Professional Documents

Culture Documents

Summary of Quality Control Tests Required For Bridges

Summary of Quality Control Tests Required For Bridges

Uploaded by

Jakka Lakshmikanth0 ratings0% found this document useful (0 votes)

7 views4 pagesYhffghh

Original Title

179173003 Summary of Quality Control Tests Required for Bridges

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentYhffghh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views4 pagesSummary of Quality Control Tests Required For Bridges

Summary of Quality Control Tests Required For Bridges

Uploaded by

Jakka LakshmikanthYhffghh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

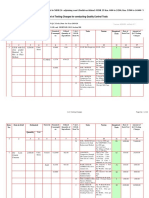

SUMMARY OF QUALITY CONTROL TESTS REQUIRED FOR BRIDGES

CONTRIBUTED by Sri P.SURESH

DEPUTY EXECUTIVE ENGINEER

(R&B) SUB DIVISION, UDAYAGIRI.

(A)MATERIALS:

Name of

S.No. Type of Test Frequency Permissible limits

material

1 CEMENT a) Fineness of One test for each <10%

Cement consignment

b) Initial setting One test for each Not less than 30 minutes

time consignment

c) Final setting time One test for each Not more than 600 minutes

consignment

d)Compressive One test for each

strength at 28 days consignment

i) OPC 33 Grade > 33 N/mm2

ii) OPC 43 Grade > 43 N/mm2

iii) OPC 53 Grade > 53 N/mm2

2 STEEL a) Weight per One test for each 6mm-0.222Kg/m

running consignment 8mm-0.395Kg/m

meter in Kg

10mm-0.620Kg/m

12mm-0.888Kg/m

16mm-1.578Kg/m

20mm-2.465Kg/m

25mm-3.852Kg/m

32mm-6.311Kg/m

b) Characteristic One test for each

yield stress ‘fy’ consignment

i) S-240(Mild) > 240 N/mm2

ii) S-415 (HYSD) > 415 N/mm2

iii) S-500 (TMT) > 500 N/mm2

c)Percentage One test for each Not Less than14.5%

elongation consignment

Name of

S.No. Type of Test Frequency Permissible limits

material

3 WATER a) PH Value One test for >6

each source

(or) monthly

b) Sulphates One test for < 400 mg/Litre

each source

(or) monthly

c) Chlorides One test for < 500 mg/Litre for RCC

each source < 2000 mg/Litre for PCC

(or) monthly

4 COARSE a) Sieve Analysis 1 Test/15m3 As per IS: 383 Table

AGGREGATE

b) AIV One test for

each source

i) Non-wearing (or) as and when < 45%

surfaces required

ii) Wearing surfaces (or) monthly < 30%

c) FIV 1 Test/30m3

i) For Structures < 35%

ii) For CC < 40% (IRC: 44)

pavements

d) Water absorption 1 Test/Day < 2%

5 FINE a) Sieve analysis 1 Test/15 m3 As per IS 383

AGGREGATE b) Fineness 1 Test/15 m3 2 to 3.50

Modulus

c) Silt Content 2 Tests/Day < 4%

d) Bulking of sand 2 Tests/Day Not required when concrete

is laid by weight

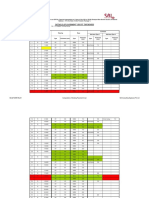

B) CONCRETE:

Name of

S No. Type of Test Frequency Permissible limits

material

1 CONCRETE a) Slump Test 2 Tests/Day 15 to 45 mm

(or) For CC pavement

1 Test/10m3 25 to 50 mm

For structures

2 CONCRETE b) Compressive Number of samples to be prepared and tested as

Strength Test per IS: 456 (one sample means 3 specimen

cubes of 150x150x150mm)

Quantity of Number of Samples to be casted for

Concrete 7 days + 28 days

i)1-5 Cum 1x3 + 1x3 = 6 No

ii) 6-15 Cum 2x3 + 2x3 = 12 No

iii) 16-30 Cum 3x3 + 3x3 = 18 No

iv) 31-50 Cum 4x3 + 4x3 = 24 No

3 CONCRETE c) Compressive As given in (b) 7 Days ≥ 70% of fck

Strength Test subject to a 28 days ≥ fck+3.0

minimum of 6 up to M15

cubes 28 days ≥ fck+4.0

above M15

As per Clause 16.1 & Table 11

of IS: 456-2000

7 Days Compressive Strength for Different Grades of Concrete

Grade of concrete Load Compressive Strength

M-10 Grade >160 KN > 7.00 N/mm2

M-15 Grade >240 KN > 10.50 N/mm2

M-20 Grade > 315 KN > 14.00 N/mm2

M-25 Grade > 395 KN > 17.50 N/mm2

M-30 Grade > 510 KN > 22.50 N/mm2

M-35 Grade > 555 KN > 24.50 N/mm2

M-40 Grade > 630 KN > 28.00 N/mm2

Name of

S.No. Type of Test Frequency Permissible limits

material

28 Days Compressive Strength for Different Grades of Concrete

Grade of concrete Load Compressive Strength

M-10 Grade > 295 KN > 13.00 N/mm2

M-15 Grade >405 KN > 18.00 N/mm2

M-20 Grade >540 KN > 24.00 N/mm2

M-25 Grade >655 KN > 29.00 N/mm2

M-30 Grade >765 KN > 34.00 N/mm2

M-35 Grade >880 KN > 39.00 N/mm2

M-40 Grade >990 KN > 44.00 N/mm2

NOTE: (i) For calculating of compressive strength of concrete, the

following values are generally considered.

(a) 10 N = 1.0 Kg (Exactly 9.80 N = 1.0Kg); (b) 10 KN = 1.0MT;

(ii) The least count of compression testing machine is generally 0.50 MT

or 5 KN and total capacity is 100 MT or 1000KN

4 CONCRETE d) Core Tests of 2 Cores for

As detailed below

Hardened Concrete every 150 m3

Strength of 150mm diameter cores with depth of 200mm for CC pavement

(Direct load on core after applying corrections)

Grade of concrete Average value Individual Value

M-25 Grade >380 KN >305 KN

M-30 Grade > 460 KN >370 KN

M-35 Grade > 535 KN > 425 KN

M-40 Grade > 610 KN > 490 KN

You might also like

- Job Mix For BM 50 MMDocument3 pagesJob Mix For BM 50 MMSOIGNE ENGINEERING CONSULTANTSNo ratings yet

- Mix Design For BC - BLS EthanolDocument4 pagesMix Design For BC - BLS EthanolSunil BoseNo ratings yet

- WMM Mix DesignDocument22 pagesWMM Mix DesignDivyesh AhirNo ratings yet

- Report - Bridge PDFDocument21 pagesReport - Bridge PDFparas rahangdale100% (1)

- FT004 - FLAKINESS & ELONGATION INDICESdDocument23 pagesFT004 - FLAKINESS & ELONGATION INDICESdjjksite voyantsNo ratings yet

- Quality TestDocument22 pagesQuality TestUmair Shaikh100% (1)

- QAP For Bitumen JobDocument2 pagesQAP For Bitumen JobSasanka SekharNo ratings yet

- What Is DLC (Dry Lean Concrete) - Advantage of DLC (Dry Lean Concrete)Document6 pagesWhat Is DLC (Dry Lean Concrete) - Advantage of DLC (Dry Lean Concrete)HIREN DESAINo ratings yet

- DBM Final ReportDocument7 pagesDBM Final ReportBilal Ahmed BarbhuiyaNo ratings yet

- InvoiceDocument1 pageInvoiceJakka LakshmikanthNo ratings yet

- Bitumen (Ext)Document1 pageBitumen (Ext)venkateswara rao PothinaNo ratings yet

- Project Report Design of Dense Bituminous Macadam: ClientDocument11 pagesProject Report Design of Dense Bituminous Macadam: ClientHarshit MoreNo ratings yet

- SDBC-Job Mix FinalDocument31 pagesSDBC-Job Mix FinalAchintya DasNo ratings yet

- QA in Highway Sector-Part-4Document10 pagesQA in Highway Sector-Part-4boomiNo ratings yet

- Base Course Aggregates StandardsDocument5 pagesBase Course Aggregates Standardsprobook450_ehsanNo ratings yet

- Laboratory Test Report: Faculty of Engineering & TechnologyDocument6 pagesLaboratory Test Report: Faculty of Engineering & TechnologySourav SahaNo ratings yet

- Modified Proctor Density Test (WBM) : Description 1 2 3 4 5Document2 pagesModified Proctor Density Test (WBM) : Description 1 2 3 4 5Quality JamNo ratings yet

- Auto Sand Sieving MachineDocument70 pagesAuto Sand Sieving MachineAbel AregayNo ratings yet

- Astm C 33Document7 pagesAstm C 33alfonso mendoza0% (1)

- Seive Analysis or Partical Size DistributionDocument11 pagesSeive Analysis or Partical Size DistributionNIKHIL BANDWALNo ratings yet

- Quality Control Check List For Documentation SL - No Description Testing Method YES NO N/A Remarks 1 Concreting For All Grades of ConcreteDocument9 pagesQuality Control Check List For Documentation SL - No Description Testing Method YES NO N/A Remarks 1 Concreting For All Grades of ConcreteRadhakrishna KPNo ratings yet

- Quality Control Format For MPR Ex Dsc-2Document7 pagesQuality Control Format For MPR Ex Dsc-2Rahmat mulyadiNo ratings yet

- DBM Job MixDocument3 pagesDBM Job MixSOIGNE ENGINEERING CONSULTANTSNo ratings yet

- Pavement Crust ThicknessDocument10 pagesPavement Crust ThicknessHarsh DeepNo ratings yet

- Sec 400 (Most Version)Document37 pagesSec 400 (Most Version)abhijit_xpNo ratings yet

- Dee Vee Offer LetterDocument1 pageDee Vee Offer LetterJakka LakshmikanthNo ratings yet

- WMM Plant Calibration (Fortune)Document12 pagesWMM Plant Calibration (Fortune)RSBIPL NH17 LABNo ratings yet

- RMM CalibrationDocument18 pagesRMM CalibrationPrasanna S KulkarniNo ratings yet

- Road Infrastructure Development Company of Rajasthan LTD.: I. Source and Location of All MaterialsDocument53 pagesRoad Infrastructure Development Company of Rajasthan LTD.: I. Source and Location of All Materialssunil kuldeepNo ratings yet

- Compaction Test by Core Cutter (Is: 2720, Part 29)Document2 pagesCompaction Test by Core Cutter (Is: 2720, Part 29)Francis Aw Soon LeeNo ratings yet

- Right of Way:: 120' 36 .00 MDocument4 pagesRight of Way:: 120' 36 .00 MV Venkata NarayanaNo ratings yet

- Summary of Quality Control Tests Required For BridgesDocument4 pagesSummary of Quality Control Tests Required For BridgesV Venkata Narayana100% (3)

- Sr. No. Name of Test IS Code Rate: Shree Bala Ji Test House Pvt. LTDDocument6 pagesSr. No. Name of Test IS Code Rate: Shree Bala Ji Test House Pvt. LTDAyan DuttaNo ratings yet

- Final BC Grade 2 With VG 40 Honeywell Titan Polymer 56 HMP 1 Lime and 0.8 PolymerDocument15 pagesFinal BC Grade 2 With VG 40 Honeywell Titan Polymer 56 HMP 1 Lime and 0.8 PolymerSunil BoseNo ratings yet

- Inspection Format RoadDocument61 pagesInspection Format Roaddhiraj dNo ratings yet

- Final Specifications of Track Ballast 20-02-23Document17 pagesFinal Specifications of Track Ballast 20-02-23Manish GanjareNo ratings yet

- Report On Internship PDFDocument24 pagesReport On Internship PDFAm C100% (5)

- Construct BC DBMDocument159 pagesConstruct BC DBMMohd AliNo ratings yet

- Astm C 144 PDFDocument2 pagesAstm C 144 PDFMuhammad NaumanNo ratings yet

- Testing ParametersDocument13 pagesTesting ParametersSwaroopa Ravinder Goud100% (1)

- Annexure 2 Form 72 (Scope) Annexure IDocument4 pagesAnnexure 2 Form 72 (Scope) Annexure IVaghasiyaBipinNo ratings yet

- QAP Test Frequency CONCRETEDocument17 pagesQAP Test Frequency CONCRETEfevahe756No ratings yet

- SR No Description of Material & Test Specifications Charges M.E Testing PNC Existing Rates CementDocument3 pagesSR No Description of Material & Test Specifications Charges M.E Testing PNC Existing Rates CementAtulNo ratings yet

- Bridge Design Format For Rural Road NQM Project AssamDocument35 pagesBridge Design Format For Rural Road NQM Project Assamarif ahmedNo ratings yet

- Combine Flakiness & Elongation TestDocument1 pageCombine Flakiness & Elongation TestFariha AzadNo ratings yet

- Sector Project-Package A:Mahua-Chuwahi RoadDocument6 pagesSector Project-Package A:Mahua-Chuwahi RoadVIMAL TIWARINo ratings yet

- Irc 063-1976Document9 pagesIrc 063-1976kruttika_apNo ratings yet

- Bitumen Content TestingDocument9 pagesBitumen Content TestingjaffnaNo ratings yet

- GSB (Coarse Graded) Summary Sheet: Physical PropertiesDocument10 pagesGSB (Coarse Graded) Summary Sheet: Physical PropertiesjitendraNo ratings yet

- Marshall Stability TestDocument10 pagesMarshall Stability Testanon_789699787No ratings yet

- Granular Sub-Base: Salient Features 2.1 MethodologyDocument2 pagesGranular Sub-Base: Salient Features 2.1 Methodologyvijay kumarNo ratings yet

- Contractor: G R Infraprojects Ltd. Coating and Stripping of Bitumen Aggregate MixturesDocument1 pageContractor: G R Infraprojects Ltd. Coating and Stripping of Bitumen Aggregate MixturesjitendraNo ratings yet

- MoRTH Specifications Pocket Book 09.04.2019 FinalDocument92 pagesMoRTH Specifications Pocket Book 09.04.2019 FinalsombansNo ratings yet

- 1 WMM Mix DesignDocument24 pages1 WMM Mix Designyuva_86No ratings yet

- WMM Calibration 05.01.2016Document8 pagesWMM Calibration 05.01.2016SRR QAQCNo ratings yet

- Is 1195-1978 Specification For Bitumen Mastic For FlooringDocument20 pagesIs 1195-1978 Specification For Bitumen Mastic For FlooringVijayakrishna Singamsetti100% (1)

- IRC 047.1972 Builtup SPray GroutDocument12 pagesIRC 047.1972 Builtup SPray GroutTk SubhashNo ratings yet

- Project ReportDocument55 pagesProject ReportAadil AhmadNo ratings yet

- Bituminous Macadam (BM) : Grading Requirement (MORTH V Table 500-10)Document4 pagesBituminous Macadam (BM) : Grading Requirement (MORTH V Table 500-10)Mozibur RahmanNo ratings yet

- WMM Mix DesignDocument23 pagesWMM Mix DesignEnd EndNo ratings yet

- Test Frequency: (As Per Mort&H 5Th Revision)Document6 pagesTest Frequency: (As Per Mort&H 5Th Revision)jitendra dixitNo ratings yet

- IS-1122 True Specific GravityDocument7 pagesIS-1122 True Specific GravitySaurav KumarNo ratings yet

- Test Method - Soil2Document25 pagesTest Method - Soil2jitendraNo ratings yet

- Astm D422 Sieve Analysis: Client: ProjectDocument1 pageAstm D422 Sieve Analysis: Client: ProjectHassan RazaNo ratings yet

- SDBC With FillerDocument8 pagesSDBC With Fillerer_kenedyNo ratings yet

- Texture Depth Measurement: National Highways Authority of IndiaDocument1 pageTexture Depth Measurement: National Highways Authority of IndiaQuality JamNo ratings yet

- Aggregate Impact Value (Is: 2386 (Part-Iv) )Document19 pagesAggregate Impact Value (Is: 2386 (Part-Iv) )ajit karandikarNo ratings yet

- CBR ProjectDocument46 pagesCBR ProjectChau Suktana EnlingNo ratings yet

- Test For Water Bound Macadam Base (WBM) Grade 3 (Sive Analysis of Aggregate)Document9 pagesTest For Water Bound Macadam Base (WBM) Grade 3 (Sive Analysis of Aggregate)Athul Matter LabNo ratings yet

- 858 CareerPDF1 Notification PDFDocument1 page858 CareerPDF1 Notification PDFJakka LakshmikanthNo ratings yet

- Curriculum Vitae: ObjectiveDocument2 pagesCurriculum Vitae: ObjectiveJakka LakshmikanthNo ratings yet

- Is 102Document1 pageIs 102Jakka Lakshmikanth100% (1)

- Simple Way of Constructing Road BridgesDocument83 pagesSimple Way of Constructing Road BridgesJakka LakshmikanthNo ratings yet

- NitDocument475 pagesNitJakka LakshmikanthNo ratings yet

- Soil ReprtDocument58 pagesSoil ReprtvrushankshahNo ratings yet

- Literature Review-1Document7 pagesLiterature Review-1amosainamani16No ratings yet

- CH02Document10 pagesCH02CHA CHANo ratings yet

- Concrete Tech PracsDocument20 pagesConcrete Tech PracsLouis KiwaNo ratings yet

- Gravel SpecsDocument3 pagesGravel SpecsShe TimbancayaNo ratings yet

- Mulondo Nicholas Final ReportDocument78 pagesMulondo Nicholas Final ReportOjullaIsaacNo ratings yet

- Concrete Cube StrengthDocument9 pagesConcrete Cube StrengthMadav BalgobinNo ratings yet

- BS 0812-104 - 1994Document24 pagesBS 0812-104 - 1994عمر عمرNo ratings yet

- Standard Practice For Reducing Samples of Aggregate To Testing SizeDocument7 pagesStandard Practice For Reducing Samples of Aggregate To Testing Sizejun floresNo ratings yet

- Module 2 - Origin of Soil and Grain SizeDocument29 pagesModule 2 - Origin of Soil and Grain SizeAyra Rolylyn DacanayNo ratings yet

- Csir Kit Gravel Presentation 1Document38 pagesCsir Kit Gravel Presentation 1Eng Hinji RudgeNo ratings yet

- Experimental Investigation of Animal Bone PowderDocument9 pagesExperimental Investigation of Animal Bone PowderSean MagdamitNo ratings yet

- Soil Mechanics Practical FinalDocument33 pagesSoil Mechanics Practical FinallofeagaiNo ratings yet

- SANS5847 - Flakiness Index of Course AggregatesDocument7 pagesSANS5847 - Flakiness Index of Course AggregatesAndrew MwindililaNo ratings yet

- BSI BS 812-103.1 Superseded by BSI BS EN 933-1 القديمةDocument12 pagesBSI BS 812-103.1 Superseded by BSI BS EN 933-1 القديمةmohaliaziz8No ratings yet

- Asphalt Concrete Wearing Course (AC - WC) : Mix DesainDocument42 pagesAsphalt Concrete Wearing Course (AC - WC) : Mix DesainDiah Syaifanayah Sahiruddin ManggarraNo ratings yet

- Dry Sieve AnalysisDocument3 pagesDry Sieve AnalysisHuda Fauzi0% (1)

- Physical PropertiesDocument209 pagesPhysical PropertiesTalhaNo ratings yet

- AS ShakerDocument2 pagesAS ShakerTutor_KLNo ratings yet

- Final Report Disk MillDocument10 pagesFinal Report Disk MillMuhammad Irfan MalikNo ratings yet

- Grain Size AnalysisDocument3 pagesGrain Size AnalysisAbdulelah SNo ratings yet

- 2 - 9 - 38 PSD SieveDocument3 pages2 - 9 - 38 PSD Sievebebo94100% (2)

- Mechanical Operation - Chapter 1 and 2Document158 pagesMechanical Operation - Chapter 1 and 2DivyamNo ratings yet