Professional Documents

Culture Documents

Division 7 - Thermal and Moisture Protection Section 07110 - Sheet Membrane Waterproofing

Uploaded by

AdnanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Division 7 - Thermal and Moisture Protection Section 07110 - Sheet Membrane Waterproofing

Uploaded by

AdnanCopyright:

Available Formats

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

DIVISION 7 – THERMAL AND MOISTURE PROTECTION

ENGG CERT

JUV

JUV

SECTION 07110 – SHEET MEMBRANE WATERPROOFING

ZFP

ZFP

PART 1 GENERAL

1.01 SECTION INCLUDES

ISSUED FOR BID (IFB) SUBMITTAL

ISSUED FOR 90% SUBMITTAL

A. Sheet, laminated membrane waterproofing products to arrest moisture migration to

the building interior including but not limited to the following:-

DESCRIPTION

1. Loose laid and adhesive bonded elastomeric sheet membrane waterproofing.

2. Cant strips.

3. Protective cover.

4. Coating.

1.02 RELATED SECTIONS

A. Section 02220 Structural Excavation & Backfilling.

JO/EWO

10-00977

10-00977

B. Section 03300 Cast in Place Concrete

APR-12

MAY-12

DATE

C. Section 07160 Bituminous, Cementitious, Epoxy, Damp proofing and Waterproofing.

D. Section 07620 Sheet Metal Flashing and Trim.

NO.

REV

B

C

DISCIPLINE

ENGINEER

MHMH/RON E. Section 07900 Joint Sealers.

MAY-12

DATE:

PROJECT 1.03 REFERENCES

ENGINEER

JCB

MAY-12 A. ASTM D 412 Test Method for Rubber Properties in Tension.

DATE:

CERTIFIED

JUV B. ASTM D 624 Test Method for Rubber Property - Tear Resistance.

MAY-12

DATE:

CONSTRUCTION C. ANSI/ASTM D 746 Test Method for Brittleness Temperature of Plastics and

AGENCY

Elastomers by Impact.

DATE:

OPERATIONS D. ASTM D 1004 Test Method for Initial Tear Resistance of Plastic Film and

Sheeting.

DATE:

E. ASTM D 2240 Test Method for Rubber Property - Durometer Hardness.

CONTROL NUMBER

VERIFICATION

EDSD

F. ASTM D 3020 Specification for Polyethylene and Ethylene Copolymer Plastic

Sheeting for Pond, Canal, and Reservoir Lining.

DATE:

BY:

G. ASTM D 3253 Specification for Vulcanized Rubber Sheeting for Pond, Canal,

(DCC) NO. 750110-EWO-2001-00C346-001

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

and Reservoir Lining.

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

C

_____________________

SECTION 07110

1 of 6

B CONSTRUCTION SPECIFICATIONS – DIV 6 TO 8 DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

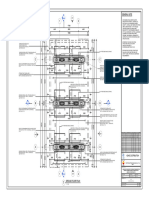

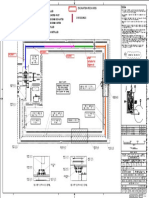

EXPAND SANITARY WASTEWATER TREATMENT PLANT DOC

212 6

(DETAILED ENGINEERING) A BE-800554 C

OF

ABQAIQ SAUDI ARABIA JO / EWO: BI-10-00977 135

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

H. ASTM D 4068 Specification for Chlorinated Polyethylene (CPE) Sheeting for

ENGG CERT

JUV

JUV

Concealed Water Containment Membrane.

ZFP

ZFP

I. ASTM D 4551 Specification for Poly Vinyl Chloride (PVC) Plastic Flexible

Concealed Water-Containment Membrane.

J. ASTM E 96 Test Methods for Water Vapor Transmission of Materials.

ISSUED FOR BID (IFB) SUBMITTAL

ISSUED FOR 90% SUBMITTAL

K. NRCA Waterproofing Manual.

DESCRIPTION

1.04 SYSTEM DESCRIPTION

A. Waterproofing System: Capable of resisting water and preventing moisture

migration to interior.

1.05 SUBMITTALS

A. Comply with Section 01300.

B. Shop Drawings: Show all installation layouts and procedures. Indicate special joint

JO/EWO

10-00977

10-00977

or termination conditions and conditions of interface with other materials.

APR-12

MAY-12

DATE

C. Product Data: Provide data for flexible flashings, joint cover sheet, and joint and

crack sealants, with temperature range for application of waterproofing membrane.

NO.

REV

B

C

DISCIPLINE

D. Manufacturer's Installation Instructions: Indicate special procedures and perimeter

MHMH/RON

ENGINEER conditions requiring special attention.

MAY-12

DATE:

PROJECT

1.06 QUALITY ASSURANCE

ENGINEER

JCB

MAY-12

A. Perform Work in accordance with NRCA Waterproofing Manual.

DATE:

CERTIFIED

JUV B. Maintain one copy of each document on site.

MAY-12

DATE:

CONSTRUCTION 1.07 QUALIFICATIONS

AGENCY

A. Membrane Manufacturer: Company specializing in waterproofing sheet membranes

DATE:

OPERATIONS

with five years experience.

B. Applicator: Company specializing in performing the work of this section with

DATE:

minimum five years documented experience and approved by manufacturer.

CONTROL NUMBER

VERIFICATION

1.08 MOCKUP

EDSD

DATE:

A. Comply with Section 01400.

BY:

(DCC) NO. 750110-EWO-2001-00C346-001

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

C

_____________________

SECTION 07110

2 of 6

B CONSTRUCTION SPECIFICATIONS – DIV 6 TO 8 DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

EXPAND SANITARY WASTEWATER TREATMENT PLANT DOC

212 7

(DETAILED ENGINEERING) A BE-800554 C

OF

ABQAIQ SAUDI ARABIA JO / EWO: BI-10-00977 135

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

B. Mockup 10 m2 of horizontal and vertical waterproofed panel; to represent finished

ENGG CERT

JUV

JUV

work including internal and external corners, seam jointing, attachment method,

counter flashing cover, drainage panel, base flashings, control and expansion joints,

ZFP

ZFP

protective cover.

C. Mockup may not remain as part of the Work.

1.09 ENVIRONMENTAL REQUIREMENTS

ISSUED FOR BID (IFB) SUBMITTAL

ISSUED FOR 90% SUBMITTAL

A. Maintain ambient temperatures above 5oC for 24 hours before and during application

and until liquid or mastic accessories have cured.

DESCRIPTION

1.10 WARRANTY

A. Comply with Section 01700.

B. Warranty: Provide 10 year warranty to include coverage for waterproofing failing to

resist penetration of water, except where such failures are the result of structural

failures of building. Hairline cracking of concrete due to temperature change of

shrinkage is not considered a structural failure.

JO/EWO

10-00977

10-00977

PART 2 PRODUCTS

APR-12

MAY-12

DATE

2.01 MANUFACTURERS

A. "Carlisle" Distributed by BMC Saudia, or equal and approved.

NO.

REV

B

C

DISCIPLINE

MHMH/RON

ENGINEER B. Substitutions: Under the provisions of Section 01630.

MAY-12

DATE:

PROJECT

2.02 MEMBRANE MATERIALS

ENGINEER

JCB

MAY-12

A. Vulcanized Rubber Membrane: EPDM conforming to ASTM D 3253 Type II 1.5 mm

DATE:

CERTIFIED

thick; 6100 mm wide roll; conforming to the following criteria.

JUV

MAY-12 Properties Test Method Min.

DATE:

CONSTRUCTION Requirement

AGENCY

Tolerance on nominal thickness, % ASTM D 412 + 10

DATE:

OPERATIONS

Tensile Strength, min. MPa ASTM D 412 9

Elongation, ultimate min. % ASTM D 412 350

Tear resistance, min, KN/m ASTM D 634 (Die C) 30.6

DATE:

Ozone resistance:

CONTROL NUMBER

VERIFICATION

Condition after exposure to 100

EDSD

pphm ozone in air for 168 h @ 10qF

(specimen under 50% strain). ASTM D 1149 No cracks

DATE:

Brittleness temperature, max. qC ASTM D746 -59

BY:

Resistance to water absorption:

(DCC) NO. 750110-EWO-2001-00C346-001

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

Change in mass. max. after

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

C

7 day immersion @ 158 qF,% ASTM D 471 4

_____________________

SECTION 07110

3 of 6

B CONSTRUCTION SPECIFICATIONS – DIV 6 TO 8 DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

EXPAND SANITARY WASTEWATER TREATMENT PLANT DOC

212 8

(DETAILED ENGINEERING) A BE-800554 C

OF

ABQAIQ SAUDI ARABIA JO / EWO: BI-10-00977 135

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

Water vapour permeability ASTM E 96 2.0

ENGG CERT

JUV

JUV

max. perm-mils (Proc B or BW)

Resistance to discoloration: ASTM D 1148

ZFP

ZFP

when coated with white hypalon No more discoloration

than glass side

Resistance to heat aging term ASTM 573

(properties after 4 weeks @ 240qF)

ISSUED FOR BID (IFB) SUBMITTAL

Tensile strength min. MPa ASTM D 412 8.3

ISSUED FOR 90% SUBMITTAL

Elongation, ultimate min. % ASTM D 412 225

Tear resistance, min KN/m ASTM D 524 26.3

DESCRIPTION

Linear dimensional change, max. % ASTM D 1204 =2

B. Seaming Materials: As recommended by membrane manufacturer.

C. Flexible Flashings: 1.52 mm thick uncured epdm.

2.03 ADHESIVE MATERIALS

A. Adhesives: As recommended by membrane manufacturer.

JO/EWO

10-00977

10-00977

B. Thinner and Cleaner: As recommended by adhesive manufacturer, compatible with

sheet membrane.

APR-12

MAY-12

DATE

2.04 ACCESSORIES

NO.

REV

B

C

DISCIPLINE

A. Sealant: As recommended by membrane manufacturer. Silicone type, manufactured

MHMH/RON

ENGINEER by American Industrial Products Int. and distributed by "Unitech" or approved

MAY-12

equivalent.

DATE:

PROJECT

ENGINEER

JCB

B. Protection Board: 13 mm thick bitumen impregnated glass fiberboard.

MAY-12

DATE:

CERTIFIED

C. Cant Strips: Bitumen impregnated fiberboard.

JUV

DATE:

MAY-12 D. Flexible Flashings: 1.52 mm thick .

CONSTRUCTION

AGENCY

E. Counter Flashings: As specified in with Section 07620.

DATE:

OPERATIONS PART 3 EXECUTION

3.01 EXAMINATION

DATE:

CONTROL NUMBER

VERIFICATION

A. Verify substrate surfaces are durable; free of matter detrimental to adhesion or

EDSD

application of waterproofing system.

DATE:

B. Verify items which penetrate surfaces to receive waterproofing are securely installed.

BY:

(DCC) NO. 750110-EWO-2001-00C346-001

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

C

_____________________

SEC TION 07110

4 of 6

B CONSTRUCTION SPECIFICATIONS – DIV 6 TO 8 DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

EXPAND SANITARY WASTEWATER TREATMENT PLANT DOC

212 9

(DETAILED ENGINEERING) A BE-800554 C

OF

ABQAIQ SAUDI ARABIA JO / EWO: BI-10-00977 135

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

3.02 PREPARATION

ENGG CERT

JUV

JUV

A. Protect adjacent surfaces not designated to receive waterproofing.

ZFP

ZFP

B. Clean and prepare surfaces to receive waterproofing in accordance with manufacturer's

instructions. Vacuum substrate clean.

C. Do not apply waterproofing to surfaces unacceptable to manufacturer.

ISSUED FOR BID (IFB) SUBMITTAL

ISSUED FOR 90% SUBMITTAL

D. Seal cracks and joints with sealant materials using depth to width ratio as

DESCRIPTION

recommended by sealant manufacturer.

E. Apply surface conditioner at a rate recommended by manufacturer. Protect

conditioner from rain or frost until dry.

3.03 INSTALLATION - LOOSE LAID (FOR HORIZONTAL APPLICATION)

A. Install membrane waterproofing in accordance with manufacturer's instructions.

B. Roll out membrane. Minimize wrinkles and bubbles.

JO/EWO

10-00977

10-00977

C. Overlap edges and ends and seal by contact adhesive minimum 75 mm. Seal

APR-12

MAY-12

DATE

permanently waterproof. Apply uniform bead of sealant to joint edge.

D. Reinforce membrane with multiple thicknesses of membrane material over static or

NO.

REV

B

C

DISCIPLINE

moving joints.

ENGINEER

MHMH/RON

MAY-12

E. Weather lap joints on sloped substrate in direction of drainage. Seal joints and

DATE:

PROJECT

seams.

ENGINEER

JCB

MAY-12

F. Install flexible flashings. Seal watertight to membrane.

DATE:

CERTIFIED

JUV G. Seal flashings to adjoining surfaces.

MAY-12

DATE:

CONSTRUCTION H. Extend membrane up cant strips and minimum of 150 mm onto vertical surfaces.

AGENCY

I. Seal items protruding to or penetrating through membrane and install counter

DATE:

OPERATIONS

flashing membrane material.

3.04 INSTALLATION - ADHESIVE BONDED FOR VERTICAL APPLICATION

DATE:

CONTROL NUMBER

VERIFICATION

A. Install membrane waterproofing in accordance with manufacturer's instructions.

EDSD

B. Roll out membrane. Minimize wrinkles and bubbles.

DATE:

BY:

C. Remove release paper layer. Roll out on substrate with a mechanical roller to

(DCC) NO. 750110-EWO-2001-00C346-001

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

encourage full contact bond.

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

C

_____________________

SECTION 07110

5 of 6

B CONSTRUCTION SPECIFICATIONS – DIV 6 TO 8 DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

EXPAND SANITARY WASTEWATER TREATMENT PLANT DOC

212 10

(DETAILED ENGINEERING) A BE-800554 C

OF

ABQAIQ SAUDI ARABIA JO / EWO: BI-10-00977 135

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

D. Apply membrane by adhesive application. Bond sheet to substrate except areas

ENGG CERT

JUV

JUV

directly over or within 75 mm of movement or control joints.

ZFP

ZFP

E. Lap sides and ends in accordance with membrane manufacturer's instructions.

F. Overlap edges and ends and seal with contact adhesive 75 mm. Seal permanently

waterproof. Apply uniform bead of sealant to joint edge.

ISSUED FOR BID (IFB) SUBMITTAL

ISSUED FOR 90% SUBMITTAL

G. Reinforce membrane with multiple thickness of membrane material over joints,

whether joints are static or dynamic.

DESCRIPTION

H. Install flexible flashings. Seal watertight to membrane.

I. Seal membrane and flashings to adjoining surfaces.

J. Seal items protruding to or penetrating through membrane and install counter

flashing membrane material.

3.05 FIELD QUALITY CONTROL

JO/EWO

10-00977

10-00977

A. Field inspection and testing will be performed under provisions of Sections 01400.

APR-12

MAY-12

DATE

B. On completion of horizontal membrane installation, dam installation area in

preparation for flood testing.

NO.

REV

B

C

DISCIPLINE

C. Flood to minimum depth of 25 mm with clean water. After 48 hours, inspect for

MHMH/RON

ENGINEER leaks.

MAY-12

DATE:

PROJECT

D. If leaking is found, remove water, repair leaking areas with new waterproofing

ENGINEER

JCB

materials as directed by Architect/Engineer; repeat flood test. Repair damage to

MAY-12

building.

DATE:

CERTIFIED

JUV E. When area is proven watertight, drain water and remove dam.

MAY-12

DATE:

CONSTRUCTION 3.06 PROTECTION OF FINISHED WORK

AGENCY

A. Comply with Section 01700.

DATE:

OPERATIONS

B. Do not permit traffic over unprotected or uncovered membrane.

DATE:

C. Protect membrane from damage by adhering protection board over membrane

CONTROL NUMBER

VERIFICATION

surface. Scribe and cut boards around projections and interruptions.

EDSD

D. Protect installed waterproofing and protection course from damage due to ultraviolet

DATE:

light, harmful weather exposure, physical abuse and other causes. Provide

BY:

temporary coverings where installation may be subject to abuse and cannot be

(DCC) NO. 750110-EWO-2001-00C346-001

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

REVISION CERTIFICATE

concealed and protected by permanent construction immediately.

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

C

END OF SECTION

_____________________

SECTION 07110

6 of 6

B CONSTRUCTION SPECIFICATIONS – DIV 6 TO 8 DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

EXPAND SANITARY WASTEWATER TREATMENT PLANT DOC

212 11

(DETAILED ENGINEERING) A BE-800554 C

OF

ABQAIQ SAUDI ARABIA JO / EWO: BI-10-00977 135

EDSD/2616-0399.doc

You might also like

- Matlab TutorialDocument243 pagesMatlab TutorialPinaki Mishra100% (4)

- Sabp Q 015Document24 pagesSabp Q 015AdnanNo ratings yet

- PDF Gi 0002721 2016 Arc Flash CompressDocument23 pagesPDF Gi 0002721 2016 Arc Flash CompressMark DingalNo ratings yet

- Ve417356 001-SowDocument38 pagesVe417356 001-Sowcean2scom0% (1)

- General Notes: S Piping and Instrument Diagram - Gen1 - System 0000Document1 pageGeneral Notes: S Piping and Instrument Diagram - Gen1 - System 0000sanjay masoodNo ratings yet

- LV Ph2020 - Bid Set - ArchitecturalDocument30 pagesLV Ph2020 - Bid Set - Architecturalart cafeNo ratings yet

- Defueling Procedure Erj 190Document4 pagesDefueling Procedure Erj 190jucamallaNo ratings yet

- 0006 SP 03Document11 pages0006 SP 03Tarik MoumeneNo ratings yet

- Be 242442 001 - Tip 0008Document63 pagesBe 242442 001 - Tip 0008sarangpuneNo ratings yet

- Material TraceabilityDocument24 pagesMaterial TraceabilityStanley AlexNo ratings yet

- GPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For RevisionDocument9 pagesGPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For Revisionrkm_rkmNo ratings yet

- AISC Design Guide 03 - Serviceability Design Considerations For Steel Buildings - 2Nd EditionDocument3 pagesAISC Design Guide 03 - Serviceability Design Considerations For Steel Buildings - 2Nd EditionAdnan100% (1)

- Wire Cable/ Wire Cable/: NotesDocument10 pagesWire Cable/ Wire Cable/: Notesmahesh reddy mNo ratings yet

- Be 243046 001 - Tip 0023Document67 pagesBe 243046 001 - Tip 0023sarangpuneNo ratings yet

- Salient Features of MycesmmDocument59 pagesSalient Features of Mycesmmracing.phreak100% (2)

- Technical Literature of Geogrid TechGridDocument18 pagesTechnical Literature of Geogrid TechGridAshokan KNo ratings yet

- Buhler 2003-Vademecum For Vitamin FormulationsDocument144 pagesBuhler 2003-Vademecum For Vitamin FormulationsRok Kopinč100% (1)

- AB 036090 001 Joints For Cement Lined Pipe PDFDocument1 pageAB 036090 001 Joints For Cement Lined Pipe PDFfdfazfzNo ratings yet

- Saudi Arabian Oil Company: SECTION 01540 Temporary Fencing and BarricadesDocument1 pageSaudi Arabian Oil Company: SECTION 01540 Temporary Fencing and BarricadesMECHKARTHIKRAJNo ratings yet

- 15500-Fire Protection SystemDocument4 pages15500-Fire Protection Systemaries82senthilNo ratings yet

- Saudi Arabian Oil Company: SECTION 15190 Mechanical IdentificationDocument3 pagesSaudi Arabian Oil Company: SECTION 15190 Mechanical Identificationthahar ali syedNo ratings yet

- Saudi Arabian Oil Company: SECTION 15001 Industry Codes and StandardsDocument6 pagesSaudi Arabian Oil Company: SECTION 15001 Industry Codes and Standardsthahar ali syedNo ratings yet

- Saudi Arabian Oil Company: SECTION 15300 Fire Protection SystemDocument7 pagesSaudi Arabian Oil Company: SECTION 15300 Fire Protection Systemthahar ali syedNo ratings yet

- Comp StatDocument6 pagesComp Stathammad21No ratings yet

- Flexible Cement System Achieves Zonal Isolation Objectives, NorwayDocument2 pagesFlexible Cement System Achieves Zonal Isolation Objectives, NorwayLeonardo Veizaga FloresNo ratings yet

- Saudi Arabian Oil Company: SECTION 01700 Close-Out RequirementsDocument3 pagesSaudi Arabian Oil Company: SECTION 01700 Close-Out RequirementsMECHKARTHIKRAJNo ratings yet

- Saudi Arabian Oil Company: SECTION 15051 Cleaning Pipe and EquipmentDocument3 pagesSaudi Arabian Oil Company: SECTION 15051 Cleaning Pipe and Equipmentthahar ali syedNo ratings yet

- Schedule Template Split Type ACDocument2 pagesSchedule Template Split Type ACGezahegnNo ratings yet

- SMD-PE-FF-91-001-01 Fire Protection System Philosophy (Indoor and Outdoor)Document17 pagesSMD-PE-FF-91-001-01 Fire Protection System Philosophy (Indoor and Outdoor)Yaser AhmadNo ratings yet

- B-H110978004V00 Fa Miscellaneous DetailsDocument1 pageB-H110978004V00 Fa Miscellaneous DetailsAnonymous X3PnFL6No ratings yet

- Technical Criteria Tenant MEP Works - APR'19Document1 pageTechnical Criteria Tenant MEP Works - APR'19Rome AdolNo ratings yet

- Data Schedule (30-TMSS-01, Revision 0) Air Break Disconnect Switches & Grounding Switches-69Kv Substation No. 001Document3 pagesData Schedule (30-TMSS-01, Revision 0) Air Break Disconnect Switches & Grounding Switches-69Kv Substation No. 001John BuntalesNo ratings yet

- Saudi Arabian Oil Company: SECTION 15060 Chilled Water PipingDocument10 pagesSaudi Arabian Oil Company: SECTION 15060 Chilled Water Pipingthahar ali syedNo ratings yet

- Standard Specification 9-11-3 External High Temperature Insulation and WeathershieldingDocument14 pagesStandard Specification 9-11-3 External High Temperature Insulation and WeathershieldingNavidNikdelNo ratings yet

- Revisions C: AG9 REDRAWN PER ECO-19-005708 BKW SFDocument1 pageRevisions C: AG9 REDRAWN PER ECO-19-005708 BKW SFMarcos MoraisNo ratings yet

- Saudi Arabian Oil Company: SECTION 02513 Sub-Base/Base Course and Asphalt Concrete PavingDocument11 pagesSaudi Arabian Oil Company: SECTION 02513 Sub-Base/Base Course and Asphalt Concrete Pavingطه حلمىNo ratings yet

- San Jose City College: Symbols Lists, General Notes and Sheet Index - Fire AlarmDocument12 pagesSan Jose City College: Symbols Lists, General Notes and Sheet Index - Fire AlarmRobel MTNo ratings yet

- BE050088-commissioning Plan PDFDocument12 pagesBE050088-commissioning Plan PDFRamziAhmedNo ratings yet

- Saudi Arabian Oil Company: SECTION 15050 Basic Mechanical Material and MethodsDocument9 pagesSaudi Arabian Oil Company: SECTION 15050 Basic Mechanical Material and Methodsthahar ali syedNo ratings yet

- ROMANIA 07-18 Schema COMPLETO Q0004958 PDFDocument129 pagesROMANIA 07-18 Schema COMPLETO Q0004958 PDFBaciu Nicolae100% (2)

- Saudi Arabian Oil Company: SECTION 15140 Piping and Ducting SupportsDocument6 pagesSaudi Arabian Oil Company: SECTION 15140 Piping and Ducting Supportsthahar ali syedNo ratings yet

- BLAST WALL Scaffolding StrategyDocument1 pageBLAST WALL Scaffolding Strategymar dapiNo ratings yet

- Mechanical FPD P.sanchezDocument9 pagesMechanical FPD P.sanchezHailley DensonNo ratings yet

- Witt (BTJ) - Sultan Iskandar MudaDocument11 pagesWitt (BTJ) - Sultan Iskandar MudaSmart TvNo ratings yet

- Master Drain Drawing From 406 To 512 (Yet To Submit)Document1 pageMaster Drain Drawing From 406 To 512 (Yet To Submit)Anal BiswasNo ratings yet

- Nfef 60 44 Ci DR TD 009 - d1 - 000Document1 pageNfef 60 44 Ci DR TD 009 - d1 - 000Abid AyubNo ratings yet

- Drawing Section A-A FRONT ViewDocument1 pageDrawing Section A-A FRONT Viewchibuzor chibugoNo ratings yet

- STR-051 Shoring Sections & Details MR. QADHEEBDocument1 pageSTR-051 Shoring Sections & Details MR. QADHEEBamr abdalhNo ratings yet

- LUXEN LUXPOWER SERIES 5 - N-TOPCon - BIFACIAL - 605-625 WDocument2 pagesLUXEN LUXPOWER SERIES 5 - N-TOPCon - BIFACIAL - 605-625 WBirshopulosNo ratings yet

- Safety Instruction Sheet For Cross Country Pipeline - Critical PipingDocument1 pageSafety Instruction Sheet For Cross Country Pipeline - Critical PipingJohn BuntalesNo ratings yet

- Typical Joint Box With U-Ditch: Weephole DetailDocument1 pageTypical Joint Box With U-Ditch: Weephole DetailAbid AyubNo ratings yet

- General Notes Cont. General Notes Line ServiceDocument1 pageGeneral Notes Cont. General Notes Line Servicezendaoui amineNo ratings yet

- Cps STRC Ifc Sept 25 2018Document57 pagesCps STRC Ifc Sept 25 2018Manimaran PNo ratings yet

- Transfame SDN BHD Paint Matrix Provision of Hook Up & Commissioning (Huc) Works For Murphy'S FacilitiesDocument2 pagesTransfame SDN BHD Paint Matrix Provision of Hook Up & Commissioning (Huc) Works For Murphy'S FacilitiesSupport RFZ2 EngineeringNo ratings yet

- Welding and Inspection Plan (Wip) Part 1: Design: Issued By: DateDocument4 pagesWelding and Inspection Plan (Wip) Part 1: Design: Issued By: DateJorgeAgustínSalgadoMirandaNo ratings yet

- Ref 189017 02Document1 pageRef 189017 02Sai Sri Harsha SurabhiNo ratings yet

- Unicoat DWF A12 (D40)Document1 pageUnicoat DWF A12 (D40)randiNo ratings yet

- BRACE and LEG Scaffolding StrategyDocument1 pageBRACE and LEG Scaffolding Strategymar dapiNo ratings yet

- Saudi Arabian Oil Company: SECTION 15411 Drainage Piping SystemsDocument3 pagesSaudi Arabian Oil Company: SECTION 15411 Drainage Piping Systemsthahar ali syedNo ratings yet

- Division Activity Div 3 Tahun 2022 Kebutuhan Unit EX Med Small 2 Wheel EP Total Outp. (TRGT /unit)Document2 pagesDivision Activity Div 3 Tahun 2022 Kebutuhan Unit EX Med Small 2 Wheel EP Total Outp. (TRGT /unit)Nur RohmanNo ratings yet

- Myk Aso Joint Tape 2000 Ver 2Document2 pagesMyk Aso Joint Tape 2000 Ver 2Devinder SokhiNo ratings yet

- General Note: Adnoc DistributionDocument1 pageGeneral Note: Adnoc DistributionShaheer.saNo ratings yet

- Plano Advance PDFDocument10 pagesPlano Advance PDFjonatancgNo ratings yet

- U32 - HCIS Cat. IIDocument1 pageU32 - HCIS Cat. IImohan sirNo ratings yet

- Salberg A4 Catalogue RevisedDocument28 pagesSalberg A4 Catalogue RevisedSinenhlanhlaNo ratings yet

- RA612003001P0A1Document1 pageRA612003001P0A1Muhammad AbrarNo ratings yet

- Material ModelsDocument31 pagesMaterial ModelsAdnanNo ratings yet

- BCP Pak 2021Document618 pagesBCP Pak 2021AdnanNo ratings yet

- Materials: Prediction of Deflection of Reinforced Concrete Beams Considering Shear EffectDocument13 pagesMaterials: Prediction of Deflection of Reinforced Concrete Beams Considering Shear EffectAdnanNo ratings yet

- On Certain Fundamental Issues in Continuum Damage Mechanics: George Z. Voyiadjis and Peter I. KattanDocument4 pagesOn Certain Fundamental Issues in Continuum Damage Mechanics: George Z. Voyiadjis and Peter I. KattanAdnanNo ratings yet

- Seismic Map of PakistanDocument1 pageSeismic Map of PakistanAdnanNo ratings yet

- Steel Rule of Thumb PDFDocument13 pagesSteel Rule of Thumb PDFAdnanNo ratings yet

- ADOT Bridge Design Guidelines 14-1Document22 pagesADOT Bridge Design Guidelines 14-1AdnanNo ratings yet

- Structural: Drawing ListDocument2 pagesStructural: Drawing ListAdnanNo ratings yet

- Particle Size (Sieve Analysis) of Plastic Materials: Standard Test Methods ForDocument5 pagesParticle Size (Sieve Analysis) of Plastic Materials: Standard Test Methods ForMichele PreghenellaNo ratings yet

- Discrimination Between Roasted Coffee, Roasted Corn and Coffee Husks by DiffuseDocument8 pagesDiscrimination Between Roasted Coffee, Roasted Corn and Coffee Husks by DiffuseJavier OrtizNo ratings yet

- Hartree-Fock For HeDocument19 pagesHartree-Fock For HeAustin Yu LiuNo ratings yet

- LCD ScreenDocument21 pagesLCD ScreenFagner Fernandes AraujoNo ratings yet

- Water and Wastewater Minimization in Dairy Plants Using Water Pinch TechnologyDocument9 pagesWater and Wastewater Minimization in Dairy Plants Using Water Pinch TechnologykrazylionNo ratings yet

- Latihan Chapter 1Document3 pagesLatihan Chapter 1Adam HakimiNo ratings yet

- 02 - Colligative PropertiesDocument46 pages02 - Colligative PropertiesamirNo ratings yet

- Design of A Pulse Oximeter For Use in MiceDocument27 pagesDesign of A Pulse Oximeter For Use in MiceIvoan VorchalasNo ratings yet

- IgsDocument6 pagesIgsmrjn1367No ratings yet

- Chapter 16 - Introduction To Chemical ReactionsDocument42 pagesChapter 16 - Introduction To Chemical ReactionsDK01No ratings yet

- Avanti CentrifugeDocument33 pagesAvanti Centrifugechito040570100% (1)

- Chapter 3 Alcohol & Ether1Document24 pagesChapter 3 Alcohol & Ether1Delicz TanNo ratings yet

- Week 02Document10 pagesWeek 02Arfin FardiansyahNo ratings yet

- Basic Tools of Analytical Chemistry: Chapter OverviewDocument28 pagesBasic Tools of Analytical Chemistry: Chapter OverviewReza LaurinaNo ratings yet

- Review of Cansolv SO Scrubbing System's First Commercial Operations in The Oil Refining IndustryDocument17 pagesReview of Cansolv SO Scrubbing System's First Commercial Operations in The Oil Refining Industryrogerh44No ratings yet

- Physica E: Qianhui Yang, Liren Lou, Guanzhong WangDocument6 pagesPhysica E: Qianhui Yang, Liren Lou, Guanzhong WangHabibi SaifuddinNo ratings yet

- 1les-7035 MSDS enDocument1 page1les-7035 MSDS enGabriela MorónNo ratings yet

- Accepted Manuscript: Materials Today NanoDocument98 pagesAccepted Manuscript: Materials Today NanocobianNo ratings yet

- Lab Activity 1 SheetDocument6 pagesLab Activity 1 SheetshaneeeeNo ratings yet

- Abrasive Water Jet Machining PDFDocument3 pagesAbrasive Water Jet Machining PDFbvnareshNo ratings yet

- Anomeric Effect, Hyperconjugation andDocument41 pagesAnomeric Effect, Hyperconjugation anddanielsad100No ratings yet

- Chemical Kinetics: CE1103 & CH1103 (Physical Chemistry)Document19 pagesChemical Kinetics: CE1103 & CH1103 (Physical Chemistry)Jillian PeteNo ratings yet

- Soal InstrumenDocument7 pagesSoal InstrumenErvin CrespoNo ratings yet

- Boliers and Pressure VesselsDocument33 pagesBoliers and Pressure VesselsUsama IqbalNo ratings yet

- Porosity Gizmo LabDocument4 pagesPorosity Gizmo LabJeneenNo ratings yet