100% found this document useful (1 vote)

459 views10 pagesHigh Strain Pile Testing Guide

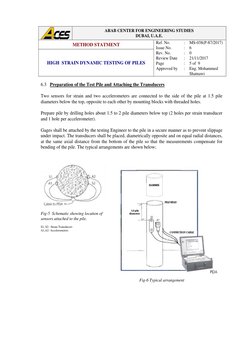

This document provides a method statement for conducting high strain dynamic testing of piles to determine their force and velocity response when impacted. The testing involves attaching sensors to piles and striking them with an impact hammer. The sensors measure strain, acceleration, velocity and displacement over time. The data is analyzed to estimate pile bearing capacity, integrity, stresses, and soil properties. The method statement describes the testing equipment, personnel requirements, sensor attachment procedure, and data collection and interpretation process.

Uploaded by

Ghayas JawedCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

459 views10 pagesHigh Strain Pile Testing Guide

This document provides a method statement for conducting high strain dynamic testing of piles to determine their force and velocity response when impacted. The testing involves attaching sensors to piles and striking them with an impact hammer. The sensors measure strain, acceleration, velocity and displacement over time. The data is analyzed to estimate pile bearing capacity, integrity, stresses, and soil properties. The method statement describes the testing equipment, personnel requirements, sensor attachment procedure, and data collection and interpretation process.

Uploaded by

Ghayas JawedCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd