50% found this document useful (2 votes)

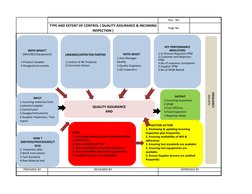

4K views1 pageTurtle Diagram Type and Extent Control For QA Department

1. The document outlines the quality assurance and incoming inspection process for materials, machines, and equipment.

2. Key aspects that are monitored include in-process rejection rates, customer end rejection rates, customer complaints, and supplier performance.

3. The process involves incoming inspections, supplier quality performance reports, first piece inspections, final inspections, and identifying non-conforming products. Risks are mitigated by regularly updating inspection plans, ensuring work instructions and test standards are available, and auditing supplier processes.

Uploaded by

suresh kumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

50% found this document useful (2 votes)

4K views1 pageTurtle Diagram Type and Extent Control For QA Department

1. The document outlines the quality assurance and incoming inspection process for materials, machines, and equipment.

2. Key aspects that are monitored include in-process rejection rates, customer end rejection rates, customer complaints, and supplier performance.

3. The process involves incoming inspections, supplier quality performance reports, first piece inspections, final inspections, and identifying non-conforming products. Risks are mitigated by regularly updating inspection plans, ensuring work instructions and test standards are available, and auditing supplier processes.

Uploaded by

suresh kumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Quality Assurance and Incoming Inspection: Explains the quality assurance process including methods, inputs, outputs, and interaction actions required for incoming inspection.