Professional Documents

Culture Documents

Tugas Khusus Nerpan Nermas Evap Bahrul

Uploaded by

Tari58Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tugas Khusus Nerpan Nermas Evap Bahrul

Uploaded by

Tari58Copyright:

Available Formats

Laporan Kerja Praktek Lampiran

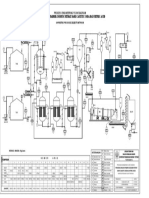

TUGAS KHUSUS NERACA MASSA DAN ENERGI STASIUN

PENGUAPAN

Data-data yang diketahui sebagai berikut :

Kapasitas giling = 15.000 ton/hari

Nira mentah = 105% tebu

Nira encer = 89,21 % tebu

Flow rate Nira encer = 105 % X 15.000 ton/hari = 15.750 ton/hari

= 656.250 kg/jam

Flow rate Nira encer = 89,21 % X 15.000 ton/hari = 13.381,5 ton/hari

= 557.562,5 kg/jam

% Brix nira encer = 11,8 %

% Brix Nira kental = 55,62 %

% Brix Nira pre-evaporator = 15,4 %

% Brix Nira evaporator I = 19,9 %

% Brix Nira evaporator II = 24,7 %

% Brix Nira evaporator III = 30,9 %

Pabrik Gula Kebon Agung, Kebon Agung – Malang vi

Laporan Kerja Praktek Lampiran

% Brix Nira evaporator IV = 44,3 %

% Brix Nira evaporator V = 59,4 %

Tekanan uap bekas = 0,8 kg/cm2

Suhu uap bekas = 118˚C

Suhu Nira masuk = 106˚C

Neraca Massa

Perhitungan Neraca Massa di setiap Evaporator

1. Pre Evaporator

Nira Nira Pekat

Encer PE

H2O

Massa Masuk

Nira Encer

Brix = 11,8% x 557.562,5 = 65.792,375

Air = 557.562,5 – 65.792,375 = 491.770,125

+

557.562,5

Massa Keluar

% 𝐵𝑟𝑖𝑥 𝑁𝑖𝑟𝑎 𝑒𝑛𝑐𝑒𝑟

H2O yang diuapkan = (1 − (% 𝐵𝑟𝑖𝑥 𝑁𝑖𝑟𝑎 𝑝𝑒𝑘𝑎𝑡 𝑃𝐸)) × 557.562,5

= (1 – (11,8/15,4)) x 557.562,5 = 130.339,286

Nira Pekat PE

Brix = 15,4% x (557.562,5-130.339,286 = 65.792,375

Air = 557.562,5 – 130.339,286 – 65.792,375 = 361.430,839

+

557.562,5

2. Evaporator I

Nira Nira Pekat

Pekat PE Evap I

H2O

Pabrik Gula Kebon Agung, Kebon Agung – Malang vii

Laporan Kerja Praktek Lampiran

Massa Masuk

Nira Pekat PE

Brix = 15,4% x (557.562,5 – 130.339,286) = 65.792,375

Air = 557.562,5 – 130.339,286 – 65.792,375 = 361.430,839

+

427.223,214

Massa Keluar

% 𝐵𝑟𝑖𝑥 𝑁𝑖𝑟𝑎 𝑒𝑛𝑐𝑒𝑟

H2O yang diuapkan = (1 − (% 𝐵𝑟𝑖𝑥 𝑁𝑖𝑟𝑎 𝑝𝑒𝑘𝑎𝑡 𝑃𝐸)) × 427.223,214

= (1 – (15,4/19,9)) x 427.223,214 = 96.608,264

Nira Pekat Evap I

Brix = 19,9% x (427.223,214 – 96.608,264) = 65.792,375

Air = 427.223,214 – 96.608,264 – 65.792,375 = 264.822,575

+

427.223,214

3. Evaporator II

Nira Nira Pekat

Evap I Evap II

H2O

Massa Masuk

Nira Pekat Evap I

Brix = 19,9% x (427.223,214 – 96.608,264) = 65.792,375

Air = 427.223,214 – 96.608,264 – 65.792,375 = 264.822,575

+

330.614,95

Massa Keluar

% 𝐵𝑟𝑖𝑥 𝑁𝑖𝑟𝑎 𝑒𝑛𝑐𝑒𝑟

H2O yang diuapkan = (1 − (% 𝐵𝑟𝑖𝑥 𝑁𝑖𝑟𝑎 𝑝𝑒𝑘𝑎𝑡 𝑃𝐸)) × 330.614,95

= (1 – (19,9/24,7)) x 330.614,95 = 64.249,059

Nira Pekat Evap II

Pabrik Gula Kebon Agung, Kebon Agung – Malang viii

Laporan Kerja Praktek Lampiran

Brix = 24,7% x (330.614,95 – 64.249,059) = 65.792,375

Air = 330.614,95 – 64.249,059 – 65.792,375 = 264.822,575

+

330.614,95

4. Evaporator III

Nira Nira Pekat

Evap II Evap III

H2O

Massa Masuk

Nira Pekat Evap II

Brix = 24,7% x (330.614,95 – 64.249,059) = 65.792,375

Air = 330.614,95 – 64.249,059 – 65.792,375 = 200.573,516

+

266.365,891

Massa Keluar

% 𝐵𝑟𝑖𝑥 𝑁𝑖𝑟𝑎 𝑒𝑛𝑐𝑒𝑟

H2O yang diuapkan = (1 − (% 𝐵𝑟𝑖𝑥 𝑁𝑖𝑟𝑎 𝑝𝑒𝑘𝑎𝑡 𝑃𝐸)) × 266.365,891

= (1 – (24,7/30,9)) x 266.365,891 = 53.445,584

Nira Pekat Evap III

Brix = 24,7% x (266.365,891 – 53.445,584) = 65.792,375

Air = 266.365,891 – 53.445,584 – 65.792,375 = 147.127,932

+

266.365,891

5. Evaporator IV

Nira Nira Pekat

Evap III Evap IV

H2O

Massa Masuk

Pabrik Gula Kebon Agung, Kebon Agung – Malang ix

Laporan Kerja Praktek Lampiran

Nira Pekat Evap III

Brix = 30,9% x (266.365,891 – 53.445,583) = 65.792,375

Air = 266.365,891 – 53.445,583 – 65.792,375 = 147.127,932

+

212.920,307

Massa Keluar

% 𝐵𝑟𝑖𝑥 𝑁𝑖𝑟𝑎 𝑒𝑛𝑐𝑒𝑟

H2O yang diuapkan = (1 − (% 𝐵𝑟𝑖𝑥 𝑁𝑖𝑟𝑎 𝑝𝑒𝑘𝑎𝑡 𝑃𝐸)) × 212.920,307

= (1 – (30,9/44,3)) x 212.920,307 = 64.404,788

Nira Pekat Evap IV

Brix = 44,3% x (212.920,307 – 64.404,788) = 65.792,375

Air = 427.223,214 – 64.404,788 – 65.792,375 = 82.723,144

+

212.920,307

6. Evaporator V

Nira Nira Pekat

Evap IV Evap V

H2O

Massa Masuk

Nira Pekat Evap IV

Brix = 44,3% x (212.920,307 – 64.404,788) = 65.792,375

Air = 212.920,307 – 64.404,788 – 65.792,375 = 82.723,144

+

148.515,519

Massa Keluar

% 𝐵𝑟𝑖𝑥 𝑁𝑖𝑟𝑎 𝑒𝑛𝑐𝑒𝑟

H2O yang diuapkan = (1 − (% 𝐵𝑟𝑖𝑥 𝑁𝑖𝑟𝑎 𝑝𝑒𝑘𝑎𝑡 𝑃𝐸)) × 148.515,519

= (1 – (44,3/59,4)) x 148.515,519 = 37.753,945

Nira Pekat Evap V

Brix = 59,4% x (148.515,519 – 37.753,945) = 65.792,375

Pabrik Gula Kebon Agung, Kebon Agung – Malang x

Laporan Kerja Praktek Lampiran

Air = 148.515,519 – 37.753,945 – 65.792,375 = 44.969,199

+

148.515,519

Hasil Perhitungan Neraca Massa di Setiap Evaporator

Pre-Evaporator

Masuk Rate (Kg/jam) Keluar Rate (Kg/jam)

Brix 65.792,375 H2O dari Pre-Evap 130.339,286

Air 491.770,125 Brix dari Pre-Evap 65.792,375

Air dari Pre-Evap 361.430,839

Total 557.562,500 Total 557.562,500

Evaporator 1

Masuk Rate (Kg/jam) Keluar Rate (Kg/jam)

Brix 65.792,375 H2O dari Evap I 96.608,264

Air 361.430,839 Brix dari Evap I 65.792,375

Air dari Evap I 264.822,575

Total 427.223,214 Total 427.223,214

Evaporator 2

Masuk Rate (Kg/jam) Keluar Rate (Kg/jam)

Brix 65.792,375 H2O dari Evap II 64.249,059

Air 264.822,575 Brix dari Evap II 65.792,375

Air dari Evap II 200.573,516

Total 330.614,950 Total 330.614,950

Evaporator 3

Masuk Rate (Kg/jam) Keluar Rate (Kg/jam)

Brix 65.792,375 H2O dari Evap III 53.445,584

Air 200.573,516 Brix dari Evap III 65.792,375

Air dari Evap III 147.127,932

Total 266.365,891 Total 266.365,891

Pabrik Gula Kebon Agung, Kebon Agung – Malang xi

Laporan Kerja Praktek Lampiran

Evaporator 4

Masuk Rate (Kg/jam) Keluar Rate (Kg/jam)

Brix 65.792,375 H2O dari Evap IV 64.404,788

Air 147.127,932 Brix dari Evap IV 65.792,375

Air dari Evap IV 82.723,144

Total 212.920,307 Total 212.920,307

Evaporator 5

Masuk Rate (Kg/jam) Keluar Rate (Kg/jam)

Brix 65.792,375 H2O dari Evap V 37.753,945

Air 82.723,144 Brix dari Evap V 65.792,375

Air dari Evap V 44.969,199

Total 148.515,519 Total 148.515,519

Perhitungan Neraca Massa Overall di Evaporator

Nira Nira Pekat

Encer Evap V

H2O

Massa Masuk

Nira Encer

Brix = 11,8 % x 557.562,5 = 65.792,375

Air = 557.562,5 – 65.792,38 = 491.770,125

+

557.562,5

Massa Keluar

% 𝐵𝑟𝑖𝑥 𝑁𝑖𝑟𝑎 𝑃𝐸

H2O yang diuapkan = (1 − (% 𝐵𝑟𝑖𝑥 𝑁𝑖𝑟𝑎 )) × 557.562,5

𝑃𝑒𝑘𝑎𝑡 𝐸𝑣𝑎𝑝 𝑉

Pabrik Gula Kebon Agung, Kebon Agung – Malang xii

Laporan Kerja Praktek Lampiran

= (1 – (11,8/59,4)) x 557.562,5 = 446.800,926

Nira Pekat Evap V

Brix = 59,4 % x (557.562,5 – 446.800,926) = 65.792,375

Air = 557.562,5 – 446.800,926 – 65.792,375 = 44.969,199

+

557.562,5

Hasil Perhitungan Neraca Massa Overall Pada Evaporator

Masuk Rate (Kg/jam) Keluar Rate (Kg/jam)

Brix 65.792,375 H2O dari Evap V 466.800,926

Air 491.770,125 Brix dari Evap V 65.792,375

Air dari Evap V 44.969,199

Total 557.562,500 Total 557.562,500

Neraca Panas

Distribusi tekanan menurut Hugot

Tekanan Uap Bekas = 0,8 kg/cm2

76 cmHg

= 1,8332 kg/cm2 abs x

1,0332 kg/cm2

= 134,846 cmHg abs

Dari hasil interpolasi pada P = 1.8332 kg/cm2 abs diperoleh :

T pre evaporator = 116,497 ˚C

(Sumber : Tabel 41.1A, “Properties of Dry Saturated Steam, Hugot, 3rd edition,

hlm. 1034)

Vacuum Evaporator V = 57 cmHg

= 76 cmHg – 57 cmHg = 19 cmHg abs

ΔP (Pressure Drop) pre evaporator sampai evaporator V = 134,846 – 19

= 115,846 cmHg abs

Perbandingan distribusi ΔP setiap evaporator

(Sumber : Tabel 32.23, “Distribution of Pressure Drop between Vessels”, Hugot,

3rd edition, hlm.579)

Pabrik Gula Kebon Agung, Kebon Agung – Malang xiii

Laporan Kerja Praktek Lampiran

- Evaporator I = 11/50

- Evaporator II = 10,5/50

- Evaporator III = 10/50

- Evaporator IV = 9,5/50

- Evaporator V = 9/50

Tekanan Evaporator I = 134,846 – (11/50 x 115,846)

= 109,36 cmHg abs

= 1,487 kg/cm2 abs

Dari hasil interpolasi pada P = 1,487 kg/cm2 abs diperoleh Tuap = 110,457 ˚C

(Sumber : Tabel 41.1A, “Properties of Dry Saturated Steam, Hugot, 3rd edition,

hlm. 1034)

Tekanan Evaporator II = 109,36 – (10,5/50 x 115,846)

= 85,032 cmHg abs

= 1,156 kg/cm2 abs

Dari hasil interpolasi pada P = 1,156 kg/cm2 abs diperoleh Tuap = 102,939 ˚C

(Sumber : Tabel 41.1A, “Properties of Dry Saturated Steam, Hugot, 3rd edition,

hlm. 1034)

Tekanan Evaporator III = 85,032 – (10/50 x 115,846)

= 61,863 cmHg abs

= 0,841 kg/cm2 abs

Dari hasil interpolasi pada P = 0,841 kg/cm2 abs diperoleh Tuap = 94,002 ˚C

(Sumber : Tabel 41.1A, “Properties of Dry Saturated Steam, Hugot, 3rd edition,

hlm. 1034)

Tekanan Evaporator IV = 61,863 – (9,5/50 x 115,846)

= 39,852 cmHg abs

= 0,542 kg/cm2 abs

Dari hasil interpolasi pada P = 0,542 kg/cm2 abs diperoleh Tuap = 82,626 ˚C

(Sumber : Tabel 41.1A, “Properties of Dry Saturated Steam, Hugot, 3rd edition,

hlm. 1034)

Tekanan Evaporator V = 39,852 – (9/50 x 115,846)

= 19 cmHg abs

= 0,258 kg/cm2 abs

Pabrik Gula Kebon Agung, Kebon Agung – Malang xiv

Laporan Kerja Praktek Lampiran

Dari hasil interpolasi pada P = 0,258 kg/cm2 abs diperoleh Tuap = 64,832 ˚C

(Sumber : Tabel 41.1A, “Properties of Dry Saturated Steam, Hugot, 3rd edition,

hlm. 1034)

Perhitungan kalor jenis (Cp) Nira pada setiap Evaporator

Rumus = Cp = 1 – (0,006 x X) kkal/kg ˚C X = % Brix Nira

- Kalor jenis (Cp) Nira Encer

Cp = 1 – (0,006 x 11,8) = 0,929 kkal/kg ˚C

- Kalor jenis (Cp) Nira Pekat

Cp (Pre Evaporator) = 1 – (0,006 x 15,4) = 0,9076 kkal/kg ˚C

Cp (Evaporator I) = 1 – (0,006 x 19,9) = 0,8806 kkal/kg ˚C

Cp (Evaporator II) = 1 – (0,006 x 24,7) = 0,8518 kkal/kg ˚C

Cp (Evaporator III) = 1 – (0,006 x 30,9) = 0,8146 kkal/kg ˚C

Cp (Evaporator IV) = 1 – (0,006 x 44,3) = 0,7342 kkal/kg ˚C

Cp (Evaporator V) = 1 – (0,006 x 59,4) = 0,6436 kkal/kg ˚C

Perhitungan Boiling Point Rise (BPR) atau Kenaikan Titik Didih Nira :

Rumus = BPR = 1,78x + 6,22x2 0C x = Fraksi Nira

(Sumber : Geankoplis, “Transport Process and Unit Operations”, 3rd edition,

hlm. 506)

Dari hasil perhitungan didapatkan hasil sebagai berikut :

Suhu Uap Suhu Nira

Komponen Fraksi Nira BPR (˚C)

Nira (˚C) (˚C)

Pre Evaporator 0,154 0,422 116,497 116,919

Evaporator I 0,199 0,601 110,457 111,058

Evaporator II 0,247 0,819 102,939 103,758

Evaporator III 0,309 1,144 94,002 95,146

Evaporator IV 0,443 2,009 82,626 84,635

Evaporator V 0,594 3,252 64,832 68,084

Pabrik Gula Kebon Agung, Kebon Agung – Malang xv

Laporan Kerja Praktek Lampiran

Data-data untuk menghitung Neraca Panas

Komponen P (kg/cm2) T (˚C) λ (kkal/kg) q (kkal/kg)

Uap Bekas 0,800 125 647,675 125,338

Nira Pekat Pre 116,497 644,799 116,697

1,833

Evaporator 116,919 644,945 117,127

Nira Pekat 110,457 642,705 110,552

1,487

Evaporator I 111,058 642,921 111,158

Nira Pekat 102,939 639,998 102,958

1,156

Evaporator II 103,758 640,293 103,786

Nira Pekat 94,002 636,641 94,002

0,841

Evaporator III 95,146 637,075 95,146

Nira Pekat 82,626 632,318 82,626

0,542

Evaporator IV 84,636 633,081 84,635

Nira Pekat 64,832 625,171 64,732

0,258

Evaporator V 68,084 626,504 67,984

λ dan q didapatkan dari interpolasi terhadap suhu

(Sumber :Tabel 41.1 A, “Properties of Dry Saturated Steam, Hugot, 3rd edition,

hlm. 1034)

Perhitungan Neraca Panas pada Evaporator

Nira Encer (F) Nira Pekat (L)

Uap (S) Kondensat (C)

H2O (V)

Neraca Panas Overall : Dimana : mV = Rate massa uap (kg/jam)

F hF + S HS = L hL + V HV + C hC mN = Rate massa Nira (kg/jam)

Panas Masuk λ = Total heat (kkal/kg)

- Uap = mV1 x λ1 q = Sensible heat (kkal/kg)

- Nira = mN1 x CP1 x T1 CP = Kalor Jenis (kkal/kg ˚C)

Panas Keluar T = Suhu (˚C)

- Kondensat = mV2 x q2

- H2O yang diuapkan = mV2 x λ2

Pabrik Gula Kebon Agung, Kebon Agung – Malang xvi

Laporan Kerja Praktek Lampiran

- Nira = mN2 x CP1 x T2

Notasi 1 = keadaan masuk

Notasi 2 = keadaan keluar

Perhitungan Neraca Panas setiap Evaporator

1. Pre Evaporator

Panas Masuk

1. Uap = mV x 647,675 = 647,675 mV

2. Nira Encer = 557.562,5 x 0,929 x 106 = 54.917.229,95

+

54.917.229,95 + 647,675 mV

Panas Keluar

1. Kondensat = mV x 125,338 = 125,338 mV

2. H2O yang diuapkan = 130.339,286 x 644,945 = 84.061.640,93

3. Nira Pekat Pre Evap = 427.223,214 x 0,908 x 116,919 = 45.335.113,77

+

129.396.754,70 + 125,338 mV

Persamaan Neraca Panas Overall :

In = Out

54.917.229,95 + 647,675 mV = 129.396.754,70 + 125,338 mV (balance)

74.479.524,75 = 522,34 mV

mV = 142.588,89 kg/jam

Pre-Evaporator

Masuk Jumlah (kcal/jam) Keluar Jumlah (kcal/jam)

Uap 63.255.016,26 Kondensat 104.566.855,6

Nira Encer 407.185.612,569 H2O yang diuapkan 623.421,3

Nira Pekat Pre Evp 337.267.282,859

Total 470.440.628,8 Total 470.440.628,8

Evaporator I

Pabrik Gula Kebon Agung, Kebon Agung – Malang xvii

Laporan Kerja Praktek Lampiran

Masuk Jumlah (kcal/jam) Keluar Jumlah (kcal/jam)

Uap 39.859.308,579 Kondensat 135.695.608,582

Nira dari pre 337.267.282,859 H2O yang diuapkan 630.895,583

Nira Pekat Evp I 240.800.087,273

Total 377.126.591,438 Total 377.126.591,438

Evaporator II

Masuk Jumlah (kcal/jam) Keluar Jumlah (kcal/jam)

Uap 34.916.825,657 Kondensat 145.754.866,456

Nira dari I 240.800.087,273 H2O yang diuapkan 222.491,468

Nira Pekat Evp II 174.939.555,006

Total 278.716.912,930 Total 278.716.912,930

Evaporator III

Masuk Jumlah (kcal/jam) Keluar Jumlah (kcal/jam)

Uap 22.470.228,967 Kondensat 127.323.904,034

Nira dari II 217.136.030,586 H2O yang diuapkan 199.682,768

Nira Pekat Evp III 122.780.672,751

Total 245.606.259,553 Total 245.606.259,553

Evaporator IV

Masuk Jumlah (kcal/jam) Keluar Jumlah (kcal/jam)

Uap 18.296.832,061 Kondensat 67.104.418,813

Nira dari III 122.780.672,751 H2O yang diuapkan 156.826,630

Nira Pekat Evp IV 68.623.259,369

Total 140.077.504,812 Total 140.077.504,812

Evaporator V

Masuk Jumlah (kcal/jam) Keluar Jumlah (kcal/jam)

Uap 15.413.264,794 Kondensat 46.405.813,337

Nira dari III 68.623.259,369 H2O yang diuapkan 140.474,397

Nira Pekat Evp IV 36.212.236,430

Total 83.036.524,164 Total 83.036.524,164

Pabrik Gula Kebon Agung, Kebon Agung – Malang xviii

You might also like

- Perhitungan EvaporatorDocument11 pagesPerhitungan EvaporatorardisixxNo ratings yet

- Laporan Kerja Ptaktik Pabrik Gula BungamayangDocument81 pagesLaporan Kerja Ptaktik Pabrik Gula BungamayangArdiSaputraNo ratings yet

- Lamp. B - Neraca PanasDocument38 pagesLamp. B - Neraca PanasAhmad Herman100% (1)

- Tabel Dasar Teori Praktikum Utilitas PDFDocument3 pagesTabel Dasar Teori Praktikum Utilitas PDFBima FernandoNo ratings yet

- Screw Conveyor (Sc-01) 2xDocument2 pagesScrew Conveyor (Sc-01) 2xRafi Theda PrabawaNo ratings yet

- Lampiran B (Neraca Panas)Document30 pagesLampiran B (Neraca Panas)Sandra IvanaNo ratings yet

- Neraca Energi Reaktor Word Kelompok 14Document8 pagesNeraca Energi Reaktor Word Kelompok 14Rani khairaniNo ratings yet

- Ruzicka CP Estimation MethodDocument11 pagesRuzicka CP Estimation MethodAndreea Cristina PetcuNo ratings yet

- Netra LizerDocument29 pagesNetra LizerElwin Putra SitinjakNo ratings yet

- Neraca MassaDocument38 pagesNeraca MassaGunNo ratings yet

- Lembar Perhitungan Size ReductionDocument10 pagesLembar Perhitungan Size ReductionNada SilviaNo ratings yet

- Pabrik Baturaja III PT. Semen Baturaja (Persero) TBKDocument3 pagesPabrik Baturaja III PT. Semen Baturaja (Persero) TBKIzzy Rss Outsiders100% (1)

- Perhitungan Neraca Panas Di Clinker CoolerDocument3 pagesPerhitungan Neraca Panas Di Clinker CoolerPutri Hanifah SNo ratings yet

- Ullia Nurul - 11.7.6 OtkDocument8 pagesUllia Nurul - 11.7.6 OtkUllia Ismala0% (1)

- Neraca Massa Dan Neraca Panas Ball Mill (Revisi FIXED)Document18 pagesNeraca Massa Dan Neraca Panas Ball Mill (Revisi FIXED)astrianyNo ratings yet

- Steam Balance TCDDocument12 pagesSteam Balance TCDSaifuddinHidayatNo ratings yet

- Prarancangan Pabrik Kimia HexamineDocument1 pagePrarancangan Pabrik Kimia HexaminesimoehchNo ratings yet

- Data Konstanta AntoineDocument32 pagesData Konstanta AntoineSurya NingrumNo ratings yet

- Appendix Tugas Akhir (Pa)Document328 pagesAppendix Tugas Akhir (Pa)AQSHANo ratings yet

- Lampiran PerhitunganDocument15 pagesLampiran PerhitunganAchmadJa'farShodiqShahabNo ratings yet

- Neraca Massa SabunDocument23 pagesNeraca Massa SabunFrhandd MuhammadNo ratings yet

- Analisa Ekonomi (Ekotek, Teknik Kimia)Document13 pagesAnalisa Ekonomi (Ekotek, Teknik Kimia)Beta PertiwiNo ratings yet

- Standard Sizes of Pipes (After Changing)Document45 pagesStandard Sizes of Pipes (After Changing)Muhammad AliNo ratings yet

- Jawaban Pemisahan PAK AMIRDocument93 pagesJawaban Pemisahan PAK AMIRRifai Partogi ManaluNo ratings yet

- Solid Gas FluidizationDocument9 pagesSolid Gas FluidizationHaris PratamaNo ratings yet

- Te HEDocument6 pagesTe HEjamieNo ratings yet

- Tugas Perpindahan PanasDocument145 pagesTugas Perpindahan PanasHime_ChiakiNo ratings yet

- NM Doni BaruDocument47 pagesNM Doni BaruAhmad SupraptoNo ratings yet

- Flash Distillation: All Rights Reserved. Armando B. Corripio, PHD, Pe. 2013Document29 pagesFlash Distillation: All Rights Reserved. Armando B. Corripio, PHD, Pe. 2013beshoy naseefNo ratings yet

- Metanol Air Data KesetimbanganDocument2 pagesMetanol Air Data KesetimbanganYou Wahyu NugrohoNo ratings yet

- Daik 6.6Document1 pageDaik 6.6Nisrina Hutti67% (3)

- Diagram Alir Allyl ChlorideDocument2 pagesDiagram Alir Allyl ChlorideCeevz Batara GuruNo ratings yet

- Perhitungan Neraca EnergiDocument18 pagesPerhitungan Neraca EnergiRian Al-ayyubNo ratings yet

- Prarancangan Pabrik Sodium Nitrat Dari Caustic Soda Dan Nitric AcidDocument1 pagePrarancangan Pabrik Sodium Nitrat Dari Caustic Soda Dan Nitric AcidAnggit Dwi WNo ratings yet

- FLOWSHEET Semen IndonesiaDocument2 pagesFLOWSHEET Semen IndonesiaAjeng FadillahNo ratings yet

- Cooling ConveyorDocument9 pagesCooling ConveyornikmahNo ratings yet

- Data Impor Xylitol 2006-2016Document3 pagesData Impor Xylitol 2006-2016Anonymous s7xTz1No ratings yet

- Tabel Antoine 1Document3 pagesTabel Antoine 1atikaindrnNo ratings yet

- Neraca Energi Pabrik Teh Ready To DrinkDocument3 pagesNeraca Energi Pabrik Teh Ready To DrinkAisy AllienNo ratings yet

- TUGAS 5 (Revisi Format) - Kelompok 6Document3 pagesTUGAS 5 (Revisi Format) - Kelompok 6Jenny AzzahraNo ratings yet

- Atk 2Document7 pagesAtk 2Nu'ainir RosyidahNo ratings yet

- Tugas Perpindahan Panas (Kelompok 7)Document2 pagesTugas Perpindahan Panas (Kelompok 7)Liwang Ulama UtamaNo ratings yet

- Daftar Konstanta AntoineDocument3 pagesDaftar Konstanta AntoineEllen Novian MufidahNo ratings yet

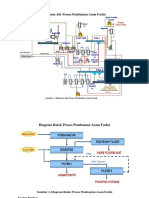

- Diagram Alir Proses Pembuatan Asam FosfatDocument4 pagesDiagram Alir Proses Pembuatan Asam FosfatGos RapNo ratings yet

- Daftar Produsen Urea Formaldehid Di IndonesiaDocument1 pageDaftar Produsen Urea Formaldehid Di IndonesiaMazroahNo ratings yet

- Operasi Teknik Kimia Iii Rizka Amalia, S.T., M.TDocument60 pagesOperasi Teknik Kimia Iii Rizka Amalia, S.T., M.TEnricoNo ratings yet

- Neraca Massa Rotary KilnDocument47 pagesNeraca Massa Rotary KilnAyu permata sariNo ratings yet

- Perhitungan Evaporator PDFDocument17 pagesPerhitungan Evaporator PDFAckmad ZhealNo ratings yet

- Perhitungan Efisiensi FurnaceDocument18 pagesPerhitungan Efisiensi FurnaceFeri Dhika Prasetya40% (5)

- Tugas Atk 1: Problem Himmelblau Edisi 7: Halaman 56Document15 pagesTugas Atk 1: Problem Himmelblau Edisi 7: Halaman 56SafefireNo ratings yet

- BAB V Tugas Khusus EvaporatorDocument6 pagesBAB V Tugas Khusus EvaporatorfauziNo ratings yet

- Water Balance 5000 TCDDocument7 pagesWater Balance 5000 TCDdgmNo ratings yet

- Fuel Consumption For Boiler SPDocument20 pagesFuel Consumption For Boiler SPaqilah liyanaNo ratings yet

- 8) Pengolahan Data DIESEL 1 Katup Gas Konstan-DikonversiDocument47 pages8) Pengolahan Data DIESEL 1 Katup Gas Konstan-DikonversiIndra Arvito ArmanNo ratings yet

- Final Report DTSDocument33 pagesFinal Report DTSNikhil SatbhaiNo ratings yet

- Meshkat Design DistillationDocument43 pagesMeshkat Design DistillationjdedfvNo ratings yet

- GPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For RevisionDocument13 pagesGPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For RevisionBrayan Dali Nattez VargasNo ratings yet

- PerhitunganDocument7 pagesPerhitunganKhairilHidayahNo ratings yet

- Task Description Task Time (Sec) Preceeding Task: Pizza AssemblyDocument8 pagesTask Description Task Time (Sec) Preceeding Task: Pizza AssemblyAngeliePanerioGonzagaNo ratings yet

- Laboratory Exercises in Astronomy: Solutions and AnswersFrom EverandLaboratory Exercises in Astronomy: Solutions and AnswersNo ratings yet