENT TEST

Meter used :DELTA4300

Make :MEGGER

Sl.No :

Calibration Date : 2017

HV WINDINGS

TAP# APPLIED VOLTAGE(V) MEASURED CURRENT( mA)

1U-1N 1V-1N 1W-1N IU IV IW

1

2

3

4

5

6

10KV

7

8

9

10

11

12

LV WINDINGS

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 17 of 18

T12

APPLIED VOLTAGE MEASURED CURRENT

2U-2N 2V-2N 2U-2N 2U 2V 2W 2N

2KV

11. DIELECTRIC BREAKDOWN TEST OF OIL

Test Instrument : OIL TESTER

Make : MEGGER

Calibration Date : 29/11/2017

Model / Sl. No. : OTS100AF/101151973

The transformer insulating oil was tested for Dielectric strength using oil tester (ASTM Std.)

1. Transformer main tank top oil sample

Dielectric strength required : 50kv

Oil Temp. In deg. C : 25

Elect

Dielectric Strength ( kV )

rode

No Average Gap Result

Number of Tests (mm)

2. Transformer main tank bottom oil sample

Dielectric strength required : 50kv

Oil Temp. In deg. C : 25

Elect

Dielectric Strength ( kV )

rode

No Average Gap Result

Number of Tests (mm)

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

SITE TEST REPORT DATE : 3/08/2017

Contractor PACOST INTL

7025 33/13.8 KV S/S, RIYADH

Site : SEC COA CONTRACT NO 4400005528

20 MVA , 33/13.8 KV POWER TRANSFORMER Sheet : Page 18 of 18

T12

Transformer OLTC oil sample

Dielectric strength required : 50kv

Oil Temp. In deg. C : 25

Elect

Dielectric Strength ( kV )

rode

No Average Gap Result

Number of Tests (mm)

NOTE: Applicable Standard For Main tank: ASTM D 1816

For OLTC : ASTM D 877

DATE :

Tested By PACOST INTL. Witnessed by SEC-COA-TESTING.

Mr. Mohamad Taguir Mr.

Date & Signature: Date & Signature:

You might also like

- A. Wound Type:: 1. What Are The Types of CT? Example?Document8 pagesA. Wound Type:: 1. What Are The Types of CT? Example?deltavijayakumarNo ratings yet

- Baranagar-TSS Relay Test ReportDocument75 pagesBaranagar-TSS Relay Test ReportHari haranNo ratings yet

- TrafoDocument1 pageTrafoSoumya BhowmickNo ratings yet

- 11 KV Power Cable Site Test Report: (NMGR103 To NMGR104)Document3 pages11 KV Power Cable Site Test Report: (NMGR103 To NMGR104)Gajendran SriramNo ratings yet

- 11KV VCBDocument3 pages11KV VCBeagles1109No ratings yet

- Ac Panel Test ReportDocument14 pagesAc Panel Test ReportUtku Can KılıçNo ratings yet

- CT Test ReportDocument2 pagesCT Test Reportdilipjoshi2000rytoiyNo ratings yet

- Itp For Commissioning Procedure For LV Switchgear SystemDocument4 pagesItp For Commissioning Procedure For LV Switchgear SystemSulimanNo ratings yet

- Transformer stability test for differential and REF protectionDocument2 pagesTransformer stability test for differential and REF protectionykh92167No ratings yet

- MRT and ProtectionDocument4 pagesMRT and ProtectionAlexander AnthonyNo ratings yet

- Dgt801b Gen - Unit ADocument30 pagesDgt801b Gen - Unit ASamraddh TiwariNo ratings yet

- O/C E/F Relay Test ReportDocument2 pagesO/C E/F Relay Test ReportMd. zahidul IslamNo ratings yet

- Commissioning Checks for LV Load Panel at King Abdul-Aziz AirportDocument3 pagesCommissioning Checks for LV Load Panel at King Abdul-Aziz Airporteswaran005No ratings yet

- Pilot Cable Specs FewaDocument13 pagesPilot Cable Specs Fewabharat_22nandulaNo ratings yet

- Cable Testing and Health Monitoring ReportDocument13 pagesCable Testing and Health Monitoring ReportRakesh KumarNo ratings yet

- COMMNG-ELEC-043 HT Motor PrecommissioningDocument6 pagesCOMMNG-ELEC-043 HT Motor PrecommissioningsantoshkumarNo ratings yet

- GVK Power (Goindwal Sahib) Limited, GVK Power (Goindwal Sahib) Limited Thermal Power PlantDocument15 pagesGVK Power (Goindwal Sahib) Limited, GVK Power (Goindwal Sahib) Limited Thermal Power PlantRohit100% (1)

- Electrical Site Tests ProceduresDocument105 pagesElectrical Site Tests ProceduresMohd SalehNo ratings yet

- Data Sheet - Rev.0Document4 pagesData Sheet - Rev.0mahesh reddy mNo ratings yet

- Test Performed By: SWCC Witness: SWCC Engineer: Date of Test Name: Jabirali. P Rashed A.Murshed 26-DEC-2020 SignatureDocument5 pagesTest Performed By: SWCC Witness: SWCC Engineer: Date of Test Name: Jabirali. P Rashed A.Murshed 26-DEC-2020 SignatureAnonymous dH3DIEtzNo ratings yet

- SP0407C01 HV Cable Commissioning Test ReportDocument2 pagesSP0407C01 HV Cable Commissioning Test Reportkajale.shrikantNo ratings yet

- HV Pressure Tests Document SummaryDocument4 pagesHV Pressure Tests Document SummaryssNo ratings yet

- GTP For TransformerDocument5 pagesGTP For TransformerSatheesh Kumar NatarajanNo ratings yet

- Bus PT-1Document2 pagesBus PT-1suraj vishvakarmaNo ratings yet

- Interlock Protection Diary-Tur1Document156 pagesInterlock Protection Diary-Tur1gARRYNo ratings yet

- 22/0.415 KV, 1000KVA TRANSFORMER Technical Specification: Balmer Lawrie & CoDocument13 pages22/0.415 KV, 1000KVA TRANSFORMER Technical Specification: Balmer Lawrie & Coshan shanzNo ratings yet

- 199-GST-0101-RevA - Electrical MV LV Transformers SpecificationDocument14 pages199-GST-0101-RevA - Electrical MV LV Transformers Specificationdhanny ma100% (1)

- National Grid: Checklist For Commissioning of Oil-Immersed Power TransformerDocument8 pagesNational Grid: Checklist For Commissioning of Oil-Immersed Power TransformerSanthosh Kumar VinayagamNo ratings yet

- Transformer ProtectionDocument19 pagesTransformer ProtectionBassem MostafaNo ratings yet

- Motor ProtectionDocument50 pagesMotor ProtectionYajidNo ratings yet

- Vol 2 - C3.4.4 Standard Specifications For Electrical WorksDocument127 pagesVol 2 - C3.4.4 Standard Specifications For Electrical Worksashutosh ambeyNo ratings yet

- Electrical Testing Report Format - SwyrdDocument20 pagesElectrical Testing Report Format - SwyrdSakib Khan100% (1)

- VCB Test Report for Jindal SteelDocument3 pagesVCB Test Report for Jindal SteelvinospaceshuttleNo ratings yet

- T Proc Notices Notices 040 K Notice Doc 39826 154073019 PDFDocument281 pagesT Proc Notices Notices 040 K Notice Doc 39826 154073019 PDFabbastceNo ratings yet

- Directional Overcurrent RelayingDocument23 pagesDirectional Overcurrent RelayingTamjid KabirNo ratings yet

- System Study of 220Kv Switchyard For Phase - Iiib Project: Petronet LNG, DahejDocument34 pagesSystem Study of 220Kv Switchyard For Phase - Iiib Project: Petronet LNG, DahejBrijesh BhadauriaNo ratings yet

- PLCC Tech SpecsDocument42 pagesPLCC Tech Specsevonik123456No ratings yet

- IMS 448-EQCL - Transformer Installation Checklist Rev01Document1 pageIMS 448-EQCL - Transformer Installation Checklist Rev01zhangjieNo ratings yet

- RSC SLDDocument1 pageRSC SLDMichael Parohinog Gregas0% (1)

- Power TransformerDocument55 pagesPower TransformerPrakash KumarNo ratings yet

- Cable Schedule For Shahzada Bagh Bay Extension WorkDocument8 pagesCable Schedule For Shahzada Bagh Bay Extension WorkAnkur SangwanNo ratings yet

- Check List For Testing: Equipment Needed To Be TestedDocument2 pagesCheck List For Testing: Equipment Needed To Be TestedKarthik EvilordNo ratings yet

- DCRP - Questions: Date: 26.08.14Document1 pageDCRP - Questions: Date: 26.08.14deltavijayakumarNo ratings yet

- ACE - 66kV GIS 03.09.2022Document236 pagesACE - 66kV GIS 03.09.2022Chandan KumarNo ratings yet

- Calculatin For Voltage Drop ¤t MV CircuitDocument9 pagesCalculatin For Voltage Drop ¤t MV CircuitSatyaNo ratings yet

- HT Cable Termination Kit 14.3.22Document8 pagesHT Cable Termination Kit 14.3.22JIGSNo ratings yet

- 8.relay Incomer 1Document5 pages8.relay Incomer 1alagurajNo ratings yet

- Method of Statement For TransformerDocument14 pagesMethod of Statement For Transformernasir habibNo ratings yet

- DCRP Written Test QuestionsDocument1 pageDCRP Written Test QuestionsSiva NandhamNo ratings yet

- Ike Electric Pvt. LTD.: System Fault Level Calculation M/S TnebDocument5 pagesIke Electric Pvt. LTD.: System Fault Level Calculation M/S TnebMohan BabuNo ratings yet

- 12kV 800A switchgear specsDocument93 pages12kV 800A switchgear specsSunil EprosysNo ratings yet

- T C Procedure For TransformerDocument11 pagesT C Procedure For TransformerĐặng Xuân ViệtNo ratings yet

- Design Guide FOR Distribution System PlanningDocument19 pagesDesign Guide FOR Distribution System Planningdhairyashil_dspNo ratings yet

- Technical Data 11kV AIS VHIHDocument6 pagesTechnical Data 11kV AIS VHIHSelvin Francis100% (2)

- Site Acceptance Test Report For 11Kv Cable: Project Equipment Client Date Contractor Location Testing CompanyDocument3 pagesSite Acceptance Test Report For 11Kv Cable: Project Equipment Client Date Contractor Location Testing CompanyGajendran SriramNo ratings yet

- Site Inspection and Test Record: 13.8/4.16KV UAT-14 TRAFO RTCC PANELDocument6 pagesSite Inspection and Test Record: 13.8/4.16KV UAT-14 TRAFO RTCC PANELAshraf MohammedNo ratings yet

- 7UT Relay XFMR PROTECTION RelayDocument9 pages7UT Relay XFMR PROTECTION RelayMoin KhanNo ratings yet

- Signature: - Signature: - Name: Name: Mohd Abdul FattahDocument2 pagesSignature: - Signature: - Name: Name: Mohd Abdul FattahafaqNo ratings yet

- 11KV Og FDR-2Document2 pages11KV Og FDR-2Sathi Reddy ThondapuNo ratings yet

- Data Motor & Pump-1Document29 pagesData Motor & Pump-1naspauzanNo ratings yet

- Power Swing BlockingDocument1 pagePower Swing BlockingAbdul RahmanNo ratings yet

- Site Test Report Date: 17-02-2016 Contractor: Pa Cost Int'L 33/13.8 KV Hudayb SubstationDocument2 pagesSite Test Report Date: 17-02-2016 Contractor: Pa Cost Int'L 33/13.8 KV Hudayb SubstationAbdul RahmanNo ratings yet

- Basics of Busbar ProtectionDocument23 pagesBasics of Busbar ProtectionAbdul RahmanNo ratings yet

- Procedure For Testing P643 Transformer Differential Relay: Prepared by Eng: Mohamad TauseefDocument36 pagesProcedure For Testing P643 Transformer Differential Relay: Prepared by Eng: Mohamad TauseefAbdul RahmanNo ratings yet

- Saco 16pmDocument15 pagesSaco 16pmAbdul RahmanNo ratings yet

- The University of Faisalabad: First Merit List For Provisional Admissions in Bachelor of Civil EngineeringDocument1 pageThe University of Faisalabad: First Merit List For Provisional Admissions in Bachelor of Civil EngineeringAbdul RahmanNo ratings yet

- Annunication Panel 4ap2Document6 pagesAnnunication Panel 4ap2Abdul RahmanNo ratings yet

- Saco64d4 en B 2 PDFDocument44 pagesSaco64d4 en B 2 PDFAbdul RahmanNo ratings yet

- Ip Instrument Index ExampleDocument1 pageIp Instrument Index Exampletkdrt2166No ratings yet

- Obeikan OfferDocument6 pagesObeikan OfferAbdul RahmanNo ratings yet

- AC Arabia Office Building Locetion Map ModelDocument1 pageAC Arabia Office Building Locetion Map ModelAbdul RahmanNo ratings yet

- Anti Pumping RelayDocument2 pagesAnti Pumping RelayAbdul RahmanNo ratings yet

- C.T. Jones - Step 7 in 7 Steps PDFDocument468 pagesC.T. Jones - Step 7 in 7 Steps PDFmitrosNo ratings yet

- M 015000 eDocument230 pagesM 015000 eAbdul RahmanNo ratings yet

- Group EDocument24 pagesGroup EAbdul RahmanNo ratings yet

- Topic: 132 KV Substation Bosan Road Multan: Echnical EportDocument28 pagesTopic: 132 KV Substation Bosan Road Multan: Echnical EportTalha Maqsood87% (15)

- HR12-350WL SpecificationDocument2 pagesHR12-350WL SpecificationGeorgeNo ratings yet

- Digital Testing of High Voltage Circuit BreakersDocument16 pagesDigital Testing of High Voltage Circuit BreakersYellaturi Siva Kishore Reddy50% (2)

- Explore Careers and Growth in India's Wires and Cables IndustryDocument37 pagesExplore Careers and Growth in India's Wires and Cables IndustryAnirudhNo ratings yet

- What is transformer rating based on temperature and insulation limitsDocument2 pagesWhat is transformer rating based on temperature and insulation limitsSugeng SumarnoNo ratings yet

- Wiring Diagram For Soft Starters in Motor Control Centers: Technical Data TD03900001EDocument4 pagesWiring Diagram For Soft Starters in Motor Control Centers: Technical Data TD03900001EHazem HassonNo ratings yet

- Review of Dual-Active-Bridge Converters With Topological ModificationsDocument31 pagesReview of Dual-Active-Bridge Converters With Topological ModificationsKenil BrahmbhattNo ratings yet

- Electronic ComponentDocument10 pagesElectronic ComponentVimalaChristinalNo ratings yet

- Tabla 130.7 C 9 A de NFPA 70EDocument4 pagesTabla 130.7 C 9 A de NFPA 70EROLANDO UMAÑANo ratings yet

- 22328-2019-Winter-Question-Paper (Msbte Study Resources)Document4 pages22328-2019-Winter-Question-Paper (Msbte Study Resources)nitinsurwadkar042No ratings yet

- PLC HoneyWellDocument44 pagesPLC HoneyWellJeremy100% (2)

- NTC 5D5 Exsense PDFDocument5 pagesNTC 5D5 Exsense PDFZamfir Vangu100% (1)

- Kretyrx ELECTRICAL Machine NotesDocument873 pagesKretyrx ELECTRICAL Machine NotesRythm100% (1)

- I N T R o D U C T I o NDocument6 pagesI N T R o D U C T I o NManikandan P Engineering EEENo ratings yet

- Cuttler Hammer BreakersDocument66 pagesCuttler Hammer BreakersedgarlimasNo ratings yet

- 12 overhead cranes and gantry cranes quotationDocument6 pages12 overhead cranes and gantry cranes quotationjurieskNo ratings yet

- Electric Motors - Energy Efficiency Reference Guide - CEATI PDFDocument166 pagesElectric Motors - Energy Efficiency Reference Guide - CEATI PDFjwsmith60No ratings yet

- Hanford Electrical Safety Program Arc Flash CalculatorDocument6 pagesHanford Electrical Safety Program Arc Flash CalculatorOscar SchmüthNo ratings yet

- MCB Cap SwitchingDocument2 pagesMCB Cap SwitchingtceterexNo ratings yet

- Best Energy Management for Electric MotorsDocument11 pagesBest Energy Management for Electric MotorsAnielle John MonteroNo ratings yet

- IRD1-G: Differential Protection Relay For Generators and MotorsDocument24 pagesIRD1-G: Differential Protection Relay For Generators and MotorsTaufiqtadNo ratings yet

- Measurement of Electrical Safety for Ultrasonic DeviceDocument9 pagesMeasurement of Electrical Safety for Ultrasonic DeviceMauricioGSNo ratings yet

- Da-2ds/da-4ds: & DB-1MD/DB-1SD PT-1211DR/C/DDocument8 pagesDa-2ds/da-4ds: & DB-1MD/DB-1SD PT-1211DR/C/DChristian AlbertiniNo ratings yet

- Electrical Components For The Railway Industry: Catalog IC 12 Edition 2019Document706 pagesElectrical Components For The Railway Industry: Catalog IC 12 Edition 2019Abraham LópezNo ratings yet

- Irrigation & Hydro ElectricDocument20 pagesIrrigation & Hydro ElectricAYANNo ratings yet

- Gek 131015Document40 pagesGek 131015Emmanuel Entzana HdzNo ratings yet

- 7XV75 Catalog SIP E6Document2 pages7XV75 Catalog SIP E6Van TienNo ratings yet

- Codeofpracticeforearthing: Indian StandardDocument86 pagesCodeofpracticeforearthing: Indian StandardNithinNo ratings yet

- Powertron - Standard Series 1600A, Product Bulletin-3048540000196262Document2 pagesPowertron - Standard Series 1600A, Product Bulletin-3048540000196262Randhir DavidNo ratings yet

- Design of Off Board Electric Vehicle Charger Using PV Array Through Matlab-SimulinkDocument10 pagesDesign of Off Board Electric Vehicle Charger Using PV Array Through Matlab-SimulinkKrishna ReddyNo ratings yet

- E-Line MK 100 160 225 PDFDocument25 pagesE-Line MK 100 160 225 PDFLe'Novo FernandezNo ratings yet