Professional Documents

Culture Documents

Course Content CNC PDF

Course Content CNC PDF

Uploaded by

Sree Vasthava RamichettyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Course Content CNC PDF

Course Content CNC PDF

Uploaded by

Sree Vasthava RamichettyCopyright:

Available Formats

COURSE : CNC TURN-MILL CENTRE - PROGRAMMING & OPERATION

(FANUC Oi-TB)

DURATION : TWO WEEKS

COURSE CONTENTS : THEORY

CNC Machines working principles.

Features of CNC System & Elements of CNC Machines

Concept of CNC Programming

Programming with basic ‘G’ Codes & ‘M’ Codes

Different co-ordinate systems

Measurement of Zero offsets

Part program of Turning- External features and Internal features using built in

Cycles

Part programming of Milling profile with ‘C’ Axis

Selection of Tools, Speed, Feed & Depth of cut

PRACTICALS : Hands on experience on

Windows based CNC Simulator.

Basic Machine Operations

Measurement of Zero offsets.

Editing of part programs

Proving selected programs & Machining of Components

EQUIPMENT PROFILE :

Turn Mill Centre, HMT make, Model : TMC-20 with control Fanuc Oi-TB

Keller - Symplus Soft ware for Simulation

COURSE : CNC TURN-MILL CENTRE - PROGRAMMING & OPERATION

(Sinumerik 802D sl)

DURATION : TWO WEEKS

COURSE CONTENTS : THEORY

CNC Machines working principles.

Features of CNC System & Elements of CNC Machines

Concept of CNC Programming

Programming with basic ‘G’ Codes & ‘M’ Codes

Different co-ordinate systems

Measurement of Zero offsets

Part program of Turning- External features and Internal features using built in

Cycles

Part programming of Milling profile with ‘C’ Axis

Selection of Tools, Speed, Feed & Depth of cut

PRACTICALS :

Hands on experience on Windows based CNC Simulator.

Basic Machine Operations

Measurement of Zero offsets.

Editing of part programs

Proving selected programs & Machining of Components

EQUIPMENT PROFILE :

Turn Mill Centre, ACE Designers make, Model : LT-2LM500MC with control

Siemens Sinumerik 802D sl

Keller - Symplus Soft ware for Simulation

COURSES : CNC TURNING - PROGRAMMING & OPERATION

(Sinumerik 810T)

DURATION : TWO WEEKS EACH

COURSE CONTENTS : THEORY

CNC Machines working principles.

Features of CNC System & Elements of CNC Machines

Concept of CNC Programming

Programming with basic ‘G’ Codes & ‘M’ Codes

Different co-ordinate systems

Measurement of Zero offsets

Part program of Turning with canned cycles

Subroutine programming

Selection of Tools, Speed, Feed & Depth of cut

PRACTICALS : Hands on experience on

Windows based CNC Simulator.

Basic Machine Operations

Measurement of Zero offsets.

Editing of part programs

Proving selected programs & Machining of Components

EQUIPMENT PROFILE :

Turning Centre, Emco make, Model : emcoturn 340 with

control Siemens Sinumerik 810 T

Keller - Symplus Soft ware for Simulation

COURSES : CNC MILLING - PROGRAMMING & OPERATION

(Sinumerik 810M)

DURATION : TWO WEEKS

COURSE CONTENTS : THEORY

CNC Machines working principles.

Features of CNC System & Elements of CNC Machines

Concept of CNC Programming

Programming with basic ‘G’ Codes & ‘M’ Codes

Different co-ordinate systems

Measurement of Zero offsets

Part program of Milling with cutter radius compensation

Selection of Tools, Speed, Feed & Depth of cut

Subroutine programming & Canned cycles

Editing of part programs

Proving selected programs & Machining of Components

PRACTICALS : Hands on experience on

Windows based CNC Simulator.

Basic Machine Operations

Measurement of Zero offsets.

Editing of part programs

Proving selected programs & Machining of Components

EQUIPMENT PROFILE :

Vertical Machining Centre, Emco make, Model : emco VMC-300 with control

Siemens Sinumerik 810 M

Keller - Symplus Soft ware for Simulation

COURSES : ADVANCED CNC MILLING - PROGRAMMING & OPERATION

(Fanuc OM)

DURATION : TWO WEEKS

COURSE CONTENTS : THEORY

CNC Machines working principles.

Features of CNC System & Elements of CNC Machines

Concept of CNC Programming

Preparatory and Miscellaneous Functions / Codes

Different co-ordinate systems

Measurement of Zero offsets

Part program of Milling for linear & Circular interpolation with cutter radius

compensation

Selection of Tools, Speed, Feed & Depth of cut

Subroutine programming, Fixed cycles

Programming – Scaling, Rotation, Mirroring, Helical interpolation, Thread

milling & Cylindrical interpolation

Macro programming

Editing & Proving the part program

PRACTICALS : Hands on experience on

Windows based CNC Simulator.

Basic Machine Operations

Measurement of Zero offsets.

Editing of part programs

Proving selected programs & Machining of Components

EQUIPMENT PROFILE :

Vertical Machining Centre, HMT make, Model : VMC-500 with control

Fanuc OM

Keller - Symplus Soft ware for Simulation

You might also like

- MTS Teachware Cnc-Basics PDFDocument208 pagesMTS Teachware Cnc-Basics PDFHasib ZuhairiNo ratings yet

- Basic Math For CNCDocument10 pagesBasic Math For CNCEdsonNo ratings yet

- General Cutting InsertDocument15 pagesGeneral Cutting Insertvipul mishra100% (1)

- Turning Tools - General InformationDocument22 pagesTurning Tools - General Informationenamicul50No ratings yet

- The Piping and Instrumentation Diagram. (P.&I D.)Document2 pagesThe Piping and Instrumentation Diagram. (P.&I D.)Jack JohnsonNo ratings yet

- Lecture Cad CamDocument84 pagesLecture Cad Camismail_69No ratings yet

- Nettur Technical Training FoundationDocument192 pagesNettur Technical Training FoundationJasopNo ratings yet

- Coffeescript TutorialDocument270 pagesCoffeescript Tutorialviru991No ratings yet

- Chapter 1Document13 pagesChapter 1Pesala WelangalleNo ratings yet

- Welcome: Industrial Trainig Institute. Palana. Centre of ExcellenceDocument100 pagesWelcome: Industrial Trainig Institute. Palana. Centre of ExcellenceAthar MahmoodNo ratings yet

- Probes HeidenhainDocument64 pagesProbes HeidenhainfbalestrinNo ratings yet

- Business Grammar Builder2Document273 pagesBusiness Grammar Builder2Danik ZuNo ratings yet

- Cam Lab ManualDocument14 pagesCam Lab Manualelangandhi0% (1)

- Part Programming Manual PDFDocument80 pagesPart Programming Manual PDFTejas KumarNo ratings yet

- Design and Analysis of Combined Hydraulic Hand-Operated Shear and Bending MachineDocument47 pagesDesign and Analysis of Combined Hydraulic Hand-Operated Shear and Bending MachineSoumen MukherjeeNo ratings yet

- CNC and Part ProgramDocument54 pagesCNC and Part ProgramAkatew Haile MebrahtuNo ratings yet

- PD PMD CadcamDocument20 pagesPD PMD CadcamVinay MishraNo ratings yet

- CNC Turning Center ProgrammingDocument29 pagesCNC Turning Center ProgrammingSrinivas Yadav100% (1)

- Computer Aided Manufacturing SyllabusDocument1 pageComputer Aided Manufacturing SyllabusDeepak KumarNo ratings yet

- اجهزة معمل صيانة وتشخيص الاعطالDocument3 pagesاجهزة معمل صيانة وتشخيص الاعطالAhmed Abdalrazek100% (2)

- Cadem VtuDocument12 pagesCadem VturajualagNo ratings yet

- CNC Programmer Job Description PostingDocument2 pagesCNC Programmer Job Description Postingsmith9krNo ratings yet

- Bending Tube E-TurnDocument1 pageBending Tube E-TurnCarlos JuniorNo ratings yet

- Invo MillingDocument8 pagesInvo MillingOvidiu StoianNo ratings yet

- CNC Common Terms PDFDocument2 pagesCNC Common Terms PDFShaival JhaNo ratings yet

- Cim Lab Exam Q SDocument17 pagesCim Lab Exam Q SMohammed ImranNo ratings yet

- Unit 4Document62 pagesUnit 4samnztNo ratings yet

- CNC Operator Naseer Ahmed: ObjectiveDocument2 pagesCNC Operator Naseer Ahmed: Objectivenaseer ahmedNo ratings yet

- CNC Milling BasicsDocument10 pagesCNC Milling Basicsjsrplc7952No ratings yet

- CNC ProgrammingDocument27 pagesCNC ProgrammingAbhijit BiswasNo ratings yet

- Brochure Tezetcad Software Tube BendingDocument5 pagesBrochure Tezetcad Software Tube BendingbehipiluwuNo ratings yet

- CNC Mill ProgrammingDocument24 pagesCNC Mill ProgrammingZahidah AmaninaNo ratings yet

- Introduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1Document11 pagesIntroduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1BabuRaoThellaNo ratings yet

- CNC Turning Programming Fundementalsls, Step by StepDocument14 pagesCNC Turning Programming Fundementalsls, Step by Stepschriener50% (2)

- Turner 4 TH Sem TTDocument223 pagesTurner 4 TH Sem TTSubhranil Dutta100% (1)

- Comparative Study of CNC Controllers Used in CNC Milling MachineDocument9 pagesComparative Study of CNC Controllers Used in CNC Milling MachineAJER JOURNALNo ratings yet

- Deep Hole Machining ENGDocument150 pagesDeep Hole Machining ENGCristian Fuentes100% (1)

- Manufacturing Process: CNC TechnologyDocument133 pagesManufacturing Process: CNC TechnologyRullyRahardianNo ratings yet

- CNC Milling Sample ProgramDocument16 pagesCNC Milling Sample ProgramjayyadavvpcNo ratings yet

- CNCDocument98 pagesCNCRohit SinghNo ratings yet

- Cad/Cam ManualDocument83 pagesCad/Cam ManualPasupathi KumarNo ratings yet

- Lab 6 - Face Milling On CNC MachineDocument5 pagesLab 6 - Face Milling On CNC MachineHaris NaveedNo ratings yet

- CNC MillingDocument48 pagesCNC MillingHKHKBOOKSNo ratings yet

- CNC Programing ConceptDocument11 pagesCNC Programing ConceptGatot PrasetyoNo ratings yet

- Design and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050Document8 pagesDesign and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050The ash Designe GalaryNo ratings yet

- Cadcam Module 2Document433 pagesCadcam Module 2Ahsan IftikharNo ratings yet

- Incremental Sheet Metal Forming On CNC Milling Machine-ToolDocument4 pagesIncremental Sheet Metal Forming On CNC Milling Machine-ToolDionysius WahyoeNo ratings yet

- 12 Different Types of CNC Machine (Complete Guide) & PDFDocument16 pages12 Different Types of CNC Machine (Complete Guide) & PDFAK KHANNo ratings yet

- Mastercam Training Guide Mill Lesson 2Document2 pagesMastercam Training Guide Mill Lesson 2DIEGO ARMANDO VANEGAS DUQUENo ratings yet

- Four Axis Lesson 1 SampleDocument27 pagesFour Axis Lesson 1 SampleLuis Enrique FloresNo ratings yet

- SAMPLE MastercamX8 Lathe TrainingTutorialDocument53 pagesSAMPLE MastercamX8 Lathe TrainingTutorialDavid ObrienNo ratings yet

- Sinumerik OPC DA Device DriverDocument8 pagesSinumerik OPC DA Device DriverMartinNo ratings yet

- CNC Stands For Computer Numerical Control, And: G-Code. CNC Was Developed inDocument4 pagesCNC Stands For Computer Numerical Control, And: G-Code. CNC Was Developed inKhateeb Ul Islam QadriNo ratings yet

- Radial Drilling MachineDocument25 pagesRadial Drilling MachinesriNo ratings yet

- Manual de CNC TornoDocument147 pagesManual de CNC TornoAbraham Pool100% (1)

- CNC Machine Operator ResumeDocument1 pageCNC Machine Operator ResumeNILESHNo ratings yet

- Milling Speeds and Feeds PDFDocument1 pageMilling Speeds and Feeds PDFrobNo ratings yet

- CNC TURNING MachineDocument14 pagesCNC TURNING MachineFaiz AhmedNo ratings yet

- Igtr Aurangabad Curriculum PDTD&CC 08Document31 pagesIgtr Aurangabad Curriculum PDTD&CC 08सचिन पटेलNo ratings yet

- CNC - Training OutlinesDocument2 pagesCNC - Training OutlinesVijay KumarNo ratings yet

- CNC MachineDocument21 pagesCNC MachineKuhely GhoshNo ratings yet

- Vol168 No.03Document40 pagesVol168 No.03edelapolloNo ratings yet

- Vol168 No.20Document40 pagesVol168 No.20edelapolloNo ratings yet

- Vol168 No.05Document39 pagesVol168 No.05edelapolloNo ratings yet

- Vol168 No.08Document40 pagesVol168 No.08edelapolloNo ratings yet

- Vol168 No.01Document47 pagesVol168 No.01edelapolloNo ratings yet

- Vol168 No.07Document40 pagesVol168 No.07edelapolloNo ratings yet

- Vol168 No.17Document36 pagesVol168 No.17edelapolloNo ratings yet

- Vol168 No.13Document39 pagesVol168 No.13edelapolloNo ratings yet

- Lock Up Your: KEY MENDocument12 pagesLock Up Your: KEY MENedelapolloNo ratings yet

- Vol168 No.16Document40 pagesVol168 No.16edelapolloNo ratings yet

- Vol168 No.15Document56 pagesVol168 No.15edelapolloNo ratings yet

- Abstract Honsel Meschede KleinDocument1 pageAbstract Honsel Meschede KleinedelapolloNo ratings yet

- Garlock Bearing Isolator Application Data SheetDocument1 pageGarlock Bearing Isolator Application Data SheetedelapolloNo ratings yet

- Pazon V Boyer: The TriggerDocument12 pagesPazon V Boyer: The TriggeredelapolloNo ratings yet

- Turnmill: Gantry-Type Multi-Professional Machining CentreDocument2 pagesTurnmill: Gantry-Type Multi-Professional Machining CentreedelapolloNo ratings yet

- 3 Phase DiagramDocument18 pages3 Phase DiagramedelapolloNo ratings yet

- Trochoidal Milling: Process DescriptionDocument7 pagesTrochoidal Milling: Process DescriptionedelapolloNo ratings yet

- Spindle OilsDocument1 pageSpindle OilsedelapolloNo ratings yet

- Hot Work Tool Steel: Z Similar SteelsDocument2 pagesHot Work Tool Steel: Z Similar SteelsedelapolloNo ratings yet

- VX-5500 - Low - VHFDocument92 pagesVX-5500 - Low - VHFDalton CarvalhoNo ratings yet

- Application To CongruencesDocument16 pagesApplication To CongruencesJUNALYN MANATADNo ratings yet

- README Linux JoystickDocument2 pagesREADME Linux JoystickaimoroidaNo ratings yet

- Basic3 Workbook 2021Document5 pagesBasic3 Workbook 2021eduardo nietoNo ratings yet

- 3583.PLAXIS - 2D - CEV22.01 - Tutorial - 05 - Excavation of An NATM TunnelDocument14 pages3583.PLAXIS - 2D - CEV22.01 - Tutorial - 05 - Excavation of An NATM TunnelPhalgun MoturuNo ratings yet

- PhysRevLett 130 221502Document6 pagesPhysRevLett 130 221502Edwin QuirogaNo ratings yet

- 1 ESO Unit 4 Homework 19Document2 pages1 ESO Unit 4 Homework 19Anna NowakNo ratings yet

- Varun Kumar ChoudharyDocument2 pagesVarun Kumar Choudharysunil khandelwalNo ratings yet

- Theology 2 Christology LasDocument2 pagesTheology 2 Christology LasEhraNo ratings yet

- Region 3Document2 pagesRegion 3idle shot0% (1)

- AlgoBulls - Frontend Developer - Coding AssignmentDocument5 pagesAlgoBulls - Frontend Developer - Coding Assignmentcodename1181No ratings yet

- Cpu ShedulingDocument22 pagesCpu ShedulingRaviteja PapeneniNo ratings yet

- PDF Installation Instructions, WindowsDocument3 pagesPDF Installation Instructions, WindowsNani SaiNo ratings yet

- Judaism's Great DebatesDocument125 pagesJudaism's Great DebatestechnicanNo ratings yet

- How To Open Hiden Price Field in Credit Memo (3204493)Document3 pagesHow To Open Hiden Price Field in Credit Memo (3204493)Vasilij123No ratings yet

- How Competitive Are AlbazDocument4 pagesHow Competitive Are Albazbaadshah wazeemNo ratings yet

- Answer KeyDocument3 pagesAnswer KeyAmanoden Mala DimalutangNo ratings yet

- Filipino Essay 4Document3 pagesFilipino Essay 4IqbalNo ratings yet

- Bachelor Thesis HTW SaarDocument4 pagesBachelor Thesis HTW Saarveronicagarciaalbuquerque100% (1)

- Andrea Mae Adano - Activity 2Document2 pagesAndrea Mae Adano - Activity 2Andrea Mae AdanoNo ratings yet

- Pacific Radio Vol 1 9 Apr 1920Document36 pagesPacific Radio Vol 1 9 Apr 1920PedralhadaNo ratings yet

- Case StudyDocument3 pagesCase StudyRashel Keith BadolNo ratings yet

- Grade 12 Physics 2nd Term Test Paper With Answers 2020 North Western ProvinceDocument58 pagesGrade 12 Physics 2nd Term Test Paper With Answers 2020 North Western ProvinceDenethi panchaliNo ratings yet

- FB Book KKaschner Sounds RF JGDocument7 pagesFB Book KKaschner Sounds RF JGmoslem vesaliNo ratings yet

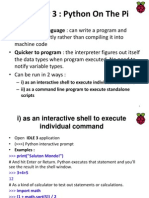

- Python On The Pi CHAPTER 3Document12 pagesPython On The Pi CHAPTER 3Azim SyahmiNo ratings yet

- Listening - Points AmebdDocument4 pagesListening - Points AmebdMatthew SalterNo ratings yet

- Listening Notetaking Skills 3 4Th Edition Full ChapterDocument29 pagesListening Notetaking Skills 3 4Th Edition Full Chapterronald.shaw161100% (25)