Professional Documents

Culture Documents

Quality Assurance Plan: Manufacturer'S Name & Address

Uploaded by

EWTROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Assurance Plan: Manufacturer'S Name & Address

Uploaded by

EWTRCopyright:

Available Formats

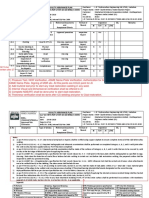

MANUFACTURER’S QUALITY ASSURANCE PLAN Purchaser : L & T Hydrocarbon Engineering Ltd (LTHE), Vadodara

NAME & ADDRESS

QAP NO: B016-RUF-LT-504-QC-QD-BHEL(1)-02006 Project Name: VRMP-Visakh Refinery Modernisation Project

BHEL- Rev.0 Customer : Hindustan Petroleum Corporation Limited- Visakhapatnam

VISAKHAPATNAM or Date : 29-08-2020 PMC : Engineers India Limited (EIL)

Approved Sub Page 16 of 16 EIL Job No. : B 016

Contractor. BHEL SO: 2438; Internal CQP No: 2499 L & T Job No.& PO No.: RUFV & REFINERY/75000-66912/NG Dt.18-03-2020

S. No Description Type of Checks Reference Documents Format of Inspection EIL Remarks

and Record M TUV AI LTHE

Acceptance Criteria

Notes:

1) As per PVM-SU-1322-H.1 – 6.3.7: Clad removal (strip back or repairs) shall be verified using copper sulphate to ensure complete removal of the clad before alloy

welding.

2) As per PVM-SU-1322-H.1 – 9.1.3: Required radiographic and ultrasonic examinations shall be performed on completed Category A, B, C, and D weld joints after

the weld overlay has been applied and any PWHT has been completed.

3) As per PVM-SU-1322-H.1 – 9.1.2: Magnetic particle examination shall be made of the surfaces of Category A, B, C, and D welds that are to be covered by weld

overlay at the last stage of fabrication prior to applying the overlay.

4) As per 6-12-0007 Rev. 4 (Supplementary specification for Clad Vessels Clause No.: 5.3 - Weld joint in the base plate shall be radiographed as specified in engg.

Drawing / data sheet for detection of cracks/flows before clad side welding is carried out. Just before clad restoration welding, the prepared surface shall be

inspected by 100% dye penetrant testing.

5) As per 6-12-0007 Rev. 4 (Supplementary specification for Clad Vessels Clause No.: 6.1.4 - 100% Ultrasonic test shall be carried out of areas where attachments

are to be welded directly to the cladding. The above areas shall include 50 mm.

6) As per PVM-SU-1322-H.1 – 9.2.2: UT according to ASME Code, Section II, SA 578, shall be made of clad plates within 1T (1 × total clad + base material plate

thickness) of the edges to be welded, and covering an area extending 1T from load-bearing internal attachments designated on the vessel drawing.

7) PQR qualification shall be as per Licensor Specification No.: PVM-SU-5004-I, Clause No.: 8.2 & 11.2.

8) As per PVM-SU-1322-H.1 – 9.3.3.1: The completed vessel bulk weld overlay (primary method of applying the internal corrosion-resistant lining) shall be checked

for bond flaw indications after PWHT by UT in accordance with ASME Code, Section II, SA 578).

9) As per PVM-SU-1322-H.1 – 9.3.4.2: Prior to any heat treatment including PWHT, PT of the entire surface shall be performed in accordance with mandatory

appendix 8 of ASME Code, Section VIII, Div. 1 or Section VIII, Div. 2, as applicable.

Legends:

P: Perform Draw ing : Approved Draw ing W PS: W elding procedure specification DFT: Dry film thickness

A-Approval Spec : Specification W PQ; W elder performance Qualification RT: Radiographic testing

W -W itness LS: Longitudinal Seam w elding TUV: TUV India Pvt Ltd., (Third party UT: Ultrasonic testing manual

RW : Random W itness M -BHEL or BHEL approved sub-contractor inspection agency appointed by M / s PT: Dye penetrant testing

H: Hold IRN: Inspection release note issued by TUV LTHE M PT: M agnetic particle testing

V: Verification of reports/ Procedures HT Chart: Heat Treatment chart R: Review

please include the above

requirements as ITP stages

You might also like

- ITP For MCC - HV - LV-switchgear Boards-PaneDocument2 pagesITP For MCC - HV - LV-switchgear Boards-Panerodel100% (1)

- SB 1803 R2 Operating TBO & HSI FrequencyDocument22 pagesSB 1803 R2 Operating TBO & HSI FrequencyDade Sobarna100% (4)

- 7 AC43-3 Non Destructive Testing PDFDocument33 pages7 AC43-3 Non Destructive Testing PDFHashib Hawa100% (2)

- 2014-4968-1L-1002 - Rev. D HVAC Specification For LQ ModuleDocument60 pages2014-4968-1L-1002 - Rev. D HVAC Specification For LQ ModuleArshavin Watashi Wa100% (1)

- Endorsement Sheet For QP: Reference / Standard / Field Quality Plan (RQP / SQP/RFQP/SFQP) To Be Filled in by NTPCDocument33 pagesEndorsement Sheet For QP: Reference / Standard / Field Quality Plan (RQP / SQP/RFQP/SFQP) To Be Filled in by NTPCEzhil Vendhan Palanisamy100% (1)

- Qcp-Pipeline ConstructionDocument20 pagesQcp-Pipeline Constructionbelhaska100% (2)

- LREF-00-VDR-BBB-PR-20-0020-A4 Procedure For Process Piping Golden Joint Fabrication, Inspection, and Final AcceptanceDocument10 pagesLREF-00-VDR-BBB-PR-20-0020-A4 Procedure For Process Piping Golden Joint Fabrication, Inspection, and Final AcceptanceNauval Labiby Noor MohammadNo ratings yet

- Inspection and Test Plan For LNG Tank InstallationDocument26 pagesInspection and Test Plan For LNG Tank InstallationjorgekarlosprNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- To 33B-1-1 2010Document794 pagesTo 33B-1-1 2010jfaitakNo ratings yet

- Astm e 1220Document6 pagesAstm e 1220KEN KNo ratings yet

- Quality Assurance Plan: Manufacturer'S Name & AddressDocument2 pagesQuality Assurance Plan: Manufacturer'S Name & AddressEWTRNo ratings yet

- HIC & SSC Test ProcedureDocument32 pagesHIC & SSC Test ProcedureMohamed FarisNo ratings yet

- Annexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Document15 pagesAnnexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Sravan DasariNo ratings yet

- 03 220 66 KV Xmer On Line Nifes r5 No QR Jun 11Document86 pages03 220 66 KV Xmer On Line Nifes r5 No QR Jun 11kvramanan_1No ratings yet

- DBB BNCPP B M v29 0015 Revb IfaDocument6 pagesDBB BNCPP B M v29 0015 Revb IfaIzzadAfif1990No ratings yet

- TGT PVCMS Q XXX PR 0012 - Dimensional Procedure B0Document18 pagesTGT PVCMS Q XXX PR 0012 - Dimensional Procedure B0ngtchungNo ratings yet

- 60-00-Qm-Itp-00039 - 0001 - 0 ITP PipingDocument109 pages60-00-Qm-Itp-00039 - 0001 - 0 ITP PipingTauqeer SalimNo ratings yet

- 003 ITP UG PipingDocument4 pages003 ITP UG Pipingrvsingh70100% (1)

- 02 MechanicalDocument44 pages02 MechanicalSigit Bintan100% (1)

- M BCW 1F4TS0 CFFF Wir 000330 - 000Document18 pagesM BCW 1F4TS0 CFFF Wir 000330 - 000afsalmechenggNo ratings yet

- (732-Itp-40 (V-6905) 42000-SNG-69-42000P-MS-5733-504-0000-06Document10 pages(732-Itp-40 (V-6905) 42000-SNG-69-42000P-MS-5733-504-0000-06sathi11189No ratings yet

- Ut - Bhe Nde Nu 700mw RH RT Rev 00 Latest Ut Procedure 14-02-2014Document17 pagesUt - Bhe Nde Nu 700mw RH RT Rev 00 Latest Ut Procedure 14-02-2014JoelNo ratings yet

- Lvac-Sat Procedure For Equipment Test-Ss1Document39 pagesLvac-Sat Procedure For Equipment Test-Ss1Balamurugan SelvarajNo ratings yet

- MS of Static Load Testing (Rev.C)Document17 pagesMS of Static Load Testing (Rev.C)Pham Quan TamNo ratings yet

- O 293 0 2017-Ind Ni T of e An Rene Ble Ner Ind Er I Ion Bloc Ompl Lo I Road, H 0003 Dated: U T, 2018 O OR ND: ND in U Ono T An Fac U Er oDocument2 pagesO 293 0 2017-Ind Ni T of e An Rene Ble Ner Ind Er I Ion Bloc Ompl Lo I Road, H 0003 Dated: U T, 2018 O OR ND: ND in U Ono T An Fac U Er oShajahan ShariefNo ratings yet

- Inspection & Test Plan FOR Concrete Work: Equipment Description: NADocument40 pagesInspection & Test Plan FOR Concrete Work: Equipment Description: NAYuvaraj PonrajNo ratings yet

- 07 Sec VIII-D1-NDE (Rev 1) PDFDocument32 pages07 Sec VIII-D1-NDE (Rev 1) PDFnguyenvanphu197776% (17)

- Welding Inspection Ass 1Document7 pagesWelding Inspection Ass 1mohd as shahiddin jafriNo ratings yet

- Indian Railways: S No. Date/month of Issue Revision /amendment No. Reasons of RevisionDocument24 pagesIndian Railways: S No. Date/month of Issue Revision /amendment No. Reasons of RevisionPremchand BeuraNo ratings yet

- Additional Scope of Work: Bharat Heavy Electricals LimitedDocument16 pagesAdditional Scope of Work: Bharat Heavy Electricals LimitedSravan DasariNo ratings yet

- Itp - Rev eDocument36 pagesItp - Rev ezaki_saddarNo ratings yet

- This Document Is The Property of CORRTECH. It Should Not Be Used, Copied or Reproduced Without Their Written PermissionDocument10 pagesThis Document Is The Property of CORRTECH. It Should Not Be Used, Copied or Reproduced Without Their Written PermissionVidyut UjalaNo ratings yet

- Hydro TestingDocument26 pagesHydro TestingMahaveer SinghNo ratings yet

- S-41-1224-001WR - Rev 1Document38 pagesS-41-1224-001WR - Rev 1heri_prasetyadiNo ratings yet

- Docu Ent Sub Ittal Sheet: Qatar Armed Forces Qatar Emiri Corps of EngineeringDocument20 pagesDocu Ent Sub Ittal Sheet: Qatar Armed Forces Qatar Emiri Corps of EngineeringMohameduwais Badurdeen Haqqiyul QadiriNo ratings yet

- Repair Procedure ANNEXUREDocument16 pagesRepair Procedure ANNEXUREShaikh AdilNo ratings yet

- R272pfci30 RDG e Pro 0001 Rev A2Document11 pagesR272pfci30 RDG e Pro 0001 Rev A2Muralimohan PandianNo ratings yet

- (Refer Annexure-I) (Refer Annexure-I) (Refer Annexure - I)Document10 pages(Refer Annexure-I) (Refer Annexure-I) (Refer Annexure - I)Manish ThakurNo ratings yet

- 02 MechanicalDocument44 pages02 Mechanicalmusaismail8863No ratings yet

- 32-Ve-711 (Hydrostatic Test Procedure Piping - FT Gas) A11 PDFDocument5 pages32-Ve-711 (Hydrostatic Test Procedure Piping - FT Gas) A11 PDFMarlon TurnerNo ratings yet

- Remote Field Eddy Current Testing Report: Address: Alpha Inspection JSC (Alphandt)Document28 pagesRemote Field Eddy Current Testing Report: Address: Alpha Inspection JSC (Alphandt)luu cong son ndtNo ratings yet

- A05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C DDocument14 pagesA05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C Dbingmin100% (4)

- IAP Structure WorkDocument64 pagesIAP Structure Workmanu_giteNo ratings yet

- Failure Analysis ReportDocument14 pagesFailure Analysis ReportpramodkumarNo ratings yet

- WMS-002 Pile Driving by Pile-Driving Barge REV.ADocument136 pagesWMS-002 Pile Driving by Pile-Driving Barge REV.AVan Cuong PhamNo ratings yet

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresNo ratings yet

- Duqm Refinery Project EPC Package OneDocument22 pagesDuqm Refinery Project EPC Package OnePrashant KumarNo ratings yet

- R05323 P 001a X009 0042 PDFDocument464 pagesR05323 P 001a X009 0042 PDFcquibajoNo ratings yet

- Acr Pathfinder 3 Sart Module BDocument4 pagesAcr Pathfinder 3 Sart Module BbaburaoNo ratings yet

- Inspection Report: 150 MW Dhamangaon Solar Project, MaharashtraDocument6 pagesInspection Report: 150 MW Dhamangaon Solar Project, Maharashtrakaushik21185No ratings yet

- Annexure 3 - Indicative Inspection Test PlanDocument3 pagesAnnexure 3 - Indicative Inspection Test PlanBob Kmn0% (1)

- Annexure III Scope of Work and Special ConditionsDocument7 pagesAnnexure III Scope of Work and Special Conditionsraj1508No ratings yet

- Method Statement Risk Assessment Form: DSP - Tecom K22-006Document14 pagesMethod Statement Risk Assessment Form: DSP - Tecom K22-006Sharvin NageebNo ratings yet

- Pneumatic TestDocument10 pagesPneumatic TestcrysNo ratings yet

- Coupler Plate DP TestDocument1 pageCoupler Plate DP Testshindemitesh17No ratings yet

- QAP of HT Breaker Panel SchneiderDocument1 pageQAP of HT Breaker Panel Schneidermadhu_bedi12No ratings yet

- HFY 3800 0000 VED 192 QC PD 0004 - A Hardness Test Procedure - Code BDocument14 pagesHFY 3800 0000 VED 192 QC PD 0004 - A Hardness Test Procedure - Code BMohamed FarisNo ratings yet

- NDE NDT Procedures Piping ADM 35313M-01 Q 153 01Document392 pagesNDE NDT Procedures Piping ADM 35313M-01 Q 153 01Neil JavierNo ratings yet

- NDE NDT Procedures Piping ADM 35313M-01 Q 153 01-1-150Document150 pagesNDE NDT Procedures Piping ADM 35313M-01 Q 153 01-1-150QC ManagerNo ratings yet

- Shic A 0008Document3 pagesShic A 000801095902062ahmedNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- 4 Binder4Document3 pages4 Binder4EWTRNo ratings yet

- (Kmatk Mkyus Osq Fy, Mkej Fof'Kf"V: HKKJRH EkudDocument6 pages(Kmatk Mkyus Osq Fy, Mkej Fof'Kf"V: HKKJRH EkudKO PNo ratings yet

- Revision No: F1 20-Oct-09 2 of 3 Equipment Data Sheet Pressure Vessel PDRP4220-8430-DS-086-2022Document2 pagesRevision No: F1 20-Oct-09 2 of 3 Equipment Data Sheet Pressure Vessel PDRP4220-8430-DS-086-2022EWTRNo ratings yet

- 3Document5 pages3EWTRNo ratings yet

- (Kmatk Mkyus Osq Fy, Mkej Fof'Kf"V: HKKJRH EkudDocument6 pages(Kmatk Mkyus Osq Fy, Mkej Fof'Kf"V: HKKJRH EkudKO PNo ratings yet

- Paving Grades SL No. Characteristics Method of Test, Ref ToDocument3 pagesPaving Grades SL No. Characteristics Method of Test, Ref ToEWTRNo ratings yet

- Bureau of Indian Standards: Telephones Website TelephonesDocument1 pageBureau of Indian Standards: Telephones Website TelephonesEWTRNo ratings yet

- Liquid-Penetrant-Testing-Level-1-Non-Destructive-Testing-And-Evaluation (Set 1)Document22 pagesLiquid-Penetrant-Testing-Level-1-Non-Destructive-Testing-And-Evaluation (Set 1)mishrateertharajNo ratings yet

- Mandatory: Bollettino TecnicoDocument61 pagesMandatory: Bollettino TecnicoAgustaNo ratings yet

- ME6019 - NON DESTRUCTIVE TESTING AND MATERIALS MCQ PadeepzDocument13 pagesME6019 - NON DESTRUCTIVE TESTING AND MATERIALS MCQ PadeepzAjithNo ratings yet

- Chapter 5 - Penetrant Testing - 2016 - Applied Welding EngineeringDocument8 pagesChapter 5 - Penetrant Testing - 2016 - Applied Welding EngineeringJhair Jhamidh Aquino PortocarreroNo ratings yet

- Sec V B SE 165-LPEDocument23 pagesSec V B SE 165-LPEAshish PatelNo ratings yet

- Lesson Five: The Final Steps in The Penetrant ProcessDocument12 pagesLesson Five: The Final Steps in The Penetrant ProcessAnonymous j3PiA3xNo ratings yet

- Curso de Motores Sistema de Combustible - CATDocument42 pagesCurso de Motores Sistema de Combustible - CATAnonymous tipWjHGVGNo ratings yet

- gs102 3Document9 pagesgs102 3medodedo2010100% (1)

- Important Questions ME8097-Non Destructive Testing and EvaluationDocument16 pagesImportant Questions ME8097-Non Destructive Testing and Evaluationpaneer selvamNo ratings yet

- Southern Inspection Services: Liquid Penetrant Testing Level Ii - QuestionsDocument8 pagesSouthern Inspection Services: Liquid Penetrant Testing Level Ii - QuestionskingstonNo ratings yet

- Forks & Accessories: Product SpecialDocument20 pagesForks & Accessories: Product Specialbara muhammadNo ratings yet

- Mex 10407Document28 pagesMex 10407Yousef Adel HassanenNo ratings yet

- Magnaflux CatalogueDocument52 pagesMagnaflux CatalogueAhmad DanielNo ratings yet

- Dye Penetrant TestDocument4 pagesDye Penetrant Testarunkumarnoola100% (1)

- API 16C Choke and KillDocument26 pagesAPI 16C Choke and Killrps197750% (2)

- Failure Analysis ReportDocument14 pagesFailure Analysis ReportpramodkumarNo ratings yet

- Astm e 1417pdfDocument12 pagesAstm e 1417pdfShabbir aliNo ratings yet

- 01 NDT Preliminary Report GT4 Bearing Inspection Oct2017Document33 pages01 NDT Preliminary Report GT4 Bearing Inspection Oct2017Puvaneswary VasuthevanNo ratings yet

- Liquid Penetrant Inspection 50 Question QuizDocument10 pagesLiquid Penetrant Inspection 50 Question QuizAnonymous gFcnQ4go100% (6)

- ASTM E1418-16 Standard Practice For Visible Penetrant Testing Using The Water-Washable ProcessDocument6 pagesASTM E1418-16 Standard Practice For Visible Penetrant Testing Using The Water-Washable ProcessLucas MlbNo ratings yet

- Comparing Various NDT TechniquesDocument4 pagesComparing Various NDT TechniquesfenasikerimNo ratings yet

- ITER Vacuum HandbookDocument46 pagesITER Vacuum HandbookvladimirNo ratings yet

- PT Acceptance CriteriaDocument8 pagesPT Acceptance Criteriaankit7588No ratings yet

- 4.1 PT Procedure ASME VIII Rev. 0 For KESB Tangguh Expansion ProjectDocument10 pages4.1 PT Procedure ASME VIII Rev. 0 For KESB Tangguh Expansion ProjectSiriepathi SeetharamanNo ratings yet

- Liquid Penetrant Testing Topical OutlinesDocument4 pagesLiquid Penetrant Testing Topical OutlinesJose Andres ContrerasNo ratings yet

- LPT Spe Level II Exam QBDocument10 pagesLPT Spe Level II Exam QBAruchamy SelvakumarNo ratings yet

- Cheatsheet YqDocument2 pagesCheatsheet YqTanamate Yong Qin FooNo ratings yet