Professional Documents

Culture Documents

Shear Lug Design

Shear Lug Design

Uploaded by

motiur basumCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shear Lug Design

Shear Lug Design

Uploaded by

motiur basumCopyright:

Available Formats

Shear Lug Design

Shear Lug Design.xls Rev. 1 01/23/09

Company Logo

Project Name Verification Project No.

Subject Shear lug design example Client

Description

Shear lug design verification

Reference Steel Design Guide 1, Base Plate and Anchor Rod Design, Second Edition, Example 4.9 and Steel Design Guide 7, Industrial Buildings, Roofs

to Anchor Rods, Second Edition, Examples 9.4.2 and 9.4.3

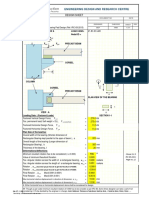

Column Pier Lug

Materials and Load

Concrete compr. strength f'c= 4,000 psi

Concrete weight modification l= 1.0 Assume normal weight concrete

factor

Reinf. bar yield strength fyreinf = 60 ksi

Lug material Lug = A36

Lug plate yield strength Fylug = 36 ksi

Factored shear load Vu = 36.8 kips

Geometry

Notes: Assume the shear lug is centered on the pier along both width Wa and width Wb

Reference SDG1 Section 4.9

Pier width perpendicular to the Wa = 20.000 in

shear load

Pier width parallel to the shear Wb = 20.000 in

load

Height of pier Hpier = 36.000 in

Column base plate thickness tbp = 1.250 in

Thickness of grout pad G= 2.000 in

Length of shear lug L= 9.000 in Perpendicular to the direction of the shear load

Shear lug depth below the top of d= 1.500 in Does not include the thickness of the grout pad

pier

Thickness of shear lug t= 1.250 in Thickness of column base plate must be >= t

*** tbp >= t, Check OK

Distance from edge of shear lug a= 5.500 in #ADDIN?

to edge of pier

Distance from face of shear lug c= 9.375 in #ADDIN?

and face of pier

Height of shear lug H= 3.500 in = d+G #ADDIN?

03/25/2019 file:///conversion/tmp/scratch/413235827.xls Page 1

16:29:45 413235827.xls of 7

Shear Lug Design

Shear Lug Design.xls Rev. 1 01/23/09

Company Logo

Project Name Verification Project No.

Subject Shear lug design example Client

Concrete Bearing

Notes: Reference SDG1 Section 4.9 and SDG7 Section 9.3 and Example 9.4.3

Bearing strength reduction jbg= 0.80

factor

Bearing area of shear lug Alug = 13.50 in2 #ADDIN?

Factored shear load Vu = 36.80 kips #ADDIN?

Design bearing strength jbgPn= 43.20 kips #ADDIN?

Capacity ratio CR = 0.85 #ADDIN? *** CR <= 1.0, Check OK

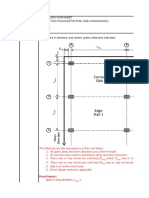

Concrete Shear

Notes: Reference SDG1 Section 4.9 and SDG7 Example 9.4.3

Shear strength reduction factor σ= 0.75

Depth of shear failure plane b= 10.88 in #ADDIN?

Width of shear failure plane f= 20.00 in #ADDIN?

Minimum Wa and L+(2*c). Assume the failure plane projects

from each end of the shear lug at a 45 degree angle toward

the face of the pier.

Projected area of shear failure Av = 204.00 in2 #ADDIN?

plane, area of shear lug not

included

Factored shear load Vu = 36.80 kips #ADDIN?

Ultimate shear strength jsVn= 38.71 kips #ADDIN?

Capacity ratio CR = 0.95 #ADDIN? *** CR <= 1.0, Check OK

Shear Lug Plate Bending

Notes: Reference SDG1 Example 4.9

Plate bending strength reduction jb= 0.90

factor

Plastic section modulus of shear Zy = 3.52 in3 #ADDIN?

lug

Factored moment in lug Mulug = 101.20 in-kips #ADDIN?

Design bending strength of jbMn= 114.05 in-kips #ADDIN?

shear lug

Required thickness of lug treqd= 1.18 in #ADDIN?

Capacity ratio CR = 0.89 #ADDIN? *** CR <= 1.0, Check OK

Weld of Shear Lug to Base Plate

Notes: Assume a continuous fillet weld along the length of the shear lug on both sides

Reference SDG1 Example 4.9 and SDG7 Example 9.4.3

Strength reduction factor for jw= 0.75

fillet welds

Electrode classification no. Fexx = 70 ksi

Thickness of fillet weld tweld = 0.375 in Generally provide fillet welds up to 0.75" before using groove

welds

Dist. c.g weld to c.g. weld s= 1.500 in #ADDIN?

Weld stress due to bending fc = 7.50 kips/in #ADDIN?

Weld stress due to shear fv = 2.04 kips/in #ADDIN?

Resultant stress in weld fr = 7.77 kips/in #ADDIN?

Design strength of weld jwRn= 8.35 kips/in #ADDIN?

Capacity ratio CR= 0.93 #ADDIN? *** CR <= 1.0, Check OK

03/25/2019 file:///conversion/tmp/scratch/413235827.xls Page 2

16:29:46 413235827.xls of 7

Shear Lug Design

Shear Lug Design.xls Rev. 1 01/23/09

Company Logo

Project Name Verification Project No.

Subject Shear lug design example Client

Pier Shear Strength

Note: Reference SDG7 Example 9.4.2

Strength reduction factor σ= 0.75

Clear cover to stirrup Cside = 1.500 in

Bar size of vertical pier Barvert = 1

reinforcing

Diameter of vert. pier reinf. dbvert = n/a in

Bar size of pier ties Bartie = 4 Ties are required at the top of all piers where anchor rods are

embedded. Min. (2) #4's or (3) #3's in the top 5". However,

calculate the nominal shear strength for the remainder of the

pier assuming no ties.

Diameter of pier tie bars dbtie = 0.500 in

Distance from c.g. of vertical c '= #VALUE! in #ADDIN?

bars to pier face

Pier width perpendicular to the Wa = 20.000 in

shear load

Pier width parallel to the shear Wb = 20.000 in

load

Depth of section from compr. d= #VALUE! in #ADDIN?

face to c.g. of reinf.

Factored shear load Vu = 36.8 kips

Design shear strength of jsVc'= #VALUE! kips #ADDIN?

pier without shear reinforcing Per ACI 11.4.6.1, piers without ties can only use 1/2 the nominal

(ties) concrete shear strength

Capacity ratio CR= #VALUE! #ADDIN? #VALUE!

Shear Reinforcing in Pier

Notes: Add ties when Vu exceeds the shear capacity of the pier without shear reinforcing.

Reference SDG7 Example 9.4.2.

Strength reduction factor ϕs = 0.75

Design shear strength for piers jsVc= #VALUE! kips

with shear reinforcing #ADDIN?

Bar size of pier ties Bartie = 4 Must provide min. (2) #4's or (3) #3's at top of piers

Diameter of pier tie bars dbtie = 0.500 in

Area of one tie bar Atie = 0.200 in2

Maximum tie bar spacing smax = #VALUE! in #ADDIN?

Spacing of tie bars stie = 8.000 in #VALUE!

Number of legs for tie bars Nlegs = 2 Minimum of two legs as bars must wrap around the reinforcing

at the corners of the pier, however, there may be additional

interior ties.

Design shear strength of pier tie jsVs= #VALUE! kips

bars #ADDIN?

Factored shear load Vu = 36.8 kips

Pier design shear strength jsVn= #VALUE! kips #ADDIN?

Capacity ratio CR= #VALUE! #ADDIN? #VALUE!

References

1. Building Code Requirements for Structural Concrete, ACI 318-08, (ACI 318)

2. Code Requirements for Nuclear Safety Related Concrete Structures, ACI 349-06, (ACI 349)

3. Steel Construction Manual, Thirteenth Edition, AISC, (SCM)

4. Steel Design Guide 1, Base Plate and Anchor Rod Design, Second Edition, AISC, (SDG1)

5. Steel Design Guide 7, Industrial Buildings, Roofs to Anchor Rods, Second Edition, AISC, (SDG7)

03/25/2019 file:///conversion/tmp/scratch/413235827.xls Page 3

16:29:49 413235827.xls of 7

Shear Lug Design

Shear Lug Design.xls Rev. 1 01/23/09

Prepared By JWT

Date 01/23/09

n, Second Edition, Example 4.9 and Steel Design Guide 7, Industrial Buildings, Roofs

Lug

ACI 318 8.6.1

SDG1 3.5

03/25/2019 file:///conversion/tmp/scratch/413235827.xls Page 4

16:29:50 413235827.xls of 7

Shear Lug Design

Shear Lug Design.xls Rev. 1 01/23/09

Prepared By JWT

Date 01/23/09

SDG1 3.5.2, ACI 349

D.4.6.2 & D.4.4(f)

ACI 318 9.3.2.3

SCM F1

SCM Table 17-27, Rect. w/

axis thru center

SCM Table J2.5

SCM Table J2.5

SDG1 2.4

SCM eq. J2-4 & J2-5

03/25/2019 file:///conversion/tmp/scratch/413235827.xls Page 5

16:29:50 413235827.xls of 7

Shear Lug Design

Shear Lug Design.xls Rev. 1 01/23/09

Prepared By JWT

Date 01/23/09

ACI 318 9.3.2.3

ACI 318 7.10.5.6

ACI 318 eq. 11-3 &

11.4.6.1

ACI 318 9.3.2.3

ACI 318 eq. 11-3

ACI 318 7.10.5.6

ACI 318 7.10.5.2

ACI 318 12.13.2.1

ACI 318 eq. 11-15 & 11.4.7.9

03/25/2019 file:///conversion/tmp/scratch/413235827.xls Page 6

16:29:50 413235827.xls of 7

Reference: CRSI

BarTable

Bar Area Wt. Dia.

Size in^2 plf in

1 2 3 4

1 n/a n/a n/a

2 n/a n/a n/a

3 0.110 0.376 0.375

4 0.200 0.668 0.500

5 0.310 1.043 0.625

6 0.440 1.052 0.750

7 0.600 2.044 0.875

8 0.790 2.670 1.000

9 1.000 3.400 1.128

10 1.270 4.303 1.270

11 1.560 5.313 1.410

12 n/a n/a n/a

13 n/a n/a n/a

14 2.250 7.650 1.693

15 n/a n/a n/a

16 n/a n/a n/a

17 n/a n/a n/a

18 4.000 13.600 2.257

19 n/a n/a n/a

You might also like

- Elevated Water Tank Design SpreadsheetDocument13 pagesElevated Water Tank Design SpreadsheetBiswajit Biswal100% (1)

- Wall FootingDocument1 pageWall FootingImranSohailNo ratings yet

- Sample 10715Document16 pagesSample 10715remya.uNo ratings yet

- Col - Stiff Properties - SAFE - CSIDocument1 pageCol - Stiff Properties - SAFE - CSIkilmasterNo ratings yet

- Design Sheet: View A Load Case= Nodal ID = α F F F Precast BeamDocument5 pagesDesign Sheet: View A Load Case= Nodal ID = α F F F Precast BeamGanesh PrabuNo ratings yet

- AWC DCA2 Design of Fire Resistive Exposed Wood Members TR10 20210209Document137 pagesAWC DCA2 Design of Fire Resistive Exposed Wood Members TR10 20210209LarryHNo ratings yet

- Strut-Tie Method - AB1011-Case-1Document70 pagesStrut-Tie Method - AB1011-Case-1phanikrishnabNo ratings yet

- 20m Tower FootingDocument3 pages20m Tower FootingAhmed ShabanNo ratings yet

- Design of Steel BeamDocument19 pagesDesign of Steel BeamAnonymous tBhJoH5wgMNo ratings yet

- Precast Concrete ConstructionDocument28 pagesPrecast Concrete ConstructionGirl in the CityNo ratings yet

- Modeling Finite Elements - TRNC03184Document43 pagesModeling Finite Elements - TRNC03184Kidd TornoNo ratings yet

- Spectrum Analysis Using StaadDocument10 pagesSpectrum Analysis Using StaadGautam PaulNo ratings yet

- Strength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsDocument6 pagesStrength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsValdemir ColaresNo ratings yet

- Steel ColumnDocument2 pagesSteel ColumnNikki Roberts100% (2)

- Design of Splice ConnectionDocument4 pagesDesign of Splice ConnectionJustinNo ratings yet

- Reinforcing Bar Development and Splice Lengths Per ACI 318-05Document8 pagesReinforcing Bar Development and Splice Lengths Per ACI 318-05cengizNo ratings yet

- Concrete Pier (Isolated Deep Foundation) Design Based On ACI 318-14Document6 pagesConcrete Pier (Isolated Deep Foundation) Design Based On ACI 318-14Matiur Rahman BasumNo ratings yet

- Flat SlabDocument69 pagesFlat Slabmukhlesh100% (1)

- ShoringDocument7 pagesShoringARUN RAWATNo ratings yet

- R5 - Design of R C Slabs - 2015!01!28Document41 pagesR5 - Design of R C Slabs - 2015!01!28Udaysingh Patil100% (1)

- Minimum & Maximum SteelDocument3 pagesMinimum & Maximum SteelSathishNo ratings yet

- Openwell StaircaseDocument8 pagesOpenwell StaircaseAbdul AzeemNo ratings yet

- Precast Rib Beam DesignDocument1 pagePrecast Rib Beam Designanshutomar7915100% (1)

- Beam-Column Base Plate DesignDocument10 pagesBeam-Column Base Plate Designthegerman34No ratings yet

- Torsion Constant WikiDocument5 pagesTorsion Constant WikiHossam T BadranNo ratings yet

- Hilti Bolt DesignDocument7 pagesHilti Bolt Designcheligp1981No ratings yet

- A Bolts Aci318 05Document6 pagesA Bolts Aci318 05RnD2013No ratings yet

- Isolated Column Footing Design in ExcelDocument11 pagesIsolated Column Footing Design in ExcelderdushaNo ratings yet

- RCC RampDocument4 pagesRCC Ramphemantkle2uNo ratings yet

- Grade SlabDocument9 pagesGrade SlabDagur PavanNo ratings yet

- Purlin and Girt DesignDocument31 pagesPurlin and Girt DesignSharyn PolleyNo ratings yet

- General Input:-: Flexural Crack Width Calculation For Rectangular RC According ACI350-06 &ACI224R-01Document6 pagesGeneral Input:-: Flexural Crack Width Calculation For Rectangular RC According ACI350-06 &ACI224R-01Anil kumar RNo ratings yet

- Plain Concrete FootingDocument4 pagesPlain Concrete Footingjoshua humirangNo ratings yet

- Shear Lug Verification Example 12Document1 pageShear Lug Verification Example 12Nasrul AdliNo ratings yet

- ANCHOR - REINFORCEMENT (Metric)Document10 pagesANCHOR - REINFORCEMENT (Metric)Tarek AbulailNo ratings yet

- STAAD - Pro - RAM Connection Mode: Structural Special Interest Group - March 2018Document8 pagesSTAAD - Pro - RAM Connection Mode: Structural Special Interest Group - March 2018Kidd TornoNo ratings yet

- STAAD - Pro and SAP (Comparison of Features)Document11 pagesSTAAD - Pro and SAP (Comparison of Features)kalpanaadhiNo ratings yet

- T-Beam DesignDocument35 pagesT-Beam DesignAmal PremachandranNo ratings yet

- Design of 75Kl Zinc Alume (Znal) Elevated Water Storage TankDocument26 pagesDesign of 75Kl Zinc Alume (Znal) Elevated Water Storage TankSmit PatelNo ratings yet

- Mathcad - Tank Foundation Design Actions - 2611-501 & 502 - Rougher WMS Feed Tank 1 & 2Document15 pagesMathcad - Tank Foundation Design Actions - 2611-501 & 502 - Rougher WMS Feed Tank 1 & 2shashank sharmaNo ratings yet

- Column Design As Per Is 456 PDFDocument2 pagesColumn Design As Per Is 456 PDFAnsNo ratings yet

- Pedestal DesignDocument18 pagesPedestal DesignAnand.5No ratings yet

- Slab Punching Design Based On ACI 318-19: Project: Client: Design By: Job No.: Date: Review byDocument2 pagesSlab Punching Design Based On ACI 318-19: Project: Client: Design By: Job No.: Date: Review byAndy BenNo ratings yet

- Floor PlateDocument3 pagesFloor Platekeat_leong_yeeNo ratings yet

- Metal Z PurlinsDocument4 pagesMetal Z PurlinstonyNo ratings yet

- Astm Steel Grade: RN FNV Ab RN 2.4 D T Fu (Critical RN Will Be The Least of The Two RN'S)Document5 pagesAstm Steel Grade: RN FNV Ab RN 2.4 D T Fu (Critical RN Will Be The Least of The Two RN'S)Kim TrixieNo ratings yet

- Pile Cap Design 3 PilesDocument1 pagePile Cap Design 3 PilesdantevariasNo ratings yet

- Corbel Design Spreadsheet To ACI318Document6 pagesCorbel Design Spreadsheet To ACI318LAU TONo ratings yet

- RC Footing Design Inaccordance With BS 8110Document1 pageRC Footing Design Inaccordance With BS 8110saman2580No ratings yet

- Warn OK OK OK: ACI 318M-14 PIP STE05121 AISC Design Guide 1Document11 pagesWarn OK OK OK: ACI 318M-14 PIP STE05121 AISC Design Guide 1hemantcabhaleNo ratings yet

- تصميم الكمرات بطريقة ultimate PDFDocument42 pagesتصميم الكمرات بطريقة ultimate PDFqaisalkurdyNo ratings yet

- Columns DesignDocument60 pagesColumns DesignifsrebraNo ratings yet

- Nameof Work:-Design of Circular Water Tank: Narok ETPDocument27 pagesNameof Work:-Design of Circular Water Tank: Narok ETPAbhay Thakur100% (1)

- Spring Mass Model For Seismic AnalysisDocument12 pagesSpring Mass Model For Seismic AnalysisPrakash SIngh RawalNo ratings yet

- Design of RCC Corbel As Per Aci 318 95Document3 pagesDesign of RCC Corbel As Per Aci 318 95Maad Ahmed Al-Maroof50% (2)

- Steel I Beam Web Shear CapacityDocument1 pageSteel I Beam Web Shear CapacityArjun RajaNo ratings yet

- Design of Biaxial ColumnDocument5 pagesDesign of Biaxial ColumndineshNo ratings yet

- Design of BeamDocument15 pagesDesign of Beamg s venkata subramaniNo ratings yet

- Secondary Beam ExampleDocument5 pagesSecondary Beam ExampleAboalmaail AlaminNo ratings yet

- Brick Guard Scaffold Tie Duty Detailed ReportDocument6 pagesBrick Guard Scaffold Tie Duty Detailed ReportjmsNo ratings yet

- PSC Girder-25m R0Document148 pagesPSC Girder-25m R0infra120100% (1)

- Fineness Modulus of Sand - Fineness Modulus of Fine Aggregate - Fineness Modulus of Sand CalculationDocument7 pagesFineness Modulus of Sand - Fineness Modulus of Fine Aggregate - Fineness Modulus of Sand CalculationWaqas SadiqNo ratings yet

- Effect of TDSDocument12 pagesEffect of TDSWaqas SadiqNo ratings yet

- Design of Concentrically Loaded Isolated Footing According To ACI 318-08Document6 pagesDesign of Concentrically Loaded Isolated Footing According To ACI 318-08Waqas SadiqNo ratings yet

- Sedimentary Rocks Are Formed by The Accumulation of SedimentsDocument10 pagesSedimentary Rocks Are Formed by The Accumulation of SedimentsWaqas SadiqNo ratings yet

- Igneous RocksDocument12 pagesIgneous RocksWaqas SadiqNo ratings yet

- Using Digimap Data in ArcgisDocument52 pagesUsing Digimap Data in ArcgisWaqas SadiqNo ratings yet

- Using Digimap Data in ArcgisDocument52 pagesUsing Digimap Data in ArcgisWaqas SadiqNo ratings yet

- Tunnel Boring Machine Positioning Automation in Tunnel Construction PDFDocument6 pagesTunnel Boring Machine Positioning Automation in Tunnel Construction PDFWaqas SadiqNo ratings yet

- Lugeon Test 2Document11 pagesLugeon Test 2Waqas Sadiq100% (1)

- Lugeon TestDocument5 pagesLugeon TestWaqas Sadiq100% (1)

- 02-Petroleum GeologyDocument48 pages02-Petroleum GeologyWaqas Sadiq100% (2)

- 04 - NTH - Project Report 1-94 Hard Rock Tunnel Boring PDFDocument165 pages04 - NTH - Project Report 1-94 Hard Rock Tunnel Boring PDFWaqas Sadiq100% (2)

- Tests On Rocks: Soil MechanicsDocument5 pagesTests On Rocks: Soil MechanicsWaqas Sadiq100% (1)

- Drill Blast Pamphlet Eng PDFDocument1 pageDrill Blast Pamphlet Eng PDFWaqas SadiqNo ratings yet

- BTC Sweep 03Document6 pagesBTC Sweep 03paradoja_hiperbolicaNo ratings yet

- Smex1045 Strength of Materials 2 1 0 3 (1) - 1Document1 pageSmex1045 Strength of Materials 2 1 0 3 (1) - 1sankarsuper83No ratings yet

- Dynamic Bending Response of CFRP Thin Walled Square Beams Filled With Aluminium HoneycombDocument10 pagesDynamic Bending Response of CFRP Thin Walled Square Beams Filled With Aluminium HoneycombIeva MisiūnaitėNo ratings yet

- RC Salient PointsDocument9 pagesRC Salient PointsJoraindo InovejasNo ratings yet

- Ce 316 Structural Theory Module 1Document29 pagesCe 316 Structural Theory Module 1Espe SaquinNo ratings yet

- Mechanical Behavior of Materials - Lecture Slides - Chapter 9Document73 pagesMechanical Behavior of Materials - Lecture Slides - Chapter 9Jun-Dong LeeNo ratings yet

- 2000 - Novo Esquema de Design - Elimination of Flat Plate Punching Failure Mode - BromsDocument8 pages2000 - Novo Esquema de Design - Elimination of Flat Plate Punching Failure Mode - BromswhitepeteNo ratings yet

- Mechanics of Materials and StructuresDocument32 pagesMechanics of Materials and StructuresRavi KhandelwalNo ratings yet

- Moment of InertiaDocument62 pagesMoment of InertiaMcr KumaraNo ratings yet

- Seismic Design of Elevated TanksDocument64 pagesSeismic Design of Elevated TanksMahadev Sastry100% (3)

- Chapter 4 Torsion Beams + SFD and BMD. (SOM-201)Document99 pagesChapter 4 Torsion Beams + SFD and BMD. (SOM-201)Raushan Jha100% (1)

- 2D Frame Analysis: User ManualDocument33 pages2D Frame Analysis: User ManualMaryNo ratings yet

- Segmental Concrete Box Girder Bridges - 1Document18 pagesSegmental Concrete Box Girder Bridges - 1Siwakorn SangwornNo ratings yet

- CH 06Document48 pagesCH 06LeonardoMadeira11No ratings yet

- Multi Stage Parabolic Leaf SpringDocument13 pagesMulti Stage Parabolic Leaf SpringahiremanojNo ratings yet

- Hull Girder Response Analysis - Prismatic BeamDocument115 pagesHull Girder Response Analysis - Prismatic BeamNvlArchNo ratings yet

- Adp 2 Final Report (1) - 1Document58 pagesAdp 2 Final Report (1) - 1FAROOK FAKRUNo ratings yet

- Design of Reinforced Concrete Beam For Shear: By: Prof. Dr. Qaisar Ali Civil Engineering DepartmentDocument23 pagesDesign of Reinforced Concrete Beam For Shear: By: Prof. Dr. Qaisar Ali Civil Engineering DepartmentaqibNo ratings yet

- Flange Leakage Check: Equivalent Pressure / Kellogg MethodDocument3 pagesFlange Leakage Check: Equivalent Pressure / Kellogg Methodtom hNo ratings yet

- A Study On The Suitability of Local SteelDocument141 pagesA Study On The Suitability of Local SteelbiniamNo ratings yet

- Chapter Seven Bearing Devices and Girder Anchorages: 7.1 GeneralDocument11 pagesChapter Seven Bearing Devices and Girder Anchorages: 7.1 GeneralArup RoyNo ratings yet

- In Response To Projectile Movement: Critical Velocity of Electromagnetic Rail GunDocument22 pagesIn Response To Projectile Movement: Critical Velocity of Electromagnetic Rail GunTomáš GajdaNo ratings yet

- Cipl MJB 1+055.734 DGN 001Document206 pagesCipl MJB 1+055.734 DGN 001rao shoaibNo ratings yet

- Foundation Calculation SheetDocument44 pagesFoundation Calculation SheetAly ReyesNo ratings yet

- FootingDocument44 pagesFootingMd. Moshiur RahmanNo ratings yet

- Purlin DesignDocument10 pagesPurlin DesignjitendraNo ratings yet

- Yield Line TheoryDocument11 pagesYield Line Theoryshubham chikuNo ratings yet

- Mechanical Properties of Unsaturated Polyester ResinDocument5 pagesMechanical Properties of Unsaturated Polyester ResinNGokce100% (1)

- Advanced Structural Analysis Prof. Devdas Menon Department of Civil Engineering Indian Institute of Technology, MadrasDocument34 pagesAdvanced Structural Analysis Prof. Devdas Menon Department of Civil Engineering Indian Institute of Technology, MadrasGirish ReddyNo ratings yet