0% found this document useful (0 votes)

2K views15 pagesLoad Test Report - Final

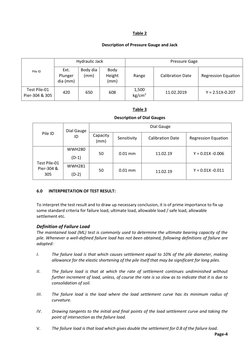

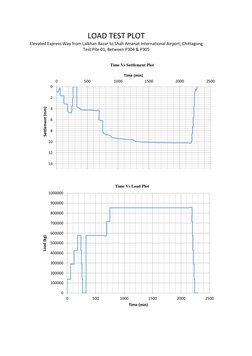

The document summarizes the results of a static axial pile load test conducted on a cast-in-situ test pile in Bangladesh. It describes the location and dimensions of the test pile. It also outlines the objectives of the test, test methodology, physical description of the test pile and equipment used, interpretation of test results, and observations on pile capacity. The test was conducted to evaluate the pile's capacity and confirm the adequacy of the design bearing capacity. Load and settlement readings were recorded during loading and unloading stages to analyze pile behavior under working loads.

Uploaded by

Shamim Mahmudur RahmanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views15 pagesLoad Test Report - Final

The document summarizes the results of a static axial pile load test conducted on a cast-in-situ test pile in Bangladesh. It describes the location and dimensions of the test pile. It also outlines the objectives of the test, test methodology, physical description of the test pile and equipment used, interpretation of test results, and observations on pile capacity. The test was conducted to evaluate the pile's capacity and confirm the adequacy of the design bearing capacity. Load and settlement readings were recorded during loading and unloading stages to analyze pile behavior under working loads.

Uploaded by

Shamim Mahmudur RahmanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd