Professional Documents

Culture Documents

BR Oasys en 1117 - 0 PDF

BR Oasys en 1117 - 0 PDF

Uploaded by

thanhquang1001Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BR Oasys en 1117 - 0 PDF

BR Oasys en 1117 - 0 PDF

Uploaded by

thanhquang1001Copyright:

Available Formats

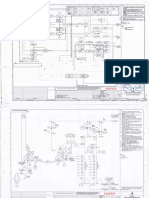

Operating principle Technical data

Model Outlet System Width Depth Height

flowrate (1) Conversion (mm) (mm) (mm)

Oasys 300A 300 l/hr 75% 1,600 (2) 1,225 1,800

Oasys 500A 500 l/hr 75% 1,600 (2) 1,225 1,800

Oasys 1000A 1,000 l/hr 75% 2,550 1,225 1,800

Oasys 1500A 1,500 l/hr 75% 2,550 1,225 1,800

Oasys 2000B 2,000 l/hr 75% 2,550 1,225 1,800

Oasys 3000B 3,000 l/hr 75% 2,900 1,670 2,200

Oasys 4000B 4,000 l/hr 75% 2,900 1,670 2,200

Oasys 5000B 5,000 l/hr 75% 2,900 1,670 2,200

Oasys 6000B 6,000 l/hr 75% 2,900 1,670 2,200

Oasys 8000B(3) 8,000 l/hr 75% 2,900 1,670 2,200

TM

(1)

Based on feed of 500 ppm TDS, 15o Celsius. Each system is designed on client exact requirements

(2)

Units can be delivered in larger frame to allow future flowrate increase.

(3)

Larger units are available on request

Purified Water Systems

Material specifications Feed water requirements

• Softened water tank Polyethylene • General potable water free from organics, colloids and

• Reverse osmosis FRP suspended matter: SDI<3

• CEDI LX FDA approved materials • Total hardness < 5 ppm as CaCO3

The pretreated (softened) water is passed throuh a filter housing (typically • Pipework 316 Stainless steel Dairy tube pre CEDI, outlet • Free chlorine < 0.05 ppm

5 µm) and analysed for free Chlorine prior to entering the RO feed tank. PRE-FILTER pipework 316L Stainless Steel, orbital welded, Internal • Iron < 0.1 ppm as Fe

The filtered water then enters the stainless storage tank, if the tank is full STORAGE TANK

surface finish <0.5 µm Ra • Temperature 10 – 30°C

the softened water is returned to the raw water tank to ensure constant • Frame 304 Stainless Steel • Pressure 2 - 6 bar.

SANITARY HIGH

movement to minimize the risk of bacterial proliferation. • Control cabinet 304 Stainless Steel.

PRESSURE PUMP

RO MEMBRANES Services: Electrical 380/415V; 3 Phase; 50Hz. Compressed Air Oil free, instrument grade >6 bar.

The softened water is then pumped at high pressure using a stainless steel

MEMBRANE DEGASSER

multistage centrifugal pump, through the RO membranes. The RO permeate

CEDI MODULE Typical product water quality

is then fed through a membrane degasser to remove dissolved Carbon

UV/UF UNIT Attribute Oasys US Pharmacopoeia PW European Pharmacopoeia

Dioxide, followed by a CEDI unit in order to remove ionic contaminants.

Conductivity (µS/cm) <0.1 <1.3 @ 25 C (Stage 1) PW=<4.3, HPW=<1.1 @ 20 C

TOC (ppb) <100 <500 <500

The purified water is then passed through an optional UV irradiator unit Bacteria (TVC CFU/ml) <10 <100(3) <100

before being fed to the storage vessel. Endotoxins (EU/ml) <0.05 (UF option) N/A HPW=<0.25 EU/ml

HPW = Highly Purified water; PW = Purified water; (3) FDA recommended action limit

Options

The Oasys is manufactured to suit client individual site requirements, Telstar Puretech work with our customers so that our

Control system system matches their needs, an example of standardization for the customers benefit.

The Oasys utilises the latest technology with touch Telstar-Puretech

screen HMI to allow ease of operation and monitoring. As a company who work to supply water purification solutions only within the Pharmaceutical Industry we offer comprehensive

support to customers including system design, project management, validation, installation, commissioning and on-site

The Oasys allows control and monitoring from a single maintenance. For further information contact your nearest sales office, details below.

interface with data logging facilities and links to user

BRAZIL

systems eg, BMS, DCS or SCADA. SPAIN

Headquarters Av. Ermano Marchetti, 1435

NORTH AMERICA

1504 Grundy's Lane

UNITED KINGDOM

Unit 4, Shaw Cross Business

Av. Font i Sagué, 55 Zandar 05038-001 Bristol PA 19007 Park, Horace Waller VC Parade,

Sao Paulo

The Oasys control system has the flexibility to operate 08227 Terrassa (Spain)

T +34 937 361 600 T+ 55 113 4612 1997

T +1 (215) 826 0770 Dewsbury, West Yorkshire

WF12 7RF

F +1 (215) 826 0222

complete turnkey packages allowing customers to F +34 937 861 380 FRANCE T +44 (0)1924 455 339

CHINA

reduce costs and simplify operation using a single Santibáñez de Béjar, 3

ZAC de la Clef de saint Pierre

5, rue du groupe Manouchian No. 30 Jin Wen Road,

F +44 (0)1924 452 295

access interface for pre-treatment, purification, storage 08042 Madrid 78990 Élancourt Zu Qiao Airport Industrial Park, JAPAN

Azbil Corporation

Pudong District

and distribution. T +34 913 717 790

F +34 913 717 791

T +33 (0)1 3013 1870

F +33 (0)1 3062 5477 201323 Shangai Tokyo Building,

T +86 21 58 093 731 2-7-3 Marunouchi, Chiyoda-ku,

INDIA

F +86 21 58 092 857 Tokyo 100-6419,

The Oasys control system ensures safe operation, MALAYSIA

17A & 17B

Office No. 312 & 313, 3r floor

BANGLADESH

T +81 3 6810 1000

Manjeera Majestic Commercial,

protecting the system and the operator, giving you Jalan PJS 1/32 KPHB, Suit No. B-4 (4th Floor) F +81 3 5220 7270

confidence and peace of mind. 46150 Petaling Jaya

T +66 111 271 3669

JNTU, Hi-Tech City Road, Anam Rangs Plaza

Plot No.61, Road No.6/A

PORTUGAL

Hyderabad - 500085 Estrada Consiglieri Pedroso, 71

T +914 042 410 172 Dhanmondi, Daka 1209

Edificio D-6º Esq

F +88 02 8192078

MEXICO 2730-055 Barcarena, Lisboa

Moliere #330-403 ITALY T +351 214 350 854

Via Girardi 27

ISO 9001: Certified Company

Col. Polanco Reforma F +351 214 350 089

CP 11540 20025 Legnano, Milano

BR-OASYS-EN-1117 Mexico, D.F. T +39 033 145 5241 marketing@telstar.com

Telstar Puretech reserves the right to improvements and specifications T +(52-55) 5282 2678 F+ 39 033 144 0752 www.telstar.com

changes without notice.

TM

Purified Water Systems Design & construction features Trusted technology, safely implemented

The Oasys Purified Water System is designed to generate Purified water

in accordance with the International Pharmacopoeial specifications

for Purified or Highly Purified water. The system has been designed

to allow chemical sanitisation of the complete unit including the

pipework feeding the Purified water into the storage vessel.

A choice of quality The Oasys unit utilizes the following major components within a fully

Telstar-Puretech introduce the Oasys, opening a new chapter protected skid so that the system can be kept clean and prevent any

in pure water delivery. Telstar-Puretech Oasys Purified injuries to operators during sanitisation.

water systems are designed and constructed to produce

Purified and Highly purified water in full compliance with

cGMP guidelines as per FDA and EMEA, EP, JP and USP Key components

requirements.

Softened water tank

Engineering and manufacturing practices follow ISO 9001 This polyethylene vessel is used as a reservoir for sanitisation and can

procedures, ASME BPE criteria, GAMP guidelines, etc. Design be used for the automatic CIP cycles.

and construction meets the most stringent Regulations and

Codes from Europe, USA and others concerning Safety and

Reverse osmosis

Pressure Vessels.

RO technology involves using a variable speed pressure pump to force

To ensure the equipment meets your requirements, we work a portion of the feed water through semi-permeable membranes. The

in partnership with you, a dedicated team follows your order permeate flow is kept constant, independent of variables such as the

as a unique project. We develop specific Quality Plans (DQ, feed water temperature.

IQ and OQ) and undertake factory acceptance testing (FAT)

to give assurance of performance and quality. Continuous electro deionisation

The water passing through the CEDI is deionised to Purified Water

using an electric current. The concentrate water exiting the CEDI unit

is reused and mixed with the RO feed water.

Purified & Highly purified Ultraviolet irradiation/ultrafiltration

The pure water exiting the CEDI passes to a UV unit or a 6,000 NMWL

water applications Ultrafilter to give added security in achieving the Purified and Highly

Purified water specifications.

Purified water is used as an excipient in the preparation of non-

sterile products and as a starting material in the preparation

of water for injection and pure steam. It’s also used for rinsing Unique selling points

purposes and in the preparation of cleaning solutions. Softened water tank Reverse osmosis Ultrafiltration Continuos electro deionisation

• Purified and Highly Purified water to USP, EP and JP

Highly Purified water is used in the preparation of medicinal • Semi Automatic chemical sanitisation

products where bacterial endotoxins need to be controlled, • Flexible outputs from 300 to 10,000 l/hr

except where water for injection is required. • Designed for simple upgrading of production rate

• Provides constant monitoring of RO status and gives warning of

requirement for cleaning

• Constructed from 316L stainless steel, orbitally welded, internal

surface finish 0.5 Ra. Designed to ASME BPE

• Choice of sophisticated control systems with inbuilt data logging

and paperless chart recorder

• GAMP and 21 CFR part 11 compliant

• Validation to regulatory and client standards

• Minimises waste water

• Remote access option to provide monitoring and control from

another location

TM

Purified Water Systems Design & construction features Trusted technology, safely implemented

The Oasys Purified Water System is designed to generate Purified water

in accordance with the International Pharmacopoeial specifications

for Purified or Highly Purified water. The system has been designed

to allow chemical sanitisation of the complete unit including the

pipework feeding the Purified water into the storage vessel.

A choice of quality The Oasys unit utilizes the following major components within a fully

Telstar-Puretech introduce the Oasys, opening a new chapter protected skid so that the system can be kept clean and prevent any

in pure water delivery. Telstar-Puretech Oasys Purified injuries to operators during sanitisation.

water systems are designed and constructed to produce

Purified and Highly purified water in full compliance with

cGMP guidelines as per FDA and EMEA, EP, JP and USP Key components

requirements.

Softened water tank

Engineering and manufacturing practices follow ISO 9001 This polyethylene vessel is used as a reservoir for sanitisation and can

procedures, ASME BPE criteria, GAMP guidelines, etc. Design be used for the automatic CIP cycles.

and construction meets the most stringent Regulations and

Codes from Europe, USA and others concerning Safety and

Reverse osmosis

Pressure Vessels.

RO technology involves using a variable speed pressure pump to force

To ensure the equipment meets your requirements, we work a portion of the feed water through semi-permeable membranes. The

in partnership with you, a dedicated team follows your order permeate flow is kept constant, independent of variables such as the

as a unique project. We develop specific Quality Plans (DQ, feed water temperature.

IQ and OQ) and undertake factory acceptance testing (FAT)

to give assurance of performance and quality. Continuous electro deionisation

The water passing through the CEDI is deionised to Purified Water

using an electric current. The concentrate water exiting the CEDI unit

is reused and mixed with the RO feed water.

Purified & Highly purified Ultraviolet irradiation/ultrafiltration

The pure water exiting the CEDI passes to a UV unit or a 6,000 NMWL

water applications Ultrafilter to give added security in achieving the Purified and Highly

Purified water specifications.

Purified water is used as an excipient in the preparation of non-

sterile products and as a starting material in the preparation

of water for injection and pure steam. It’s also used for rinsing Unique selling points

purposes and in the preparation of cleaning solutions. Softened water tank Reverse osmosis Ultrafiltration Continuos electro deionisation

• Purified and Highly Purified water to USP, EP and JP

Highly Purified water is used in the preparation of medicinal • Semi Automatic chemical sanitisation

products where bacterial endotoxins need to be controlled, • Flexible outputs from 300 to 10,000 l/hr

except where water for injection is required. • Designed for simple upgrading of production rate

• Provides constant monitoring of RO status and gives warning of

requirement for cleaning

• Constructed from 316L stainless steel, orbitally welded, internal

surface finish 0.5 Ra. Designed to ASME BPE

• Choice of sophisticated control systems with inbuilt data logging

and paperless chart recorder

• GAMP and 21 CFR part 11 compliant

• Validation to regulatory and client standards

• Minimises waste water

• Remote access option to provide monitoring and control from

another location

TM

Purified Water Systems Design & construction features Trusted technology, safely implemented

The Oasys Purified Water System is designed to generate Purified water

in accordance with the International Pharmacopoeial specifications

for Purified or Highly Purified water. The system has been designed

to allow chemical sanitisation of the complete unit including the

pipework feeding the Purified water into the storage vessel.

A choice of quality The Oasys unit utilizes the following major components within a fully

Telstar-Puretech introduce the Oasys, opening a new chapter protected skid so that the system can be kept clean and prevent any

in pure water delivery. Telstar-Puretech Oasys Purified injuries to operators during sanitisation.

water systems are designed and constructed to produce

Purified and Highly purified water in full compliance with

cGMP guidelines as per FDA and EMEA, EP, JP and USP Key components

requirements.

Softened water tank

Engineering and manufacturing practices follow ISO 9001 This polyethylene vessel is used as a reservoir for sanitisation and can

procedures, ASME BPE criteria, GAMP guidelines, etc. Design be used for the automatic CIP cycles.

and construction meets the most stringent Regulations and

Codes from Europe, USA and others concerning Safety and

Reverse osmosis

Pressure Vessels.

RO technology involves using a variable speed pressure pump to force

To ensure the equipment meets your requirements, we work a portion of the feed water through semi-permeable membranes. The

in partnership with you, a dedicated team follows your order permeate flow is kept constant, independent of variables such as the

as a unique project. We develop specific Quality Plans (DQ, feed water temperature.

IQ and OQ) and undertake factory acceptance testing (FAT)

to give assurance of performance and quality. Continuous electro deionisation

The water passing through the CEDI is deionised to Purified Water

using an electric current. The concentrate water exiting the CEDI unit

is reused and mixed with the RO feed water.

Purified & Highly purified Ultraviolet irradiation/ultrafiltration

The pure water exiting the CEDI passes to a UV unit or a 6,000 NMWL

water applications Ultrafilter to give added security in achieving the Purified and Highly

Purified water specifications.

Purified water is used as an excipient in the preparation of non-

sterile products and as a starting material in the preparation

of water for injection and pure steam. It’s also used for rinsing Unique selling points

purposes and in the preparation of cleaning solutions. Softened water tank Reverse osmosis Ultrafiltration Continuos electro deionisation

• Purified and Highly Purified water to USP, EP and JP

Highly Purified water is used in the preparation of medicinal • Semi Automatic chemical sanitisation

products where bacterial endotoxins need to be controlled, • Flexible outputs from 300 to 10,000 l/hr

except where water for injection is required. • Designed for simple upgrading of production rate

• Provides constant monitoring of RO status and gives warning of

requirement for cleaning

• Constructed from 316L stainless steel, orbitally welded, internal

surface finish 0.5 Ra. Designed to ASME BPE

• Choice of sophisticated control systems with inbuilt data logging

and paperless chart recorder

• GAMP and 21 CFR part 11 compliant

• Validation to regulatory and client standards

• Minimises waste water

• Remote access option to provide monitoring and control from

another location

Operating principle Technical data

Model Outlet System Width Depth Height

flowrate (1) Conversion (mm) (mm) (mm)

Oasys 300A 300 l/hr 75% 1,600 (2) 1,225 1,800

Oasys 500A 500 l/hr 75% 1,600 (2) 1,225 1,800

Oasys 1000A 1,000 l/hr 75% 2,550 1,225 1,800

Oasys 1500A 1,500 l/hr 75% 2,550 1,225 1,800

Oasys 2000B 2,000 l/hr 75% 2,550 1,225 1,800

Oasys 3000B 3,000 l/hr 75% 2,900 1,670 2,200

Oasys 4000B 4,000 l/hr 75% 2,900 1,670 2,200

Oasys 5000B 5,000 l/hr 75% 2,900 1,670 2,200

Oasys 6000B 6,000 l/hr 75% 2,900 1,670 2,200

Oasys 8000B(3) 8,000 l/hr 75% 2,900 1,670 2,200

TM

(1)

Based on feed of 500 ppm TDS, 15o Celsius. Each system is designed on client exact requirements

(2)

Units can be delivered in larger frame to allow future flowrate increase.

(3)

Larger units are available on request

Purified Water Systems

Material specifications Feed water requirements

• Softened water tank Polyethylene • General potable water free from organics, colloids and

• Reverse osmosis FRP suspended matter: SDI<3

• CEDI LX FDA approved materials • Total hardness < 5 ppm as CaCO3

The pretreated (softened) water is passed throuh a filter housing (typically • Pipework 316 Stainless steel Dairy tube pre CEDI, outlet • Free chlorine < 0.05 ppm

5 µm) and analysed for free Chlorine prior to entering the RO feed tank. PRE-FILTER pipework 316L Stainless Steel, orbital welded, Internal • Iron < 0.1 ppm as Fe

The filtered water then enters the stainless storage tank, if the tank is full STORAGE TANK

surface finish <0.5 µm Ra • Temperature 10 – 30°C

the softened water is returned to the raw water tank to ensure constant • Frame 304 Stainless Steel • Pressure 2 - 6 bar.

SANITARY HIGH

movement to minimize the risk of bacterial proliferation. • Control cabinet 304 Stainless Steel.

PRESSURE PUMP

RO MEMBRANES Services: Electrical 380/415V; 3 Phase; 50Hz. Compressed Air Oil free, instrument grade >6 bar.

The softened water is then pumped at high pressure using a stainless steel

MEMBRANE DEGASSER

multistage centrifugal pump, through the RO membranes. The RO permeate

CEDI MODULE Typical product water quality

is then fed through a membrane degasser to remove dissolved Carbon

UV/UF UNIT Attribute Oasys US Pharmacopoeia PW European Pharmacopoeia

Dioxide, followed by a CEDI unit in order to remove ionic contaminants.

Conductivity (µS/cm) <0.1 <1.3 @ 25 C (Stage 1) PW=<4.3, HPW=<1.1 @ 20 C

TOC (ppb) <100 <500 <500

The purified water is then passed through an optional UV irradiator unit Bacteria (TVC CFU/ml) <10 <100(3) <100

before being fed to the storage vessel. Endotoxins (EU/ml) <0.05 (UF option) N/A HPW=<0.25 EU/ml

HPW = Highly Purified water; PW = Purified water; (3) FDA recommended action limit

Options

The Oasys is manufactured to suit client individual site requirements, Telstar Puretech work with our customers so that our

Control system system matches their needs, an example of standardization for the customers benefit.

The Oasys utilises the latest technology with touch Telstar-Puretech

screen HMI to allow ease of operation and monitoring. As a company who work to supply water purification solutions only within the Pharmaceutical Industry we offer comprehensive

support to customers including system design, project management, validation, installation, commissioning and on-site

The Oasys allows control and monitoring from a single maintenance. For further information contact your nearest sales office, details below.

interface with data logging facilities and links to user

BRAZIL

systems eg, BMS, DCS or SCADA. SPAIN

Headquarters Av. Ermano Marchetti, 1435

NORTH AMERICA

1504 Grundy's Lane

UNITED KINGDOM

Unit 4, Shaw Cross Business

Av. Font i Sagué, 55 Zandar 05038-001 Bristol PA 19007 Park, Horace Waller VC Parade,

Sao Paulo

The Oasys control system has the flexibility to operate 08227 Terrassa (Spain)

T +34 937 361 600 T+ 55 113 4612 1997

T +1 (215) 826 0770 Dewsbury, West Yorkshire

WF12 7RF

F +1 (215) 826 0222

complete turnkey packages allowing customers to F +34 937 861 380 FRANCE T +44 (0)1924 455 339

CHINA

reduce costs and simplify operation using a single Santibáñez de Béjar, 3

ZAC de la Clef de saint Pierre

5, rue du groupe Manouchian No. 30 Jin Wen Road,

F +44 (0)1924 452 295

access interface for pre-treatment, purification, storage 08042 Madrid 78990 Élancourt Zu Qiao Airport Industrial Park, JAPAN

Azbil Corporation

Pudong District

and distribution. T +34 913 717 790

F +34 913 717 791

T +33 (0)1 3013 1870

F +33 (0)1 3062 5477 201323 Shangai Tokyo Building,

T +86 21 58 093 731 2-7-3 Marunouchi, Chiyoda-ku,

INDIA

F +86 21 58 092 857 Tokyo 100-6419,

The Oasys control system ensures safe operation, MALAYSIA

17A & 17B

Office No. 312 & 313, 3r floor

BANGLADESH

T +81 3 6810 1000

Manjeera Majestic Commercial,

protecting the system and the operator, giving you Jalan PJS 1/32 KPHB, Suit No. B-4 (4th Floor) F +81 3 5220 7270

confidence and peace of mind. 46150 Petaling Jaya

T +66 111 271 3669

JNTU, Hi-Tech City Road, Anam Rangs Plaza

Plot No.61, Road No.6/A

PORTUGAL

Hyderabad - 500085 Estrada Consiglieri Pedroso, 71

T +914 042 410 172 Dhanmondi, Daka 1209

Edificio D-6º Esq

F +88 02 8192078

MEXICO 2730-055 Barcarena, Lisboa

Moliere #330-403 ITALY T +351 214 350 854

Via Girardi 27

ISO 9001: Certified Company

Col. Polanco Reforma F +351 214 350 089

CP 11540 20025 Legnano, Milano

BR-OASYS-EN-1117 Mexico, D.F. T +39 033 145 5241 marketing@telstar.com

Telstar Puretech reserves the right to improvements and specifications T +(52-55) 5282 2678 F+ 39 033 144 0752 www.telstar.com

changes without notice.

Operating principle Technical data

Model Outlet System Width Depth Height

flowrate (1) Conversion (mm) (mm) (mm)

Oasys 300A 300 l/hr 75% 1,600 (2) 1,225 1,800

Oasys 500A 500 l/hr 75% 1,600 (2) 1,225 1,800

Oasys 1000A 1,000 l/hr 75% 2,550 1,225 1,800

Oasys 1500A 1,500 l/hr 75% 2,550 1,225 1,800

Oasys 2000B 2,000 l/hr 75% 2,550 1,225 1,800

Oasys 3000B 3,000 l/hr 75% 2,900 1,670 2,200

Oasys 4000B 4,000 l/hr 75% 2,900 1,670 2,200

Oasys 5000B 5,000 l/hr 75% 2,900 1,670 2,200

Oasys 6000B 6,000 l/hr 75% 2,900 1,670 2,200

Oasys 8000B(3) 8,000 l/hr 75% 2,900 1,670 2,200

TM

(1)

Based on feed of 500 ppm TDS, 15o Celsius. Each system is designed on client exact requirements

(2)

Units can be delivered in larger frame to allow future flowrate increase.

(3)

Larger units are available on request

Purified Water Systems

Material specifications Feed water requirements

• Softened water tank Polyethylene • General potable water free from organics, colloids and

• Reverse osmosis FRP suspended matter: SDI<3

• CEDI LX FDA approved materials • Total hardness < 5 ppm as CaCO3

The pretreated (softened) water is passed throuh a filter housing (typically • Pipework 316 Stainless steel Dairy tube pre CEDI, outlet • Free chlorine < 0.05 ppm

5 µm) and analysed for free Chlorine prior to entering the RO feed tank. PRE-FILTER pipework 316L Stainless Steel, orbital welded, Internal • Iron < 0.1 ppm as Fe

The filtered water then enters the stainless storage tank, if the tank is full STORAGE TANK

surface finish <0.5 µm Ra • Temperature 10 – 30°C

the softened water is returned to the raw water tank to ensure constant • Frame 304 Stainless Steel • Pressure 2 - 6 bar.

SANITARY HIGH

movement to minimize the risk of bacterial proliferation. • Control cabinet 304 Stainless Steel.

PRESSURE PUMP

RO MEMBRANES Services: Electrical 380/415V; 3 Phase; 50Hz. Compressed Air Oil free, instrument grade >6 bar.

The softened water is then pumped at high pressure using a stainless steel

MEMBRANE DEGASSER

multistage centrifugal pump, through the RO membranes. The RO permeate

CEDI MODULE Typical product water quality

is then fed through a membrane degasser to remove dissolved Carbon

UV/UF UNIT Attribute Oasys US Pharmacopoeia PW European Pharmacopoeia

Dioxide, followed by a CEDI unit in order to remove ionic contaminants.

Conductivity (µS/cm) <0.1 <1.3 @ 25 C (Stage 1) PW=<4.3, HPW=<1.1 @ 20 C

TOC (ppb) <100 <500 <500

The purified water is then passed through an optional UV irradiator unit Bacteria (TVC CFU/ml) <10 <100(3) <100

before being fed to the storage vessel. Endotoxins (EU/ml) <0.05 (UF option) N/A HPW=<0.25 EU/ml

HPW = Highly Purified water; PW = Purified water; (3) FDA recommended action limit

Options

The Oasys is manufactured to suit client individual site requirements, Telstar Puretech work with our customers so that our

Control system system matches their needs, an example of standardization for the customers benefit.

The Oasys utilises the latest technology with touch Telstar-Puretech

screen HMI to allow ease of operation and monitoring. As a company who work to supply water purification solutions only within the Pharmaceutical Industry we offer comprehensive

support to customers including system design, project management, validation, installation, commissioning and on-site

The Oasys allows control and monitoring from a single maintenance. For further information contact your nearest sales office, details below.

interface with data logging facilities and links to user

BRAZIL

systems eg, BMS, DCS or SCADA. SPAIN

Headquarters Av. Ermano Marchetti, 1435

NORTH AMERICA

1504 Grundy's Lane

UNITED KINGDOM

Unit 4, Shaw Cross Business

Av. Font i Sagué, 55 Zandar 05038-001 Bristol PA 19007 Park, Horace Waller VC Parade,

Sao Paulo

The Oasys control system has the flexibility to operate 08227 Terrassa (Spain)

T +34 937 361 600 T+ 55 113 4612 1997

T +1 (215) 826 0770 Dewsbury, West Yorkshire

WF12 7RF

F +1 (215) 826 0222

complete turnkey packages allowing customers to F +34 937 861 380 FRANCE T +44 (0)1924 455 339

CHINA

reduce costs and simplify operation using a single Santibáñez de Béjar, 3

ZAC de la Clef de saint Pierre

5, rue du groupe Manouchian No. 30 Jin Wen Road,

F +44 (0)1924 452 295

access interface for pre-treatment, purification, storage 08042 Madrid 78990 Élancourt Zu Qiao Airport Industrial Park, JAPAN

Azbil Corporation

Pudong District

and distribution. T +34 913 717 790

F +34 913 717 791

T +33 (0)1 3013 1870

F +33 (0)1 3062 5477 201323 Shangai Tokyo Building,

T +86 21 58 093 731 2-7-3 Marunouchi, Chiyoda-ku,

INDIA

F +86 21 58 092 857 Tokyo 100-6419,

The Oasys control system ensures safe operation, MALAYSIA

17A & 17B

Office No. 312 & 313, 3r floor

BANGLADESH

T +81 3 6810 1000

Manjeera Majestic Commercial,

protecting the system and the operator, giving you Jalan PJS 1/32 KPHB, Suit No. B-4 (4th Floor) F +81 3 5220 7270

confidence and peace of mind. 46150 Petaling Jaya

T +66 111 271 3669

JNTU, Hi-Tech City Road, Anam Rangs Plaza

Plot No.61, Road No.6/A

PORTUGAL

Hyderabad - 500085 Estrada Consiglieri Pedroso, 71

T +914 042 410 172 Dhanmondi, Daka 1209

Edificio D-6º Esq

F +88 02 8192078

MEXICO 2730-055 Barcarena, Lisboa

Moliere #330-403 ITALY T +351 214 350 854

Via Girardi 27

ISO 9001: Certified Company

Col. Polanco Reforma F +351 214 350 089

CP 11540 20025 Legnano, Milano

BR-OASYS-EN-1117 Mexico, D.F. T +39 033 145 5241 marketing@telstar.com

Telstar Puretech reserves the right to improvements and specifications T +(52-55) 5282 2678 F+ 39 033 144 0752 www.telstar.com

changes without notice.

You might also like

- The Rain For KidsDocument27 pagesThe Rain For KidsValen Valibia100% (1)

- Distribution of Water On EarthDocument25 pagesDistribution of Water On EarthGogîia Alexandru DenisNo ratings yet

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Swimming Pool Check ListDocument4 pagesSwimming Pool Check ListVISWANATH AHIR0% (1)

- Bauer Compressors Spare Part List 2017 PDFDocument192 pagesBauer Compressors Spare Part List 2017 PDFCosta AmanatidisNo ratings yet

- Mass Transfer PartDocument36 pagesMass Transfer Partoctoviancletus90% (67)

- Ambatale Treatment PlantDocument5 pagesAmbatale Treatment PlantRisath Azeez75% (4)

- Tetra Pak Homogenizer 300: Homogenizer or High Pressure Pump For Liquid Food ApplicationsDocument2 pagesTetra Pak Homogenizer 300: Homogenizer or High Pressure Pump For Liquid Food ApplicationsFátima RomeroNo ratings yet

- AHRI Standard 230-2013 PDFDocument13 pagesAHRI Standard 230-2013 PDFthanhquang1001No ratings yet

- Witte - Liquid-Gas Ejektor Design PDFDocument114 pagesWitte - Liquid-Gas Ejektor Design PDFOssian89No ratings yet

- How Reverse Osmosis Works: A Look at Industrial ROFrom EverandHow Reverse Osmosis Works: A Look at Industrial RORating: 2.5 out of 5 stars2.5/5 (2)

- The AtmosphereDocument7 pagesThe AtmospherewynnthomasNo ratings yet

- Akshaya Enterprises: Office Address: Door Mail Id: Mb.9390113339,9951923339Document6 pagesAkshaya Enterprises: Office Address: Door Mail Id: Mb.9390113339,9951923339Praveen Rs SNo ratings yet

- Sizing Medical Gas PipingDocument6 pagesSizing Medical Gas PipingYoke Shu100% (1)

- Attachment 05 - BFD, ELD and P&I Diagrams-PearlDocument77 pagesAttachment 05 - BFD, ELD and P&I Diagrams-Pearlum er100% (1)

- Lighthouse ISO 14644-1 Whats New PDFDocument21 pagesLighthouse ISO 14644-1 Whats New PDFmaikaNo ratings yet

- Pharmceutical Production WaterDocument16 pagesPharmceutical Production Waterthanhquang10010% (1)

- 2000 LPH Ro PlantDocument17 pages2000 LPH Ro PlantKamatchi NathanNo ratings yet

- Ufbw-2202063 TD & CD Shamara 1Document21 pagesUfbw-2202063 TD & CD Shamara 1ali mohammedNo ratings yet

- Ecolutia - Proteus Fact Sheet PDFDocument2 pagesEcolutia - Proteus Fact Sheet PDFJoselito CortesNo ratings yet

- Midiro ™: Reverse Osmosis SystemsDocument2 pagesMidiro ™: Reverse Osmosis SystemsEta TrutaNo ratings yet

- Ionpro LXDocument2 pagesIonpro LXAlon CarlosNo ratings yet

- 760-0006 Miox 300-1200Document2 pages760-0006 Miox 300-1200namNo ratings yet

- Saset Catalogue-1Document12 pagesSaset Catalogue-1Kinuthia Mathew100% (1)

- MKT Mun PolarisMED Brochure LR Draft v08Document6 pagesMKT Mun PolarisMED Brochure LR Draft v08Wagner LimaNo ratings yet

- Dialyser Filter-Meditechsys RevaclearDocument4 pagesDialyser Filter-Meditechsys Revaclearhojjat ghaznaviNo ratings yet

- SBR Systems 2Document2 pagesSBR Systems 2cornerhome369No ratings yet

- Polyflux R Dialyzers Spec SheetDocument2 pagesPolyflux R Dialyzers Spec SheetShshank87100% (1)

- Uv Open ChannelDocument2 pagesUv Open ChannelChillie HuNo ratings yet

- PBP Operation TrainingDocument24 pagesPBP Operation TrainingWqyou Sanha PrabuNo ratings yet

- 700 Series Portable: Reverse Osmosis System 650 To 2600 Ml/minDocument2 pages700 Series Portable: Reverse Osmosis System 650 To 2600 Ml/mineduardoNo ratings yet

- Technical Paper Aruba Conference EWP X3Document13 pagesTechnical Paper Aruba Conference EWP X3buildmetNo ratings yet

- 250 LPH Ro Plant - Techfilt (Standard Model) : Basic DetailsDocument4 pages250 LPH Ro Plant - Techfilt (Standard Model) : Basic DetailsKamatchi NathanNo ratings yet

- Design Advantages For SWRO Using Advanced Membrane TechnologyDocument12 pagesDesign Advantages For SWRO Using Advanced Membrane TechnologyJestin RajNo ratings yet

- Water System (OSR ECO) PDFDocument1 pageWater System (OSR ECO) PDFirfan hussainNo ratings yet

- 2019 Adrona - Crystal EXDocument3 pages2019 Adrona - Crystal EXDusan MaksimovicNo ratings yet

- FS1622ENDocument2 pagesFS1622ENquimica 2117No ratings yet

- Design of 750 MW Combined Cycle Power Plant: Water LoopDocument19 pagesDesign of 750 MW Combined Cycle Power Plant: Water LoopAdrian BundalianNo ratings yet

- Aerators Data SheetDocument2 pagesAerators Data SheetRafael CarmoNo ratings yet

- PK1024-MKF-MDB060-365097 01Document9 pagesPK1024-MKF-MDB060-365097 01waqas_a_shaikh4348No ratings yet

- Simplifying Water: Reverse OsmosisDocument3 pagesSimplifying Water: Reverse Osmosisdurgesh008No ratings yet

- Duplex SoftenersDocument2 pagesDuplex Softenersanwer tahaNo ratings yet

- BBT BBT D TwoStageRadiallySplit E00585Document6 pagesBBT BBT D TwoStageRadiallySplit E00585ana lucia VarasNo ratings yet

- Goulds 3355 BulletinDocument7 pagesGoulds 3355 BulletinJOSE INES100% (1)

- Fistreem Cyclon Water Still - 2011Document4 pagesFistreem Cyclon Water Still - 2011Anonymous cSS3RXQ3aVNo ratings yet

- Ocean Whisper - Technical SpecificationsDocument8 pagesOcean Whisper - Technical SpecificationsAtanasio PerezNo ratings yet

- Sulzer OHH OHHL FeaturesDocument6 pagesSulzer OHH OHHL FeaturesScott TorgussonNo ratings yet

- Clearwater Tech, LLC: Microzone SeriesDocument2 pagesClearwater Tech, LLC: Microzone SeriesStaman1988No ratings yet

- Proteus RO Type Fresh Water Generators: Seawater Desalination SystemsDocument2 pagesProteus RO Type Fresh Water Generators: Seawater Desalination SystemsFDNo ratings yet

- ReNEW Series Fact SheetDocument4 pagesReNEW Series Fact Sheetjpsingh75No ratings yet

- Jacobi Ab Resinex Softening A4 Eng A0613Document2 pagesJacobi Ab Resinex Softening A4 Eng A0613Dzulkifli MuhamadNo ratings yet

- CS1310ENDocument2 pagesCS1310ENMohammedNo ratings yet

- Curie Reduction of Liquid Effluent at Nuclear Power Plants: Presented by Tim CarrawayDocument41 pagesCurie Reduction of Liquid Effluent at Nuclear Power Plants: Presented by Tim Carrawaymanojrawat21No ratings yet

- Manual Boiler Feed IND 18 PDFDocument1 pageManual Boiler Feed IND 18 PDFHicham IdrisiNo ratings yet

- Bluebasic Adblue Production machine-EBR1500B 20ft Container Type 219030 CHINADocument7 pagesBluebasic Adblue Production machine-EBR1500B 20ft Container Type 219030 CHINAAram AseerNo ratings yet

- MP-Filtri Catalogue ProtectedDocument48 pagesMP-Filtri Catalogue Protectedvut73 aNo ratings yet

- 65L, 95L, 120L, 160L, 250L, 320L: 6" Stainless Steel Submersible PumpsDocument9 pages65L, 95L, 120L, 160L, 250L, 320L: 6" Stainless Steel Submersible PumpsTimothy Joshua GatchalianNo ratings yet

- Conferencista Magistral Larry EoffDocument28 pagesConferencista Magistral Larry Eoffjose angel luna trinidadNo ratings yet

- Ecomix GBDocument16 pagesEcomix GBvinod patilNo ratings yet

- Ceplfreeztech Urbox CatalogueDocument6 pagesCeplfreeztech Urbox CatalogueAndy KrishnanNo ratings yet

- R.O. Watermaker - 200,000 Liters/Day: Leader in Reverse Osmosis TechnologyDocument1 pageR.O. Watermaker - 200,000 Liters/Day: Leader in Reverse Osmosis TechnologyHerik AziziNo ratings yet

- Hydrogen Generators: Hydrogen On Demand Up To 1,300 Ml/minDocument2 pagesHydrogen Generators: Hydrogen On Demand Up To 1,300 Ml/minAnish KarthikeyanNo ratings yet

- MSD Axially Split Multistage Pump E00577Document6 pagesMSD Axially Split Multistage Pump E00577chijioke ekekeNo ratings yet

- About Reverse Osmosis What Is Reverse OsmosisDocument4 pagesAbout Reverse Osmosis What Is Reverse OsmosismateenNo ratings yet

- Data Sheet - Pharmed® BPT Biocompatible Peristaltic Pump Tubing PDFDocument3 pagesData Sheet - Pharmed® BPT Biocompatible Peristaltic Pump Tubing PDFildarNo ratings yet

- 75 KLD MBBR STP Offer For Residential SocietyDocument11 pages75 KLD MBBR STP Offer For Residential SocietyrepublicfoodsindiaNo ratings yet

- Mobilecip System: Aws Bio-Pharma TechnologiesDocument2 pagesMobilecip System: Aws Bio-Pharma Technologiesخبراء التصنيع الدوائي-اليمنNo ratings yet

- Lopressurero System (L.P.R.O.) : Culligan Commercial Reverse Osmosis Water SystemsDocument5 pagesLopressurero System (L.P.R.O.) : Culligan Commercial Reverse Osmosis Water SystemsIyad AlemNo ratings yet

- Optimum Brochure 1Document2 pagesOptimum Brochure 1Ahmed Al-OsoulyNo ratings yet

- DataSheet AriaDocument3 pagesDataSheet AriaRendraNo ratings yet

- 2020 - Cat - Water Still - Purification Systems - Eng PDFDocument16 pages2020 - Cat - Water Still - Purification Systems - Eng PDFRakibul HasanNo ratings yet

- Equipment Sizing Worksheet: Water Treatment Systems From SterisDocument2 pagesEquipment Sizing Worksheet: Water Treatment Systems From SterisAfraz ShaikhNo ratings yet

- Western States-Tomoe - High-Speed Tubular Centrifuge - Pages 1-4Document4 pagesWestern States-Tomoe - High-Speed Tubular Centrifuge - Pages 1-4gaby2003No ratings yet

- BR Etosterilization en 1117 2Document6 pagesBR Etosterilization en 1117 2thanhquang1001No ratings yet

- Sound Intensity Testing Procedures For Determining Sound Power of HVAC EquipmentDocument13 pagesSound Intensity Testing Procedures For Determining Sound Power of HVAC Equipmentthanhquang1001No ratings yet

- Public Review Draft 2066Document7 pagesPublic Review Draft 2066thanhquang1001No ratings yet

- Rath Sanitary Tube Uid182010340122 PDFDocument2 pagesRath Sanitary Tube Uid182010340122 PDFthanhquang1001No ratings yet

- How To Select A Particle CounterDocument2 pagesHow To Select A Particle Counterthanhquang1001No ratings yet

- Calc Air Tanks 2Document1 pageCalc Air Tanks 2thanhquang1001No ratings yet

- Lab Report 4Document9 pagesLab Report 4zulaika fahmiNo ratings yet

- Rain DescriptionDocument3 pagesRain DescriptionAnonymous WGtE7JNo ratings yet

- Enright 006941966Document429 pagesEnright 006941966fajar sulistyoNo ratings yet

- Vol 05.Baras-SBDocument11 pagesVol 05.Baras-SBMark MartinezNo ratings yet

- Cryogenic Air SeparationDocument8 pagesCryogenic Air Separationkishna009No ratings yet

- Adsorbents Solutions For Compressed Air DryingDocument5 pagesAdsorbents Solutions For Compressed Air Dryingpmfg847633No ratings yet

- WSP Training Pack Mod2Document11 pagesWSP Training Pack Mod2Hanzla UsmanNo ratings yet

- Condensate PotsDocument2 pagesCondensate PotsBOUAOUDIANo ratings yet

- Water Supply Engineering ProjectDocument18 pagesWater Supply Engineering Projectnikita kaliyerNo ratings yet

- FL ModelDocument1 pageFL ModelmanhngoducNo ratings yet

- Lab 6 (Protection)Document2 pagesLab 6 (Protection)mudassir ahmadNo ratings yet

- BetaQua UFDocument2 pagesBetaQua UFbuattugasmetlitNo ratings yet

- PDFDocument565 pagesPDFOki NurpatriaNo ratings yet

- Gas Behavior and SeparationDocument58 pagesGas Behavior and SeparationAhmed Sabry El-sotohyNo ratings yet

- Enviormental Studies Microproject1Document22 pagesEnviormental Studies Microproject1jaya bhutekarNo ratings yet

- Activated Alumina F2000 Data SheetDocument2 pagesActivated Alumina F2000 Data SheetAmir RahbariNo ratings yet

- LNG & PT PGN LNG: Fatahillah Syach I Putu Gede Adhi DarsanaDocument8 pagesLNG & PT PGN LNG: Fatahillah Syach I Putu Gede Adhi DarsanaI Putu Gede Adhi DarsanaNo ratings yet

- Water Quality Index For Assessment of Water Quality of Duhok Lake, Kurdistan Region of IraqDocument6 pagesWater Quality Index For Assessment of Water Quality of Duhok Lake, Kurdistan Region of IraqKanhiya MahourNo ratings yet

- Pamantasan NG Lungsod NG ValenzuelaDocument2 pagesPamantasan NG Lungsod NG ValenzuelaDiane de OcampoNo ratings yet

- Auroras Grade5Document3 pagesAuroras Grade5Oğuzhan OlgunNo ratings yet