Professional Documents

Culture Documents

Saudi Arabian Oil Company: SECTION 15050 Basic Mechanical Material and Methods

Saudi Arabian Oil Company: SECTION 15050 Basic Mechanical Material and Methods

Uploaded by

thahar ali syedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Arabian Oil Company: SECTION 15050 Basic Mechanical Material and Methods

Saudi Arabian Oil Company: SECTION 15050 Basic Mechanical Material and Methods

Uploaded by

thahar ali syedCopyright:

Available Formats

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

SECTION 15050

ENGG CERT

BASIC MECHANICAL MATERIAL AND METHODS

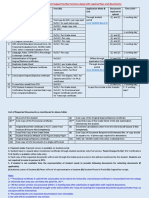

SUBSECTION INDEX

Part 1 - General

1.01 Description

1.02 Quality Assurance

DESCRIPTION

1.03 Product Delivery, Storage and Handlings

Part 2 - Products

2.01 Materials

Part 3 - Execution

3.01 General

JO/EWO

3.02 Access Panels

3.03 Builders Work

3.04 Cleaning Pipe and Equipment

NO. DATE

REV

PART 1 - GENERAL

DISCIPLINE

ENGINEER

1.01 Description

DATE:

PROJECT

ENGINEER

A. This Section defines the materials and methods to be used in fabrication, erection,

and installation of piping systems, components and equipment. These provisions are

DATE:

in addition to the requirements of all other Sections in Division 15 - Mechanical. The

CERTIFIED installation of all mechanical system shall conform to the Drawing Layouts. Any

alternation to the design must be in writing and approved by Saudi Aramco

DATE: Representative.

CONSTRUCTION

AGENCY

1.02 Quality Assurance

DATE:

OPERATIONS A. Reference Codes and Standards: Comply with applicable Codes and Standards in

Section 15001 - Industry Codes and Standards of this Specifications and as specified

DATE:

herein.

CONTROL NUMBER

VERIFICATION

B. General: All pipe, valves, fittings specialties and equipment unless otherwise

EDSD

specified, shall be new, full weight, full length and scale free. In addition to the test

required for specific materials and systems, the manufacturer shall test or guarantee

DATE:

BY:

all materials and equipment to be as specified prior to delivery.

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

C. Testing shall comply with IPC and NFPA requirements.

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. _____________________

Section 15050

Construction Specifications & Scope of Work DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

30% Detailed Design for 4 Typical Design of DOC 1

Saudi Aramco Built Government Schools A SK-DMBE03-101

of 0

SAUDI ARABIA BI / JO:

Dammam BI-23-10029 9

EDSD/2616-0399.doc

703B: KH1815 Specs - Dam

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

1.03 Product Delivery, Storage and Handlings

ENGG CERT

A. Handling: Receive and handle all materials with care so as not cause damage. Use

padded or strap slings, etc. as appropriate for the materials being handled. Stainless

steel shall not be allowed to contact carbon steel during handling, storage or

installation. Lift points shall be provided as recommended by the manufacturer.

B. Delivery: Upon receipt, inspect all materials for defects and for compliance with

Specifications. Tag, stencil, or otherwise permanently identify all materials with

particular care to adequately identify special items. Properly identify and file all mil

test reports, affidavits of compliance with Specifications, and other such papers

DESCRIPTION

pertinent to the materials received, and deliver such files to Saudi Aramco

Representative per his instructions.

C. Storage: Properly store all pipe and piping materials, etc., so as to prevent

deterioration while in storage. Store all materials off the ground or floor. Store inside

or cover all materials subject to deterioration from weather as per manufacturer’s

recommendations.

1. Store loose materials such as fittings, gaskets, bolts, nuts, small valves, traps,

and specialties, in bins of sufficient number to provide proper separation.

JO/EWO

Protect the ends of large fittings, valves and pipe from the weather and abuse.

Properly grease all machined surfaces.

DATE

2. All solvent cement and primer for joining PVC pipe shall be stored within an

air conditioned building with a maximum temperature of 26 deg. C and shall

NO.

REV

be less than one year old from date of manufacture.

DISCIPLINE

ENGINEER

D. Comply with the requirements of Section 01005.

DATE:

PROJECT

ENGINEER

PART 2 - PRODUCTS

DATE:

CERTIFIED

2.01 Materials

DATE:

CONSTRUCTION

A. Submittals: Submit three (3) copies to Saudi Aramco Representative for approval,

AGENCY manufacturer’s literature and samples specifying and describing the physical

characteristics and recommend installation instructions for all materials prior to

DATE:

procurement.

OPERATIONS

B. In addition to specific requirements listed in each Section of this division, Contractor

DATE: shall submit to Saudi Aramco Representative, for approval, list of manufacturers and

CONTROL NUMBER

equipment proposed to be provided for the Mechanical Scope of Work. Contractor

VERIFICATION

shall submit a list of shop drawings, technical data, bulletins etc., with submittals

EDSD

dates, in coordination with construction schedule dates when equipment and material

DATE:

is required on site. A delay of construction, due to lack of equipment, materials etc,

BY:

not being a site on time is unacceptable.

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. _____________________

Section 15050

Construction Specifications & Scope of Work DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

30% Detailed Design for 4 Typical Design of DOC 2

Saudi Aramco Built Government Schools A SK-DMBE03-101

of 0

SAUDI ARABIA BI / JO:

Dammam BI-23-10029 9

EDSD/2616-0399.doc

703B: KH1815 Specs - Dam

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

C. In addition to specific requirements listed in each section of this division, Contractor

shall submit to Saudi Aramco Representative the following information for approval,

ENGG CERT

but not limited to;

1. Complete materials list of all items proposed to be provided under this

division.

2. Manufacturers specification and other data required to demonstrate

compliance with the specified requirements.

3. Part number, physical dimension and weight of each.

DESCRIPTION

4. Mode of operation (if applicable).

5. Electrical rating (if applicable).

D. Pipe and Tube:

1. Pipe and Tube Specifications: Pipe and tube shall be of the material and

dimension specified in the service specifications and to the dimensions of:

JO/EWO

a. ASTM A53, Specification for Pipe Steel, Black and Hot-Dipped, Zinc-

Coated Welded and Seamless.

DATE

b. ASTM D2665, Specification for Poly Vinyl Chloride (PVC) Plastic

NO.

REV

drain, Waste and Vent Pipe and Fittings.

DISCIPLINE

ENGINEER

c. ASTM F441, Specification for Chlorinated Poly Vinyl Chloride (CPVC)

DATE:

Plastic Pipe, Schedule 80.

PROJECT

ENGINEER

d. ASTM F1412, Specification for Polyofin Pipe and Fittings for Corrosive

DATE:

Drainage Systems.

CERTIFIED

2. Pipe Threads: Pipe Threads, General Purpose (Inch).

DATE:

CONSTRUCTION

AGENCY

a. ANSI B 2.10.1: Pipe Threads, General Purpose (Inch).

DATE:

E. Valves:

OPERATIONS

1. Lengths: Face to face dimensions of flanged valves, unless otherwise

DATE:

specified shall conform to:

CONTROL NUMBER

VERIFICATION

a. ANSI B16.10: Face to face and end-to-end Dimensions of Ferrous

EDSD

Valves.

DATE:

BY:

2. Size: Valves shall be full line size unless otherwise specified.

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

3. All valves controlling main risers and branches shall be tagged as to

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

designation.

(DCC) NO. _____________________

Section 15050

Construction Specifications & Scope of Work DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

30% Detailed Design for 4 Typical Design of DOC 3

Saudi Aramco Built Government Schools A SK-DMBE03-101

of 0

SAUDI ARABIA BI / JO:

Dammam BI-23-10029 9

EDSD/2616-0399.doc

703B: KH1815 Specs - Dam

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

F. Pipe Supports, Guides and Anchors:

ENGG CERT

1. General: Provide in accordance with the Drawings, Specifications and

manufacturer’s instructions, all necessary hangers, supports, slides, guides,

beam, clamps, hanger rods, turnbuckles, bracing, rolls, plates, brackets,

saddles, miscellaneous steel, and other accessories necessary to support the

pipes from the buildings. Piping at valves and equipment shall be supported

so that the valves and equipment can be removed for servicing with a

minimum necessity for installing temporary pipe supports. The spacing and

type of hangers and supports shall meet the requirements of IPC and/or

DESCRIPTION

NFPA Standards where applicable.

2. Unless shown in the Drawings or specifically approved by Saudi Aramco

Representative, no drilling, welding, or cutting or building columns and beams

is permissible.

3. All pipe lines shall be provided with complete hanger assemblies, and shall

include the pipe hanger washers, nuts, turnbuckles, rods, straps, clip angels,

beam clamps and through bolts. Any adjustable items shall have a locking

device to hold it together during shock. Dissimilar metals shall be adjustable

JO/EWO

against galvanic reaction.

DATE

G. Thread Compounds: Unless otherwise specified, use TFE tape, 13 mm x 3 mil

thickness, Scotch brand or approved equal; Plastic Lead Seal (PLS), John Crane or

approved equal. Thread compounds shall be non-toxic for raw water and sweet

NO.

REV

water.

DISCIPLINE

ENGINEER

H. Pipe Sleeves: Unless otherwise specified, use 50mm (2”) internal diameter larger

DATE:

than the outside of the pipe or one nominal pipe size larger than O.D. of the pipe.

PROJECT

ENGINEER Material shall be standard weight galvanized steel pipe.

DATE: I. Provide penetration shields to encase insulated pipes penetrating fire walls or floors in

CERTIFIED

a 360o, 24 gauge minimum sheet metal hanger shield with insert of high density, 100

psi. Waterproofed calcium silicate the same thickness as insulation and further

DATE:

CONSTRUCTION

enclosed within the sleeve, sized for maximum 25 mm. Spacing between sleeve and

AGENCY insulation shield, pack annular space between sleeve and shield on both ends with

double neoprene coated asbestos rope. Install an escutcheon plate to completely

DATE:

cover the wall penetration opening and fit snugly over the pipe insulation shield.

OPERATIONS

Insert shall extend at least 25 mm beyond penetrated surface and escutcheon.

DATE:

CONTROL NUMBER

PART 3 - EXECUTION

VERIFICATION

EDSD

3.01 General

DATE:

BY:

A. Workmanship: Fabrication and installation shall be executed in the best and most

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

workmanlike manner by qualified, careful, and efficient mechanics in strict accordance

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

with the Drawings, and Specifications. When Work is not being performed on a pipe,

(DCC) NO. _____________________

Section 15050

Construction Specifications & Scope of Work DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

30% Detailed Design for 4 Typical Design of DOC 4

Saudi Aramco Built Government Schools A SK-DMBE03-101

of 0

SAUDI ARABIA BI / JO:

Dammam BI-23-10029 9

EDSD/2616-0399.doc

703B: KH1815 Specs - Dam

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

including at the end of work each day, all openings shall be plugged to prevent entry

of foreign matter.

ENGG CERT

B. Routing: Piping Drawings are generally to scale but piping, etc. shall be place by

calculated dimensions rather than dimensions scaled from Drawings. Piping shall be

routed by the shortest run consistent with good installation practice, clearance

requirements, and expansion flexibility provisions. Major variations form locations

shown on the Drawings shall be approved by the Saudi Aramco Representative. All

piping shall be arranged to facilitate support of the piping and ease of removal for

inspection or servicing.

DESCRIPTION

1. Maintenance areas shall be clear of piping. Pipe shall be cut and hung to

align freely with flanges and fittings.

2. Pipe alignment and gradient shall be straight or shall follow true curves as

near as practicable. Curvature in pipe lines, where required, shall be well

within the allowable radii for the pipe, horizontal or vertical. Space pipe

supports and arrange reducers to allow system to be drained at low points

and vented at high points. Pockets shall be avoided in all lines where

possible.

JO/EWO

C. Fabrication: All piping systems shall be arranged so that the loads and moments

applied at the permissible reactions for this equipment as specified by the

DATE

manufacturers of the equipment. Provisions for expansion shall preferably be made

with pipe loops.

NO.

REV

DISCIPLINE D. Welding:

ENGINEER

DATE:

1. Welding procedure must be submitted to Saudi Aramco Representative for

PROJECT

ENGINEER

approval prior to any welder’s testing.

DATE:

2. Welders must all be qualified and tested to specific welding procedures.

CERTIFIED Saudi Aramco Representative to witness the testing of welders if required.

DATE: 3. Stitch welding on plate that is going to be coated is not permitted, full seal

CONSTRUCTION

AGENCY

welding is required.

DATE:

4. Steel plates that are going to be hot dipped galvanized must have any welding

OPERATIONS done to the plate prior to galvanizing.

DATE:

E. Drainage System: Building sewer piping shall comply with applicable chapter in IPC.

CONTROL NUMBER

VERIFICATION

F. Water System: Pipe and fittings shall comply with IPC.

EDSD

G. Valve Installation: Install valves with hand wheel stems aligned horizontally or

DATE:

BY:

vertically upward unless specifically shown otherwise. Install all valves in accessible

locations to facilitate easy removal for repair or replacement. Connect all threaded

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

end valves installed in PVC lines where joints are ordinarily solvent cemented to the

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. _____________________

Section 15050

Construction Specifications & Scope of Work DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

30% Detailed Design for 4 Typical Design of DOC 5

Saudi Aramco Built Government Schools A SK-DMBE03-101

of 0

SAUDI ARABIA BI / JO:

Dammam BI-23-10029 9

EDSD/2616-0399.doc

703B: KH1815 Specs - Dam

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

tubing by means of adaptors screwed into the valves and solvent cemented to the

tubing. Provide union adjacent to each threaded valve in metallic system.

ENGG CERT

H. Piping Connections to Equipment and Control Valves: Provide unions at all final

connections to equipment and control valves to facilitate dismantling. Arrange

connections so that the equipment served may be removed without disturbing the

remaining piping. Dielectric unions or coupling shall be used in connection of ferrous

to non-ferrous metals.

I. Sleeves, Shields and Escuthcheons: Provide all pipe penetrations through walls, roof,

partitions and slabs with sleeves large enough to adequately accommodate the pipe

DESCRIPTION

plus any insulation and thermal movement. In no case shall such sleeves be less

than 50mm larger than the outside diameter of the pipe insulation. Sleeves shall be

set in place as walls and slabs are constructed. If the sleeves are missed during wall

and slab construction, masonry and/or concrete shall be drilled to accommodate

sleeves. Space between pipe and sleeve shall be packed with mineral wool in interior

walls and oakum sealed with watertight mastic or asphalt for exterior walls, or seal

sleeves with link seal unit. Provide galvanized steel shields 200mm under all insulated

piping at hangers to protect insulation. Provide escutcheons and floor ceiling plates

on both sides of pipe penetrations through walls, ceilings, partitions and floors for all

pipes exposed to view in finished areas. All escutcheons and floor/ceiling plates shall

JO/EWO

be chrome plated brass. Sleeve shall be steel pipe, Schedule 40.

DATE

J. Equipment: Contractor to install all new equipment as called for on the Drawings or in

the Construction Specification. Equipment shall be assembled, using proper rigging

to avoid damage, and installed units are to be located and oriented in accordance

NO.

REV

with Drawings, subject to modifications occasioned by supplier’s shop drawings. All

DISCIPLINE

ENGINEER equipment shall be leveled, supported, aligned and grouted per manufacturer’s

recommendations.

DATE:

PROJECT

ENGINEER K. Provide auxiliary drains for wet pipe systems when capacity of trapped sections of

pipe is five gallons or more or when change in piping direction prevents drainage of

DATE: sections of branch lines or mains through main drain valve. Auxiliary drain consists

CERTIFIED

of one inch nipple and cap or brass plug.

DATE:

CONSTRUCTION

L. Contractor shall provide and use all precision tool required for proper setting.

AGENCY Installation shall be such that tightening of anchor bolts, piping connections, etc. does

not induce stresses or, distortion. Equipment shall be cleaned and tested as required.

DATE:

Coatings shall be touched up in accordance with Section-09900, “Painting.”

OPERATIONS

M. When installation is complete, equipment shall be ready for operation, final

DATE: supports shall be in place, and erection scaffolding, tools, and debris shall be

CONTROL NUMBER

removed from the surrounding area. Utilize International and local applicable

VERIFICATION

Standards for handling, preparation and installation of equipment. Conform to

EDSD

International and local applicable Standard, Mechanical(HVAC) Standard together

DATE:

with International Mechanical Code.

BY:

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. _____________________

Section 15050

Construction Specifications & Scope of Work DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

30% Detailed Design for 4 Typical Design of DOC 6

Saudi Aramco Built Government Schools A SK-DMBE03-101

of 0

SAUDI ARABIA BI / JO:

Dammam BI-23-10029 9

EDSD/2616-0399.doc

703B: KH1815 Specs - Dam

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

3.02 Access Panels

ENGG CERT

A. Contractor shall provide removable access panels in all permanently fixed drop

ceilings (like gypsum board ceilings).

B. Access panels shall provide ready access to concealed control valve, traps,

cleanouts, motors, dampers, and all other items requiring operation, adjustment or

maintenance.

C. Location of access panels shall be coordinated with other trades and shall have Saudi

Aramco’s Representative approval.

DESCRIPTION

3.03 Builders Work

A. Contractor shall provide all builder’s Work in connection with all mechanical

requirements to complete Work acceptable to Saudi Aramco Representative.

B. Builder’s Work include, but is not limited, to providing equipments bases, pads and

supports setting and patching of walls and slabs for passage of pipes and ducts,

repatching, fixing of pipe hangers and supports to structures, excavation and

backfilling, scaffolding, rigging, hoisting, waterproofing, cleaning and painting.

JO/EWO

C. Contractor shall provide pipe sleeves and escutcheon plates as required in para 3.01-

DATE

I of this section.

D. Contractor shall provide housekeeping pads for all floor mounted equipment as

NO.

REV

shown on the Drawings.

DISCIPLINE

ENGINEER

E. Contractor shall perform all required excavation and backfilling as required in para

DATE:

3.02 of this section.

PROJECT

ENGINEER

F. Contractor shall provide concrete insertion bases and vibration isolators as required in

DATE: Section 15240.

CERTIFIED

G. Contractor shall provide all hangers, supports and their respective accessories as

DATE:

CONSTRUCTION

required in Section 15140.

AGENCY

H. Contractor shall clean equipment, material, ductwork and piping etc. inside and

DATE:

outside by effective and approved methods to remove loose mill scale, blisters, sand,

OPERATIONS

plaster, paint, droppings, debris, dirt soil, grease, labels and all foreign matters. Clean

and brush work in stages as directed before painting or concealing.

DATE:

CONTROL NUMBER

I. Contractor shall provide painting as per Section 09900.

VERIFICATION

EDSD

3.04 Cleaning Pipe and Equipment

DATE:

BY:

A. Preparation Work:

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

1. Prior to Erection: All piping prior to erection, unless otherwise specified, shall

(DCC) NO. _____________________

be cleaned as follows:

Section 15050

Construction Specifications & Scope of Work DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

30% Detailed Design for 4 Typical Design of DOC 7

Saudi Aramco Built Government Schools A SK-DMBE03-101

of 0

SAUDI ARABIA BI / JO:

Dammam BI-23-10029 9

EDSD/2616-0399.doc

703B: KH1815 Specs - Dam

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

a. Hammer, brush, soap with rags, etc., to loosen sand, dirt or scale

ENGG CERT

when necessary, except for cement lined steel pipe where the bore

shall be swabbed clean and the outside wire brushed to avoid shock

damage to the lining.

b. Blow with air, or hose with clean water, and inspect before erection.

c. On pipe stored before erection, dry and seal the ends with a rigid plug

or flange protector and tape.

DESCRIPTION

Note: Physical cleaning procedures shall not damage materials or mark the

surface of such materials. Damaged materials or equipment shall be replaced

at no additional cost to Company.

2. Prior to Flushing:

a. Removals: All control valves, safety valves and other instruments and

fittings designated by Saudi Aramco Representative or which might be

damaged by cleaning procedures shall be removed from the lines and

equipment and replaced with spool pieces, plugs, or blind flanges. All

JO/EWO

such item, except safety valves, shall be cleaned separately. New

gaskets, thread lubricant, etc., shall be used when the removed items

DATE

are reinstalled after cleaning.

b. System Protection: Protect all piping equipment against over-pressure,

NO.

REV

collapse from vacuum and hydraulic shock during the flushing and

DISCIPLINE

ENGINEER draining procedures.

DATE:

B. Flushing Piping and Equipment

PROJECT

ENGINEER

1. Filling System: With branch line valves closed or branch lines disconnected,

DATE: fill the headers slowly with clean water until air is dispelled from the system.

CERTIFIED

2. Flushing Headers: Increase the flow until the fluid velocity reaches a level

DATE:

CONSTRUCTION

which will sweep trash and debris from the headers. This shall be done even

AGENCY if larger systems have to be flushed in segments or if booster pumps must be

used to attain the required velocity without over-pressuring portions of the

DATE:

system. (The velocity of 10FPS (3.0 MPS) is required in the lines).

OPERATIONS

3. Flushing Branches: After headers have been flushed clean, open branch line

DATE: valves and flush branch lines until clean. Flush only so many branches

CONTROL NUMBER

simultaneously as the water source can supply with an adequate flow.

VERIFICATION

EDSD

C. Special Requirements

DATE:

BY:

1. Drinking Water Systems:

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

a. Flush system thoroughly as above and drain system completely.

(DCC) NO. _____________________

Section 15050

Construction Specifications & Scope of Work DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

30% Detailed Design for 4 Typical Design of DOC 8

Saudi Aramco Built Government Schools A SK-DMBE03-101

of 0

SAUDI ARABIA BI / JO:

Dammam BI-23-10029 9

EDSD/2616-0399.doc

703B: KH1815 Specs - Dam

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

b. Flush system with clear water and then drain.

ENGG CERT

c. Disinfect the system in accordance with the latest published procedure

of the American Water Works Association “A Standard Procedure of

Disinfecting Water Mains”, AWWA C651, Uniform Building Code.

Drain the system thoroughly.

d. Flush with clear water until there is no trace of the residual chlorine.

e. Contractor shall submit to Saudi Aramco Representative the test

results from the water pipe cleaning and disinfections no later than

DESCRIPTION

one (1) week after the Work is completed.

- END OF SECTION -

NO. JO/EWO

DATE

REV

DISCIPLINE

ENGINEER

DATE:

PROJECT

ENGINEER

DATE:

CERTIFIED

DATE:

CONSTRUCTION

AGENCY

DATE:

OPERATIONS

DATE:

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. _____________________

Section 15050

Construction Specifications & Scope of Work DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

30% Detailed Design for 4 Typical Design of DOC 9

Saudi Aramco Built Government Schools A SK-DMBE03-101

of 0

SAUDI ARABIA BI / JO:

Dammam BI-23-10029 9

EDSD/2616-0399.doc

703B: KH1815 Specs - Dam

You might also like

- CEH Practical NotesDocument42 pagesCEH Practical NotesSundeel Bin Haleem100% (7)

- Ve417356 001-SowDocument38 pagesVe417356 001-Sowcean2scom0% (1)

- Saudi Arabian Oil Company: SECTION 15051 Cleaning Pipe and EquipmentDocument3 pagesSaudi Arabian Oil Company: SECTION 15051 Cleaning Pipe and Equipmentthahar ali syedNo ratings yet

- Saudi Arabian Oil Company: SECTION 15300 Fire Protection SystemDocument7 pagesSaudi Arabian Oil Company: SECTION 15300 Fire Protection Systemthahar ali syedNo ratings yet

- Saudi Arabian Oil Company: SECTION 15190 Mechanical IdentificationDocument3 pagesSaudi Arabian Oil Company: SECTION 15190 Mechanical Identificationthahar ali syedNo ratings yet

- Saudi Arabian Oil Company: SECTION 13300 InstrumentationDocument7 pagesSaudi Arabian Oil Company: SECTION 13300 InstrumentationMECHKARTHIKRAJNo ratings yet

- Saudi Arabian Oil Company: SECTION 15140 Piping and Ducting SupportsDocument6 pagesSaudi Arabian Oil Company: SECTION 15140 Piping and Ducting Supportsthahar ali syedNo ratings yet

- Saudi Arabian Oil Company: SECTION 01580 Project Identification and SignsDocument3 pagesSaudi Arabian Oil Company: SECTION 01580 Project Identification and SignsMECHKARTHIKRAJNo ratings yet

- Saudi Arabian Oil Company: SECTION 01700 Close-Out RequirementsDocument3 pagesSaudi Arabian Oil Company: SECTION 01700 Close-Out RequirementsMECHKARTHIKRAJNo ratings yet

- Saudi Arabian Oil Company: SECTION 13320 Programmable Logic ControllersDocument8 pagesSaudi Arabian Oil Company: SECTION 13320 Programmable Logic ControllersMECHKARTHIKRAJNo ratings yet

- Saudi Arabian Oil Company: SECTION 15411 Drainage Piping SystemsDocument3 pagesSaudi Arabian Oil Company: SECTION 15411 Drainage Piping Systemsthahar ali syedNo ratings yet

- Comp StatDocument6 pagesComp Stathammad21No ratings yet

- Saudi Arabian Oil Company: SECTION 02513 Sub-Base/Base Course and Asphalt Concrete PavingDocument11 pagesSaudi Arabian Oil Company: SECTION 02513 Sub-Base/Base Course and Asphalt Concrete Pavingطه حلمىNo ratings yet

- Saudi Arabian Oil Company: SECTION 15060 Chilled Water PipingDocument10 pagesSaudi Arabian Oil Company: SECTION 15060 Chilled Water Pipingthahar ali syedNo ratings yet

- Saudi Arabian Oil Company: SECTION 01560 Environmental ProtectionDocument5 pagesSaudi Arabian Oil Company: SECTION 01560 Environmental ProtectionMECHKARTHIKRAJNo ratings yet

- Saudi Arabian Oil Company: SECTION 15001 Industry Codes and StandardsDocument6 pagesSaudi Arabian Oil Company: SECTION 15001 Industry Codes and Standardsthahar ali syedNo ratings yet

- Saudi Arabian Oil Company: SECTION 01540 Temporary Fencing and BarricadesDocument1 pageSaudi Arabian Oil Company: SECTION 01540 Temporary Fencing and BarricadesMECHKARTHIKRAJNo ratings yet

- BE050088-commissioning Plan PDFDocument12 pagesBE050088-commissioning Plan PDFRamziAhmedNo ratings yet

- Saudi Aramco Oil Company: SECTION 03250 Water StopsDocument4 pagesSaudi Aramco Oil Company: SECTION 03250 Water Stopssaneela bibiNo ratings yet

- Section 9Document43 pagesSection 9Yahya AsiriNo ratings yet

- Project Time IampiDocument51 pagesProject Time IampiDistria Putri WulandariNo ratings yet

- Saudi Aramco Oil Company: SECTION 03251 Construction, Expansion and Contraction JointsDocument6 pagesSaudi Aramco Oil Company: SECTION 03251 Construction, Expansion and Contraction Jointssaneela bibiNo ratings yet

- 15500-Fire Protection SystemDocument4 pages15500-Fire Protection Systemaries82senthilNo ratings yet

- 000 ZA E 09403 SITE NC MNGMT ProcedureDocument11 pages000 ZA E 09403 SITE NC MNGMT Procedurealinor_tn100% (1)

- MaSa-1-PC-F-07 - Attachment E - Safety & Fire Prevention Management PlanDocument15 pagesMaSa-1-PC-F-07 - Attachment E - Safety & Fire Prevention Management PlanSabheeh AliNo ratings yet

- Division 7 - Thermal and Moisture Protection Section 07110 - Sheet Membrane WaterproofingDocument6 pagesDivision 7 - Thermal and Moisture Protection Section 07110 - Sheet Membrane WaterproofingAdnanNo ratings yet

- Instruction Manual: Multi-Smart MPPT Solar Charge ControllerDocument12 pagesInstruction Manual: Multi-Smart MPPT Solar Charge ControllerMiguel Cayuela de PedroNo ratings yet

- SafeSPI Specification v0.15 PublishedDocument16 pagesSafeSPI Specification v0.15 Publishedpunk.tent8244No ratings yet

- (SupplHi Standard Categorization) Booklet Rev18Document98 pages(SupplHi Standard Categorization) Booklet Rev18NZ NZNo ratings yet

- TEC-WEL-03 Rev 00 IngleseDocument42 pagesTEC-WEL-03 Rev 00 IngleseFlorin TrNo ratings yet

- Saudi Aramco Oil Company: SECTION 03210 Epoxy Coated Concrete ReinforcementDocument8 pagesSaudi Aramco Oil Company: SECTION 03210 Epoxy Coated Concrete Reinforcementsaneela bibiNo ratings yet

- X3 Hybrid User Manual PDFDocument37 pagesX3 Hybrid User Manual PDFEduardo GarcíaNo ratings yet

- Instruction Manual: MPPT Solar Charge ControllerDocument12 pagesInstruction Manual: MPPT Solar Charge ControllerNkosilozwelo SibandaNo ratings yet

- 197-3003-00 - Rev G - Savant SPD131DDA SpeedVac Concentrator - Instruction ManualDocument20 pages197-3003-00 - Rev G - Savant SPD131DDA SpeedVac Concentrator - Instruction ManualJesus OrozcoNo ratings yet

- TKT-CM-01-OM-1060-I-R1-O&M Manual - Control & Monitoring System PDFDocument144 pagesTKT-CM-01-OM-1060-I-R1-O&M Manual - Control & Monitoring System PDFThái Đức NhơnNo ratings yet

- X1 Boost Install ManualDocument24 pagesX1 Boost Install Manualfritzzag100% (1)

- Schneider Electric Australia - Catalogue 2016Document788 pagesSchneider Electric Australia - Catalogue 2016Florentina Veronica PanaiteNo ratings yet

- General Notes: S Piping and Instrument Diagram - Gen1 - System 0000Document1 pageGeneral Notes: S Piping and Instrument Diagram - Gen1 - System 0000sanjay masoodNo ratings yet

- Specification For Smoke Bomb Test PDFDocument4 pagesSpecification For Smoke Bomb Test PDFARUNNo ratings yet

- Silotop Zero M A 0117 enDocument62 pagesSilotop Zero M A 0117 enTiago FerreiraNo ratings yet

- GEMSS-E-16 Rev 01voltage TransformersDocument12 pagesGEMSS-E-16 Rev 01voltage Transformersmohammad kassarNo ratings yet

- 10-EA-E-41023 Load Flow & Motor Starting Study ReportDocument148 pages10-EA-E-41023 Load Flow & Motor Starting Study ReportArunava DasguptaNo ratings yet

- Initial Punch List - WWTP - 17.12.2018 - Final FinalDocument10 pagesInitial Punch List - WWTP - 17.12.2018 - Final FinalBebe BucătaruNo ratings yet

- MS For MEP (Installation of Eathing and Ligthning Protection Rev 1 LDocument17 pagesMS For MEP (Installation of Eathing and Ligthning Protection Rev 1 LHorasto ReyesNo ratings yet

- Sector Screenveurope1009Document1 pageSector Screenveurope1009buyanalystlondonNo ratings yet

- H274743003P00 PDFDocument27 pagesH274743003P00 PDFMohamed Amr0% (1)

- PTS-20WM319 - Appendix XVIII 115KV, 13.8KV Cable Installation (Interconnection)Document18 pagesPTS-20WM319 - Appendix XVIII 115KV, 13.8KV Cable Installation (Interconnection)Durgaprasad RyaliNo ratings yet

- GEMSS-M-35 Rev 01 Painting & Coating Protection SystemDocument11 pagesGEMSS-M-35 Rev 01 Painting & Coating Protection SystemAzhar AliNo ratings yet

- GEMSS-E-03 Rev 02neutral EquipmentDocument12 pagesGEMSS-E-03 Rev 02neutral Equipmentmohammad kassarNo ratings yet

- SE - OS Integrated Security SystemDocument33 pagesSE - OS Integrated Security Systemآية الطنبوليNo ratings yet

- GEMSS-E-02BRev 03excitation System and EquipmentDocument21 pagesGEMSS-E-02BRev 03excitation System and Equipmentmohammad kassarNo ratings yet

- PP-965029 - C Instrument NamePlate SpecDocument6 pagesPP-965029 - C Instrument NamePlate Speczizu1234No ratings yet

- FMDS1701Document21 pagesFMDS1701Cesar RomeroNo ratings yet

- 1 3 Engineering Business PlanningDocument2 pages1 3 Engineering Business PlanningBILAL FAROOQUINo ratings yet

- Emesb-Msa-Mtn-002 MTN CLM R1Document7 pagesEmesb-Msa-Mtn-002 MTN CLM R1Ain TieyNo ratings yet

- GEMSS-E-15 Rev 02current TransformersDocument12 pagesGEMSS-E-15 Rev 02current Transformersmohammad kassarNo ratings yet

- Process and Material Specification: AIPI05-03-006 01-02-71 A1 FEB 01/21Document17 pagesProcess and Material Specification: AIPI05-03-006 01-02-71 A1 FEB 01/21schembriryanNo ratings yet

- Saudi Arabian Oil Company: SECTION 15411 Drainage Piping SystemsDocument3 pagesSaudi Arabian Oil Company: SECTION 15411 Drainage Piping Systemsthahar ali syedNo ratings yet

- Project Title: Al Ula Primary & Childhood School Client Name: Royal Commission For Al UlaDocument2 pagesProject Title: Al Ula Primary & Childhood School Client Name: Royal Commission For Al Ulathahar ali syedNo ratings yet

- Saudi Arabian Oil Company: SECTION 15060 Chilled Water PipingDocument10 pagesSaudi Arabian Oil Company: SECTION 15060 Chilled Water Pipingthahar ali syedNo ratings yet

- Pump Room - Mech-ModelDocument1 pagePump Room - Mech-Modelthahar ali syedNo ratings yet

- Saudi Arabian Oil Company: SECTION 15001 Industry Codes and StandardsDocument6 pagesSaudi Arabian Oil Company: SECTION 15001 Industry Codes and Standardsthahar ali syedNo ratings yet

- Subject: QC Site InstructionDocument2 pagesSubject: QC Site Instructionthahar ali syedNo ratings yet

- SOP For Engineering ManagementDocument1 pageSOP For Engineering Managementthahar ali syedNo ratings yet

- P Employee ManualDocument383 pagesP Employee ManualAnurag SinghNo ratings yet

- Best Capstone SampleDocument25 pagesBest Capstone SampleVienna Jane FloresNo ratings yet

- Cka PDFDocument58 pagesCka PDFpardhunani143No ratings yet

- Digital Marketing: What Is Digital Marketi NG?Document2 pagesDigital Marketing: What Is Digital Marketi NG?Aaroohi DudejaNo ratings yet

- Commerical InvoiceDocument1 pageCommerical Invoiceml ml100% (1)

- Rahul Singh ResumeDocument2 pagesRahul Singh Resumeashu.mahendruNo ratings yet

- Manual M032500 Gen6A A15X00-V1.2Document360 pagesManual M032500 Gen6A A15X00-V1.2Abraham Dominguez SandovalNo ratings yet

- Tecumseh Quick Reference: Service InformationDocument73 pagesTecumseh Quick Reference: Service InformationMike CryerNo ratings yet

- 18 Setting Up Letsencrypt On Freebsd Younis Said HaniwriterDocument5 pages18 Setting Up Letsencrypt On Freebsd Younis Said HaniwriterNJ LinNo ratings yet

- E2 - 5 Toshiba SasakiDocument32 pagesE2 - 5 Toshiba SasakiGhulam Khairul IlhamNo ratings yet

- My Resume - 2024-01-15 16 - 15 - 08Document2 pagesMy Resume - 2024-01-15 16 - 15 - 08rahulrobinson38No ratings yet

- SGS 002 (A) Minutes of Supervision Meeting FormDocument3 pagesSGS 002 (A) Minutes of Supervision Meeting Formsaif nazirNo ratings yet

- A Critical Review of Grid Operations in Nigeria.: A.O. Ibe, Ph.D. and E.K. Okedu, M.EngDocument5 pagesA Critical Review of Grid Operations in Nigeria.: A.O. Ibe, Ph.D. and E.K. Okedu, M.EngOgunranti RasaqNo ratings yet

- Apps Develop HTS 2Document11 pagesApps Develop HTS 2dinaabhiNo ratings yet

- SOP - Student Support Section ServicesDocument2 pagesSOP - Student Support Section ServicespiyushNo ratings yet

- Writing The Review of Related Literature RRL V1Document18 pagesWriting The Review of Related Literature RRL V1Danah Verniz BaldozNo ratings yet

- Bitdefender Installation GuideDocument6 pagesBitdefender Installation GuideGary LaynNo ratings yet

- SK-600I - Operator's Manual v1.0 (En)Document68 pagesSK-600I - Operator's Manual v1.0 (En)Zákány ZoltánNo ratings yet

- BUS 302 Assignment 1 - Innovation From Google's Free Food StrategyDocument2 pagesBUS 302 Assignment 1 - Innovation From Google's Free Food Strategyteacher.theacestudNo ratings yet

- Apple Supply Chain ManagementDocument14 pagesApple Supply Chain Managementmaryam1214khanNo ratings yet

- Parking Principles 1Document37 pagesParking Principles 1Nina ImperialNo ratings yet

- Portable Laser Marker Series User Manual V1.8.2Document146 pagesPortable Laser Marker Series User Manual V1.8.2Enzo Gallo Ruiz FlorianNo ratings yet

- ISA 95 Framework & LayersDocument3 pagesISA 95 Framework & LayersPINAKI MAITYNo ratings yet

- Cooling System Installation - T2250Document3 pagesCooling System Installation - T2250RDM SERVICENo ratings yet

- IE 3353 Homework 2Document2 pagesIE 3353 Homework 2Simay ÇelikNo ratings yet

- IAS Lesson 3. Security Systems Development Life CycleDocument5 pagesIAS Lesson 3. Security Systems Development Life CycleJunard CalmaNo ratings yet

- Amity School of Engineering & TechnologyDocument37 pagesAmity School of Engineering & TechnologyDipesh SNo ratings yet

- A Rough Guide To MLC 2006 Regulation 3.1: HabitabilityDocument1 pageA Rough Guide To MLC 2006 Regulation 3.1: Habitability757rustamNo ratings yet