Professional Documents

Culture Documents

Saad Bin Sadaqat: Objective

Uploaded by

saadbinsadaqat123456Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saad Bin Sadaqat: Objective

Uploaded by

saadbinsadaqat123456Copyright:

Available Formats

Saad Bin Sadaqat

E-mail : saadbinsadaqat@hotmail.com Phone : 03462730268

Address : R 1/66, GULSHAN-E-AKBAR, MALIR CITY

KARACHI

Objective

An Industrial and Manufacturing engineer who is academically consistent ready to take on a new challenge in my career.

Main fields of interests include but are not limited to Manufacturing, Production Planning & Control, Quality and HSE.

Work experience

Plastech Autosafe Pvt Ltd Dec, 2017 — Present

Senior Executive Production

·Production Department Audits of Safety, Food Safety, Quality Management system, Environment, Materials , and

other internal audits.

·Making Daily Production and Rejection Sheets.

·Promoting safety culture and implementation of 5S on the floor.

·Daily Material Receiving and parts dispatching to store.

·Supervision of Shifts in absence of Molding Supervisor.

·Operation of TOYO (Automatic Closure Production) machine.

·Operation of Demag machines from 60 Tonnage to 250 Tonnage.

·Operation of BOY machine 50 Tonnage.

·Operation of HAITIAN machine 120 Tonnage.

·SOPs making and successful implementation.

·Injection Molding Training to all Molding Employees.

·Statistical analysis of the parameters to find the root cause.

Omar Jibran Engineering Industries July, 2016 — Dec, 2017

Limited

Production Engineer

·Learnt about Injection molding, machines, functioning and operating along with part setting.

·Production Planning to ensure that right part is produced at correct time with right quantity

·Ensure Safety at the Floor and implementing 5S

·Ensuring that each process is performed according to the standards

·Operation of Jon Wai machines ranging from 100 Tonnage to 3000 Tonnage.

Saad Bin Sadaqat 1

·Monitor and control raw material issuance in accordance to parts standards

·Monitor and Supervise production shifts.

·Methods improvements, including work station layout, process design, tooling etc.

·Quality Control Charts to aim at finding the root Cause analysis of problems

·Maintaining SOPs and records of production related documents.

·Training of the workforce

·Interview/Selection of the production workers/Operators/Trimmers/Supervisors/Loaders

·Represent the Production Department in Daily meetings and weekly meeting (OBEYA).

GENERAL TYRES & RUBBER July 2015 — Aug 2015

COMPANY OF PAKISTAN

Internship (Production/Quality Department)

Experienced and learnt about all the process involved in the designing and Manufacturing of the Tyres of all kinds, Safety

and QA dept

KTDMC June 2015 — June 2015

Internship (Production Department)

Increased knowledge regarding the CAM, CAD, heat treatment, Cutting tools, Reverse Engineering, G&M codes, and

conventional machining

Atlas Honda Sept, 2015 — Jun, 2016

Final Year Project

Designing and Simulation of Automated Systems for the Blanking Process of “Frame Body Panel of CG-125” Motorcycles

at “Atlas Honda”

Qualifications

1. Event management (2015)

2. Maritime Policies and OSHA Compliance(2015)

3. Leadership Skills and Practices(2014)

4. HR & Work Force Management(2015)

5. Human Resource Management(2014)

6. Computer software and hardware(2009)

Education

BE (Industrial and Manufacturing) Sept, 2011 — June, 2016

NUST

Obtained the BE degree with GPA 3.22

Softwarer Skills

Proficient in MS Office

AutoCAD

Saad Bin Sadaqat 2

CES EDU-pack

Solid works

Solid Edge

Mini TAB

References

Will be provided as per request

Saad Bin Sadaqat 3

You might also like

- Industrial Engineer Saad Bin Sadaqat Seeks New ChallengeDocument3 pagesIndustrial Engineer Saad Bin Sadaqat Seeks New Challengesaad bin sadaqatNo ratings yet

- Saad Bin Sadaqat: Industrial & Manufacturing EngineerDocument3 pagesSaad Bin Sadaqat: Industrial & Manufacturing EngineerSaad Bin SadaqatNo ratings yet

- Experienced Production Engineer Seeking New OpportunitiesDocument2 pagesExperienced Production Engineer Seeking New Opportunitiesw john franklinNo ratings yet

- HardikBSheth_13533410_-10_00-_1Document5 pagesHardikBSheth_13533410_-10_00-_1Mayur ShindeNo ratings yet

- Usama Ali: Profile SummaryDocument3 pagesUsama Ali: Profile SummaryAbdul RehmanNo ratings yet

- Sourabh Chatterjee VisualCV ResumeDocument4 pagesSourabh Chatterjee VisualCV Resumecsourabh69No ratings yet

- CV of Saadat Ali For IndustriesDocument2 pagesCV of Saadat Ali For Industriesapi-19787320No ratings yet

- Raj Kumar Vishwakarma - New-5Document3 pagesRaj Kumar Vishwakarma - New-5ankitNo ratings yet

- Objective: To work in an effective and progressive environmentDocument2 pagesObjective: To work in an effective and progressive environmentMuhammad AbrarNo ratings yet

- MD Shahnewaz: Manufacturing EngineerDocument4 pagesMD Shahnewaz: Manufacturing Engineerkiran2710No ratings yet

- Sandesh Ramesh ThulDocument14 pagesSandesh Ramesh ThulRoshanNo ratings yet

- Gowthaman Pazhanisamy: Career ObjectiveDocument3 pagesGowthaman Pazhanisamy: Career Objectivegowthaman rajNo ratings yet

- AbhijitBarik (12 0)Document3 pagesAbhijitBarik (12 0)SAMSON GLOBALNo ratings yet

- MD Shahnewaz Sabit Faisal: Phone: Home: EmailDocument4 pagesMD Shahnewaz Sabit Faisal: Phone: Home: Emailkiran2710No ratings yet

- Mr. Siddhesh A. Gharge: 2/16, Jyotirling Sadan Ratanbai Compound, Shivaji Nagar, Wagle Industrial Estate Thane-400604Document5 pagesMr. Siddhesh A. Gharge: 2/16, Jyotirling Sadan Ratanbai Compound, Shivaji Nagar, Wagle Industrial Estate Thane-400604pratik bhoiteNo ratings yet

- AbhijitBarik 12 0Document3 pagesAbhijitBarik 12 0almamunmolla96No ratings yet

- Shine Daya Shankar 4yrs 1m Delhi 4.05 LPA New Product Development Senior EngineerDocument2 pagesShine Daya Shankar 4yrs 1m Delhi 4.05 LPA New Product Development Senior EngineerPooja PoojaNo ratings yet

- Shine Daya Shankar 4yrs 1m Delhi 4.05 LPA New Product Development Senior EngineerDocument2 pagesShine Daya Shankar 4yrs 1m Delhi 4.05 LPA New Product Development Senior EngineerPooja PoojaNo ratings yet

- Quality Engineer Resume - 3+ Years ExperienceDocument4 pagesQuality Engineer Resume - 3+ Years ExperiencebeerNo ratings yet

- Mechanical Engineer ResumeDocument6 pagesMechanical Engineer Resumearshad shahNo ratings yet

- Zahoor Ud Din: ObjectiveDocument4 pagesZahoor Ud Din: ObjectiveAnas ZakaNo ratings yet

- (VIKAS MESHRAM) Docs. (1) CVDocument4 pages(VIKAS MESHRAM) Docs. (1) CVViKAS MeshramNo ratings yet

- Mr.ToshitYuvrajPatil_13435410_-05_04-_1Document2 pagesMr.ToshitYuvrajPatil_13435410_-05_04-_1Mayur ShindeNo ratings yet

- Naukri RajKumarArora (27y 0m)Document5 pagesNaukri RajKumarArora (27y 0m)Amit SinhaNo ratings yet

- CV Design Engineer seeking opportunitiesDocument5 pagesCV Design Engineer seeking opportunitiesaditya_pandey_77No ratings yet

- Dear Sir. Am Interested in Production ND QualityDocument2 pagesDear Sir. Am Interested in Production ND QualitySinkar ManojNo ratings yet

- Confidential Resume of Experienced Process EngineerDocument3 pagesConfidential Resume of Experienced Process EngineerBubbleNo ratings yet

- KhalidDocument3 pagesKhalidMuhammad FarooqNo ratings yet

- 3456YHBNMDocument7 pages3456YHBNMSPECTRUM DRIILING TOOLS INTERNATIONALNo ratings yet

- Kamalendra 2022Document3 pagesKamalendra 2022kamalendra singhNo ratings yet

- Vikas Brajkishor SinghDocument2 pagesVikas Brajkishor SinghSwapnil SawantNo ratings yet

- Resume for Production EngineerDocument3 pagesResume for Production EngineerbksinghsNo ratings yet

- Pradeep Kumar Updated CVDocument4 pagesPradeep Kumar Updated CVMallesh QCNo ratings yet

- Engr - Mohsin October 2021Document4 pagesEngr - Mohsin October 2021AliNo ratings yet

- Arshad Resume - Dot PDFDocument6 pagesArshad Resume - Dot PDFArshad AnsariNo ratings yet

- Sameer C CV 23Document5 pagesSameer C CV 23Sameer SaxenaNo ratings yet

- Prakash SainiDocument3 pagesPrakash SainiRahul SainiNo ratings yet

- Deepak ResumeDocument4 pagesDeepak ResumeDeepak SinghNo ratings yet

- Monster CV Template Graduate - Mechanical - EngineeringDocument2 pagesMonster CV Template Graduate - Mechanical - EngineeringZaid Bin AkberNo ratings yet

- Curriculum Vitae: ObjectiveDocument8 pagesCurriculum Vitae: ObjectiveChittibabu MuddanaNo ratings yet

- UTKARSH GAUTAM'S RESUMEDocument2 pagesUTKARSH GAUTAM'S RESUMEUtkarsh GautamNo ratings yet

- Muhammad Shafique : CONTACT #: +92-308-4593005 +92-321-6934750 Email AddressDocument3 pagesMuhammad Shafique : CONTACT #: +92-308-4593005 +92-321-6934750 Email AddressSunny MeharNo ratings yet

- Quazi AsifDocument8 pagesQuazi AsifQuazi Asif Afzal HaseebNo ratings yet

- ProfileDocument7 pagesProfileRahmat Tilang MusaNo ratings yet

- Muhammed Arshad: Education B.tech in Mechanical Engineering 6.8 CGPADocument2 pagesMuhammed Arshad: Education B.tech in Mechanical Engineering 6.8 CGPADeepak DineshNo ratings yet

- Experienced Production Professional Seeking New OpportunitiesDocument1 pageExperienced Production Professional Seeking New OpportunitiesNirav MakwanaNo ratings yet

- ProfileDocument3 pagesProfileMohamed Ali AssandiNo ratings yet

- G.suresh B.e., M.b.a.Document5 pagesG.suresh B.e., M.b.a.shafeeq ahmedNo ratings yet

- For Quality and FettlingDocument4 pagesFor Quality and FettlingSubhashNo ratings yet

- SandeepDubey (2,4)Document5 pagesSandeepDubey (2,4)ujwalbabarNo ratings yet

- CV of Muhammad Adeel RajputDocument4 pagesCV of Muhammad Adeel RajputFarhan SaghirNo ratings yet

- Resume of An Automobile Engineer (Kuldipsingh)Document4 pagesResume of An Automobile Engineer (Kuldipsingh)thakurkuldip82% (11)

- Saulo Trejo.: Mechanical EngineerDocument1 pageSaulo Trejo.: Mechanical EngineerSaulo TrejoNo ratings yet

- Shrikant R S - Quality ManagerDocument2 pagesShrikant R S - Quality ManagerParag WadekarNo ratings yet

- For AmantitDocument3 pagesFor AmantitShahbaz AhmedNo ratings yet

- Zeeshan Pathan Mechanical EngineerDocument4 pagesZeeshan Pathan Mechanical EngineerZeeshan PathanNo ratings yet

- Curriculum Vitae:: Akhil - Tripathi@yahoo - Co.in (M.) : 09891771791 9311142126Document3 pagesCurriculum Vitae:: Akhil - Tripathi@yahoo - Co.in (M.) : 09891771791 9311142126Anil SharmaNo ratings yet

- CV SummaryDocument3 pagesCV SummarysidramNo ratings yet

- Resume SabiqAzmiDocument2 pagesResume SabiqAzmiAcab AimiNo ratings yet

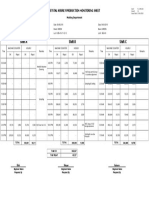

- Netstal Hourly Production Monitoring Sheet 08-08-2018Document1 pageNetstal Hourly Production Monitoring Sheet 08-08-2018saadbinsadaqat123456No ratings yet

- Netstal Hourly Production Monitoring Sheet 09-08-2018Document1 pageNetstal Hourly Production Monitoring Sheet 09-08-2018saadbinsadaqat123456No ratings yet

- Saad Bin Sadaqat ResumeDocument2 pagesSaad Bin Sadaqat Resumesaadbinsadaqat123456No ratings yet

- Sadaqat Hussain: Summary of QualificationsDocument3 pagesSadaqat Hussain: Summary of Qualificationssaadbinsadaqat123456No ratings yet

- Setup Operator ResponsibilitiesDocument4 pagesSetup Operator Responsibilitiessaadbinsadaqat123456No ratings yet

- New Text Docu MentDocument1 pageNew Text Docu Mentsaadbinsadaqat123456No ratings yet

- Chapman, Greg Lr410 3450 Dulong, Jef Kt801 875 Carlson, Ty M645 1200 Keiser, Debra A908 450 Moreland, Barbarapl700 5000Document1 pageChapman, Greg Lr410 3450 Dulong, Jef Kt801 875 Carlson, Ty M645 1200 Keiser, Debra A908 450 Moreland, Barbarapl700 5000saadbinsadaqat123456No ratings yet

- Netstal Hourly Production Monitoring Sheet 08-08-2018Document1 pageNetstal Hourly Production Monitoring Sheet 08-08-2018saadbinsadaqat123456No ratings yet

- Plastic Injection MoldsDocument5 pagesPlastic Injection MoldsMue ChNo ratings yet

- Sameer Bin Sadaqat: About MeDocument2 pagesSameer Bin Sadaqat: About Mesaadbinsadaqat123456No ratings yet

- Lakson Group PresentationDocument32 pagesLakson Group PresentationFasih Ur RehmanNo ratings yet

- Lakson Group PresentationDocument32 pagesLakson Group PresentationFasih Ur RehmanNo ratings yet

- Linear Programming Sensitivity Analysis: © 2007 Pearson EducationDocument37 pagesLinear Programming Sensitivity Analysis: © 2007 Pearson Educationhussain.aabid309No ratings yet

- Policy Quota SeatsDocument13 pagesPolicy Quota Seatssaadbinsadaqat123456100% (4)

- Mcdonald'S Operations Management, 10 Decisions, ProductivityDocument2 pagesMcdonald'S Operations Management, 10 Decisions, Productivitysaadbinsadaqat123456No ratings yet

- Mcdonald'S Operations Management, 10 Decisions, ProductivityDocument2 pagesMcdonald'S Operations Management, 10 Decisions, Productivitysaadbinsadaqat123456No ratings yet

- Service Record of EngineersDocument1 pageService Record of Engineerssaadbinsadaqat123456No ratings yet

- Sensitivity 2Document28 pagesSensitivity 2saadbinsadaqat123456No ratings yet

- B56Document3 pagesB56saadbinsadaqat123456No ratings yet

- CSC Scholarship ProgramDocument3 pagesCSC Scholarship Programsaadbinsadaqat123456No ratings yet

- New Text DoncumentDocument1 pageNew Text Doncumentsaadbinsadaqat123456No ratings yet

- Study Programmes Eligible FinalDocument943 pagesStudy Programmes Eligible Finalsaadbinsadaqat123456No ratings yet

- Noori MehfilDocument2 pagesNoori Mehfilsaadbinsadaqat123456No ratings yet

- Issb 1Document7 pagesIssb 1saadbinsadaqat123456No ratings yet

- HEC Form HungaryDocument6 pagesHEC Form HungaryHasan AhmedNo ratings yet

- Automate lab exercises with ASRS and robotic armsDocument5 pagesAutomate lab exercises with ASRS and robotic armssaadbinsadaqat123456No ratings yet

- Two-Year Diploma Curriculum for Physiotherapy TechniciansDocument21 pagesTwo-Year Diploma Curriculum for Physiotherapy Technicianssaadbinsadaqat123456No ratings yet

- New Text DoncumentDocument1 pageNew Text Doncumentsaadbinsadaqat123456No ratings yet

- Issb 1Document7 pagesIssb 1saadbinsadaqat123456No ratings yet

- Cottle-Taylor: Expanding The Oral Care in IndiaDocument9 pagesCottle-Taylor: Expanding The Oral Care in IndiaSiddharthNo ratings yet

- RequiredDocuments For SLBDocument2 pagesRequiredDocuments For SLBRenesha AtkinsonNo ratings yet

- Impact ModelDocument4 pagesImpact Modelapi-569081456No ratings yet

- Allen Kyle ResumeDocument2 pagesAllen Kyle ResumeJB July SantanderNo ratings yet

- AE 07 - Module 1 - Lesson 1 and 2 - Intro To Law, Prescription PDFDocument109 pagesAE 07 - Module 1 - Lesson 1 and 2 - Intro To Law, Prescription PDF유니스No ratings yet

- Types of MediaDocument1 pageTypes of MediaІрина КізіловаNo ratings yet

- Oracle Apps Fast Formulas DB ItemsDocument8 pagesOracle Apps Fast Formulas DB ItemsimranNo ratings yet

- Ramirez, C. Week8 Gokongwei CULSOCPDocument3 pagesRamirez, C. Week8 Gokongwei CULSOCPChristine Ramirez82% (11)

- Bengson vs. Cruz GR NO 142840Document2 pagesBengson vs. Cruz GR NO 142840Atheena Marie PalomariaNo ratings yet

- Enhancing Content Literacy in Physical EducationDocument7 pagesEnhancing Content Literacy in Physical Educationapi-549544904No ratings yet

- Performance Appraisal Form (FY 2018-19)Document7 pagesPerformance Appraisal Form (FY 2018-19)DU VIBESNo ratings yet

- Understanding and Perception of Data Privacy Act in Barangay TagaranDocument11 pagesUnderstanding and Perception of Data Privacy Act in Barangay TagaranKarl ButacNo ratings yet

- Southern Expressway-New Toll Fees 1Document4 pagesSouthern Expressway-New Toll Fees 1Ada DeranaNo ratings yet

- Telangana State OBMMS - CGG (ST CORPORATION)Document2 pagesTelangana State OBMMS - CGG (ST CORPORATION)Banoth NithinNo ratings yet

- Labor Congress v. NLRC Ruling Favors WorkersDocument3 pagesLabor Congress v. NLRC Ruling Favors WorkersRal CaldiNo ratings yet

- Ventajas y Desventajas / Advantages and Disadvantages AdsDocument1 pageVentajas y Desventajas / Advantages and Disadvantages AdsLuis OrlandoNo ratings yet

- Non Refoulement PDFDocument11 pagesNon Refoulement PDFM. Hasanat ParvezNo ratings yet

- Mentoring of Student - Hafiz RahmanDocument12 pagesMentoring of Student - Hafiz RahmanReevaldo CalvinNo ratings yet

- Project Based Learning Science (Form 1) : Useful WebsiteDocument2 pagesProject Based Learning Science (Form 1) : Useful WebsiteNg Chiew Ping100% (1)

- Interview Observation Sheet For English Classroom Action ResearchDocument4 pagesInterview Observation Sheet For English Classroom Action ResearchDeyra Isra mirazhitaNo ratings yet

- BSP Circular 949Document6 pagesBSP Circular 949MARC CHRISTIAN LOPEZNo ratings yet

- Career ObjectiveDocument1 pageCareer ObjectiveNitin MahawarNo ratings yet

- The Icelandic Coast Guard: "Always Prepared"Document16 pagesThe Icelandic Coast Guard: "Always Prepared"Julie ClarkNo ratings yet

- Micro AssignmentDocument1 pageMicro AssignmentVamika SachdevaNo ratings yet

- Mathematics: Quarter 1-Module 2: Place Value and ValueDocument7 pagesMathematics: Quarter 1-Module 2: Place Value and ValuekristofferNo ratings yet

- NP WD 3 Wireless TarinSearleDocument5 pagesNP WD 3 Wireless TarinSearleTarin SearleNo ratings yet

- Goals of The Volunteers: Approved by The Officers and Advisers This 24 Day of April 2020Document2 pagesGoals of The Volunteers: Approved by The Officers and Advisers This 24 Day of April 2020Levi Lazareno EugenioNo ratings yet

- Filipino First Policy EnshrinedDocument24 pagesFilipino First Policy EnshrinedJANNNo ratings yet

- Financial Management, Ethics, & SustainabilityDocument12 pagesFinancial Management, Ethics, & SustainabilityLucky CommasNo ratings yet

- Hinesburg Record 040626 PDFDocument20 pagesHinesburg Record 040626 PDFjosh kisoiNo ratings yet