Professional Documents

Culture Documents

Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) Remarks

Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) Remarks

Uploaded by

VAIBHAV INSTRUMENTATIONOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) Remarks

Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) Remarks

Uploaded by

VAIBHAV INSTRUMENTATIONCopyright:

Available Formats

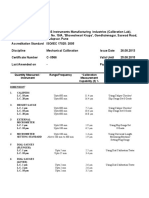

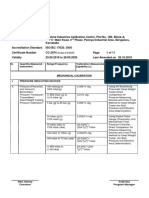

Laboratory S. M.

Engineers, 1210/B, Sadashiv Peth, Indira Apartment, Pune,

Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2639 (in lieu of C-0114, C-1366) Page 1 of 12

Validity 05.02.2018 to 04.02.2020 Last Amended on 13.04.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

MECHANICAL CALIBRATION

I. DIMENSION (BASIC MEASURING INSTRUMENT, GAUGE ETC.)

1. Caliper (Dial/Digital)$ 0 to 300 mm 8.0 µm Using Slip Gauges,

L.C.: 0.01 mm 0 to 450 mm 10.0 µm Length Bars

0 to 600 mm 12.0 µm Length Measuring

0 to 1000 mm 15.0 µm Machine (LMM) By

0 to 1500 mm 20.0 µm Comparison Method

As per IS: 3651

L.C.: 0.02 mm 0 to 2000 mm 25.0 µm Part-I, II & III and

NABL-122-01

2. Depth Vernier$ 0 to 300 mm 10.0 µm Using Slip Gauges &

L.C.: 0.01 mm 0 to 600 mm 12.0 µm Length Measuring

Machine (LMM) By

Comparison Method

As per IS : 4213 and

NABL-122-01

3. External Micrometer$ 0 to 25 mm 1.5 µm Using Micrometer

L.C.: 0.001 mm 25 mm to 100 mm 2.0 µm Checking Set & Length

100 mm to 200 mm 3.0 µm Bars By Comparison

200 mm to 600 mm 5.1 µm Method As per IS: 2967

600 mm to 1000 mm 6.0 µm and NABL-122-01

4. Hole Test 3 mm to 200 mm / 0.001 3 µm Using Plain Ring

Micrometer/ Three Gauges Set By

Point Micrometer$ Comparison Method

5. Inside Micrometer$ Micrometer Head Using Length Measuring

(Stick Micrometer) Up to 50 mm 2 µm Machine (L.M.M.) By

L.C.: 0.001 mm Up to 250 mm 3 µm Comparison Method

As per I.S. 2966 &

NABL-122-01

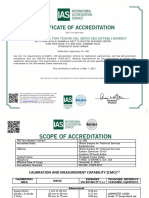

Ashish Kakran Avijit Das

Convenor Program Director

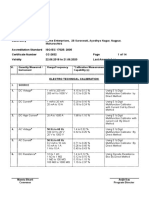

Laboratory S. M. Engineers, 1210/B, Sadashiv Peth, Indira Apartment, Pune,

Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2639 (in lieu of C-0114, C-1366) Page 2 of 12

Validity 05.02.2018 to 04.02.2020 Last Amended on 13.04.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Extension Rod / Up to 300 mm 3.5 µm Using Length Measuring

Overall Length$ Up to 1000 mm 6.0 µm Machine (L.M.M.) By

Comparison Method

6. Dial Gauge$ 0 to 1 mm 1 µm Using Electronics Dial

(Plunger Type) 0 to 10 mm 1.5 µm Tester By Comparison

L.C.: 0.0005/ 0 to 25 mm 2.8 µm Method As per IS 2092

0.001 mm & NABL-122-01

0 to 50 mm 3.0 µm Using Length Measuring

0 to 100 / 200 mm 3.0 µm Machine

7. Dial Gauge$ 0 to 0.2 mm / 0.001 2.7 µm Using Electronics Dial

(Lever Type) 0 to 2.0 mm / 0.01 4.0 µm Tester By Comparison

Method As per IS: 11498

& NABL-122-01

8. Micrometer Up to 100 mm 1.2 µm Using Slip Gauges,

Setting Bar / 100 mm to 300 mm 3.0 µm Electronic Comparator,

Setting Masters$ 300 mm to 1000 mm 7.0 µm Length Bars, Profile

Projector etc. By

Comparison Method

9. Plain Plug Gauge / Up to 25 mm 1.1 µm Using Slip Gauges,

Taper Plug Gauge$ 25 mm to 100 mm 2.5 µm Electronic Comparator,

100 mm to 300 mm 1.5 µm L.M.M By Comparison

Half Included angle 20 sec of arc. Method As per IS: 3455 ,

Up to 60 ° IS: 2251, IS: 9475

IS: 9529 & NABL-122-01

10. Snap Gauge$ 3 mm to 25 mm 0.8 µm Using Slip Gauges &

25 mm to 100 mm 1.2 µm L.M.M & By Comparison

100 mm to 750 mm 5.4 µm Method As per IS: 3455

& NABL-122-01

Ashish Kakran Avijit Das

Convenor Program Director

Laboratory S. M. Engineers, 1210/B, Sadashiv Peth, Indira Apartment, Pune,

Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2639 (in lieu of C-0114, C-1366) Page 3 of 12

Validity 05.02.2018 to 04.02.2020 Last Amended on 13.04.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

11. Plain Ring Gauge / 3 mm to 25 mm 1.5 µm Using Setting Ring

Taper Ring Gauge$ 25 mm to 100 mm 2.0 µm Gauges & Length

100 mm to 300 mm 2.5 µm Measuring Machine By

Half Included angle 30 sec of arc. Comparison Method As

Up to 60 ° per IS: 3455,

IS: 2251, IS:9475 &

NABL-122-01

12. Measuring Pins$ Up to 20 mm 1.2 µm Using Length Measuring

Machine By Comparison

Method As per

IS :11103 &

NABL-122-01

13. Thread Measuring 0.17 mm to 6.35 mm 1.2 µm Using Length Measuring

Wires$ Machine By Comparison

Method As per IS: 6311

& NABL-122-01

14. Feeler Gauge$ Up to 2 mm 1.2 µm Using Length Measuring

Machine By Comparison

Method As per IS : 3179

& NABL-122-01

15. Thickness Gauge$ 0 to 50 mm / 0.01 3.0 µm Using Slip Gauge Set &

50 mm to 100 mm / 0.01 7.0 µm By Comparison Method

16. Pistol Caliper $ 0 to 100 mm / 0.1 mm 58.0 µm Using Slip Gauge Set

By Comparison Method

17. Thickness Foils$ 0 to 2 mm 1.2 µm Using Electronic

Comparator By

Comparison Method

18. Coating Thickness 0 to 2 mm 6.0 µm Using Thickness Foils

Gauge$ By Comparison Method

Ashish Kakran Avijit Das

Convenor Program Director

Laboratory S. M. Engineers, 1210/B, Sadashiv Peth, Indira Apartment, Pune,

Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2639 (in lieu of C-0114, C-1366) Page 4 of 12

Validity 05.02.2018 to 04.02.2020 Last Amended on 13.04.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

19. Measuring Scale$ Up to 2 mtr (150*√2L) µm Using Length Measuring

For each additional L in meters Machine By Comparison

meter Method As per IS 3481

& NABL -122-01

20. Measuring Tape / 0 to 50 mtr (150*√2L) µm Using Length Measuring

PI Tape$ For each additional For any length, Machine By Comparison

0.5 Mtr L in m or first 0.5 m Method As per IS1269 &

(150*√2L) µm NABL -122-01

21. Height Gauge$ 0 to 300 mm 8 µm Using Slip Gauges &

(Dial / Digital/ Analog) 0 to 600 mm 10 µm Length Bars By

L.C.: 0.01 mm 0 to 1000 mm 15 µm Comparison Method

As per IS 2921 &

NABL-122-01

22. Dial Calibration 0 to 25 mm / 0.0001 mm 2 µm Using Slip Gauge,

Tester$ Electronic Probe By

Comparison Method

As per NABL-122-01

23. Thread Plug Gauge$ Up to 300 mm 3 µm Using Length Measuring

Machine

24. Taper Thread Plug Half included angle 3√2 µm By Comparison Method

Gauges$ Up to 60º As per I.S.:4218 &

NABL-122-01

25. Thread Ring Gauge$ Up to 300 mm 4 µm Using Length Measuring

Machine

26. Taper Thread Ring Half included angle upto 4√2 µm By Comparison Method

Gauge$ 60º As per I.S.:4218 &

NABL-122-01

Ashish Kakran Avijit Das

Convenor Program Director

Laboratory S. M. Engineers, 1210/B, Sadashiv Peth, Indira Apartment, Pune,

Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2639 (in lieu of C-0114, C-1366) Page 5 of 12

Validity 05.02.2018 to 04.02.2020 Last Amended on 13.04.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

27. Bore Gauge$ Only 2 mm 2 µm Using Length Measuring

L.C.: 0.001 / 0.01 mm Transmission Machine By Comparison

Mechanism Only Method As per

NABL-122-01

28. Angle Gauge 0º to 90º 3 min. Using Sine Setting

Bevel Protractor 0º to 360º Device Angle Gauge

Inclinometer$ Blocks As per IS 4239 &

NABL-122-01

29. Angle Gauge / 0 to 90º 20 sec. Using Sine Setting

Setting Gauge$ 0º to 180º Device Angle Gauge

Blocks & Slip Gauge &

Profile Projector As per

IS 4239 & NABL-122-01

30. Combination Set 0 to 360º 35 min. Using Slip Gauge Set

Angle Protractor$ Profile Projector

As per IS 4239 &

NABL-122-01

31. Radius Gauge$ Up to 100 mm 10 µm Using Profile Projector

By Comparison Method.

As per IS 5237 &

NABL-122-01

32. Thread Pitch Gauge$ 55, 60º 10 min Using Profile Projector

Pitch 0.3 mm to 6 mm 10 µm By Comparison Method.

As per I.S.4211 &

NABL-122-01

33. Comparator Stand$ Up to 300 mm 5.05 µm Using Plunger Dial

By Comparison Method.

As per I.S. 7599

Ashish Kakran Avijit Das

Convenor Program Director

Laboratory S. M. Engineers, 1210/B, Sadashiv Peth, Indira Apartment, Pune,

Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2639 (in lieu of C-0114, C-1366) Page 6 of 12

Validity 05.02.2018 to 04.02.2020 Last Amended on 13.04.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

34. Right Angle / 0 to 300 mm 11.4 µm Using V-Block, Plunger

Engineer’s Square$ 0 to 600 mm Dial, Master Cylinder,

S.P & Height Master

By Comparison Method.

As per I.S. 2103 &

NABL-122-01

35. V Block For Using Plunger Dial &

Parallelism 150 mm 5.7 µm Mandrel By Comparison

Squareness 150 mm 5.6 µm Method As per IS 2949

Symmetricity$ 150 mm 5.8 µm & NABL-122-01

36. Straight Edge$ Up to 5 mtr. 1.65 x (L+W /100) µm Using Digital Level

Meter & Slip Gauge

By Comparison Method.

As per IS 2220, IS12937

& NABL-122-01

37. Angle Plate$ Up to 500 mm 8.0 µm Using Plunger Dial &

Surface Plate

By Comparison Method.

As per I.S. 2554 IS 6232

& NABL-122-01

38. Glass Scale$ Up to 10 mm 3.0 µm Using L.M.M / By

Up to 300 mm 5.0 µm Comparison Method

& NABL-122-01

39. Test Sieve$ 20 µm to 100 mm 11.3 µm Using Profile Projector

By Comparison Method.

As per IS :460 Part.-I,

II & III & NABL-122-01

40. Electronic 0 to 25 mm 0.52 µm Using Slip Gauge Set

Comparator With By Comparison Method.

Probe$ NABL- 122- 01

Ashish Kakran Avijit Das

Convenor Program Director

Laboratory S. M. Engineers, 1210/B, Sadashiv Peth, Indira Apartment, Pune,

Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2639 (in lieu of C-0114, C-1366) Page 7 of 12

Validity 05.02.2018 to 04.02.2020 Last Amended on 13.04.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

41. Digital Height 0 - 600 mm / 0.0001 4.0 µm Using Slip Gauge Set,

Master# 0 - 1000 mm / 0.0001 8.7 µm Length Bar By

Comparison Method

NABL- 122- 01

42. Surface Plate# Up to 3 m x 3 m 3.0* (√2 L+W )/100 Using Electronic Level

(Flatness) ( Grade 0 / I / II ) (L & W are in mm) By Comparison Method

(Grade 0/I/II) As per IS 2285,

IS 7327 & NABL -122-01

43. Depth Micrometer$ 0 to 100 mm / 0.001 3.0 µm Using Length Measuring

L.C.: 0.001 mm 0 to 300 mm / 0.01 8.0 µm Machine Micrometer

L.C.: 0.01 mm Checking Set By

Comparison Method

As per BS : 6468 &

NABL-122-01

44. Surface Roughness$ Using Surface

a. Tester Up to 6.3 µm 8.0 % Roughness Specimen,

b. Test Block 7.5 % Reference Depth Master

(Specimens) By Comparison Method

As per IS : 3073,

IS:10707

NABL-122-01

45. Spherical Diameter$ 1 mm to 100 mm 2.8 µm Using Electronic

Comparator By

Comparison Method

As per NABL-122-01

46. Caliper Checker$ Up to 600 mm 3.0 µm Using Slip Gauge Set

Up to 1000 mm 7.41 µm and Length Bar

By Comparison Method

Ashish Kakran Avijit Das

Convenor Program Director

Laboratory S. M. Engineers, 1210/B, Sadashiv Peth, Indira Apartment, Pune,

Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2639 (in lieu of C-0114, C-1366) Page 8 of 12

Validity 05.02.2018 to 04.02.2020 Last Amended on 13.04.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

47. Spirit Level / Using Slip Gauge Set

Square Type$ By Comparison Method

L.C.: 0.02 mm / Meter Up to 300 mm 8.0 µm As per NABL-122-01

II. DIMENSION (PRECISION INSTRUMENTS)

1. Profile Projector / Up to 25 mm - Linear 2.0 µm Using Glass Scale,

Optical Microscope# Up to 300 mm - Linear 7.6 µm Angle Gauge Set By

0 to 360 º - Angular 5 min. Comparison Method

Up to 1000 X – 0.5 % As per NABL-122-01

Magnification

III. PRESSURE INDICATING DEVICES

1. Hydraulic Pressure# 0 to 40 bar 0.15 bar Using Digital Test

Gauge (Dial/Digital) 40 bar to 700 bar 1.1 bar Gauge & Pump

By Comparison Method

DKD-R6-1 &

NBAL-122-13

IV. WEIGHING SCALE AND BALANCE

1. Electronic 20 g to 5 kg 2g Using F-2 Class

Weighing Balance♣ (d ≥ 1 g ) 20 g Standards Weights

200 g to 50 kg 1 mg- 200 g &

(d ≥ 10 g ) M1 Class Weights

1 to 50 kg Calibration of

class 3 Weighing

Balance and courser

as per OIML R-76

Ashish Kakran Avijit Das

Convenor Program Director

Laboratory S. M. Engineers, 1210/B, Sadashiv Peth, Indira Apartment, Pune,

Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2639 (in lieu of C-0114, C-1366) Page 9 of 12

Validity 05.02.2018 to 04.02.2020 Last Amended on 13.04.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

V. VOLUME

1. Volume Glasswares 10 ml ˂ V ˂ 1000 ml 0.6 ml Using Precision Balance

(All Types) Like, & Standard Weights

Burette, Pipette, Jar By Gravimetric Method

Measuring Flask As per ISO 4784 &

Cylindrical Flask etc.$ NBAL-122-13

VI. MOBILE FORCE MEASURING SYSTEM

1. Force : Up to 500 N 0.15% Pull Mode Using Newton weights &

Push Pull Gauge$ 0.13% Push Mode Fixture As per VDI/

VDE 2624 Part 2.1 &

As per NABL-122-08

VII. TORQUE GENERATING DEVICE

1. Torque Tools / 0.2 Nm to 20 Nm 1.50 % Using Torque Calibration

Torque Wrench / 20 Nm to 200 Nm 1.40 % Systems Transducers

Screw Driver / 200 Nm to 2000 Nm 1.30 % with Indicators As per

Torque Meter IS / ISO 6789:2003

( Type I-Class NABL -122-10

B,C,D,E &

Type II – Class

A,B,D,E)$

VIII. HARDNESS TESTING MACHINES

1. Shore A Hardness 0 to 100 Shore A 2.10 Shore A Using Rubber Hardness

Tester Tester Calibrator

Shore D Hardness 0 to 100 Shore D 2.05 Shore D ASTM D 2240-05 &

Tester$ ISO : 18898 -2006 &

As per & NABL -122-15

Ashish Kakran Avijit Das

Convenor Program Director

Laboratory S. M. Engineers, 1210/B, Sadashiv Peth, Indira Apartment, Pune,

Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2639 (in lieu of C-0114, C-1366) Page 10 of 12

Validity 05.02.2018 to 04.02.2020 Last Amended on 13.04.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

IX. ACCELERATION & SPEED

1. RPM Using Digital

Tachometer Tachometer &

Contact Type 50 rpm to 5000 rpm 05 rpm Electric Motor with

Non Contact Type$ 50 rpm to 10000 rpm 10 rpm Rotating Disc.

Tacho Generator

By Comparison Method

2. Vibration : Acceleration: Acceleration 6.40 % Using Vibration Meter

Vibration Meter / Up to 200 m/s2 Calibrator By

Accelerometer$ (Peak) Comparison Method

a) Acceleration Velocity : Velocity 6.00 % As per ISO: 16063-21

b) Velocity & Up to 200 mm/s

c) Displacement (RMS)

Displacement : Displacement 2.60 %

Up to 1500 µm

(Peak to Peak)

X. ACOUSTICS

1. Sound Level Meter$ 94 dB and 114 dB 0.75 dB Using Sound Level

Range 40- 130 dB Meter Calibrator By

Comparison Method

As per IEC: 61672,

Part-I

XI. DENSITY AND VISCOSITY

1. Viscosity$ 10 cSt to 370 cSt 3.05 cSt Using Newtonian Liquid

Ford Cups All Type : of Known Kinematic

B1 To B5 Viscosity & Timer for

Calibration of Ford cups

based on ISO 2431 by

determining the Flow

Time

Ashish Kakran Avijit Das

Convenor Program Director

Laboratory S. M. Engineers, 1210/B, Sadashiv Peth, Indira Apartment, Pune,

Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2639 (in lieu of C-0114, C-1366) Page 11 of 12

Validity 05.02.2018 to 04.02.2020 Last Amended on 13.04.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

2. Viscosity$ 370 cSt to 1800 cSt 11.66 cSt Using Newtonian Liquid

(All Types Of of Known Kinematic

Viscosity Cups) Viscosity & Timer For

Calibration of Dip Type

Viscosity cups (Zahn &

Shell) Based on

ASTM 4212-16 by

determining the Flow

Time

Ashish Kakran Avijit Das

Convenor Program Director

Laboratory S. M. Engineers, 1210/B, Sadashiv Peth, Indira Apartment, Pune,

Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2639 (in lieu of C-0114, C-1366) Page 12 of 12

Validity 05.02.2018 to 04.02.2020 Last Amended on 13.04.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

OPTICAL CALIBRATION

I. OPTICAL

1. Lux Meter$ Up to 2000/10000 lx 3.4% Using Certified Light

Source & Reference

Illuminance Meter By

Comparison Method

2. Lux Meter$ Above 10000 to 3.4% Using Certified Light

20000 lx Source & Reference

Illuminance Meter By

Comparison Method

* Measurement Capability is expressed as an uncertainty () at a confidence probability of 95%

$

Only in Permanent Laboratory

♣

Only for Site Calibration

#

The laboratory is also capable for site calibration however, the uncertainty at site depends on the

prevailing actual environmental conditions and master equipment used.

Ashish Kakran Avijit Das

Convenor Program Director

You might also like

- Wartsila VASA 6R 32 - ManualDocument603 pagesWartsila VASA 6R 32 - ManualSudarshan Ravindranathan100% (3)

- WPC-21-0851 Field Scale Polymer Flooding of Heavy Oil The Pelican Lake Story - Heavy Oil - GoodDocument29 pagesWPC-21-0851 Field Scale Polymer Flooding of Heavy Oil The Pelican Lake Story - Heavy Oil - GoodGilbert OmittaNo ratings yet

- Lightnin Impeller Technology PDFDocument8 pagesLightnin Impeller Technology PDFNaila TheExplore HorisonNo ratings yet

- Fluids Past Papers PDFDocument65 pagesFluids Past Papers PDFAnushaBheenuckNo ratings yet

- MikronixDocument3 pagesMikronixrohanmanimaniNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument18 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- Sitarc - C - 0135Document7 pagesSitarc - C - 0135Ravichandran DNo ratings yet

- Godrej Nabl ScopeDocument11 pagesGodrej Nabl ScopeRavichandran DNo ratings yet

- 24.scope Location 1 CC-2833Document4 pages24.scope Location 1 CC-2833Ravichandran DNo ratings yet

- Laboratory: Micro Measures, "Gruhalaxmi" Bunglow No. 49, Serene Meadows, Gangapur Road, Nashik, MaharashtraDocument12 pagesLaboratory: Micro Measures, "Gruhalaxmi" Bunglow No. 49, Serene Meadows, Gangapur Road, Nashik, MaharashtraVAIBHAV INSTRUMENTATIONNo ratings yet

- Reliance 333Document7 pagesReliance 333Ravichandran DNo ratings yet

- Accurate Chennai ScopeDocument7 pagesAccurate Chennai ScopeRavichandran DNo ratings yet

- Quantity Measured/ Instrument Range / Frequency Calibration Measurement Capability ( ) RemarksDocument6 pagesQuantity Measured/ Instrument Range / Frequency Calibration Measurement Capability ( ) RemarksRavichandran DNo ratings yet

- 3.scope Location 1 CC-2706Document8 pages3.scope Location 1 CC-2706Ravichandran DNo ratings yet

- Accurate Pune.C0052Document12 pagesAccurate Pune.C0052Ravichandran DNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument2 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksrohanmanimaniNo ratings yet

- G.B.Central Laboratory, TrichyDocument3 pagesG.B.Central Laboratory, TrichyRavichandran DNo ratings yet

- FIE Research InstituteDocument8 pagesFIE Research InstituteAcuteNo ratings yet

- Indoshell - C - 0400Document2 pagesIndoshell - C - 0400Ravichandran DNo ratings yet

- 4.scope Location 1 CC-2878Document8 pages4.scope Location 1 CC-2878Ravichandran DNo ratings yet

- 6092 01Document8 pages6092 01Laura MarquezNo ratings yet

- Perfect 684Document4 pagesPerfect 684Ravichandran DNo ratings yet

- 5666 01Document18 pages5666 01Laura MarquezNo ratings yet

- CL 222 CertDocument5 pagesCL 222 CertS SHALUNo ratings yet

- Tespa 0091 - ChennaiDocument8 pagesTespa 0091 - ChennaiRavichandran DNo ratings yet

- Measured Qty / Instrument Range Calibration Measurement Capability ( ) RemarksDocument4 pagesMeasured Qty / Instrument Range Calibration Measurement Capability ( ) RemarksRavichandran DNo ratings yet

- Laboratory NameDocument13 pagesLaboratory NameVikram BillalNo ratings yet

- Measured Qty / Instrument Range Calibration Measurement Capability ( ) RemarksDocument4 pagesMeasured Qty / Instrument Range Calibration Measurement Capability ( ) RemarksRavichandran DNo ratings yet

- CMTI ScopeDocument13 pagesCMTI ScopeRavichandran DNo ratings yet

- Test CMM 2016 Hand-OutDocument42 pagesTest CMM 2016 Hand-OutHernanda ImawanNo ratings yet

- Using Gauge Block Set, Length Bar & Caliper Checker by Comparison Method As Per IS 3651Document13 pagesUsing Gauge Block Set, Length Bar & Caliper Checker by Comparison Method As Per IS 3651rohanmanimaniNo ratings yet

- CL 221 CertDocument4 pagesCL 221 CertS SHALUNo ratings yet

- Scope CC 2331Document5 pagesScope CC 2331snsarangi06No ratings yet

- 4150 01Document21 pages4150 01Jhonny BarberoNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument9 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksSyarif MaulanaNo ratings yet

- Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) % RemarksDocument3 pagesQuantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) % RemarksrohanmanimaniNo ratings yet

- TespaDocument15 pagesTespaDhinagaran ANo ratings yet

- ScopeDocument25 pagesScopeAlbert E. Cairns JrNo ratings yet

- 5825 01Document100 pages5825 01OSCAR YOBANY VEGA HERNANDEZNo ratings yet

- UVDocument4 pagesUVJavier CarrizoNo ratings yet

- Lab Scope of SigmaDocument2 pagesLab Scope of SigmaVivek katariaNo ratings yet

- Perfect 243 - ChennaiDocument11 pagesPerfect 243 - ChennaiRavichandran DNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument26 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksBALAJINo ratings yet

- Flaw Detector Scope Sample PG 4-4150-01Document22 pagesFlaw Detector Scope Sample PG 4-4150-01ebbasinghNo ratings yet

- Alpha A2LA CertificateDocument5 pagesAlpha A2LA CertificateNg Wei LihNo ratings yet

- 1741 14Document22 pages1741 14Laura MarquezNo ratings yet

- 3467 01Document19 pages3467 01Sheik Mohamed AliNo ratings yet

- Global Insignia For Technical Services Establishment: This Is To Attest ThatDocument3 pagesGlobal Insignia For Technical Services Establishment: This Is To Attest ThatAlmansoori MPSNo ratings yet

- Northlab HosurDocument25 pagesNorthlab HosurVikram BillalNo ratings yet

- Adobe Scan 02-Jul-2022Document5 pagesAdobe Scan 02-Jul-2022Shamsher SinghNo ratings yet

- Lab Procedure Wi 71Document3 pagesLab Procedure Wi 71VikasNo ratings yet

- 3467 01Document20 pages3467 01Laura MarquezNo ratings yet

- 75عDocument3 pages75عFikry FaradinnaNo ratings yet

- Scope 87693 CC 2029 1699440503Document10 pagesScope 87693 CC 2029 1699440503YAMA ENGINEERSNo ratings yet

- Metrology InstrumentsDocument1 pageMetrology InstrumentsVrinda NilotpalNo ratings yet

- 2806 01 PDFDocument33 pages2806 01 PDFAmitNo ratings yet

- Metravi PRO 7273 10A Microohms Meter Catalogue WebDocument3 pagesMetravi PRO 7273 10A Microohms Meter Catalogue WebGaurav kumarNo ratings yet

- 24K Mech Lab-IS ExtDocument3 pages24K Mech Lab-IS ExtVikasNo ratings yet

- Calibration Area Range & Resolution Calibration & Measurement Capability (CMC) ( ) Technique, Reference Standard, EquipmentDocument5 pagesCalibration Area Range & Resolution Calibration & Measurement Capability (CMC) ( ) Technique, Reference Standard, EquipmentWael BouabdellahNo ratings yet

- 0866 01Document11 pages0866 01ebbasinghNo ratings yet

- 1823-01 - A2la - Iso 17025 - Schope - Cert - 2020-2022 - Rlws - Concord-Ca - RevisedDocument22 pages1823-01 - A2la - Iso 17025 - Schope - Cert - 2020-2022 - Rlws - Concord-Ca - RevisedLeandroNo ratings yet

- ASTM B 499 09 Yr 14Document9 pagesASTM B 499 09 Yr 14Juan Sebastián Martinez NunciNo ratings yet

- Quito 170408, EcuadorDocument10 pagesQuito 170408, EcuadorJhonny BarberoNo ratings yet

- Position Sensing: Angle and Distance Measurement for EngineersFrom EverandPosition Sensing: Angle and Distance Measurement for EngineersNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument19 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- Questionnaire For Mass GroupDocument3 pagesQuestionnaire For Mass GroupVAIBHAV INSTRUMENTATIONNo ratings yet

- Sushma Industries Calibration CentreDocument11 pagesSushma Industries Calibration CentreVAIBHAV INSTRUMENTATIONNo ratings yet

- (In Lieu of C-0579, C-0766 & C-0767) : TH RDDocument24 pages(In Lieu of C-0579, C-0766 & C-0767) : TH RDVAIBHAV INSTRUMENTATIONNo ratings yet

- Institute For DesignDocument48 pagesInstitute For DesignVAIBHAV INSTRUMENTATIONNo ratings yet

- Tempsens Calibration CentreDocument5 pagesTempsens Calibration CentreVAIBHAV INSTRUMENTATIONNo ratings yet

- ZXX ZXDocument35 pagesZXX ZXVAIBHAV INSTRUMENTATIONNo ratings yet

- Sri Gokul Cal Lab.Document4 pagesSri Gokul Cal Lab.VAIBHAV INSTRUMENTATIONNo ratings yet

- Perfect CalibrationDocument25 pagesPerfect CalibrationVAIBHAV INSTRUMENTATIONNo ratings yet

- Laboratory: Micro Measures, "Gruhalaxmi" Bunglow No. 49, Serene Meadows, Gangapur Road, Nashik, MaharashtraDocument12 pagesLaboratory: Micro Measures, "Gruhalaxmi" Bunglow No. 49, Serene Meadows, Gangapur Road, Nashik, MaharashtraVAIBHAV INSTRUMENTATIONNo ratings yet

- Indigo Passenger (S) : Delhi MumbaiDocument2 pagesIndigo Passenger (S) : Delhi MumbaiVAIBHAV INSTRUMENTATIONNo ratings yet

- Laboratory: Acme Enterprises, 28 Saraswati, Ayodhya Nagar, Nagpur, MaharashtraDocument14 pagesLaboratory: Acme Enterprises, 28 Saraswati, Ayodhya Nagar, Nagpur, MaharashtraVAIBHAV INSTRUMENTATIONNo ratings yet

- Automotive Research Association of IndiDocument31 pagesAutomotive Research Association of IndiVAIBHAV INSTRUMENTATIONNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument18 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- Hi Tech Calibration Services PDFDocument28 pagesHi Tech Calibration Services PDFVAIBHAV INSTRUMENTATIONNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument25 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument20 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- CeramicsDocument41 pagesCeramicsRhenzo YuNo ratings yet

- Magnet Drive Gear Pumps MK200/MK300 Series: Main ApplicationsDocument4 pagesMagnet Drive Gear Pumps MK200/MK300 Series: Main ApplicationsMareReaNo ratings yet

- Tablets Aqeuos Film CoatingDocument38 pagesTablets Aqeuos Film CoatingYuppie RajNo ratings yet

- Journal of Food EngineeringDocument8 pagesJournal of Food EngineeringPendar BiruNo ratings yet

- A-Hydraulics 2 7-12-05 (Rev 2-06) .PpsDocument138 pagesA-Hydraulics 2 7-12-05 (Rev 2-06) .Ppscarolina Portocarrero100% (1)

- EXAMPLE 8-68: Prof. Dr. Ali PınarbaşıDocument29 pagesEXAMPLE 8-68: Prof. Dr. Ali PınarbaşıWallefer RodriguesNo ratings yet

- A Study On Computational Fluid Dynamics Modeling of A Refrigerated Container For COVID-19 Vaccine Distribution With Experimental ValidationDocument8 pagesA Study On Computational Fluid Dynamics Modeling of A Refrigerated Container For COVID-19 Vaccine Distribution With Experimental ValidationAndre spurvonovNo ratings yet

- 11th Physics Practical ManualDocument24 pages11th Physics Practical ManualAmol MahajanNo ratings yet

- Article Nernst Equation PDFDocument8 pagesArticle Nernst Equation PDFMiguel BrionesNo ratings yet

- Black Oil PropDocument25 pagesBlack Oil PropHaziq YussofNo ratings yet

- ALL Purpose WorksheetDocument239 pagesALL Purpose WorksheetSyed Misbah UddinNo ratings yet

- (9-25) Performance Graded Bitumen SpecificationsDocument10 pages(9-25) Performance Graded Bitumen Specificationshasif21No ratings yet

- Applications: Tranself NFP 75W-80Document1 pageApplications: Tranself NFP 75W-80AlexNo ratings yet

- SPE 135339 Modeling CO Injection Including Diffusion in A Fractured-Chalk ExperimentDocument11 pagesSPE 135339 Modeling CO Injection Including Diffusion in A Fractured-Chalk ExperimentMudassir KhanNo ratings yet

- Analysis of The Physical and Chemical Characteristics of Vegetable Oils As FuelDocument10 pagesAnalysis of The Physical and Chemical Characteristics of Vegetable Oils As FuelAbhishek MundeNo ratings yet

- Binary Diffusion Coefficient 1Document11 pagesBinary Diffusion Coefficient 1Farouk BassaNo ratings yet

- Power Consumption in Shaking Flasks I Buchs 2000Document5 pagesPower Consumption in Shaking Flasks I Buchs 2000Diego Chicaíza FinleyNo ratings yet

- Minerals 09 00079 PDFDocument17 pagesMinerals 09 00079 PDFMunhbayar ZayabatarNo ratings yet

- Viva QuestionsDocument4 pagesViva Questionsjanumech80100% (1)

- International Journal of Thermal Sciences: Massimo CorcioneDocument11 pagesInternational Journal of Thermal Sciences: Massimo CorcioneParvez AhmedNo ratings yet

- Tranself NFJ 75w-80Document1 pageTranself NFJ 75w-80Ionita RalucaNo ratings yet

- Front Matter PDFDocument8 pagesFront Matter PDFYosephine TanNo ratings yet

- Viscosity of Crude OilsDocument6 pagesViscosity of Crude OilsMD Redwan IslamNo ratings yet

- SKF Hub Bearing UnitsDocument32 pagesSKF Hub Bearing UnitsJavi GGNo ratings yet

- SSC Je 02-03-2017Document17 pagesSSC Je 02-03-2017vikash kumarNo ratings yet

- B Tech Auto 2016 17 PDFDocument167 pagesB Tech Auto 2016 17 PDFBAPUSAHEB WATHOLENo ratings yet