Professional Documents

Culture Documents

Final Assessment Report E-2225B

Uploaded by

vancongthanhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final Assessment Report E-2225B

Uploaded by

vancongthanhCopyright:

Available Formats

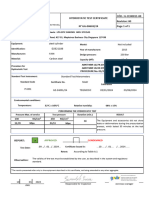

TÜV SÜD China Chemical Oil & Gas Services

Inspection Certificate of Final Assessment

according to Annex I No. 3.2 of the Directive 2014/68/EU

Requirements: Directive 2014/68/EU in connection with Annex III Module G

EN 13445:2014

Test report no.: PED-TCCS-SHA2017005 Equipment no.: 009900000000002752

Item Number: E-2225B

Manufacturer: Customer:

Xxxxxxx Special Equipments Co., Ltd xxxxxxx Deutschland GmbH

No.xxxxx Road, Zhangpu Town, Kunshan Alte Straße 201

City, Jiangsu, China 50769 Köln

Serial no.: 16-A3195-2 Germany

Year of construction: 2017

Description of pressure vessel: Vessel

Design approval: TÜV SÜD Chemie Service GmbH, D-51368 Leverkusen, TP7-M035-

140001412388

Date of design approval: 2017-02-24 Drawing no.: BSA16-453-00 Rev.04

Category: IV Module : G

Chamber: Tube Side Shell Side Coil tube

Max. allow. pressure (PS) [bar]: -1/+8 -1/+8 /

Min./max. allow. temp. (TS) [°C]: -10/+120 -10/+120 /

Capacity [Liter]: 2900 2840 /

Fluidgroup: 1 1 /

Proof test according to Annex I No. 3.2.2

Test pressure (PT) [bar]: 12.9 (Horizontal) 12.9 (Horizontal) /

Test medium: water water /

Date of proof test: 2017-01-13 2017-01-03 /

Final inspection according to Annex I No. 3.2.1

Date of final inspection: 2016-12-30

Remarks: Metal temperature during proof test > 15 °C, Pressure test holding time > 60

minutes, Number of used pressure gauges: shell side: 140466810, 141104706, tube side:

140466810, 141104706

Result: According to the results of the final inspection and the proof test the pressure vessel is

in a proper condition. The requirements of the Directive 2014/68/EU and of the above

mentioned code and regulations are fulfilled.

Test stamp: on the: rivet flanges vessel shell

screwed parts name plate

Summary of tests and results: accepted rejected annex Remarks:

TÜV SÜD China Chemical Oil & Gas Service phone: + 86 21 61410711

No.151 Heng Tong Road fax + 86 21 61408600

Shanghai 200070 P.R.China e-mail: xin.wang@tuv-sud.cn

page 1 of 2

Final Assessment Report E-2225B.doc

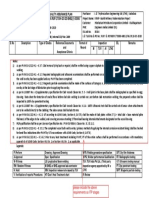

TÜV SÜD China Chemical Oil & Gas Services

1. Materials: EN-Standard , EAM ,

particular material appraisal

2. Traceability of materials (Material certificates)

3. Approvals of the manufacturer

ASME U-Stamp

4. Applicability of filler materials

5. Qualification of welders

6. Qualification of welding procedures

7. Production tests

8. Qualification of NDE personnel

9. Reports of non-destructive examination

10. Reports of heat treatment

11. Calibration of measuring and test instrument Attestation of manufacturer was present

12. Visual testing

13. Dimensional check by manufacturer

14. Marking (name plate)

15. Risk and hazard analysis was present

16. Operating instruction was present

17. Report of non conformity

18. Declaration of conformity

Indications: 1. The pressure vessel was tested without accessories.

2. The summary test results refer solely to the above described pressure vessel.

The right to an extract reproduction is to the TÜV SÜD Chemie Service.

3. There might be further requirements to the pressure vessel e.g inspection before initial

operation or requirements of further Directives.

TÜV SÜD China Chemical Oil & Gas

on behalf of

TÜV SÜD Chemie Service GmbH

Notified Body, No. 1682

Shanghai, 2017-03-01

_____________________________________ _____________________________________

Place and date expert

Watson, Wang xin

Annex:

As built drawings, Material certificates, reports of NDE, Operating instruction, Declaration of conformity

TÜV SÜD China Chemical Oil&GAS Service phone: + 86 21 61410711

No.151 Heng Tong Road fax + 86 21 61408600

Shanghai 200070 P.R.China e-mail: xin.wang@tuv-sud.cn

page 2 of 2

Final Assessment Report E-2225B.doc

You might also like

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Hydro Test Procedure: ItemDocument6 pagesHydro Test Procedure: Itemtulasirao.nammiNo ratings yet

- Test ReportDocument15 pagesTest Reportthien dinh ba0% (1)

- Audit Check list-PEDDocument9 pagesAudit Check list-PEDABHISHEK DOLLENo ratings yet

- 32-Ve-711 (Hydrostatic Test Procedure Piping - FT Gas) A11 PDFDocument5 pages32-Ve-711 (Hydrostatic Test Procedure Piping - FT Gas) A11 PDFMarlon TurnerNo ratings yet

- Selection Guide To Determine Temperature Control Valves: 1. RequestDocument1 pageSelection Guide To Determine Temperature Control Valves: 1. RequestNofriandi SusantoNo ratings yet

- Hydro Test ProcedureDocument6 pagesHydro Test Procedurevijay padaleNo ratings yet

- Pneumatic TestDocument10 pagesPneumatic TestcrysNo ratings yet

- Certificate of Relief Valve Capacity (PROCA) 7 PDFDocument1 pageCertificate of Relief Valve Capacity (PROCA) 7 PDFAdeoye OkunoyeNo ratings yet

- Hydrostatic and Pneumatic Testing ProcedureDocument8 pagesHydrostatic and Pneumatic Testing ProcedurejorgekarlosprNo ratings yet

- Pneumatic Test Procedure for Industrial SuppliersDocument4 pagesPneumatic Test Procedure for Industrial SuppliersSalman Khan100% (1)

- Hydro Test ProceduresDocument6 pagesHydro Test ProcedureswillNo ratings yet

- CMM AutoQAL QAL1 TUVDocument6 pagesCMM AutoQAL QAL1 TUVMuhamad JemadiNo ratings yet

- Leak Test ProcedureDocument5 pagesLeak Test ProcedureAhmed AlaaNo ratings yet

- TUV SUD - PT Procedure Rev.05Document13 pagesTUV SUD - PT Procedure Rev.05HassanNo ratings yet

- ECE R110-ReceptaclesDocument29 pagesECE R110-ReceptaclessleonNo ratings yet

- Hydrostatico D2321186Document1 pageHydrostatico D2321186Iandeyara CarvalhoNo ratings yet

- Astec Valves Inspection Certificate SummaryDocument4 pagesAstec Valves Inspection Certificate SummaryShankar RajNo ratings yet

- Oily Water Separator Inspection CertificateDocument6 pagesOily Water Separator Inspection CertificateMohamed MohamedNo ratings yet

- Test Report QO7NG3051S30KW 1588883Document124 pagesTest Report QO7NG3051S30KW 1588883Nishant PandyaNo ratings yet

- Btanl0200rev2en 001Document13 pagesBtanl0200rev2en 001TajmirMahmudNo ratings yet

- Procedure For Vacuum Test Procedure For Tube To Tubesheet Joint - Rev.0 - 07.09.2020Document6 pagesProcedure For Vacuum Test Procedure For Tube To Tubesheet Joint - Rev.0 - 07.09.2020Aravind AravindNo ratings yet

- lTRF+IEC 61215-23A2 Part 1 of 2-Solar PanelDocument42 pageslTRF+IEC 61215-23A2 Part 1 of 2-Solar PanelGrupo CardogalNo ratings yet

- Beispiel EMPBDocument3 pagesBeispiel EMPBchandra9000No ratings yet

- MED(Module B)Document3 pagesMED(Module B)yucai.chenNo ratings yet

- By Sekar - Rajesh at 6:47 PM, Jun 17, 2015Document11 pagesBy Sekar - Rajesh at 6:47 PM, Jun 17, 2015Rahmat BasukiNo ratings yet

- Adco - Dodsal - Welspun: Inspection ReportDocument6 pagesAdco - Dodsal - Welspun: Inspection ReportejazalmNo ratings yet

- Quality Assurance Plan: Manufacturer'S Name & AddressDocument1 pageQuality Assurance Plan: Manufacturer'S Name & AddressEWTRNo ratings yet

- Test ReportDocument9 pagesTest ReportAlberto Aleman AquinoNo ratings yet

- Hydro Test Report for Air Heat ExchangerDocument1 pageHydro Test Report for Air Heat ExchangerChethan Nagaraju KumbarNo ratings yet

- BK91 1310 CPF VED 003 QAC H03 0001 - A NDE Procedure For Centrifugal PumpsDocument69 pagesBK91 1310 CPF VED 003 QAC H03 0001 - A NDE Procedure For Centrifugal PumpsPanneer SelvamNo ratings yet

- Test Report DM Proprietary 3473404Document43 pagesTest Report DM Proprietary 3473404Abram BaileyNo ratings yet

- Item Inspected: CBLT-TPI-00F-186-12623Document16 pagesItem Inspected: CBLT-TPI-00F-186-12623Zulfadli RaniNo ratings yet

- Nde Manual Nov 2010Document186 pagesNde Manual Nov 2010Navneet Singh100% (4)

- MD & LVD Test ReportDocument30 pagesMD & LVD Test Reportluke MaNo ratings yet

- Certificate of Absorbent RoHSDocument2 pagesCertificate of Absorbent RoHSprismatama.kreasindoNo ratings yet

- Dokumen Pengujian Tera HertzDocument57 pagesDokumen Pengujian Tera HertzAhmad HariyantoNo ratings yet

- Air Reciver Vessel-1 (Compressor Unit-2)Document5 pagesAir Reciver Vessel-1 (Compressor Unit-2)MD Shadikul Huq ShezanNo ratings yet

- Leak Test Proc DemoDocument7 pagesLeak Test Proc DemoroeslanteaNo ratings yet

- Pressure Test ProcedureDocument6 pagesPressure Test ProcedureAppleuk SudarNo ratings yet

- 583-9738 Procedure For Piping 00Document22 pages583-9738 Procedure For Piping 00sivaramNo ratings yet

- Hydrotesting Procedure Rev 4Document6 pagesHydrotesting Procedure Rev 4Rajesh K PillaiNo ratings yet

- Hidrostatic Test Procedure: Hafizul - HasrolDocument7 pagesHidrostatic Test Procedure: Hafizul - HasrolRafique MunirNo ratings yet

- Grinnell DNV Certificate PDFDocument3 pagesGrinnell DNV Certificate PDFAna Carolina SantosNo ratings yet

- 02 Durag DR290 enDocument11 pages02 Durag DR290 ensyahrial ramadhanNo ratings yet

- Pressure TestDocument10 pagesPressure TestRanus unarNo ratings yet

- DNV GL - SP568 - TAK00001HG - Exp 24 - 01 - 2024Document3 pagesDNV GL - SP568 - TAK00001HG - Exp 24 - 01 - 2024carlos ivan carvajal ortizNo ratings yet

- XNB-58 Protec-195 TC 20RSx20RS-195gsm Dark RedDocument5 pagesXNB-58 Protec-195 TC 20RSx20RS-195gsm Dark RedashrafbookNo ratings yet

- 135355-04-Pro-02-005 - Rev 01 - Hydrotest Procedure For Station PipingDocument19 pages135355-04-Pro-02-005 - Rev 01 - Hydrotest Procedure For Station PipingHanLe DuyNo ratings yet

- 9 Relief 2Document1 page9 Relief 2uceskaNo ratings yet

- 恒名HSS-CW LVD测试报告Document30 pages恒名HSS-CW LVD测试报告fabies84No ratings yet

- Pneumatic Test ProcedureDocument10 pagesPneumatic Test ProcedureahmadNo ratings yet

- Hydrostatic Test ChartDocument10 pagesHydrostatic Test ChartAnanda ShofwanNo ratings yet

- DNV-GL CertificateDocument3 pagesDNV-GL Certificategetfarhan786No ratings yet

- ANEXO7Document14 pagesANEXO7liuming farfanNo ratings yet

- NBES140100003101_unlockedDocument107 pagesNBES140100003101_unlockedFabiano SanchesNo ratings yet

- API 610 Hydrostatic TestDocument3 pagesAPI 610 Hydrostatic TestgabrielNo ratings yet

- Ped Certification ProcedureDocument7 pagesPed Certification Procedureabhinandan100% (1)

- Batch Test Certificate: Notes: 2. Form No: F/QC/008/1 3 Rev: 05/2022Document1 pageBatch Test Certificate: Notes: 2. Form No: F/QC/008/1 3 Rev: 05/2022gauravNo ratings yet

- Ultrasonic Testing Transmission Technique BSEN 583-3 PDFDocument11 pagesUltrasonic Testing Transmission Technique BSEN 583-3 PDFvancongthanhNo ratings yet

- Ov11 AetDocument41 pagesOv11 AetvancongthanhNo ratings yet

- Overviewfullmatrixcapture Totalfocusingmethod 170714164126 PDFDocument60 pagesOverviewfullmatrixcapture Totalfocusingmethod 170714164126 PDFvancongthanhNo ratings yet

- Ov01 PDFDocument30 pagesOv01 PDFnato2410No ratings yet

- 3 05 A Welding Specification of Carbon Steel Alloy SteelDocument40 pages3 05 A Welding Specification of Carbon Steel Alloy SteelvancongthanhNo ratings yet

- ASME B31 3 Code Case 181Document8 pagesASME B31 3 Code Case 181AkbarNo ratings yet

- Inconel Alloy 625Document18 pagesInconel Alloy 625Gustavo Palacios100% (1)

- Profile Laminate IPEDocument1 pageProfile Laminate IPEKarlaNo ratings yet

- Ped Pressure Equipment Certification PDFDocument8 pagesPed Pressure Equipment Certification PDFProkopNo ratings yet

- 4 6023697383601211598 PDFDocument232 pages4 6023697383601211598 PDFmahshid kianiNo ratings yet

- NJM3771D2Document9 pagesNJM3771D2mahdi elmayNo ratings yet

- Legris Compression Fitting With PLDocument36 pagesLegris Compression Fitting With PLhannahveluz_iasNo ratings yet

- Math in The Modern WorldDocument8 pagesMath in The Modern WorldMichael JoavanniNo ratings yet

- Cylinder Head: SpecificationsDocument5 pagesCylinder Head: SpecificationsFares100% (1)

- Linux Unit 4Document34 pagesLinux Unit 4Adeefa AnsariNo ratings yet

- Communication Education For AdultsDocument7 pagesCommunication Education For AdultsHaechan MarkNo ratings yet

- TD Tip Tinner PDFDocument2 pagesTD Tip Tinner PDFbehzadNo ratings yet

- Manual - de - Bolso - Fanuc 16i 18i 21i MODEL BDocument988 pagesManual - de - Bolso - Fanuc 16i 18i 21i MODEL BJeffsouza2016100% (4)

- LogicDocument6 pagesLogicpppppiiiiiNo ratings yet

- CCP403Document18 pagesCCP403api-3849444100% (1)

- GLA University - Student's No Dues DetailsDocument2 pagesGLA University - Student's No Dues DetailsRishi JakarNo ratings yet

- CBC-Tailoring NC IIDocument66 pagesCBC-Tailoring NC IICharmaine Mae RetizaNo ratings yet

- Method of Statement - Testing and CommissioningDocument1 pageMethod of Statement - Testing and CommissioningTiam Yee YongNo ratings yet

- RESUMEDocument3 pagesRESUMEravi 1234No ratings yet

- PA 201 Course SyllabusDocument9 pagesPA 201 Course SyllabusFayyaz DeeNo ratings yet

- Implantable Technology: History, Controversies, and Social ImplicationsDocument11 pagesImplantable Technology: History, Controversies, and Social ImplicationssolomongNo ratings yet

- Jack Welch's Leadership Transforms GEDocument2 pagesJack Welch's Leadership Transforms GEkimNo ratings yet

- فايبر L.3Document13 pagesفايبر L.3Alaa AdeebNo ratings yet

- BP B1 Tests Unit1Document6 pagesBP B1 Tests Unit1JovanaNo ratings yet

- Panasonic CX 491 P Datasheet PDFDocument24 pagesPanasonic CX 491 P Datasheet PDFGanesh MandpeNo ratings yet

- Dynamic Modeling of Variable Ballast Tank For Spherical Underwater RobotDocument6 pagesDynamic Modeling of Variable Ballast Tank For Spherical Underwater RobotRaseem VpNo ratings yet

- Anatomy of FirearmsDocument9 pagesAnatomy of Firearmswerdna67No ratings yet

- Universal Summit Nozzles Data SheetDocument2 pagesUniversal Summit Nozzles Data SheetNordson Adhesive Dispensing SystemsNo ratings yet

- Laguna Kosmetik MC1 PlusDocument2 pagesLaguna Kosmetik MC1 PlusLaguna Karaoke TarakanNo ratings yet

- JAA ATPL BOOK 02 - Oxford Aviation - Jeppesen - Airframes and SystemsDocument421 pagesJAA ATPL BOOK 02 - Oxford Aviation - Jeppesen - Airframes and SystemsRicardo BorbaNo ratings yet

- Taper Roller BearingDocument130 pagesTaper Roller BearingAbhishek KumarNo ratings yet

- Project Review: Arun III Hydroelectric Project: Background Location and AccessibilityDocument2 pagesProject Review: Arun III Hydroelectric Project: Background Location and AccessibilitySachin ChakradharNo ratings yet

- Powerdrive X6: Rotary Steerable System For High-Performance Drilling and Accurate Wellbore PlacementDocument6 pagesPowerdrive X6: Rotary Steerable System For High-Performance Drilling and Accurate Wellbore PlacementClOudyo VirgílioNo ratings yet

- Mann KendallDocument4 pagesMann KendallOm Prakash SahuNo ratings yet