Professional Documents

Culture Documents

Air Conditioning: Maintenance Manual and Illustrated Parts Catalogue Extra EA - 400

Uploaded by

Chinnu AmbiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Conditioning: Maintenance Manual and Illustrated Parts Catalogue Extra EA - 400

Uploaded by

Chinnu AmbiCopyright:

Available Formats

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Chapter 21

Air Conditioning

Page Date: 8. December 1999 21 Page 1

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

Table of Contents

21-00-00 GENERAL .........................................................................................................5

Description ..........................................................................................................5

Troubleshooting...................................................................................................6

Service and Maintenance.....................................................................................8

Removal / Installation..........................................................................................8

21-20-00 DISTRIBUTION................................................................................................9

Description ..........................................................................................................9

21-20-01 Panel Vent Fans .................................................................................................9

Removal (Pilot’s Side) ........................................................................................9

Installation (Pilot’s Side) ...................................................................................10

Removal (Copilot’s Side)..................................................................................12

Installation (Copilot’s Side) ..............................................................................13

21-30-00 PRESSURIZATION CONTROL ..................................................................15

Description ........................................................................................................15

Handling ............................................................................................................16

Removal / Installation........................................................................................18

21-30-01 Cabin Outflow Control Valve Filter..............................................................18

Replacement ......................................................................................................18

21-30-02 Cabin Outflow Control Valve.........................................................................18

Removal / Installation........................................................................................18

21-30-03 Safety Valve......................................................................................................19

Removal / Installation........................................................................................19

21-60-00 TEMPERATURE CONTROL .......................................................................20

Description ........................................................................................................20

Page 2 21 Page Date: 13. July 2001

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

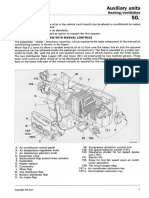

Figure 21-01a

Cabin Air Condition and Pressurization Scheme (SN 03 to 19)

Page Date: 13. July 2001 21 Page 3

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

Figure 21 – 01b

Cabin Air Condition and Pressurization Scheme (from SN 20 foll.)

Page 4 21 Page Date: 13. July 2001

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

21-00-00 GENERAL

Description

Refer to Figure 21-01a/b. For ventilation either pressurized or ram air is

available. The air source can be selected by the cabin air selection knob located

on the middle console controlling the cabin air selection valve.

If pressurized air is selected, air is guided from the combustion air intake

through an air filter, the turbocharger, the intercooler, a sonic venturi and then

either through the cabin cooler or directly through the cabin inflow check valve

into the cabin. At the same time ram air is guided from the ventilation air ram

intake to the vacuum pumps for cooling.

Note If maximum air flow for ventilating is desired it is advisable to select

pressurized air.

If ram air is selected, air is guided from the ventilation air ram intake through

the cabin inflow check valve into the cabin, while pressurized air now feeds the

vacuum pumps.

SN 03 through 19

Inside the cabin air can be guided to the windshield dispensers for defogging

and defrosting and to the legroom dispenser or through the RH armrest channel

to the rear, which depends on the position of the windshield defrost flap

controlled by the respective knob on the middle console. In the pressure dome

area an electric heater and the evaporators of the air conditioning system are

installed. The evaporators also work as cabin fans. The air conditioning system

including a compressor condenser module located in the tail cone sucks cabin

air and blows cool air through hoses to the eyeball vents and the leg room

dispenser in the front cockpit area and to the adjustable nozzles in the overhead

air channel of the passenger compartment ceiling.

SN 20 through 25

From SN 20, the ventilation system has been modified. Instead of the rear

overhead air channel, the cooled air is now routed through the LH arm rest duct

to the lower LH cockpit section as well as through the RH arm rest duct to the

RH cockpit section. The overhead air channel is furnished with a vent fan to

feed the adjustable air deflectors with ventilated cabin air.

The eyeball vents have been replaced by two independent adjustable air outlets,

which are combined with two panel vent fans to re-circulate the cockpit air.

Finally, the leg room dispenser has been removed.

When the evaporator blowers are operating, either cooled (air condition on) or

ventilated (air condition off) air is pressed through both side armrest channels.

From the RH evaporator blower, air is led into a duct in the RH armrest to the

right cockpit section. From the LH evaporator blower, air is ducted first

through the electrical heater in the LH armrest duct. This duct leads through the

Page Date: 13. July2002

5. July 2001 21 Page 5

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

cabin door where it is sealed with two oval rubber seals, and finally is routed

into the lower LH cockpit section. When the electrical heater is engaged the

compressor module is disengaged, and vice versa.

From SN 20, operation of the heating, ventilating and air conditioning system

implies the following characteristics: (Refer to Section 7, Pilot’s Operating

Handbook, figures 7-3, 4, 6, 13)

1 The cabin ventilation system, including both evaporator blowers and the

overhead air channel vent fan, is controlled by the VENT HI / LO switch in

the CABIN area of the left side panel. Both evaporator blowers work with

different power settings in low or high mode, whereas overhead air channel

fan operation features only one power rate for both switch positions LO / HI.

2 Heating and air conditioning system work exclusively. For either operating the

heating or the air conditioning, the ventilation system must run in high mode

simultaneously (VENT switch to position HI).

SN 26 following

The LH duct ends in the LH armrest behind the switch/breaker panel. The other

system components remain unchanged.

Troubleshooting

Complaint Possible Cause Remedy

No or inadequate Excessive cabin leakage Identify and seal

pressurization

Excessive door seal leakage Replace door seal

Excessive emergency exit seal Replace emergency exit seal

leakage

Dump solenoid energized Check dump switch and squat

switch

Controller failure Replace controller

Pressurization system inactive Switch pressurization system

ON

Control valve failure Replace control valve

Safety valve failure Replace safety valve

Incorrect pressurization or Pressurization system inactive Switch pressurization system

pressurization rate control ON

Control valve static reference Clean static reference

blocked connection

Control valve filter blocked Replace filter

Controller defective Replace controller

Page 6 21 Page Date: 13. July 2002

5. July 2001

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

Complaint Possible Cause Remedy

Incorrect pressurization or Control valve defective Replace control valve

pressurization rate control

Pressure differential exceeding Control valve static reference Clean static reference

5.5 psi blocked connection

Control valve differential Replace control valve

failure

No dump Pressurization system inactive Switch pressurization system

ON

Squat switch setting incorrect Correct squat switch setting

Safety valve static reference Clean static reference

blocked connection

Dump switch defective Replace dump switch

Squat switch defective Replace squat switch

Safety valve solenoid failure Replace safety valve

Safety valve blind plug at Install blind plug

vacuum port not installed

Erroneous CAB PRESS Differential pressure switch Replace differential pressure

warning (5.65 psig) defective switch

Absolute pressure switch Replace absolute pressure

(10,000 ft) defective switch

Page Date: 13. July 2002

5. July 2001 21 Page 7

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

Service and Maintenance

Servicing of the air-conditioning unit shall be performed by an approved air-

conditioning service station, only R-134a type refrigerant must be used.

The air-conditioning compressor condenser module is equipped with

conventional evacuating and charging connections.

After new system plumbing installation, component replacement or line or

hose rupture, a leak check is required, see General Operating, Servicing and

Maintenance Manual for Airborne R-134a Air-conditioning Systems for leak

check and general charging procedures.

Refer to General Operating, Servicing and Maintenance Manual for Airborne

R-134a Air-conditioning Systems for component maintenance procedures..

Access to the compressor condenser module is gained through the tailcone

access hatch.

Charging quantity of the installation is 1.050 kg +/- 0.050 kg, proper charging

can be verified at the sight glass on the receiver dryer. With the system fully

charged and operating, observe the suction and discharge pressures. Typical

values at various ambient temperatures, with hot cabins are shown below:

OAT Suction pressure Discharge pressure

(°C) (psig) (psig)

20 28 112

25 30 133

30 31 156

35 32 180

Removal / Installation

For removal and installation of air-conditioning, heating or temperature control

system components, contact EXTRA Flugzeugbau GmbH.

Page 8 21 Page Date: 13. July 2001

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

21-20-00 DISTRIBUTION

Description

Valid for Serial - No. 20 following

For better ventilation in the forward cabin section two vent fans (Micronel type

D603L-024KA-3) are installed in the LH and RH side of the instrument panel.

Each vent fan sucks air through a composite tube from the lower side of the

panel shelf. On the blow side each vent fan is connected to a vent grid, which

can be adjusted to either direct or shut off the air flow. Two jiggle switches

(marked 0/1), placed on the instrument panel near the resp. air outlet, control

the vent fans. The electric fan motors are protected by a 1A - fuse each.

21-20-01 Panel Vent Fans

Valid for Serial - No. 20 following

CAUTION With some installations, it might not be required to remove the main panel

completely, depending on individual wire and hose length. Take care not

to damage instrument wiring and gyro air hoses.

Removal (Pilot’s Side)

Detail Steps/Work Items Key Items

Main Panel Removal

1 Remove 8 Phillips screws around left main

panel

2 Remove 4 Phillips screws securing EHSI

ED - 461 to panel

3 Remove 4 Phillips screws securing EADI

ED - 462 to panel

4 Slightly swivel down left main panel Take care not to dama ge

flexible hoses and electrical

wiring

5 Disconnect illumination wires on instru-

ments without D-Sub-Connections

6 Disconnect D-Sub-Connection on Warning

Panel

7 Disconnect D-Sub-Connection on Fuel Flow

Indicator

8 Disconnect electrical wiring on OAT

Indicator

9 Disconnect DME Hold Switch

Page Date: 13. July 2001 21 Page 9

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

Detail Steps/Work Items Key Items

10 Disconnect electrical wiring on Turn

Coordinator

11 Disconnect electrical wiring on Slaving

Control KA - 51 B

12 Disconnect wiring from Amperemeter Molex plug

(prop de- ice)

13 Unscrew flexible hose on Manifold / Fuel

Pressure Gauge

14 Pull off pitot and static hoses from Airspeed

Indicator

15 Pull off static hose to Altimeter at T-fitting

next to Altimeter

16 Pull off static hose to Vertical Speed

Indicator at T- fitting next to Vertical Speed

Indicator

17 Remove main panel completely

Vent Fan Removal

18 Carefully remove vent grid from panel Use a lever to pull out four

guide lugs at the edges

19 Remove composite tube from vent fan back Loosen clamp

side

20 Cut off two electrical wires about 5…10 Sign connection

inches from fan connection or de-solder

wires from fan connection

21 Loosen 4 Allen bolts and nuts securing fan

to LH panel corner

22 Remove vent fan inclined backwards

Installation (Pilot’s Side)

Detail Steps/Work Items Key Items

Vent Fan Installation

1 Move fan to back side of LH panel corner

2 Install 4 Allen bolts and nuts securing fan to

panel

3 Re-solder electrical wires to fan connection

Page 10 21 Page Date: 13. July 2001

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

Detail Steps/Work Items Key Items

4 Lead composite tube from underside of

instrument shelf to vent fan back side.

Install tube with clamp.

5 Snap vent grid into panel

Main Panel Installation

6 Move left main panel in reach of

connections

7 Connect D-Sub-Connections on Warning

Panel

8 Connect D-Sub-Connections on Fuel Flow

Indicator

9 Connect electrical wiring to OAT Indicator

10 Connect DME Hold Switch

11 Connect electrical wiring to Turn Coor-

dinator

12 Connect electrical wiring to Slaving Control

KA - 51 B

13 Connect Molex - plug to Amperemeter

(prop de- ice)

14 Connect illumination wires to instruments

without D-Sub-Connections

15 Connect flexible hose to Manifold / Fuel

Pressure Gauge

16 Connect pitot and static hoses to Airspeed

Indicator

17 Connect Altimeter static hose to T- fitting

18 Connect Vertical Speed Indicator static hose

to T- fitting

19 Insert panel into instrument shelf Take care not to damage

flexible hoses and electrical

wiring

20 Re- install Phillips screws to panel

21 Re- install Phillips screws to ED - 461

22 Re- install Phillips screws to ED - 462

Page Date: 13. July 2001 21 Page 11

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

Removal (Copilot’s Side)

Detail Steps/Work Items Key Items

1 Remove 8 Phillips screws around right main

panel

2 Slightly swivel down right main panel Take care not to damage

flexible hoses and electrical

wiring

3 Remove two 37-pin-connections from

Annunciator Panel

4 Remove 30-pin-connection from KNI-204

VOR/LOC and Glide Slope Indicator

5 Pull off static and pitot hoses from Airspeed

Indicator

6 Disconnect wiring from Airspeed Indicator Molex plug

7 Pull off static hose from Altimeter

8 Disconnect wiring from Altimeter Molex plug

9 Remove Vac., Gage and Air Inlet hoses

from Sigma Tek 5000 Vacuum Horizon

10 Disconnect wiring from Sigma Tek 5000 Molex plug

Vacuum Horizon

11 Remove Vac., Gage and Air Inlet hoses

from Sigma Tek 4000 Directional Gyro

12 Disconnect wiring from Sigma Tek 4000 Molex plug

Directional Gyro

13 Remove 3 single pin connections from

Coolant Temperature Gage

14 Remove 4 single pin connections from

CHT/EGT Gage

15 Remove 5 single pin connections from Oil

Temperature / Oil Pressure Gage

16 Remove 2 single pin connections from TIT

Gage

17 Remove 2 single plugs and 1 triple plug

from LH Fuel Quantity Gage

18 Remove 2 single plugs and 1 triple plug

from RH Fuel Quantity Gage

Page 12 21 Page Date: 13. July 2001

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

Detail Steps/Work Items Key Items

19 Remove 2 screwed cable clamps (+, -) from

Ammeter

20 Remove 2 screwed cable clamps (+, -) from

Voltmeter

21 Remove 4 air hoses Vent, Vac, R, L from

Dual Suction Gage

22 Remove main panel completely

Vent Fan Removal

23 Carefully remove vent grid from panel Use a lever to pull out four

guide lugs at the edges

24 Remove composite tube from vent fan back Loosen clamp

side

25 Cut off two electrical wires about 5…10 Sign connection

inches from fan connection or de-solder

wires from fan connection

26 Loosen 4 Allen bolts and nuts securing fan

to LH panel corner

27 Remove vent fan inclined backwards

Installation (Copilot’s Side)

Detail Steps/Work Items Key Items

Vent Fan Installation

1 Position fan to back side of RH panel corner

2 Install 4 Allen bolts and nuts securing fan to

panel

3 Re-solder electrical wires to fan connection

4 Lead composite tube from underside of

instrument shelf to vent fan back side.

Install tube with clamp.

5 Snap vent grid into panel

Main Panel Installation

6 Move right main panel in reach of

instrument connections

7 Screw cable clamps (+,-) to Voltmeter

8 Screw cable clamps (+,-) to Ammeter

Page Date: 13. July 2001 21 Page 13

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

Detail Steps/Work Items Key Items

9 Install single plugs and triple plug to LH

Fuel Quantity Gage

10 Install single plugs and triple plug to RH

Fuel Quantity Gage

11 Install 2 single pin connections to TIT Gage

12 Install 5 single pin connections to Oil

Temperature / Oil Pressure Gage

13 Install 4 single pin connections to CHT /

EGT Gage

14 Install 3 single pin connections to Coolant

Temperature Gage

15 Connect Molex plug to Sigma Tek 4000

Directional Gyro

16 Install Vac., Gage and Air Inlet hoses to

Sigma Tek 4000 Directional Gyro

17 Connect Molex plug to Sigma Tek 5000

Vacuum Horizon

18 Install Vac., Gage and Air Inlet hoses to

Sigma Tek 5000 Vacuum Horizon

19 Install 4 air hoses Vent, Vac, R, L to Dual

Suction Gage

20 Connect static hose with Altimeter

21 Connect Molex plug to Altimeter

22 Connect static and pitot hoses with Airspeed

Indicator

23 Connect Molex plug to Airspeed Indicator

24 Install 30-pin-connection to KNI-204

VOR/LOC and Glide Slope Indicator

25 Install two 37-pin-connections to

Annunciator Panel

26 Insert panel into instrument shelf Take care not to damage

flexible hoses and electrical

wiring

27 Re- install Phillips screws to panel

Page 14 21 Page Date: 13. July 2001

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

21-30-00 PRESSURIZATION CONTROL

Description

The system consists of the engine turbocharger, a sonic venturi (flow limiter), a

cabin control outflow valve, an unregulated safety valve, the cabin

pressurization switch, the cabin pressure controller, a dump safety switch, the

landing gear squat switch, and two indicators, one for cabin altitude and

differential pressure and one for cabin rate-of-climb.

Pressurization air is supplied from the engine turbocharger through the sonic

venturi and then through a check valve into the cabin. Adequate flow to

maintain pressurization up to the maximum differential pressure of 5.5 PSI is

provided by the engine at normal power setting. Power changes should be

made smoothly to prevent sudden changes in pressurization air inflow resulting

in cabin pressure transients.

The airplane may be operated in either the pressurized or depressurized mode.

The mode selection is made with the cabin pressurization switch, whic h either

opens the safety valve for depressurized mode, or closes the safety valve and

thus activating the cabin control outflow valve for pressurized mode, on

condition that pressurized air is selected on the cabin air knob and the dump

safety switch is in OFF-position. Mode operation should be selected prior to

takeoff. If a change from pressurized to depressurized mode must be made

while airborne, depressurize the cabin following the procedure given below

before turning the dump switch as otherwise a rapid decompression occurs,

which would cause discomfort to the passengers. When changing from

unpressurized to pressurized mode, the cabin altitude rate of change will be

limited by the pressurization controller. The valves are also opened by the

landing gear squat switch assuring depressurized mode when aircraft is on

ground to avoid bursting the cabin door due to cabin pressure when opening.

However this is only a safety device: landing in pressurized mode is

prohibited !

In the pressurized mode cabin pressure is regulated by the cabin control

outflow valve allowing air to exhaust either to the pressure level preselected by

the cabin pressure controller or to maximum differential pressure level. Setting

the center dial (identified as “Flight Level”) of the cabin pressure controller

will suggest the system being at a certain flight altitude. So the system will

maintain the corresponding cabin altitude (about 5.5 PSI above static pressure

of flight level) or reach it with the rate set by the rate control knob located on

the lower left corner of the pressurization controller. Only in case of maximum

differential pressure is reached or flight level is below the selected cabin

altitude, cabin altitude changes with the same rate the flight altitude does.

In case of failure of the cabin outflow control valve the safety valve will open

at a differential pressure of slightly above 5.5 PSI to avoid structure damage.

Page Date: 13. July 2001 21 Page 15

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

Handling

Use the cabin pressure controller as follows. Also refer to the sample chart

(Figure 21-02).

1 Activate the pressurization controller by turning on the cabin pressurization

switch. Make sure that the dump switch is off and the pressurized cabin air is

selected.

2 Set the published official airport altitude (such as shown on flight charts) under

the index arrow by turning the center control knob.

3 Turn the index arrow of the rate control knob (lower left corner of the control)

to the 12 o’clock position (approx. 500 fpm).

These steps set the system to pressurize at approximately 700 feet above the

runway after takeoff. The system will hold this cabin altitude until the

maximum differential altitude is reached (see “Cabin Altitude with minimum

Flight Level Setting” line of Figure 21-02) or a different cabin pressure is

selected.

4 After having cleared the airport area and established the climb and being on

course to the destination (see “a” on Figure 21-02), select the flight level

corresponding to the intended cruise altitude in the center dial and align that

with the index arrow. This alignment also indicates the approximate cabin

altitude (within approx. 700 feet) at the index on the larger numbers marked

“Airport Alt.”.

5 Increase or decrease the rate at which the cabin changes altitude for the best

comfort level from normally 500 fpm by turning the rate knob counter

clockwise for decreasing or clockwise for increasing the rate.

Usually it is the best method to set the rate to reach the changed cabin pressure

(referenced from the “Airport Alt.”) slightly ahead of reaching the cruising

altitude (550 fpm in the sample of Figure 21-02). This selected altitude will be

maintained until the aircraft changes altitude sufficiently to reach the max.

differential pressure or descends sufficiently to go below the selected airport

altitude.

6 When the aircraft reaches the proximity of the destination and starts to descent

(see “b” on Figure 21-02), set the selector knob to the published airport

altitude.

7 Set the rate so that the selected airport altitude is reached in the cabin prior to

descending to that altitude (650 fpm in the sample of Figure 21-02).

When approaching the runway, the pressurization will cease approximately 700

feet above the landing prior to landing. Should any slight pressure remain, the

remainder will dump when the squat switch closes. However, this is an

additionally safety device, because landing with cabin pressurized is not

allowed.

CAUTION If pressurization mode shall be finished during flight, follow the procedure

above, setting the airport altitude equal to the momentary flight altitude.

Switch to the depressurized mode not before the selected airport altitude is

reached.

Page 16 21 Page Date: 13. July 2001

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

Figure 21-02 Cabin Pressurization Sample Chart

Page Date: 13. July 2001 21 Page 17

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

Removal / Installation

For removal and installation of pressurization system components, contact

EXTRA Flugzeugbau GmbH.

21-30-01 Cabin Outflow Control Valve Filter

Replacement

Detail Steps/Work Items Key Items

1 Gain access to the inner side of the rear

pressure bulkhead by removing the aft cabin

liner

2 Loosen the filter retention screw on the

control outflow valve housing until the filter

flange is free to rotate. It is not necessary to

remove the screw entirely.

3 Rotate the filter until the flat on the filter

clears the screw head.

4 Remove the filter cartridge and replace with

new one.

5 Rotate the filter so filter flange is captured

by the screw head.

6 Tighten filter retaining screw.

21-30-02 Cabin Outflow Control Valve

The valve is attached to the LH side of the pressure dome.

Removal / Installation

Detail Steps/Work Items Key Items

Removal

1 Remove upper half of rear baggage Machine screws AN 526

compartment wall 10-32

2 Remove tail cone access panel on LH

fuselage side

3 Remove valve flange from pressure dome 8 stop nuts MS 21044 AN3

with washers AN960 – 10L

(3/8 inch.)

Page 18 21 Page Date: 13. July 2001

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

Detail Steps/Work Items Key Items

4 Remove 2 overflow tubes 9/16 fitting; retain with 11/16

wrench at pressure dome

fitting

5 Lift up valve from pressure dome

Installation

Install in reverse sequence of removal

21-30-03 Safety Valve

The valve is attached to the RH side of the pressure dome.

Removal / Installation

Detail Steps/Work Items Key Items

Removal

1 Remove upper half of rear bagga ge Machine screws AN 526

compartment wall 10-32

2 Remove tail cone access panel on LH

fuselage side

3 Remove battery Refer to Ch. 24-30-01

3 Remove valve flange from pressure dome 8 stop nuts MS 21044 AN3

with washers AN960 – 10L

(3/8 inch.)

4 Remove 2 overflow tubes 9/16 fitting; retain with 11/16

wrench at pressure dome

fitting

5 Lift up valve from pressure dome

Installation

Install in reverse sequence of removal

NOTE Verify that blind plug at vacuum port is installed correctly. With

installed valve, the vacuum port is accessible behind the rear baggage

compartment wall.

Page Date: 13. July 2001 21 Page 19

Maintenance Manual and Illustrated Parts Catalogue

Extra EA -400

Air Conditioning

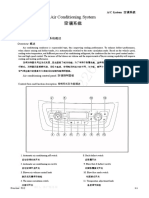

21-60-00 TEMPERATURE CONTROL

Description

If pressurized air is selected the temperature mainly can be regulated by means

of the cabin cooler bypass valve controlled by the cabin temperature knob

located on the middle console. Additional regulating is possible by either

activating the electric heater or by switching on or off the air conditioning

system and changing the operation mode of the cabin ventilation.

Note The heater and the air conditioning system operate only if cabin

ventilation is running at least in low mode.

If ram air is selected the cabin temperature knob has no function.

Page 20 21 Page Date: 13. July 2001

You might also like

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- SDS1230 21 51 00Document30 pagesSDS1230 21 51 00นาถวัฒน์ ฉลาดแย้มNo ratings yet

- Quy Trinh Xoa Hien Thi Thay Loc Khi Dieu HoaDocument15 pagesQuy Trinh Xoa Hien Thi Thay Loc Khi Dieu HoatuannholttNo ratings yet

- Air Distribution: Training ManualDocument19 pagesAir Distribution: Training ManualRicardo zafraNo ratings yet

- ml-b-390-MM-Chapter 21 Air Conditioning PDFDocument342 pagesml-b-390-MM-Chapter 21 Air Conditioning PDFAndres GuerreroNo ratings yet

- Ata 37 - VacuumDocument13 pagesAta 37 - VacuumPapa Bebe FamilyNo ratings yet

- ML B 200 b200mm145Document12 pagesML B 200 b200mm145robson lopes bezerraNo ratings yet

- Isuzu Engine Heating and VentilationDocument7 pagesIsuzu Engine Heating and Ventilationwade100% (51)

- BEECHCRAFT KING AIR B200 SYSTEMS OVERVIEWDocument117 pagesBEECHCRAFT KING AIR B200 SYSTEMS OVERVIEWrav80% (5)

- Airbus 21 A300 A310 Air ConditioningDocument146 pagesAirbus 21 A300 A310 Air ConditioningElijah Paul Merto100% (3)

- McDonnell Douglas DC-10-40-Air Cond and Press PDFDocument15 pagesMcDonnell Douglas DC-10-40-Air Cond and Press PDFFMMServicesNo ratings yet

- Ac PDFDocument79 pagesAc PDFmarkoNo ratings yet

- SN Agusta Chap 21Document84 pagesSN Agusta Chap 21Guy Ulrich DouoguiNo ratings yet

- Description and Operation: Component Maintenance ManualDocument12 pagesDescription and Operation: Component Maintenance ManualserdoukNo ratings yet

- 24-Heating & Air ConditioningDocument128 pages24-Heating & Air ConditioningPedro AlexandreNo ratings yet

- Vapor Cycle Air Conditioning System TR-134 SMDocument33 pagesVapor Cycle Air Conditioning System TR-134 SMDavid BondNo ratings yet

- Training Manual A 318: ATA 21 Air ConditionDocument17 pagesTraining Manual A 318: ATA 21 Air ConditionbnolascoNo ratings yet

- Prius Airco PDFDocument17 pagesPrius Airco PDFTrisa VoNo ratings yet

- AIR CONDITIONING TRAINING MANUAL OVERVIEWDocument129 pagesAIR CONDITIONING TRAINING MANUAL OVERVIEWA WongNo ratings yet

- 21 Air ConditioningDocument222 pages21 Air ConditioningteminaniNo ratings yet

- Cl605-Air Conditioning and PressDocument25 pagesCl605-Air Conditioning and PressMax MellmingerNo ratings yet

- Air ConditioningDocument16 pagesAir ConditioningPUNEETNo ratings yet

- A/C-Heater System - Manual: 1990 Nissan 240SXDocument11 pagesA/C-Heater System - Manual: 1990 Nissan 240SXRonald FernandezNo ratings yet

- CH21Document15 pagesCH21ranjit prasadNo ratings yet

- B737-6 21 Jar B1 e (Jun2004 CMP)Document198 pagesB737-6 21 Jar B1 e (Jun2004 CMP)Belisario Sergio Llacchas rodasNo ratings yet

- ThermoCond 19 enDocument4 pagesThermoCond 19 enAnonymous 7z6OzoNo ratings yet

- B737-6_21_B2_EDocument20 pagesB737-6_21_B2_EBelisario Sergio Llacchas rodasNo ratings yet

- P180 Avanti-Environmental Control SystemDocument6 pagesP180 Avanti-Environmental Control SystemravNo ratings yet

- Fiat Barchetta: Auxiliary UnitsDocument14 pagesFiat Barchetta: Auxiliary UnitsHallex OliveiraNo ratings yet

- # Air Conditioning - General:: Note For CPC Manual ModeDocument30 pages# Air Conditioning - General:: Note For CPC Manual Modejontis jasoliyaNo ratings yet

- Ata 21 Air Conditioning PDFDocument38 pagesAta 21 Air Conditioning PDFEDUARDO RAFAEL GRANJA RIVERA100% (1)

- Axial Flow Mine Fans: AXFLMINEFANSDocument6 pagesAxial Flow Mine Fans: AXFLMINEFANSEdgar LuchoNo ratings yet

- Zone Temperature Control OverviewDocument330 pagesZone Temperature Control Overviewmarcelojm7No ratings yet

- 21 Air ConditioningDocument232 pages21 Air ConditioningAle Torrico TamayoNo ratings yet

- Air ConditioningDocument13 pagesAir ConditioningNazimNo ratings yet

- 15 1963 Ch-Heater & AccDocument40 pages15 1963 Ch-Heater & AccJose LaproviteraNo ratings yet

- Low Speed Fans Application Guide MiningDocument20 pagesLow Speed Fans Application Guide MiningsanthoshdonNo ratings yet

- GEA32335 Low Speed Fans AP Guide R2Document20 pagesGEA32335 Low Speed Fans AP Guide R2berkahharianNo ratings yet

- Automobile Ac by Utilising Waste Heat & GasesDocument18 pagesAutomobile Ac by Utilising Waste Heat & Gasesraveesh11150% (2)

- Section - III Systems DescriptionDocument18 pagesSection - III Systems DescriptionJose LaraNo ratings yet

- Model Yt G0 A1 B1 Thru Yt L6 D8 F2 (Style H) HCFC-123 (Cooling Only)Document60 pagesModel Yt G0 A1 B1 Thru Yt L6 D8 F2 (Style H) HCFC-123 (Cooling Only)Lorena Correa100% (1)

- Heater, Air Conditioning and VentilationDocument12 pagesHeater, Air Conditioning and VentilationrjlafortezaNo ratings yet

- Cooling: Air Conditioning Pack (21-51-00) Aircraft Maintenance Manual System Description SectionDocument23 pagesCooling: Air Conditioning Pack (21-51-00) Aircraft Maintenance Manual System Description Sectionnishat529No ratings yet

- Cooling: Air Conditioning Pack (21-51-00) Aircraft Maintenance Manual System Description SectionDocument7 pagesCooling: Air Conditioning Pack (21-51-00) Aircraft Maintenance Manual System Description Sectionnishat529No ratings yet

- Air Conditioning Service Manual GuideDocument77 pagesAir Conditioning Service Manual Guideplagueira50% (2)

- Chapter 21-40-00 Enviromental System - HeatingDocument38 pagesChapter 21-40-00 Enviromental System - HeatingAnggarda Bagus SejatiNo ratings yet

- Chapter 21-50-00 Enviromental System - CoolingDocument48 pagesChapter 21-50-00 Enviromental System - CoolingAnggarda Bagus SejatiNo ratings yet

- 2 AC System空调系统Document55 pages2 AC System空调系统BorisNo ratings yet

- 12-10-01 (Printed Data Must Not Be Retained For Future Reference.)Document8 pages12-10-01 (Printed Data Must Not Be Retained For Future Reference.)Andres GuerreroNo ratings yet

- 13 747 400F Differences V11Document12 pages13 747 400F Differences V11Alfonso Enrrique Maya FlorezNo ratings yet

- 16 Heater PDFDocument22 pages16 Heater PDFFrezgi BirhanuNo ratings yet

- 15 1964 CH-Heater & AccDocument59 pages15 1964 CH-Heater & AccJose LaproviteraNo ratings yet

- Air Conditioning Unit, DescriptionDocument6 pagesAir Conditioning Unit, Descriptionsunil singhNo ratings yet

- Heating and Air Conditioning: Fig. 1 Fixed Displacement Compressor-Model 10PA17Document84 pagesHeating and Air Conditioning: Fig. 1 Fixed Displacement Compressor-Model 10PA17Christian MartinezNo ratings yet

- Suzuki SwiftDocument7 pagesSuzuki SwiftAsher GinsbergNo ratings yet

- Tempmatic Climate ControlDocument144 pagesTempmatic Climate ControlGreg HannaNo ratings yet

- E46 IHKR System Components and OperationDocument15 pagesE46 IHKR System Components and OperationSalisburNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Warm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationFrom EverandWarm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationNo ratings yet

- Automotive Job Openings for Hil Testing, BMS Hil Testing & MBDDocument3 pagesAutomotive Job Openings for Hil Testing, BMS Hil Testing & MBDChinnu AmbiNo ratings yet

- Budget 2018-19 BenefitsDocument2 pagesBudget 2018-19 BenefitsChinnu AmbiNo ratings yet

- Budget 2018-19 Benefits PDFDocument2 pagesBudget 2018-19 Benefits PDFChinnu AmbiNo ratings yet

- Form CompletionDocument4 pagesForm CompletionChinnu AmbiNo ratings yet

- Listening Sample Task - Form CompletionDocument4 pagesListening Sample Task - Form CompletionTrần Đăng Khoa100% (1)

- A380 Integrated Modular AvionicsDocument45 pagesA380 Integrated Modular AvionicsHugues de Payens100% (4)

- Avionics ArchitectureDocument2 pagesAvionics ArchitectureChinnu AmbiNo ratings yet

- How To Start A Onversation and Make DFDrive - Com)Document29 pagesHow To Start A Onversation and Make DFDrive - Com)Chinnu AmbiNo ratings yet

- I e Lts ApplicationformDocument8 pagesI e Lts ApplicationformAnonymous Kg9gacf7y4No ratings yet

- I e Lts ApplicationformDocument8 pagesI e Lts ApplicationformAnonymous Kg9gacf7y4No ratings yet

- Airbus NotesDocument54 pagesAirbus NotesAlessandro Polo Del VecchioNo ratings yet

- Troubleshooting Cat PDFDocument215 pagesTroubleshooting Cat PDFmisaelandres1100% (3)

- Hydraulic Principles: Service Manual-ElectronicsDocument25 pagesHydraulic Principles: Service Manual-ElectronicsHiarom ServiceNo ratings yet

- Francis Turbine: Abbas Bilal Sami Hussein Name: Subject: Third Power Plant Class /branch: D.Laith Ayad SupervisorDocument6 pagesFrancis Turbine: Abbas Bilal Sami Hussein Name: Subject: Third Power Plant Class /branch: D.Laith Ayad Supervisorabbas bilalNo ratings yet

- Torito Crom Z Gasolina (Referencial) (1) - 1-82-41-82Document42 pagesTorito Crom Z Gasolina (Referencial) (1) - 1-82-41-82Darwin PeñaNo ratings yet

- Shop Manual Engine E683 Part - 2Document31 pagesShop Manual Engine E683 Part - 2arif nadafNo ratings yet

- CD34x Freshening 2 2L Duratorq TDCi DW Diesel DW12 PDFDocument106 pagesCD34x Freshening 2 2L Duratorq TDCi DW Diesel DW12 PDFĐức Hòang100% (2)

- Service Manual: Tennant A80Document33 pagesService Manual: Tennant A80Павел КорчагинNo ratings yet

- Transmission Rebuild PDFDocument29 pagesTransmission Rebuild PDFTeguh PriyonoNo ratings yet

- Diesel Power Plantfinal PDFDocument26 pagesDiesel Power Plantfinal PDFVedant NoNo ratings yet

- Catalog SchwitzerDocument43 pagesCatalog SchwitzerHilal MelhemNo ratings yet

- Manual BrochesDocument52 pagesManual BrochesEnrique PerezNo ratings yet

- GD D807 Blower PartsDocument2 pagesGD D807 Blower PartsManuelG.CastilloR.No ratings yet

- 811.35 11229979 99999999 05702516 Engine MountsDocument14 pages811.35 11229979 99999999 05702516 Engine Mountseshopmanual EnamNo ratings yet

- Maintenance ChecklistDocument2 pagesMaintenance ChecklistChrist Archer SanchezNo ratings yet

- Gas Lift Válvula PilotoDocument2 pagesGas Lift Válvula PilotoFabio ParceroNo ratings yet

- Seltec AC Compressor Catalog 2010Document39 pagesSeltec AC Compressor Catalog 2010Erisson100% (1)

- Access 125 NM Bs4Document95 pagesAccess 125 NM Bs4Rushabh DoshiNo ratings yet

- FlowMasterII PumpDocument3 pagesFlowMasterII Pumpsugiyono81No ratings yet

- Order Your Custom LHA 25 Hydraulic CylinderDocument20 pagesOrder Your Custom LHA 25 Hydraulic CylinderMarcel StoianNo ratings yet

- Volvo EW145BDocument502 pagesVolvo EW145Bnamvinh100% (8)

- Harley Davidson xr1000 Racing SpecsDocument12 pagesHarley Davidson xr1000 Racing Specsmacio853100% (2)

- SM 3 PDFDocument152 pagesSM 3 PDFeko sulistyo utomoNo ratings yet

- Sutorbilt Legend Model 3H R & S-Version DSL & GreaseDocument1 pageSutorbilt Legend Model 3H R & S-Version DSL & GreaseJosue UrgilésNo ratings yet

- Suspension Bushing Service Tool: Go The DistanceDocument2 pagesSuspension Bushing Service Tool: Go The DistancePatricio G. ArrienNo ratings yet

- Anilkumar Kanjibhai Patel (Mechanical Technician) Updated CVDocument5 pagesAnilkumar Kanjibhai Patel (Mechanical Technician) Updated CVpavitravpatelNo ratings yet

- 2011 Ford Explorer 3.5L Ti-VCT Engine: Key FeaturesDocument2 pages2011 Ford Explorer 3.5L Ti-VCT Engine: Key Featuresraumil1237590No ratings yet

- Marine Motor - MTU 538Document2 pagesMarine Motor - MTU 538rashid kNo ratings yet

- Perhitungan HPPDocument66 pagesPerhitungan HPPFahrul Nur ArifinNo ratings yet

- P222 Parts BookDocument66 pagesP222 Parts BookMustafa A.WNo ratings yet

- UL 60335 2 40 CSA C22 2 No 60335 2 40 Rev 9 15 2017 ED 11 30 2020Document23 pagesUL 60335 2 40 CSA C22 2 No 60335 2 40 Rev 9 15 2017 ED 11 30 2020Joel AndradeNo ratings yet