Professional Documents

Culture Documents

Pile Integrity Test

Uploaded by

Rolly Marc G. SoteloCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pile Integrity Test

Uploaded by

Rolly Marc G. SoteloCopyright:

Available Formats

Document Reference

FREY-FIL CORPORATION FFC

Rev. No. Rev. Date

INFRA MANAGEMENT SYSTEM 00

Page Document No.

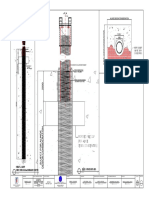

PILE INTEGRITY TEST 1 of 7 FFC-DBCB3-MS-004

Construction of Abusag Bridge Location

Baggao - Dalin - Sta. Margarita Road

Baggao, Cagayan

FREY-FIL CORPORATION

INFRASTRUCTURE MANAGEMENT SYSTEM

Method Statement for

Pile Integrity Test

Revision and Approval Block

Re Prepared By Verified By Approved By Noted By

Issue

v Description Details

Date DPM PM

No

Sign

Date

Sign

Date

Sign

Date

Print Date: 05/Jun/2020

Contents

1. Purpose......................................................................................................................................3

2. Scope..........................................................................................................................................3

3. Responsibilities.........................................................................................................................3

4. Method of Application..............................................................................................................3

5. Resources..................................................................................................................................4

5.1 Manpower................................................................................................................................4

5.2 Materials..................................................................................................................................4

5.3 Equipment...............................................................................................................................4

6. Annexes...................................................................................................................................4-6

1. Purpose

This method statement covers the requirement and procedure of Pile Integrity.

2. Scope

The Seismic echo method of assessing piles is able to analyze acoustic anomalies corresponding to the

following:

Print Date: 05/Jun/2020

Pile Toe Level

Shaft restraints

Overbreak

Cracks

Reductions in section

Zones of poor quality concrete

3. Responsibilities

It is the responsibility of the Project Manager and concerned Site personnel to ensure that all activities are

performed in compliance with this Procedure and applicable Contract Specifications. On projects where

designated QC Engineers are not available, the Site Engineer will be responsible for performing the duties of the

QC Engineer.

4. Method of Application

Pile head preparation

In order to obtain the very best data possible when testing a pile, it is essential that the pile head is

prepared properly prior to testing. Without good data any interpretation carried out will be

meaningless. It is essential that the measurement transducers are mounted in the correct position and

on sound concrete. The essentials of pile head preparation for integrity testing are given below:

1. Piles should if possible be tested at the cut-off level and trimmed to sound concrete. Any weak,

broken concrete that sounds hollow should be removed and the pile top left roughly horizontal over the

complete cross section.

2. Reinforcing bars should be bent slightly away if practicable and the helical removed to allow for a

good swing of the test hammer.

3. Two areas should be prepared for the transducers, one for the hammer in the center of the pile and

the other for the geophone close to the pile perimeter. The areas should be approximately 100 mm in

diameter and prepared as flat and level as possible using a scabbler, scutch hammer or even a hammer

and chisel, then brushed free of debris.

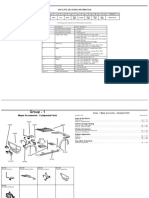

Placing the Sensor

Place the accelerometer with a small amount of Pietoplast to the top of the pile, ensuring that the

sensor is vertical. Choose a relatively flat, off-center spot and press with hand weight. (The Pietoplast

helps transfer the signal and damp the resonance from pile to sensor.) Do not position the sensor close

to the location of impact. Note: If the pile top is not easily accessible, the accelerometer can also be

attached to the pile shaft.

5. Resources

5.1 Manpower

i. Project Manager

ii. Bored Pile Manager

iii. Field Engineer

iv. General Foreman

v. Leadman

vi. Laborer

Print Date: 05/Jun/2020

5.2 Materials

i. PIT materials

5.3 Equipment

i. PIT electronic equipment

ii. Chipping tools

6. Annexes

Print Date: 05/Jun/2020

Print Date: 05/Jun/2020

Print Date: 05/Jun/2020

Print Date: 05/Jun/2020

You might also like

- Piling and Foundation Works for Multipurpose Warehouse and Bulk Warehouse - Phase II at Arshiya Northern FTWZ Limited Thurga Hist Bulandshahar Uttar PradeshDocument4 pagesPiling and Foundation Works for Multipurpose Warehouse and Bulk Warehouse - Phase II at Arshiya Northern FTWZ Limited Thurga Hist Bulandshahar Uttar PradeshAjay MalikNo ratings yet

- 26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodDocument16 pages26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodpdksubudhiNo ratings yet

- Moisture Correction SheetDocument4 pagesMoisture Correction SheetSasanka SekharNo ratings yet

- Six Laning of Shamlaji to Motachiloda GSB Trial Patch ReportDocument2 pagesSix Laning of Shamlaji to Motachiloda GSB Trial Patch ReportMd YasinNo ratings yet

- Remedial Works for Excessive Deflections in PilesDocument8 pagesRemedial Works for Excessive Deflections in Pilestin aungtunNo ratings yet

- Contractor: Edward and ChristieDocument5 pagesContractor: Edward and ChristieSubasinghe DharmapalaparkNo ratings yet

- Pile Load Test MethodologyDocument4 pagesPile Load Test MethodologyAkhilesh Dwivedi100% (1)

- Blockwork and Plastering - HalulDocument14 pagesBlockwork and Plastering - HalulDindo QuintanNo ratings yet

- Compressive Strength Test of Concrete Cylinders Specimen: CP06/RIW/190828/CVL/SWY/02630Document1 pageCompressive Strength Test of Concrete Cylinders Specimen: CP06/RIW/190828/CVL/SWY/02630Shoyeeb AhmedNo ratings yet

- Lateral Load Test Pile - General Arrangement & Test ProcedureDocument7 pagesLateral Load Test Pile - General Arrangement & Test ProcedureDipesh Chandra BaruaNo ratings yet

- 114 - Method Statement For Bored Cast in Situ Pile - R2 PDFDocument42 pages114 - Method Statement For Bored Cast in Situ Pile - R2 PDFDadi YashwantNo ratings yet

- SOP of Pull Out, Lateral & Compression - REV01Document8 pagesSOP of Pull Out, Lateral & Compression - REV01Prince MittalNo ratings yet

- Methodology For Water Tightness Test For Expansion JointDocument1 pageMethodology For Water Tightness Test For Expansion Jointvenkateswara rao PothinaNo ratings yet

- 14a Prime CoatDocument3 pages14a Prime CoatAkhilesh DwivediNo ratings yet

- Method Statement For Embankment and SubgradeDocument19 pagesMethod Statement For Embankment and SubgradeBiswajit BarikNo ratings yet

- Cb2 Q Zen 05 60211 Itp For Earth Work - Rev.bDocument6 pagesCb2 Q Zen 05 60211 Itp For Earth Work - Rev.bAnonymous wIPMQ5rhNo ratings yet

- Concrete Inspection and Testing PlanDocument3 pagesConcrete Inspection and Testing PlanMohammed Ghareib NasrNo ratings yet

- Larsen & Toubro Limited - Ecc Division: Page 1 of 4Document4 pagesLarsen & Toubro Limited - Ecc Division: Page 1 of 4Akhilesh Dwivedi100% (1)

- Sand Calibration FormetDocument2 pagesSand Calibration FormetAnish PanchalNo ratings yet

- Road Work For GSB, WMM & Bitumen Job QAPDocument2 pagesRoad Work For GSB, WMM & Bitumen Job QAPSasanka SekharNo ratings yet

- Initial Pile Load Test Methodology - R0Document20 pagesInitial Pile Load Test Methodology - R0Lalit Pratap Singh Tomar100% (1)

- Dowel Bar GroutingDocument3 pagesDowel Bar GroutingAkhilesh DwivediNo ratings yet

- Repair Grouting ChecklistDocument1 pageRepair Grouting ChecklistSushil GuptaNo ratings yet

- Bored Pile Construction MethodDocument5 pagesBored Pile Construction MethodVijay Jamadar100% (2)

- Pile Load Test PDFDocument11 pagesPile Load Test PDFAjit P. SinghNo ratings yet

- Field Quality PlanDocument15 pagesField Quality PlanManoj ShahNo ratings yet

- Tuglakabad Corridor Load Test ReportDocument8 pagesTuglakabad Corridor Load Test Reportarif_rubinNo ratings yet

- Cube Failure ReportDocument15 pagesCube Failure ReportVenu PrasadNo ratings yet

- WMM Mix DesignDocument57 pagesWMM Mix Designp. kiran kuamrNo ratings yet

- Light - Standard Proctor Compaction Test of Soil (Is-2720-Part-7-1980)Document5 pagesLight - Standard Proctor Compaction Test of Soil (Is-2720-Part-7-1980)Kantrathi BhaskarNo ratings yet

- Pile Dynamic Test MethodologyDocument3 pagesPile Dynamic Test Methodologykom1984No ratings yet

- NR Letter Submission of ITP For HSFG BoltsDocument2 pagesNR Letter Submission of ITP For HSFG BoltsLakhwant Singh KhalsaNo ratings yet

- Comparison of Static and Dynamic Load Test of PileDocument11 pagesComparison of Static and Dynamic Load Test of PilehangNo ratings yet

- Method Statement For Pile Load Test by Kentledge MDocument4 pagesMethod Statement For Pile Load Test by Kentledge MCza ManNo ratings yet

- TUNNEL CONSTRUCTIONDocument1 pageTUNNEL CONSTRUCTIONRitik RajNo ratings yet

- Lateral Load Test Methodology and Design For Agra-TundlaDocument13 pagesLateral Load Test Methodology and Design For Agra-Tundlabp chaudharuNo ratings yet

- NHAI 4-Laning Cholapuram to Thanjavur Section NH-45CDocument1 pageNHAI 4-Laning Cholapuram to Thanjavur Section NH-45CDwijendra Chanumolu100% (2)

- Test Pile MethodologyDocument7 pagesTest Pile MethodologyCOME TO KNOWNo ratings yet

- BBS For Test Pile-03 at OMG - 1000mm DiaDocument5 pagesBBS For Test Pile-03 at OMG - 1000mm DiaAjay MalikNo ratings yet

- Method Statement For WMMDocument6 pagesMethod Statement For WMMKeerti BonguNo ratings yet

- Fosroc Nitocote EM 300 protects concrete from corrosionDocument2 pagesFosroc Nitocote EM 300 protects concrete from corrosionAarish Khan100% (1)

- Slump Cone and Rod - CalibrationDocument1 pageSlump Cone and Rod - CalibrationKannan MurugesanNo ratings yet

- Initial Load Test ReportDocument6 pagesInitial Load Test ReportRAHUL RAVINDRANNo ratings yet

- Larsen & Toubro Limited - Ecc Division: Page 1 of 3Document3 pagesLarsen & Toubro Limited - Ecc Division: Page 1 of 3Akhilesh DwivediNo ratings yet

- Form Work, Reinforcement & Concreting - MethodologyDocument10 pagesForm Work, Reinforcement & Concreting - MethodologyRabnawaz ImamNo ratings yet

- Mix Design by Various MethodsDocument113 pagesMix Design by Various MethodsrahuldasbiNo ratings yet

- External NCR MonitoringDocument7 pagesExternal NCR MonitoringGhayas JawedNo ratings yet

- Method Statement: Granular Sub Base (GSB) Layer Compaction ProcessDocument1 pageMethod Statement: Granular Sub Base (GSB) Layer Compaction ProcessjitendraNo ratings yet

- Method Statement For PIT TestDocument4 pagesMethod Statement For PIT TestArifur Rahman Apu100% (1)

- Pile Integrity TestDocument7 pagesPile Integrity TestFazren KamarudinNo ratings yet

- Tiki Tar's "AsphaltosealDocument41 pagesTiki Tar's "Asphaltosealnagaraj_qce3499100% (1)

- QAP For Bitumen JobDocument2 pagesQAP For Bitumen JobSasanka SekharNo ratings yet

- Load Test Report - FinalDocument15 pagesLoad Test Report - FinalShamim Mahmudur RahmanNo ratings yet

- QA-000-AA-5016 ITP For Stone Colume Rev. 0 (Approved)Document15 pagesQA-000-AA-5016 ITP For Stone Colume Rev. 0 (Approved)AbrahamAbraciaNo ratings yet

- Plate Load Test Report for Stone Columns at 220 KV SubstationDocument34 pagesPlate Load Test Report for Stone Columns at 220 KV SubstationSushant Giri100% (1)

- Soundar L&TDocument8 pagesSoundar L&TSoundar PachiappanNo ratings yet

- Pileload Tes ReportDocument22 pagesPileload Tes ReportMahmudle HassanNo ratings yet

- Frey-Fil Corporation: Pile Dynamic TestDocument7 pagesFrey-Fil Corporation: Pile Dynamic TestRolly Marc G. SoteloNo ratings yet

- Concrete Sheet Pile Construction MethodologyDocument15 pagesConcrete Sheet Pile Construction MethodologyRolly Marc G. Sotelo100% (1)

- Piping Design CriteriaDocument23 pagesPiping Design CriteriaJafar Al-iraqiNo ratings yet

- Estimated Actual Materials-1Document1 pageEstimated Actual Materials-1Rolly Marc G. SoteloNo ratings yet

- Design Analysis SummaryDocument47 pagesDesign Analysis SummaryRolly Marc G. SoteloNo ratings yet

- Structural drawing detailsDocument1 pageStructural drawing detailsRolly Marc G. SoteloNo ratings yet

- CAFETERIA ELECTRICAL LOAD SCHEDULE AND GENERAL NOTESDocument1 pageCAFETERIA ELECTRICAL LOAD SCHEDULE AND GENERAL NOTESRolly Marc G. SoteloNo ratings yet

- Ee 2Document1 pageEe 2Rolly Marc G. SoteloNo ratings yet

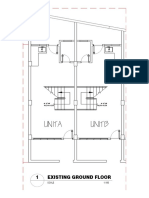

- Existing Unit A&b-Ground FloorDocument1 pageExisting Unit A&b-Ground FloorRolly Marc G. SoteloNo ratings yet

- Detailed Material Cost EstimateDocument5 pagesDetailed Material Cost EstimateRolly Marc G. SoteloNo ratings yet

- Concrete Column Schedule: CC1 CC2 CC3 CC4 CC5 CC6 CC7 CC8 CC9 CC10 CC11 CC12 CC13Document1 pageConcrete Column Schedule: CC1 CC2 CC3 CC4 CC5 CC6 CC7 CC8 CC9 CC10 CC11 CC12 CC13Rolly Marc G. SoteloNo ratings yet

- S 3 PDFDocument1 pageS 3 PDFRolly Marc G. SoteloNo ratings yet

- (EL. 4700 MM) : Rolly Marc G. SoteloDocument1 page(EL. 4700 MM) : Rolly Marc G. SoteloRolly Marc G. SoteloNo ratings yet

- Structural Steel: 2 10 Two Storey Duplex Type Residential BuildingDocument1 pageStructural Steel: 2 10 Two Storey Duplex Type Residential BuildingRolly Marc G. SoteloNo ratings yet

- 1CB5:Elevation (Scale 1:25) : A B C D E A B C D E 7 7Document1 page1CB5:Elevation (Scale 1:25) : A B C D E A B C D E 7 7Rolly Marc G. SoteloNo ratings yet

- Antipolo Project Cad-ModelDocument1 pageAntipolo Project Cad-ModelRolly Marc G. SoteloNo ratings yet

- Sr. No. Length (M) Weight (KG) 1 10 2,949.3 1,817 2 16 1,360.2 2,147Document1 pageSr. No. Length (M) Weight (KG) 1 10 2,949.3 1,817 2 16 1,360.2 2,147Rolly Marc G. SoteloNo ratings yet

- Santor Umc Baggao PDFDocument1 pageSantor Umc Baggao PDFRolly Marc G. SoteloNo ratings yet

- Design Criteria: GeneralDocument1 pageDesign Criteria: GeneralRolly Marc G. SoteloNo ratings yet

- Medley HOUSE GROUND FLOOR PDFDocument1 pageMedley HOUSE GROUND FLOOR PDFRolly Marc G. SoteloNo ratings yet

- Teaching Profession Part 1Document3 pagesTeaching Profession Part 1Floravie Oñate-AsombradoNo ratings yet

- Commercial Building Floor Plan LayoutDocument1 pageCommercial Building Floor Plan LayoutRolly Marc G. SoteloNo ratings yet

- Proposed Pile Cap: PDD Option 2 For Pier 7 LeftDocument1 pageProposed Pile Cap: PDD Option 2 For Pier 7 LeftRolly Marc G. SoteloNo ratings yet

- Ch'I Asia, Inc.: Somerset Salcedo, Makati CityDocument1 pageCh'I Asia, Inc.: Somerset Salcedo, Makati CityRolly Marc G. SoteloNo ratings yet

- DotrDocument20 pagesDotrAlma M. LaraNo ratings yet

- DotrDocument20 pagesDotrAlma M. LaraNo ratings yet

- Designing Resilient Structures Handbook 2016 PDFDocument132 pagesDesigning Resilient Structures Handbook 2016 PDFRich'kid AListadoNo ratings yet

- Santor Umc Baggao PDFDocument1 pageSantor Umc Baggao PDFRolly Marc G. SoteloNo ratings yet

- Construction of Multi-Level ParkingDocument13 pagesConstruction of Multi-Level Parkingdunknown15No ratings yet

- CBA-115c BEACON SIGNAGE DETAILSDocument1 pageCBA-115c BEACON SIGNAGE DETAILSRolly Marc G. SoteloNo ratings yet

- Multi-purpose roof deck planDocument1 pageMulti-purpose roof deck planRolly Marc G. SoteloNo ratings yet

- Commercial Building Floor Plan LayoutDocument1 pageCommercial Building Floor Plan LayoutRolly Marc G. SoteloNo ratings yet

- 2storey Second-FloorDocument1 page2storey Second-FloorRolly Marc G. SoteloNo ratings yet

- SDRRM Earthquake Drill TemplateDocument3 pagesSDRRM Earthquake Drill TemplateChristian Bonne MarimlaNo ratings yet

- Marine Ecotourism BenefitsDocument10 pagesMarine Ecotourism Benefitsimanuel wabangNo ratings yet

- Handwashing and Infection ControlDocument23 pagesHandwashing and Infection ControlLiane BartolomeNo ratings yet

- P150EDocument4 pagesP150EMauro L. KieferNo ratings yet

- 1 MergedDocument93 pages1 MergedAditiNo ratings yet

- GFEI International Comparison of Light-Duty Vehicle Fuel Economy - Evolution Over Eight Years From 2005 To 2013 - TransportDocument21 pagesGFEI International Comparison of Light-Duty Vehicle Fuel Economy - Evolution Over Eight Years From 2005 To 2013 - TransportRayane LimaNo ratings yet

- Cloud Computing For Industrial Automation Systems - A ComprehensiveDocument4 pagesCloud Computing For Industrial Automation Systems - A ComprehensiveJason FloydNo ratings yet

- Course 4Document3 pagesCourse 4Ibrahim SalahudinNo ratings yet

- 2010 - Caliber JEEP BOITE T355Document484 pages2010 - Caliber JEEP BOITE T355thierry.fifieldoutlook.comNo ratings yet

- Mfi in GuyanaDocument19 pagesMfi in Guyanadale2741830No ratings yet

- EPON ONU with 4FE+WiFi EONU-04WDocument4 pagesEPON ONU with 4FE+WiFi EONU-04WAndres Alberto ParraNo ratings yet

- H2 Physic 2010 A Level SolutionsDocument32 pagesH2 Physic 2010 A Level Solutionsonnoez50% (4)

- Introduction To Human Anatomy & Physiology: Prepared by Mr. Abhay Shripad Joshi Yash Institute of Pharmacy AurangabadDocument18 pagesIntroduction To Human Anatomy & Physiology: Prepared by Mr. Abhay Shripad Joshi Yash Institute of Pharmacy AurangabadMourian AmanNo ratings yet

- Far Eastern University Institute of Tourism and Hotel Management Tourism Management Program 1 Semester A.Y. 2019 - 2020Document46 pagesFar Eastern University Institute of Tourism and Hotel Management Tourism Management Program 1 Semester A.Y. 2019 - 2020Mico BolorNo ratings yet

- Water Booster Pump Calculations - Plumbing Engineering - Eng-TipsDocument3 pagesWater Booster Pump Calculations - Plumbing Engineering - Eng-TipsNeal JohnsonNo ratings yet

- Cellular Tower: Bayombong, Nueva VizcayaDocument17 pagesCellular Tower: Bayombong, Nueva VizcayaMonster PockyNo ratings yet

- A319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 33 LightsDocument224 pagesA319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 33 LightsAhmedHamdyElsaidy100% (3)

- Year 7 Bugs Lesson 2Document1 pageYear 7 Bugs Lesson 2api-293503824No ratings yet

- Chapter Three 3.0 Research MethodologyDocument5 pagesChapter Three 3.0 Research MethodologyBoyi EnebinelsonNo ratings yet

- Telegram Log File Details Launch Settings Fonts OpenGLDocument5 pagesTelegram Log File Details Launch Settings Fonts OpenGLThe nofrizalNo ratings yet

- Dental Pulp TissueDocument77 pagesDental Pulp TissueJyoti RahejaNo ratings yet

- Alicrite StringDocument4 pagesAlicrite Stringtias_marcoNo ratings yet

- Grammar Pages 109-112 2 PDFDocument4 pagesGrammar Pages 109-112 2 PDFSteve SernaNo ratings yet

- Performance Evaluation of Root Crop HarvestersDocument15 pagesPerformance Evaluation of Root Crop HarvestersIJERDNo ratings yet

- Electrical Experimenter 1915-08Document1 pageElectrical Experimenter 1915-08GNo ratings yet

- Basic of Seismic RefractionDocument43 pagesBasic of Seismic Refractionfitriah wulandariNo ratings yet

- PRM Vol1 SystemsDocument1,050 pagesPRM Vol1 SystemsPepe BondiaNo ratings yet

- Python operators and data types quizDocument34 pagesPython operators and data types quizATUL SHARMANo ratings yet

- APMP Certification Syllabus and Program V3.1 March 2019 PDFDocument20 pagesAPMP Certification Syllabus and Program V3.1 March 2019 PDFMuhammad ZubairNo ratings yet

- Book Notes - The Life Changing Magic of Tidying Up PDFDocument6 pagesBook Notes - The Life Changing Magic of Tidying Up PDFAilyn Bagares AñanoNo ratings yet