Professional Documents

Culture Documents

32-06 Lead in - Lead Out PDF

Uploaded by

David BumbaloughOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

32-06 Lead in - Lead Out PDF

Uploaded by

David BumbaloughCopyright:

Available Formats

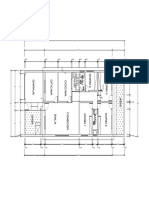

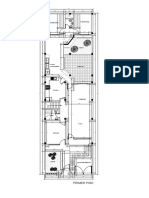

32-06 Lead In - Lead Out

Peripheral milling is also known as contour milling. For various reasons, such as surface finish quality, cutter ra-

dius offset application and work clearances, the cutting tool (usually an end mill) cannot start directly on the con-

tour, but must start away from it. The motion from this initial position to the contour itself is called a lead-in mo-

tion. The same method applies when the tool leaves the contour, in a lead-out motion.

This programming project requires a CNC program that will rough out and finish three slots and one spigot. Use

a Æ3/8 end mill on aluminum, and program the roughing and finishing contours with lead-in and lead-out motions.

R0.2 R0.1875

3.0

2.625

2.0

R0.22

1.0

R0.25

0.375

0.0

0.1

4.0

0.0

0.0

0.5

3.5

0.5

2.3925

2.8925

2.25

0.15

ALUMINUM

USE Ø3/8 CENTER CUTTING END MILL

& Reference: Chapter 32 Peripheral Milling

Chapter 33 Slots and Pockets

Peter Smid CNC Programming Handbook 32-06 [ 1 ]

You might also like

- Tortort Manufacturing 80% Milled Receivers AK47Document6 pagesTortort Manufacturing 80% Milled Receivers AK47David BumbaloughNo ratings yet

- GD&T IntroductionDocument147 pagesGD&T IntroductionPrithviraj Daga100% (6)

- Design of Source Degenerated Cascode Dual FunctionDocument25 pagesDesign of Source Degenerated Cascode Dual Functionmaia.df11No ratings yet

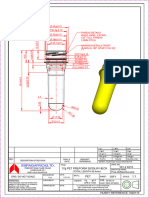

- Pattern of 10 Holes: 10X Ø1/4 DRILL 4.0 0.5Document1 pagePattern of 10 Holes: 10X Ø1/4 DRILL 4.0 0.5David BumbaloughNo ratings yet

- 實驗五數據Document4 pages實驗五數據林家新No ratings yet

- Limits Fits TolerancesDocument77 pagesLimits Fits Tolerancessunil_gundNo ratings yet

- EE391 Senior Project - Finalized 4 (97-03)Document25 pagesEE391 Senior Project - Finalized 4 (97-03)higherclawsNo ratings yet

- PC 17K4Document4 pagesPC 17K4Angga JuliantaraNo ratings yet

- Datasheet PC-17K1 OPTOCOUPLERDocument3 pagesDatasheet PC-17K1 OPTOCOUPLERvanmarteNo ratings yet

- AA TN-202 CollateralDataDocument2 pagesAA TN-202 CollateralDataIan RidzuanNo ratings yet

- 30-05 Cutter Radius Offset - Part 1Document1 page30-05 Cutter Radius Offset - Part 1David BumbaloughNo ratings yet

- Take Home ExamDocument2 pagesTake Home ExamOscar Alam GuzmánNo ratings yet

- E Cores and Accessories E42/21/15: General Data For 10-Pins E42/21/15 Coil Former Parameter SpecificationDocument1 pageE Cores and Accessories E42/21/15: General Data For 10-Pins E42/21/15 Coil Former Parameter SpecificationAngamuthu AnanthNo ratings yet

- Structural Drawings-S C 002Document1 pageStructural Drawings-S C 002Bakir JaberNo ratings yet

- Trubka Ocel ST 37 4 Bezesva Cerna Uk Katalogovy ListDocument2 pagesTrubka Ocel ST 37 4 Bezesva Cerna Uk Katalogovy ListVratislav Němec ml.No ratings yet

- Datasheet k104Document3 pagesDatasheet k104Luigi PortugalNo ratings yet

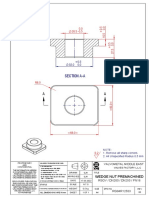

- RG04R12503 - Wedge Nut Premachined - RSGV - DN 250 - PN 16 Rev 00Document1 pageRG04R12503 - Wedge Nut Premachined - RSGV - DN 250 - PN 16 Rev 00Aakash KumarNo ratings yet

- Chart Title: 0.35 0.4 F (X) 0.686x + 0.0048 R 0.9991592214 AbsDocument2 pagesChart Title: 0.35 0.4 F (X) 0.686x + 0.0048 R 0.9991592214 AbsAnonymous xGICX3YNo ratings yet

- Analitik 1Document2 pagesAnalitik 1Anonymous xGICX3YNo ratings yet

- BRUSH and BRUSH-HOLDER TOLERANCES On T and A DIMENSIONS - Carbone Lorraine - INGDocument2 pagesBRUSH and BRUSH-HOLDER TOLERANCES On T and A DIMENSIONS - Carbone Lorraine - INGClaylson Figueiredo JúlioNo ratings yet

- 2023-12 - 02 18-62-24-36 Shift Rail (YA-E) ตัวเก่าDocument1 page2023-12 - 02 18-62-24-36 Shift Rail (YA-E) ตัวเก่าWarajak N.No ratings yet

- Calculation of Hvap From Experimented DataDocument2 pagesCalculation of Hvap From Experimented DataDozdiNo ratings yet

- Curves 17H SeriesDocument2 pagesCurves 17H SeriesJulio ConfortoNo ratings yet

- Planta ByNDocument1 pagePlanta ByNJose Mauricio Lopez GarciaNo ratings yet

- 30-06 Cutter Radius Offset - Part 2Document1 page30-06 Cutter Radius Offset - Part 2David BumbaloughNo ratings yet

- RL RL RL: 2.5 L Ajuste Lineal 2L Linear (2L) 3L Linear (3L)Document6 pagesRL RL RL: 2.5 L Ajuste Lineal 2L Linear (2L) 3L Linear (3L)Wiler MoranNo ratings yet

- E4fac 17gDocument1 pageE4fac 17gmrityunjaysatapatiNo ratings yet

- DSASL0056537Document1 pageDSASL0056537Jose ReyesNo ratings yet

- Single: Seri H Q H QDocument2 pagesSingle: Seri H Q H QHadi NurhidayatNo ratings yet

- SLD 02 Plate 430Document1 pageSLD 02 Plate 430Stefan MilojevicNo ratings yet

- P Culvert Plan - ModelDocument1 pageP Culvert Plan - ModelAlie JallohNo ratings yet

- 1 y 2 NivelDocument1 page1 y 2 Nivelrodrigo isidro trebejoNo ratings yet

- Timers On DelayDocument5 pagesTimers On DelayOJ ACNo ratings yet

- AN6650, AN6650S: Motor Control CircuitsDocument3 pagesAN6650, AN6650S: Motor Control CircuitsJohn Jaque CaleNo ratings yet

- Casa Negro CarrDocument1 pageCasa Negro Carrjosevc317No ratings yet

- Abaque CH1 40Document1 pageAbaque CH1 40shoshaNo ratings yet

- Effective Width CalculationDocument2 pagesEffective Width CalculationtosifsayyedNo ratings yet

- PC 17L1Document4 pagesPC 17L1HenryAmayaLarrealNo ratings yet

- 59710Document1 page59710nguyenanhquocdhdiNo ratings yet

- ADK Kelompok 9Document13 pagesADK Kelompok 9Milani AyutamiaNo ratings yet

- Accuspiral: Worm Shaft 20 12 0201 34Document1 pageAccuspiral: Worm Shaft 20 12 0201 34SherinNo ratings yet

- CV Vs Nre Co Vs Nre: Axis TitleDocument3 pagesCV Vs Nre Co Vs Nre: Axis TitleCrezpo YzNo ratings yet

- Plano Casa OkDocument5 pagesPlano Casa OkJymmitho M BulloniNo ratings yet

- Ansox Industry: XXX S.S. Jadhav A4 013 8250 00 XDocument1 pageAnsox Industry: XXX S.S. Jadhav A4 013 8250 00 XHimanshu MishraNo ratings yet

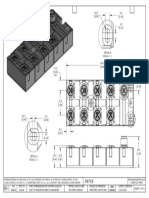

- 59719Document1 page59719nguyenanhquocdhdiNo ratings yet

- BP Vs BTH Eff: BTE BP Diesel B10 B20 B30Document6 pagesBP Vs BTH Eff: BTE BP Diesel B10 B20 B30Babu JonnalagaddaNo ratings yet

- Banvechitiet trucIIDocument1 pageBanvechitiet trucIILe HuynhNo ratings yet

- Proyecto 18 de Abril 2023-ModelDocument1 pageProyecto 18 de Abril 2023-ModelWily CuevaNo ratings yet

- RC Mprotator emDocument2 pagesRC Mprotator emiliecNo ratings yet

- HW1 STRDocument1 pageHW1 STRosaidsrourNo ratings yet

- Brush and Brush-Holder Tolerances On "T" and "A" Dimensions: Technical Note Sta Be 16-4 GBDocument2 pagesBrush and Brush-Holder Tolerances On "T" and "A" Dimensions: Technical Note Sta Be 16-4 GBloulou_beNo ratings yet

- Part1 1Document1 pagePart1 1Nguyên TúNo ratings yet

- SCR T8 Weatherproof Series: Your Partner in Lighting TechnologyDocument2 pagesSCR T8 Weatherproof Series: Your Partner in Lighting Technologygenius solutionNo ratings yet

- Validation of Fps Wizard Horizontal Lifeline CalculatorDocument1 pageValidation of Fps Wizard Horizontal Lifeline CalculatorperundingtsteohgmailcomNo ratings yet

- Inverter - Anodizing DC Bus Capacitors - v1-1 - ENDocument4 pagesInverter - Anodizing DC Bus Capacitors - v1-1 - ENВиталий ПокотиленкоNo ratings yet

- 51gm PreformDocument1 page51gm PreformmrityunjaysatapatiNo ratings yet

- MVCHB015Document1 pageMVCHB015api-3707540No ratings yet

- 1f RCPDocument1 page1f RCPStephen EvangelistaNo ratings yet

- Successful Service Design for Telecommunications: A comprehensive guide to design and implementationFrom EverandSuccessful Service Design for Telecommunications: A comprehensive guide to design and implementationNo ratings yet

- This Little Weed Is One of The Most Useful Medicines On The PlanetDocument6 pagesThis Little Weed Is One of The Most Useful Medicines On The PlanetDavid BumbaloughNo ratings yet

- The Complete Guide To Growing Corn in Containers - Garden and HappyDocument17 pagesThe Complete Guide To Growing Corn in Containers - Garden and HappyDavid BumbaloughNo ratings yet

- Tomato Fertilizer - How To Feed Your Plants For The Ultimate HarvestDocument11 pagesTomato Fertilizer - How To Feed Your Plants For The Ultimate HarvestDavid BumbaloughNo ratings yet

- How To Become Untrackable - Part 1 - SurvivopediaDocument12 pagesHow To Become Untrackable - Part 1 - SurvivopediaDavid Bumbalough100% (1)

- 12 Plants You'Ll Want in Your SHTF Garden - SurvivopediaDocument21 pages12 Plants You'Ll Want in Your SHTF Garden - SurvivopediaDavid BumbaloughNo ratings yet

- Gun Control and The Founding Fathers Intent - The - Truth - and - JusticeDocument9 pagesGun Control and The Founding Fathers Intent - The - Truth - and - JusticeDavid BumbaloughNo ratings yet

- Exercises After Abdominal SurgeryDocument5 pagesExercises After Abdominal SurgeryDavid BumbaloughNo ratings yet

- Scaling Function Q+A: # Answer 1Document2 pagesScaling Function Q+A: # Answer 1David BumbaloughNo ratings yet

- Providers - PrivacytoolsDocument7 pagesProviders - PrivacytoolsDavid BumbaloughNo ratings yet

- Feedrate Q+A: # Answer 1Document2 pagesFeedrate Q+A: # Answer 1David BumbaloughNo ratings yet

- 15-01 Reference Points - MillDocument1 page15-01 Reference Points - MillDavid BumbaloughNo ratings yet

- HK94, MP5, Parts KitsDocument6 pagesHK94, MP5, Parts KitsDavid BumbaloughNo ratings yet

- Scaling Exercise: Use T01 Ø20 End MillDocument1 pageScaling Exercise: Use T01 Ø20 End MillDavid BumbaloughNo ratings yet

- 44-01 Machining With TailstockDocument1 page44-01 Machining With TailstockDavid BumbaloughNo ratings yet

- 53-02 Locators PDFDocument1 page53-02 Locators PDFDavid BumbaloughNo ratings yet

- 49-01 Documenting Programs Q+ADocument1 page49-01 Documenting Programs Q+ADavid BumbaloughNo ratings yet

- CNC Machining Q+A: # Answer 1Document2 pagesCNC Machining Q+A: # Answer 1David BumbaloughNo ratings yet

- 46-01 Horizontal MachiningDocument1 page46-01 Horizontal MachiningDavid BumbaloughNo ratings yet

- Verifying Programs Q+A: # Answer 1Document2 pagesVerifying Programs Q+A: # Answer 1David BumbaloughNo ratings yet

- 49-01 Documenting Programs Q+A PDFDocument1 page49-01 Documenting Programs Q+A PDFDavid BumbaloughNo ratings yet

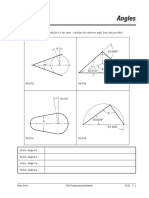

- Angles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDocument1 pageAngles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDavid BumbaloughNo ratings yet

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocument1 pageBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNo ratings yet

- 53-03 Contour Points 1Document1 page53-03 Contour Points 1David BumbaloughNo ratings yet

- 53-04 Contour Points 2Document1 page53-04 Contour Points 2David BumbaloughNo ratings yet

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocument1 pageBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNo ratings yet

- 19-01 Tool LengthDocument1 page19-01 Tool LengthDavid BumbaloughNo ratings yet

- Trig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDocument1 pageTrig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDavid BumbaloughNo ratings yet

- Unknown Radius: Chine Shop MagazineDocument1 pageUnknown Radius: Chine Shop MagazineDavid BumbaloughNo ratings yet

- 20-02 Rapid Motion FormulasDocument2 pages20-02 Rapid Motion FormulasDavid BumbaloughNo ratings yet

- Oil&Gas ProjectDocument4 pagesOil&Gas ProjectMelannie Adante100% (1)

- Company Profile For ConstructionDocument9 pagesCompany Profile For ConstructionRavindra AgrawalNo ratings yet

- Micropiles Seminar ReportDocument42 pagesMicropiles Seminar ReportAbhishek Trivedi100% (2)

- POSTER Civil Engineering ProjectDocument1 pagePOSTER Civil Engineering ProjectEr Zahir Gulamjilani MahidaNo ratings yet

- Irc LoadingDocument5 pagesIrc LoadingSeethapathi Asst. Professor-Sr.ScaleNo ratings yet

- Power and Distribution Transformers Sizing Calculations 2Document10 pagesPower and Distribution Transformers Sizing Calculations 2hashimelecNo ratings yet

- Fee Go2016he Ms39Document9 pagesFee Go2016he Ms39kumarNo ratings yet

- CV - Aqeel Ahmed Qazi Updated - Rev - CompressedDocument4 pagesCV - Aqeel Ahmed Qazi Updated - Rev - Compressedsidiq7No ratings yet

- Preliminary Investigation On The Overstrength and Force Reduction Factors For Industrial Rack Clad BuildingsDocument11 pagesPreliminary Investigation On The Overstrength and Force Reduction Factors For Industrial Rack Clad BuildingssaurabhsubhuNo ratings yet

- A Repository of Modern Software Testing LaboratoryDocument9 pagesA Repository of Modern Software Testing LaboratorySonali AgarwalNo ratings yet

- Transmission and Distribution - Lecture Notes, Study Material and Important Questions, AnswersDocument7 pagesTransmission and Distribution - Lecture Notes, Study Material and Important Questions, AnswersM.V. TVNo ratings yet

- Steam Tracing 101Document2 pagesSteam Tracing 101fawmer61100% (1)

- LNG and Condensate Loading Jetty Projectsheet DMCDocument2 pagesLNG and Condensate Loading Jetty Projectsheet DMCRaymond Jackson100% (1)

- Astm A178Document2 pagesAstm A178Nomala Srinivas0% (1)

- HaTelit Presentation 2Document18 pagesHaTelit Presentation 2Bagas YandiNo ratings yet

- Birhanu CVDocument3 pagesBirhanu CVabdulber kedirNo ratings yet

- A Reaction Paper SeminarDocument2 pagesA Reaction Paper SeminarNormanBalean100% (2)

- Calculation Sheet: Design CodeDocument1 pageCalculation Sheet: Design CodeCak AndiNo ratings yet

- Flat Plate-VoidedDocument12 pagesFlat Plate-VoidedVinitNo ratings yet

- System Administration Lab ManualDocument34 pagesSystem Administration Lab ManualVishal BurrewarNo ratings yet

- Resume Ummer QS Cost ControllerDocument2 pagesResume Ummer QS Cost ControllerMohammad UmmerNo ratings yet

- Assignment LeedDocument6 pagesAssignment LeedDhivya RamachandranNo ratings yet

- Ethylene Plant ExperienceDocument2 pagesEthylene Plant ExperienceArun Kumar Kar100% (1)

- NX9.0 Manual PDFDocument240 pagesNX9.0 Manual PDFToni Pérez100% (3)

- Situational Report (C3 - 050817)Document7 pagesSituational Report (C3 - 050817)Kaj Hojilla EstradaNo ratings yet

- Full TextDocument112 pagesFull TextShinjiNaviNo ratings yet

- George Ross CVDocument1 pageGeorge Ross CVWarren PetersenNo ratings yet

- TENSACCIAI - Rock and Soil AnchorsDocument0 pagesTENSACCIAI - Rock and Soil Anchorsnovakno1No ratings yet

- Euro CokeDocument13 pagesEuro Cokedhawal gargNo ratings yet

- Report On Industrial Visit ScribdDocument11 pagesReport On Industrial Visit ScribdJakeer CJNo ratings yet