Professional Documents

Culture Documents

Nfef 60 44 Ci DR TD 009 - d1 - 000

Uploaded by

Abid AyubOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nfef 60 44 Ci DR TD 009 - d1 - 000

Uploaded by

Abid AyubCopyright:

Available Formats

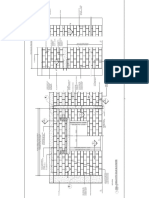

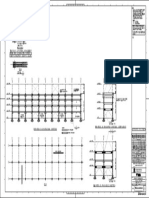

1 2 3 4 5 8 9 10 11

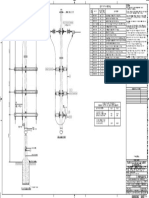

NOTES :

TABLE-1 DIMENSIONAL TOLERANCE IN PRECAST UNITS 1. PVC SLEEVE PIPE MATERIAL AND PART OF

LIFTING DEVICE, IF REQ'D, SHALL CONFORM TO

ASTM D2729.

GRID

ITEM FIGURE TOLERANCE

2. LIFTING LUGS SHALL CONFORM TO ASTM A3,

ASTM A615 OR EQUIVALENT AND SHALL BE HOT

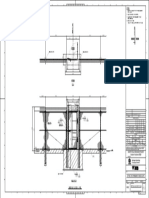

CROSS-SECTION LB LB < 600MM, +10MM/-3MM DIP GALVANIZED. AFTER ERECTION, LIFTING

COLUMN WIDTH SPLICE ZONE

A OVERALL DIMENSION 600MM < LB < 900MM, +12MM/-6MM LUGS MAY BE CUT. IN CASE LIFTING LUGS A

(LB) LB > 900MM, +15MM/-6MM WILL BE CUT, MIN 75MM THICK OF CONC.

STIRRUPS MORTAR OR GROUT SHALL BE PROVIDED ON

TOP BAR

LB

THE CUT PORTION.

DEPTH

3. THE DIMENSION OF THE PRECAST UNITS

SHALL BE WITHIN THE TOLERANCE LISTED

TABLE 1.

L1

COLUMN

LENGTH SPECIAL CARE SUCH AS SOLDIER BEAM

SHALL BE USED FOR THE COLUMN INSTALLATION

(Ln) ±6MM OR 3MM PER 3M

L2

TO MEET CONSTRUCTION TOLERANCE.

OF LENGTH (FOR L1, L2, L3),

L3

GRID

WHICHEVER IS GREATER 4. SPLICE ZONE LENGTH SHALL BE DETERMINED

BOTTOM BAR STIRRUPS IN ACCORDANCE WITH ACI 318.

MECHANICAL COUPLER APPROVED BY COMPANY MAY

ROUGHENED SURFACE BE USED INSTEAD OF SPLICE.

IN THE CASE COUPLERS SHALL BE STAGGERED

APPROPRIATELY TO AVOID CONGESTION.

PRECAST COLUMN

TWIST THE LOCATION OF STARTER BAR AND BEAM

L

B REBAR SHALL BE DECIDED SO THAT THE MINIMUM B

(e)

CONCRETE COVER 50mm IS MAINTAINED.

SECTION A e = e1 + e2

e < 6L/1000 5. EPC CONTRACTOR SHALL DEVELOP REBAR SIZE.

-

6. TEMPORARY PROVISION TO SECURE BEAM

e1 e2 STABILITY PRIOR TO FIXING OF PIN CONNECTION

BEAM SHALL BE CONSIDERED BY CONTRACTOR.

Ls D1

CENTER TO CENTER OF

DIRECTED COLUMN (Ls)

GRID GRID ± 5MM

50 SPLICE ZONE

(SEE NOTE 4) EMBEDDED PLATE EMBEDDED PLATE

50

50 TOP BAR

10

TOP BAR WEB BAR

70

C TOP BAR STRAIGHTNESS OF C

70

EDGES AND FLATNESS e

L

e < L/500, MAX. 15MM

OF SURFACES

WEB BAR (e)

WEB BAR ANCHOR BAR

e

STIRRUPS

STIRRUPS INCLINATION OF

A

UNIT

(TYP.)

- e < L/500, MAX. 15MM

L

ANCHOR BAR (e)

ANCHOR BAR

50

BOTTOM BAR

50

BOTTOM BAR

L

BOTTOM BAR WARP e < L/500, MAX. 15MM

TIE BAR (e)

ROUGHENED SURFACE

D TO A FULL AMPLITUDE D

e

OF APPROXIMATELY 5mm.

120 PRECAST COLUMN BOTH END MIDDLE

a±e2

50

LOCATION

ANCHOR BOLT AND

e1 < ± 3MM

SLEEVE (e1, e2)

e2 < ± 2MM

C

L L

a,b = BOLT PITCH FROM C

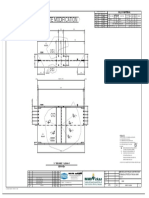

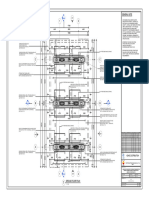

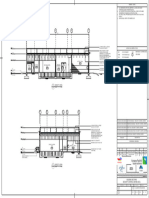

TYPICAL DETAIL OF CAST-IN-SITU CONCRETE FOR BEAM/GIRDER (MOMENT CONNECTION)

b±e1

e1 C

L

DETAIL 2 LOCATION OF

e2

008 EMBEDDED PLATE (e1, e2) e1 < ± 5MM

E e2 < ± 5MM E

PRE-CAST COLUMN

e1

150 (MIN.)

50

(TYP.) ELEVATION OF

EMBEDDED PLATE

(FOR HORIZONTAL ELEMENT) e1 < ± 5MM

(MIN.)

50

25 50

FINISHING GRADE

300

LEVEL

APPROVED FOR DESIGN

250

NOTE: L = LENGTH OF MEMBER

F F

75

(TYP.) NON-SHRINK GROUT

NFEF-60-44-CI-DR-TD-008 STANDARD DETAILS FOR PRECAST CONCRETE PIPE RACK 2/3

NFEF-60-44-CI-DR-TD-007 STANDARD DETAILS FOR PRECAST CONCRETE PIPE RACK 1/3

DWG NO. TITLE

REFERENCE DRAWINGS

25 L 25

C.J. D1 APPROVED FOR DESIGN D.O S.I Y.H OCT.19.'18

250

(TYP.) C1 ISSUED FOR APPROVAL D.O S.I Y.H JUL.12.'18

A1 ISSUED FOR INTERNAL REVIEW D.O S.I Y.H JUN.27.'18

TOP BAR NO. DESCRIPTION BY CHKD APVD APVD DATE

50

B STIRRUPS WEB BAR REVISIONS

B.O.COL

- REV DATE APPROVED

ISSUED FOR CONSTRUCTION

DATE

G BY G

DRAWN DSGND CHKD APVD APVD

1:5 CHAMFER ALL RIGHTS RESERVED

THIS DOCUMENT IS THE PROPERTY OF QATARGAS OPERATING COMPANY LIMITED AND CONTAINS

TO BOTTOM OF COLUMN INFORMATION WHICH IS PROPRIETARY. THIS INFORMATION IS TO BE HELD IN CONFIDENCE.

NO DISCLOSURE OR OTHER USE OF THIS DOCUMENT IS TO BE MADE WITHOUT THE PRIOR

WRITTEN CONSENT OF QATARGAS OPERATING COMPANY LIMITED.

NORTH FIELD EXPANSION PROJECT

Onshore Facilities FEED

Contract No.

SECTION B BOTTOM BAR

BEFORE INSTALLATION OF PRECAST COLUMN, NOTE 6 D1

LEAN CONCRETE - Qatargas Operating

NON-SHRINK GROUT TO BE PLACED WITH

1-16mmx250x250 LEVELING SHIM PLATE Company Limited

QATARGAS

(CARBON STEEL WITHOUT COATING/GARVANIZING)

TITLE

STANDARD DETAILS FOR

H TYPICAL DETAIL OF FOUNDATION H

0.125L 0.75L 0.125L PRECAST CONCRETE

PIPE RACK 3/3

SCALE NONE JOB NO.

DETAIL 1 TYPICAL DETAIL OF PRECAST GIRDER PROJECT DRAWING NO. REVISION

008

NFEF-60-44-CI-DR-TD-009

(PIN CONNECTION) NFEF D1

1 2 3 4 5 8 9 10 11 WORK NO.

FILE NAME : NFEF-60-44-D1-DR-TD-009_D1_000.dgn

You might also like

- General Notes Table 1: Bearing Baseplate AssemblyDocument20 pagesGeneral Notes Table 1: Bearing Baseplate AssemblyLeon ZhouNo ratings yet

- Soil Machine Dynamics LTD: SCALE: 1: 15Document1 pageSoil Machine Dynamics LTD: SCALE: 1: 15jsNo ratings yet

- Ar Ged 04 001 01Document1 pageAr Ged 04 001 01Bahaa MohamedNo ratings yet

- Plano de Blindaje 24MDocument2 pagesPlano de Blindaje 24MAndree Ayma NuñezNo ratings yet

- Grating Specifications.: 40 THK Grating 40 THK GratingDocument1 pageGrating Specifications.: 40 THK Grating 40 THK GratingsivagnanamNo ratings yet

- Saudi Arabian Oil Company: VA-291301 001 P 0A2 K11 RestrictedDocument1 pageSaudi Arabian Oil Company: VA-291301 001 P 0A2 K11 Restrictedsaleem naheedNo ratings yet

- Single Dead End, Terminal Pole, Dead End Riser Pole: Saudi Arabian Oil CompanyDocument1 pageSingle Dead End, Terminal Pole, Dead End Riser Pole: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- List of Material: Saudi Arabian Oil CompanyDocument1 pageList of Material: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- Project: Codelco El Salvador Rajo Inca 2: Certified For ConstructionDocument1 pageProject: Codelco El Salvador Rajo Inca 2: Certified For ConstructionRoberto RevinsacNo ratings yet

- Welding Procedure For BOXNR Wagon (WPS)Document8 pagesWelding Procedure For BOXNR Wagon (WPS)Shekher NikhilNo ratings yet

- 2VB15 (KSS021-D-671) - Ver Bracing-R1Document1 page2VB15 (KSS021-D-671) - Ver Bracing-R1mo3azNo ratings yet

- AB-036386 Hardness Testing For Welding Procedure QualificationDocument1 pageAB-036386 Hardness Testing For Welding Procedure QualificationAmr MahmoudNo ratings yet

- 1 No. Ver Bracing Required As Drawn MKD' - 2Vb-5: Bolt List For Assembly MKD' 2Vb-5 X 1 Dia. Qty. Bolt GradeDocument1 page1 No. Ver Bracing Required As Drawn MKD' - 2Vb-5: Bolt List For Assembly MKD' 2Vb-5 X 1 Dia. Qty. Bolt Grademo3azNo ratings yet

- 12173ME01EN05 - Draft Tube 257m3Document1 page12173ME01EN05 - Draft Tube 257m3Alan Figueroa PobleteNo ratings yet

- P92-4998 Harness Aftertreatment PDFDocument4 pagesP92-4998 Harness Aftertreatment PDFDiego LiraNo ratings yet

- 66 Ihd 0003 ADocument1 page66 Ihd 0003 AMbalekelwa MpembeNo ratings yet

- Plano Advance PDFDocument10 pagesPlano Advance PDFjonatancgNo ratings yet

- Col & Fot ScheduleDocument1 pageCol & Fot Schedulece mgnregsNo ratings yet

- Site Modification: Bill of MaterialDocument1 pageSite Modification: Bill of MaterialRaziKhanNo ratings yet

- Item Qty Part No.: Finish: GreyDocument1 pageItem Qty Part No.: Finish: GreyDario CisnerosNo ratings yet

- Site Modification: Bill of MaterialDocument1 pageSite Modification: Bill of MaterialRaziKhanNo ratings yet

- J3BGDF02BR005 01 01Document1 pageJ3BGDF02BR005 01 01saleem naheedNo ratings yet

- Bsi STD DWG El 001 Electrical Standard Installation 2of6Document1 pageBsi STD DWG El 001 Electrical Standard Installation 2of6dharuNo ratings yet

- 02.MRTCPL - Reinf - RCC Box-Ret, Wall-Ch-362.231Document1 page02.MRTCPL - Reinf - RCC Box-Ret, Wall-Ch-362.231kumardityaNo ratings yet

- Sadev R1003Document1 pageSadev R1003Najib KiwanNo ratings yet

- 2012 KW Oem Engine HarnessDocument4 pages2012 KW Oem Engine HarnessSergio HernandezNo ratings yet

- Canal Flow Data:-: Sectional ElevationDocument1 pageCanal Flow Data:-: Sectional ElevationerfewNo ratings yet

- SRD - 111 - S CWDT 01 02.05.2022Document1 pageSRD - 111 - S CWDT 01 02.05.2022Nishant KarthikeyanNo ratings yet

- Ajv DPW 10 525 CL DWG 0695 03 R03Document1 pageAjv DPW 10 525 CL DWG 0695 03 R03sivagnanamNo ratings yet

- RCC Design & DetailsDocument1 pageRCC Design & DetailsKanhaiya PanwarNo ratings yet

- Aa 036142 012Document1 pageAa 036142 012Mohamed RamadanNo ratings yet

- Typical Weir Box Type-1 Typical Sanitary Manhole: NotesDocument1 pageTypical Weir Box Type-1 Typical Sanitary Manhole: NotesAbid AyubNo ratings yet

- 32 Gfc-P2c3-Tu02-Crp-Dr-Btn-73106-01-ADocument1 page32 Gfc-P2c3-Tu02-Crp-Dr-Btn-73106-01-ASUBHASH KUMARNo ratings yet

- WH2 GaDocument5 pagesWH2 GaRaveendra Babu CherukuriNo ratings yet

- Notes: Total No. of Installation 1noDocument1 pageNotes: Total No. of Installation 1noaung aungNo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- List of Material: Saudi Arabian Oil CompanyDocument1 pageList of Material: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- General Note: Adnoc DistributionDocument1 pageGeneral Note: Adnoc DistributionShaheer.saNo ratings yet

- Ist Floor Punch Layout With Beam-Layout1Document1 pageIst Floor Punch Layout With Beam-Layout1A.K.M Shafiq MondolNo ratings yet

- Hold Class 2: 102B15 - W21X68 - 29'-10 1/2" - ONE REQ'D CAMBER 3/4"Document1 pageHold Class 2: 102B15 - W21X68 - 29'-10 1/2" - ONE REQ'D CAMBER 3/4"ai ambaraNo ratings yet

- Detail Detail: Issued For Public CommentDocument1 pageDetail Detail: Issued For Public CommentChilakamarri SrikamalNo ratings yet

- Sa-Ami-521-Mosu-000xxx (SCC Building Sections)Document1 pageSa-Ami-521-Mosu-000xxx (SCC Building Sections)tanyadeasis8No ratings yet

- Confidential Information: Fire Water Tanks TAG NO. 62-T-1001A/B 51.2 M. DIA. X 17 M. HT. (CR)Document1 pageConfidential Information: Fire Water Tanks TAG NO. 62-T-1001A/B 51.2 M. DIA. X 17 M. HT. (CR)shravan.office11No ratings yet

- 1 No. Ver Bracing Required As Drawn MKD' - 2Vb-36: Bolt List For Assembly MKD' 2Vb-36 X 1 Dia. Qty. Bolt GradeDocument1 page1 No. Ver Bracing Required As Drawn MKD' - 2Vb-36: Bolt List For Assembly MKD' 2Vb-36 X 1 Dia. Qty. Bolt Grademo3azNo ratings yet

- Wa-0636860 0001 0001Document1 pageWa-0636860 0001 0001Bilal ChohanNo ratings yet

- Notes:-: Reinforcement Detail Bar ShapeDocument8 pagesNotes:-: Reinforcement Detail Bar ShapeDushyant JadaunNo ratings yet

- 1500 GPM DIESEL W ENCLDocument1 page1500 GPM DIESEL W ENCLProyectos e Ingeniería - Inprofuego, C.A.No ratings yet

- P4059zor 62 22 1 T1001 018 002 - ADocument1 pageP4059zor 62 22 1 T1001 018 002 - Ashravan.office11No ratings yet

- List of Material: Saudi Arabian Oil CompanyDocument1 pageList of Material: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- List of Material: Saudi Arabian Oil CompanyDocument1 pageList of Material: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- Handrail For Staircase-2: HR 005 HR 022Document1 pageHandrail For Staircase-2: HR 005 HR 022KARTHIK SGNo ratings yet

- Racking SystemDocument1 pageRacking SystemdaveNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-FR2-0601 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-FR2-0601 - Rev 0Darshan PanchalNo ratings yet

- As Aigc Ga TCTV 001 3Document1 pageAs Aigc Ga TCTV 001 3engrabbas75No ratings yet

- Detail at A: Sinhgad College of Architecture PuneDocument1 pageDetail at A: Sinhgad College of Architecture Puneamruta potdarNo ratings yet

- Detail at A: Sinhgad College of Architecture PuneDocument1 pageDetail at A: Sinhgad College of Architecture Puneamruta potdarNo ratings yet

- Pages From P24019-30-99-63-1601 - 1-3sggDocument1 pagePages From P24019-30-99-63-1601 - 1-3sggRaeesNo ratings yet

- 2205042800-01 DWGDocument1 page2205042800-01 DWGJuan Carlos TolabaNo ratings yet

- Site Modification: Bill of MaterialDocument1 pageSite Modification: Bill of MaterialRaziKhanNo ratings yet

- Onshore Facilities FEED North Field Expansion Project: Qatargas OperatingDocument1 pageOnshore Facilities FEED North Field Expansion Project: Qatargas OperatingAbid AyubNo ratings yet

- Approved For Design: Onshore Facilities FEED North Field Expansion ProjectDocument1 pageApproved For Design: Onshore Facilities FEED North Field Expansion ProjectAbid AyubNo ratings yet

- (For Wall) : Note: Prior To Backfill of Duct Bank, All Opening Shall Be PluggedDocument1 page(For Wall) : Note: Prior To Backfill of Duct Bank, All Opening Shall Be PluggedAbid AyubNo ratings yet

- Notes:: (Alloy Steel A.Bolt) (Alloy Steel A.Bolt)Document1 pageNotes:: (Alloy Steel A.Bolt) (Alloy Steel A.Bolt)Abid AyubNo ratings yet

- Onshore Facilities FEED North Field Expansion Project: Qatargas OperatingDocument1 pageOnshore Facilities FEED North Field Expansion Project: Qatargas OperatingAbid AyubNo ratings yet

- LPP: Lowest Level For Concrete Paving: Qatargas OperatingDocument1 pageLPP: Lowest Level For Concrete Paving: Qatargas OperatingAbid AyubNo ratings yet

- Nfef 60 87 Ci DR TD 001 - d1 - 000Document1 pageNfef 60 87 Ci DR TD 001 - d1 - 000Abid AyubNo ratings yet

- Major Road: 2% Slope 2% Slope 2% SlopeDocument1 pageMajor Road: 2% Slope 2% Slope 2% SlopeAbid AyubNo ratings yet

- Nfef 60 44 Ci DR TD 001 - d2 - 000Document1 pageNfef 60 44 Ci DR TD 001 - d2 - 000Abid AyubNo ratings yet

- Notes:: Onshore Facilities FEED North Field Expansion ProjectDocument1 pageNotes:: Onshore Facilities FEED North Field Expansion ProjectAbid AyubNo ratings yet

- On-Pave Foundation: Embedded Type Anchor Bolt TypeDocument1 pageOn-Pave Foundation: Embedded Type Anchor Bolt TypeAbid AyubNo ratings yet

- Typical Weir Box Type-1 Typical Sanitary Manhole: NotesDocument1 pageTypical Weir Box Type-1 Typical Sanitary Manhole: NotesAbid AyubNo ratings yet

- Onshore Facilities FEED North Field Expansion Project: Qatargas OperatingDocument1 pageOnshore Facilities FEED North Field Expansion Project: Qatargas OperatingAbid AyubNo ratings yet

- Typical Joint Box With U-Ditch: Weephole DetailDocument1 pageTypical Joint Box With U-Ditch: Weephole DetailAbid AyubNo ratings yet

- Nfef 60 43 ST DR TD 015 - d1 - 000Document1 pageNfef 60 43 ST DR TD 015 - d1 - 000Abid AyubNo ratings yet

- Onshore Facilities FEED North Field Expansion Project: Qatargas OperatingDocument1 pageOnshore Facilities FEED North Field Expansion Project: Qatargas OperatingAbid AyubNo ratings yet

- Removable Type HR Normal Type HR: NotesDocument1 pageRemovable Type HR Normal Type HR: NotesAbid AyubNo ratings yet

- Angle Column, Post, Brace Column, Post, Brace Tee Shape Beam Column, Post, Brace H-ShapeDocument1 pageAngle Column, Post, Brace Column, Post, Brace Tee Shape Beam Column, Post, Brace H-ShapeAbid AyubNo ratings yet

- I WI I 5: GR AT NG Plat Form DTH NSI DER ADI US NDocument1 pageI WI I 5: GR AT NG Plat Form DTH NSI DER ADI US NAbid AyubNo ratings yet

- Sec Sec Det: 6 0 (P P R) 6 0 (P P R)Document1 pageSec Sec Det: 6 0 (P P R) 6 0 (P P R)Abid AyubNo ratings yet

- Onshore Facilities FEED North Field Expansion Project: Qatargas OperatingDocument1 pageOnshore Facilities FEED North Field Expansion Project: Qatargas OperatingAbid AyubNo ratings yet

- Joist Connections: - 2 7 Detail DetailDocument1 pageJoist Connections: - 2 7 Detail DetailAbid AyubNo ratings yet

- Elevation 01 Elevation 04: C03 C01 C02 D01 D02 D03 D04 D05 D06 D07Document1 pageElevation 01 Elevation 04: C03 C01 C02 D01 D02 D03 D04 D05 D06 D07Abid AyubNo ratings yet

- Approved For Design: Onshore Facilities FEED North Field Expansion ProjectDocument1 pageApproved For Design: Onshore Facilities FEED North Field Expansion ProjectAbid AyubNo ratings yet

- OFFICE BLDG PLAN ELV-3ModelDocument1 pageOFFICE BLDG PLAN ELV-3ModelAbid AyubNo ratings yet

- Fire Pump Room Details Guard Room Details: M01 M02 M01 M02Document1 pageFire Pump Room Details Guard Room Details: M01 M02 M01 M02Abid AyubNo ratings yet

- Nfef 60 43 ST DR TD 012 - d1 - 000Document1 pageNfef 60 43 ST DR TD 012 - d1 - 000Abid AyubNo ratings yet

- Onshore Facilities FEED North Field Expansion Project: A P P R O X T Y PDocument1 pageOnshore Facilities FEED North Field Expansion Project: A P P R O X T Y PAbid AyubNo ratings yet

- LAY OUT PLAN-Ware House-Structure-RL-1-ModelDocument1 pageLAY OUT PLAN-Ware House-Structure-RL-1-ModelAbid AyubNo ratings yet

- Purlin Roof Syste S6Document1 pagePurlin Roof Syste S6Abid AyubNo ratings yet

- ACI Shrinkage CalculationDocument15 pagesACI Shrinkage Calculationaavlv100% (1)

- 07a BoQDocument15 pages07a BoQDean KoortzenNo ratings yet

- Chapter 2 - Conceptual Framework Review of Related Literature and StudiesDocument8 pagesChapter 2 - Conceptual Framework Review of Related Literature and StudiesraifelNo ratings yet

- Pop A Plug MaterialDocument2 pagesPop A Plug MaterialHijau Auliya Keramat Al-qadiryNo ratings yet

- Indian StandardDocument17 pagesIndian StandardMd Tajijul IslamNo ratings yet

- BS 5160Document29 pagesBS 5160PD AWSSIESPNo ratings yet

- Abrasive Flyer TMRDocument4 pagesAbrasive Flyer TMRherysyam1980No ratings yet

- ASTM C150 Aashto M 85Document5 pagesASTM C150 Aashto M 85J O M A RNo ratings yet

- Manual (Aitech) : ON Accreditation of Innovative Technologies For HousingDocument40 pagesManual (Aitech) : ON Accreditation of Innovative Technologies For HousingAl Patrick Dela CalzadaNo ratings yet

- Data Sheets Kga Plus Knife Gate Valves Clarkson en en 5196860Document8 pagesData Sheets Kga Plus Knife Gate Valves Clarkson en en 5196860Cristian Mena HidalgoNo ratings yet

- 0511 Grob PDFDocument7 pages0511 Grob PDFJ VeluNo ratings yet

- Open Kitchen Design GuidelinesDocument16 pagesOpen Kitchen Design GuidelinesAnthony Brian RelayoNo ratings yet

- Murex Oxy Welding Poster 2008 PDFDocument1 pageMurex Oxy Welding Poster 2008 PDFPCNo ratings yet

- Model F350 Sectional Test & Drain 5.6K (80K) Test Orifice For Use With Field-Fabricated Sectional Control Arrangements General DescriptionDocument4 pagesModel F350 Sectional Test & Drain 5.6K (80K) Test Orifice For Use With Field-Fabricated Sectional Control Arrangements General DescriptionLe DucNo ratings yet

- Imran & Brothers: Item Expance TotalDocument2 pagesImran & Brothers: Item Expance Totalbehzad haiderNo ratings yet

- Microsoft PowerPoint - LECTURE3Document36 pagesMicrosoft PowerPoint - LECTURE3Bassel AlshamiNo ratings yet

- Client: Supplier: Location: Sheet: Item: Large Size Gear BoxDocument1 pageClient: Supplier: Location: Sheet: Item: Large Size Gear BoxirwanNo ratings yet

- Electrochemical Behavior of Corrosion Resistance of X65/Inconel 625 Welded JointsDocument11 pagesElectrochemical Behavior of Corrosion Resistance of X65/Inconel 625 Welded JointsÉlida AlvesNo ratings yet

- TN31Document21 pagesTN31Anthony RuthNo ratings yet

- Welding Procedures and Welding Qualiy Control For PipingDocument18 pagesWelding Procedures and Welding Qualiy Control For PipingImam BuchairiNo ratings yet

- ZubehoerDocument15 pagesZubehoerimtiyazNo ratings yet

- Elems 02Document101 pagesElems 02Reynald de VeraNo ratings yet

- Long Form Specification For Structural Glazed TileDocument13 pagesLong Form Specification For Structural Glazed TileElgin ButlerNo ratings yet

- Adhesive Guide FinalDocument8 pagesAdhesive Guide FinalBogdanNo ratings yet

- V Archi of PunjabDocument30 pagesV Archi of Punjabar jain57% (7)

- Breast Wall DWGDocument1 pageBreast Wall DWGkanagarajodishaNo ratings yet

- Aluminium AloyDocument2 pagesAluminium AloyGian GiovaniNo ratings yet

- Product36 - File - 0 - MCM Product Guide - Fastening Technology P - PDFDocument50 pagesProduct36 - File - 0 - MCM Product Guide - Fastening Technology P - PDFmuathNo ratings yet

- TRM 150Document3 pagesTRM 150Jefferson fernandesNo ratings yet

- Stop LogDocument7 pagesStop LogMarceloNo ratings yet