Professional Documents

Culture Documents

Malwa-Ii - Punch Point Status As On 04-May-19 SR No. Received From Uom Grand Total Balance Liquidated As On 27-Apr-19 Liquidated This Week Liquidated As On 04-May-19

Uploaded by

NavindraDadhichOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Malwa-Ii - Punch Point Status As On 04-May-19 SR No. Received From Uom Grand Total Balance Liquidated As On 27-Apr-19 Liquidated This Week Liquidated As On 04-May-19

Uploaded by

NavindraDadhichCopyright:

Available Formats

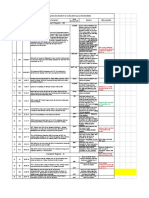

Malwa-II - Punch Point Status as on 04-May-19

Sr No. Received From UoM Grand Total Liquidated as on Liquidated Liquidated as on Balance

27-Apr-19 this week 04-May-19

1 BED Nos. 58 20 0 20 38

2 BMD Nos. 67 30 0 30 37

3 Chemistry Nos. 650 144 2 146 504

4 CHP Nos. 238 112 0 112 126

5 Civil Nos. 265 60 12 72 193

6 Commissioning Nos. 19 8 0 8 11

7 EED / EMD Nos. 1689 336 12 348 1341

8 IED / IMD Nos. 507 105 131 236 271

9 Operation Nos. 318 78 44 122 196

10 TED Nos. 90 75 0 75 15

11 TED-OS Nos. 71 53 0 53 18

12 TMD Nos. 79 15 11 26 53

Grand Total Nos. 4051 1036 212 1248 2803

# Sensitivity : This Document is Classified as "LNT Internal Use".

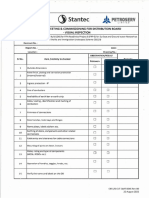

TYPE OF Status Shutdown

Sr No. AREA SUB AREA POINT DESCRIPTION Package Remarks

DEFECT (Open/Closed) Requirement

There is not proper Illumination in RAPH Both (A&B) and AB C&I & Commissioning points to be jointly checked at

315 - EMD 15 Open

elevation between E.H pump and J.O.P. Site/CCR by 20-Feb-19

C&I & Commissioning points to be jointly checked at

321 - HFO Street light not working 15 Open Site/CCR in next meeting @CCR on 06-Mar-19

ESP-A (HNAO5AA101) Puss O/L damper show abnormal on DCS C&I & Commissioning points to be jointly checked at

337 - Also, 2RY SH DSH SPR BYP ISO V/V LACO AA 416 shows abnormal IMD/TMD 15 Open

Site/CCR by 20-Feb-19

on DCS.

C&I & Commissioning points to be jointly checked at

351 - there is no light Arrangement in APRDS Floor EMD 15 Open

Site/CCR by 20-Feb-19

All cable galleries no proper cable laying dressing and cables C&I & Commissioning points to be jointly checked at

536 - EMD/CIVIL 15 Open

damaged Site/CCR by 20-Feb-19

545 - HT/LT switchgear,unit/station rubber mating not provided EMD 15 Open

STATION TRANSFORMER 3 -OIL LEAKAGE CONT. SINCE IT C&I & Commissioning points to be jointly checked at

554 - EMD 15 Open

ERECTION AND COMM. Site/CCR by 20-Feb-19

CPU -

691 CPU Regeneration Area Earthing flat of various tank/area not proper assembled. electrical 15 Open

CPU regeneration

720 CPU area - PLC Room Installation of electrical socket is to be done electrical 15 Open

CPU regeneration

725 CPU area - PLC Room Cable Trench pit of PLC room is not covered. Electrical 15 Open

731 CPU CPU - Service Area #3 Installation of electrical socket is to be done Electrical 15 Open

PLC Room

734 CPU CPU - Service Area #3 Ceiling lighting not fit properly Electrical 15

PLC Room

# Sensitivity : This Document is Classified as "LNT Internal Use".

Sr No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

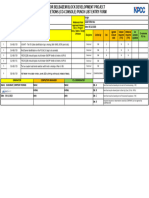

Package

Steam Generator (Boiler)

ESP

STG

Auxiliaries of Main Plant

RW Intake System

Plant Water System

Circulating Water System

BoP Systems like Compressed Air System, MRHS, H2, CO2, N2 Cylinders, Chemical lab and LP Piping.

CHP

FOHS

Fire Detection & Protection System

AHP

Power Transformer (GT, ST & UT)

Switchyard

E&I

NDCT

Chimney

S. No Boiler-CLCS Status Remark

1 O2 Master demand Closed

2 Calorie correction Closed

under observation,needs to be

3 Soot blower steam presure control from SH Put in auto

checked

under observation,needs to be

4 Soot blower steam presure control from CRH Put in auto

checked

Soot blower steam presure control from aux

5 Put in auto -

steam

6 2ndry pass bypass control Closed

Aux air corner 1,2,7,8,&3,4,5,&6 damper Not Put in to be done during combustion

7

control auto tunning before PG

Not Put in to be done during combustion

8 Additional air port damper control

auto tunning before PG

not working properly,needs to

9 Turbine master control Put in auto

be checked/tuned in cc mode

10 Boiler master control Closed

Most of the time during trial

opn. Unit was running in BITF

mode,only 3 to 4 times unit

was put in CC mode for short

time , but it was not working

satisfactorily in CC mode

during load increase/decrease,

11 Unit coordinate control Closed run back/fast cut back.

Fluctuation in load observed

more upto 30 MW up and

down from the load set

value.Fluctuation in EH oil pr.

is also observed due main

steam presss. variation.NOT

WORKING Satisfactorily

Not Put in to be done during combustion

12 Burner nozzle angle control

auto tunning before PG

13 Pulverizer inert steam pressure control working needs tuning

Pulverizer seal air cleaner diff. Pressure Not Put in to be done during combustion

14

control auto tunning before PG

Not Put in to be done during combustion

15 Classifier MOV control

auto tunning before PG

Not Put in

16 Flash tank level& temp. Control Not demonstrated till yet.

auto

1ry SH spray CV control/1ry SH-DSH main

17 Closed -

spray CV

18 Closed cooling water diff. Press control Closed

19 Burner atomizing air press control Closed

# Sensitivity : This Document is Classified as "LNT Internal Use".

20 Burner atomizing steam press. Control Closed

21 Water fuel ratio (WFR) Closed

2ndry SH spray CV control/2ndry SH-DSH

22 Closed

main spray CV

23 CCCW expansion tank level control Closed -

Boiler recirculation control valve (BR flow

24 -

control) Closed

not working properly,needs to

25 WSDT level control Closed

be checked/tuned .

not working properly,needs to

26 WSDT warming MOV

be checked/tuned .

27 Furnace draft control Closed

28 Total air flow control Closed

29 Primary air header pressure control Closed

30 HFO flow control Closed

31 LDO flow control Closed

32 Pulverizer I/L air flow control Closed -

33 Pulverizer O/L temp. Control Closed -

34 Pulverizer Hydraulic pressure control Closed -

35 Pulverizer lube oil temprature control Closed -

36 Mill hydraulic oil temprature control Closed -

37 SADC of oil burner Closed -

38 SADC of coal burner Closed -

39 Main steam press. Control Closed -

40 Feedwater flow control Closed -

41 Fuel flow control (coal master) Closed -

42 RAPH drain temprature control Closed -

43 Gas distribution damper (RH/SH/pass) Closed -

due to HPBP passing

44 RH steam temp. control Put in auto temperature is increasing

,tuning required

Not Put in all damper actuators are in

45 Burner windbox sec. Air damper control

auto manual from starting.

46 SCAPH air temp. control Put in auto -

Turbine CLCS Status Remark

VENTILATOR LINE DE SUPERHEATER

1 Put in auto working

TEMP

not maintaining normal lvl(b/w

2 HEATER 8 DRAIN CONTROL VALVES Put in auto Hi and low limits),Tuning

required

not maintaining normal lvl(b/w

3 HEATER 7 DRAIN CONTROL VALVES Put in auto Hi and low limits),Tuning

required

not maintaining normal lvl(b/w

4 HEATER 6 DRAIN CONTROL VALVES Put in auto Hi and low limits),Tuning

required

not maintaining normal lvl(b/w

5 HEATER 4 DRAIN CONTROL VALVES Put in auto Hi and low limits),Tuning

required

not maintaining normal lvl(b/w

6 HEATER 3 DRAIN CONTROL VALVES Put in auto Hi and low limits),Tuning

required

# Sensitivity : This Document is Classified as "LNT Internal Use".

not maintaining normal lvl(b/w

LPH DRAIN TANK NORMAL &

7 Put in auto 1100 & 1600 MMWC),Tuning

EMERGENCY DRAIN LCV

required

8 HEATER 1 DRAIN CONTROL VALVES Put in auto

Not Put in

9 DEAERATOR OVERFLOW DRAIN LCV needs to be demonstrate

auto

10 CCW PUMP RECIRCULATION PCV Put in auto working

1)Most of the time during trial

operation as emergency

occured ( Runback/FCB

operated,turbine tripped,load

throw off), controller became

unhealthy and valves became

abnormal/inoperative due to

downstream temp. rise beyond

11 HPBP STATION 1/2 PCV Put in auto

the limit and feedback problem

in TCV.

2) There is passing in HPBP

2 (PCV).Thus due to closing

of HPBP PCV, Boiler tripped

on Reheater protection every

time.

Most of the time during trial

operation as emergency

occured ( Runback/FCB

operated,turbine tripped,load

throw off),controller became

12 HPBP STATION 1/2 TCV Put in auto

unhealthy and valves became

abnormal/inoperative due to

downstream temp. rise beyond

the limit and feedback problem

in TCV.

Most of the time during trial

operation when runback/FCB

13 LPBP STATION 1/2 PCV Put in auto occured, controller became

unhealthy and valves became

abnormal/inoperative.

# Sensitivity : This Document is Classified as "LNT Internal Use".

1)This autoloop malfunctioned

many times as TCV flow

transmitters readings are

erratic and spray valves could

not maintained downstream

temperature upto the limit

when emergency occured

( Runback/FCB

operated,turbine tripped,load

throw off),controller became

unhealthy and pressure control

valves became

abnormal/inoperative due to

downstream temp. rise beyond

14 LPBP STATION 1/2 TCV Put in auto the limit.Thus due to closing

of LPBP PCV, Boiler tripped

on Reheater protection every

time.At higher load when

LPBP PCV is in closed

condition,it is observed that

TCV is opened and spray is

continuously going while it

should be zero.logic needs to

be checked. 2) LP Bypass

HYD Station oil pressure

drops when LP Bypass valves

PCV opens 100% suddenly

and HYD station becomes

abnormal.

Isolation vlv b/w existing unit

of phase -I & u#3 either should

AUXILIARY STEAM HT HDR CONTROL be inching valve or control

15 Put in auto

VALVES valve for maintaining the

respective hdr pressure as per

their design .

LT hdr spray line not

AUXILIARY STEAM LT HDR CONTROL commissioned(Frm BFP

16 Not Put in auto

VALVES interstage),HT to LT Isolation

MOV Actuator broken

Spray line-1 and 2 PCV, TCV

control valve hunts

abnormally. Spray line 1/2

AUXILIARY STEAM HT HDR SPRAY

17 Put in auto Isolation MOV, PCV, TCV is

LINE PCV

having passing due to which

auxiliary steam temperature is

uncontrollable.

# Sensitivity : This Document is Classified as "LNT Internal Use".

DEAERATOR PEG AUXILIARY STEAM Not sustained and under

18 Put in auto

PCV & CRH STEAM PCV observation.

19 MDBFP SCOOP TUBE CONTROL Put in auto working

20 FEEDWATER 30%FCV Put in auto working

21 TDBFP-A MIN RECIRC FCV Put in auto working

22 TDBFP-B MIN RECIRC FCV Put in auto working

23 MDBFP MIN RECIRC FCV Put in auto working

24 TDBFP -A SPEED CONTROL Put in auto working

25 TDBFP-B SPEED CONTROL Put in auto working

HW NORMAL MKUP CV, EMERG FILL Emergency fill PCV,Cond.

Partially Put

26 PCV, COND DUMP CV& PUMP RECIRC Dump CV & PUMP recirc CV

in auto

CV pending

After GSC , condensate flow is

greater than sum of the

27 GSC/CEP MIN RECIRC FCV Put in auto

individual CEP dish flow in

the system

28 DA INLT 30%, 100% & 100% STBY LCV Put in auto under observation

29 NH3 DOS PMP-A STRK CONTROL Put in auto under observation

HYDRAZENE DOSING PUMP STROKE

30 Put in auto under observation

LENGTH

Not Put in

31 O2 DOS TO CPU FCV -

auto

32 FW MASTER AND TDBFP -A BIAS Put in auto working

33 FW MASTER AND TDBFP-B BIAS Put in auto working

34 FW MASTER AND MDBFP BIAS Put in auto working

# Sensitivity : This Document is Classified as "LNT Internal Use".

Discussion held on 28-Feb-19

Will be jointly resolved by 01-Mar-19

Will be jointly resolved by 01-Mar-19

Will be jointly resolved by 01-Mar-19

Will be jointly resolved by 01-Mar-19

Will be jointly resolved by 01-Mar-19

Will be jointly resolved by 01-Mar-19

Will be jointly resolved by 01-Mar-19

# Sensitivity : This Document is Classified as "LNT Internal Use".

Will be jointly resolved by 01-Mar-19

Will be jointly resolved by 01-Mar-19

Will be jointly resolved by 01-Mar-19

Will be jointly resolved by 01-Mar-19

Closed

Closed

Will be jointly resolved by 01-Mar-19

Will be jointly resolved by 01-Mar-19

Will be jointly resolved by 01-Mar-19

Will be jointly resolved by 01-Mar-19

Will be jointly resolved by 01-Mar-19

# Sensitivity : This Document is Classified as "LNT Internal Use".

Will be jointly resolved by 01-Mar-19

Closed

Will be jointly resolved by 01-Mar-19

Closed

Will be completed during shutdown (7

days)

Will be completed during shutdownWill

be completed during shutdown (7 days)

Will be completed during shutdown (7

days)

# Sensitivity : This Document is Classified as "LNT Internal Use".

Will be completed during shutdown (7

days)

Works completed as per dwg.

Point deleted.

Mech point (K Manohar)

Will be taken up with OEM by 31-Mar-

19

# Sensitivity : This Document is Classified as "LNT Internal Use".

Point Closed

Point Closed

Point Closed

Point Closed

Point Closed

Point Closed

Point Closed

Point Closed

Will be taken up during trial by 28-Feb-

19

Condensate flow error will be rectified

during shutdown.

2-Mar-19

Logic will be checked in DCS by 04-

Mar-19

Logic will be checked in DCS by 04-

Mar-19

Logic will be checked in DCS by 04-

Mar-19

Point Closed

Point Closed

Point Closed

# Sensitivity : This Document is Classified as "LNT Internal Use".

Group/SubGroups Sequence status Annexure-2

S.No. Description Status

1 Condensate Water Trial Pending

2 Feedwater Trial Pending

3 Auxiliary Steam Trial Pending

4 LP Sys Line Clean Up Blow Trial Pending

5 HP Sys Line Clean UP Blow Trial Pending

6 LP Drain Line Clean UP Recirculation Trial Pending

7 HP Drain Line Clean UP Blow Trial Pending

8 LP/P Recirc Clean UP Trial Pending

9 LP HDP-1 Trial Pending

10 LP HDP-2 Trial Pending

11 Condenser Vacuum Trial Pending

12 Chemical Dosing Trial Pending

13 Chemical Dosing in AVT Mode Trial Pending

14 Chemical Dosing in CWT Mode Trial Pending

15 Circulating Water Trial Pending

Turbine Sub Group Sequence

S.No. Description Status

1 CEP-A Trial Pending

2 CEP-B Trial Pending

3 CEP-C Trial Pending

4 LP HEATER INLINE/BYPASS Trial Pending

5 MDBFP Trial Pending

6 TDBFP A Trial Pending

7 TDBFP B Trial Pending

8 CWP A Trial Pending

9 CWP B Trial Pending

10 CWP C Trial Pending

11 BFPT-A OIL Trial Pending

12 BFPT-B OIL Trial Pending

13 BFPT-A STEAM Trial Pending

14 BFPT-B STEAM Trial Pending

15 LPVP-A Trial Pending

16 LPVP-B Trial Pending

17 HPVP-A Trial Pending

18 HPVP-B Trial Pending

19 HP HEATER Trial Pending

20 ACWP-A Trial Pending

21 ACWP-B Trial Pending

22 HP EXTRACTION STEAM Trial Pending

23 LP EXTRACTION STEAM Trial Pending

# Sensitivity : This Document is Classified as "LNT Internal Use".

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 02.03.2021 Ref 1MOMDocument41 pages02.03.2021 Ref 1MOMravitejatalatamNo ratings yet

- DR - Tejal DalalDocument3 pagesDR - Tejal DalalNaman ValandNo ratings yet

- Solar Net Metering Installation ReportDocument4 pagesSolar Net Metering Installation ReportNaman ValandNo ratings yet

- DORC Contract No. DORC Project No. Request No. To: ATTACHNENT-5 (For Inspection Management and Coordination Procedure)Document1 pageDORC Contract No. DORC Project No. Request No. To: ATTACHNENT-5 (For Inspection Management and Coordination Procedure)Moorthy NaveenNo ratings yet

- Event Analysis Report for Unit 3 Trip Due to BTLDocument3 pagesEvent Analysis Report for Unit 3 Trip Due to BTLSE ESTNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument3 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- Restricted EP Wells Daily Operations Report SummaryDocument5 pagesRestricted EP Wells Daily Operations Report Summarymohamed gadallahNo ratings yet

- Complaint Register - I&IIDocument10 pagesComplaint Register - I&IIramki kitttuNo ratings yet

- FEKOLA warranty claims document title generatorDocument33 pagesFEKOLA warranty claims document title generatorChristian SarrNo ratings yet

- GVR Stamping Report 30.12.22Document1 pageGVR Stamping Report 30.12.22ShãrãnNo ratings yet

- 1616585316635-TKD Shed RTIDocument29 pages1616585316635-TKD Shed RTIMD NADEEMNo ratings yet

- Fato Pos DT05.07.21Document1 pageFato Pos DT05.07.21Ashish GuptaNo ratings yet

- KU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFDocument7 pagesKU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFRexx Mexx100% (1)

- DORC Project No. Request No. To DORC Contract No.: ATTACHNENT-5 (For Inspection Management and Coordination Procedure)Document1 pageDORC Project No. Request No. To DORC Contract No.: ATTACHNENT-5 (For Inspection Management and Coordination Procedure)Moorthy NaveenNo ratings yet

- 1526532134736-Pos Feb 2018Document179 pages1526532134736-Pos Feb 2018ramsundarsingh6243No ratings yet

- Mrir (Al-Ez Format)Document4 pagesMrir (Al-Ez Format)adeel akbarNo ratings yet

- July Quality MeetingDocument58 pagesJuly Quality MeetingKrishna Mohan ChauhanNo ratings yet

- Plano de SaturadorDocument6 pagesPlano de SaturadorRodrigo Andres CeledonNo ratings yet

- Isolator & Earth Switch - For SwitchayrdDocument6 pagesIsolator & Earth Switch - For SwitchayrdSindhuKumarNo ratings yet

- Mom 04-07-2019Document7 pagesMom 04-07-2019Jawad AmjadNo ratings yet

- Dangote Refinery Project InspectionDocument1 pageDangote Refinery Project InspectionMoorthy NaveenNo ratings yet

- Detailed visual inspection of forward cargo compartment scuff plateDocument24 pagesDetailed visual inspection of forward cargo compartment scuff plateUguffcNo ratings yet

- RESULTS SUMMARYDocument5 pagesRESULTS SUMMARYwillyNo ratings yet

- Results Summary Log: Motor ID Time Temp Resist Megohm DA/PI DC SurgeDocument5 pagesResults Summary Log: Motor ID Time Temp Resist Megohm DA/PI DC SurgewillyNo ratings yet

- Ku-Twk-41-Ic-Lst-0200 A Instrument Index Io List-Peshkbir PDFDocument28 pagesKu-Twk-41-Ic-Lst-0200 A Instrument Index Io List-Peshkbir PDFLienu PrinceNo ratings yet

- Shift-Wise Production Report (Under Ground) Form 1 - ADocument2 pagesShift-Wise Production Report (Under Ground) Form 1 - Aagrawalharshit27No ratings yet

- Results Summary Log: Motor ID Time Temp Resist Megohm DA/PI DC SurgeDocument7 pagesResults Summary Log: Motor ID Time Temp Resist Megohm DA/PI DC SurgewillyNo ratings yet

- Coil 2 Piece T U: o - Ljaccn-WcDocument3 pagesCoil 2 Piece T U: o - Ljaccn-WcsselhbbplNo ratings yet

- Crown Specialized For Steel Contracting Co. Ltd. Welding Inspection ReportDocument1 pageCrown Specialized For Steel Contracting Co. Ltd. Welding Inspection ReportYasar AliNo ratings yet

- DB ChecklistDocument4 pagesDB ChecklistJabinNo ratings yet

- CHD-4 02.08.2015Document3 pagesCHD-4 02.08.2015SE ESTNo ratings yet

- Punch List Interim 05-12-23Document1 pagePunch List Interim 05-12-23IGNATIUS MANOSAYNo ratings yet

- Service Report: Specify Scope of WorkDocument3 pagesService Report: Specify Scope of WorkKevin QuijanoNo ratings yet

- Daily Position of Mansoon Preacoution For The Year of 2020 (NAGPUR DIVISION)Document2 pagesDaily Position of Mansoon Preacoution For The Year of 2020 (NAGPUR DIVISION)Pranay S. WankhedeNo ratings yet

- Draft Work Order - BCF: (Mining Site Only) ) If Yes, Please Attach DBS Print Screen DSPSCMACDocument1 pageDraft Work Order - BCF: (Mining Site Only) ) If Yes, Please Attach DBS Print Screen DSPSCMACFajar WinarkoNo ratings yet

- 404 Bus 2 CVT 181021030334Document6 pages404 Bus 2 CVT 181021030334SARAVANAN ANo ratings yet

- C15 Additional Part Bushing Cam ShaftDocument7 pagesC15 Additional Part Bushing Cam ShaftYeremiaNo ratings yet

- IC#9 HBL Inspection Waiver ProfomaDocument2 pagesIC#9 HBL Inspection Waiver ProfomaAashish MoyalNo ratings yet

- Motor test results summaryDocument5 pagesMotor test results summarywillyNo ratings yet

- Less Than Three Vendors of RdsoDocument11 pagesLess Than Three Vendors of RdsoYOU COMFY YOU LOSENo ratings yet

- Esa Report FormatDocument12 pagesEsa Report FormatKailash PandeyNo ratings yet

- Jetty - Various Size - Load In - Bare - Downtime ReportDocument6 pagesJetty - Various Size - Load In - Bare - Downtime ReportBlade ChannelTvNo ratings yet

- Results Summary Log: Motor ID Time Temp Resis T Megoh M Da/P I DC Surg eDocument7 pagesResults Summary Log: Motor ID Time Temp Resis T Megoh M Da/P I DC Surg ewillyNo ratings yet

- BCM 1Document3 pagesBCM 1Alfredo jose Medina revattaNo ratings yet

- Ye - TPLTDocument136 pagesYe - TPLTAtilla AkdoganNo ratings yet

- Pilot Defect ReportDocument2 pagesPilot Defect ReportRachyita SinghNo ratings yet

- 2nd PVC ONA Bill FormatDocument8 pages2nd PVC ONA Bill FormatSuresh PatilNo ratings yet

- WNC 35 16 152 Vol-7.7.20Document5 pagesWNC 35 16 152 Vol-7.7.20lakshNo ratings yet

- IRFORINSPECTEDTAN-364-05 Compressed 20220504203057156Document4 pagesIRFORINSPECTEDTAN-364-05 Compressed 20220504203057156kaushik21185No ratings yet

- WE-386398 - R0 - 13.8kV Relay Setting CalculationDocument80 pagesWE-386398 - R0 - 13.8kV Relay Setting Calculationpb21100% (1)

- MKL Nofn FINAL WO-4Document18 pagesMKL Nofn FINAL WO-4DeepGillNo ratings yet

- Foot Plate Inspection Observation Action Taken Remarks Engineering BranchDocument10 pagesFoot Plate Inspection Observation Action Taken Remarks Engineering BranchSaadFarazKhanNo ratings yet

- Power CarDocument36 pagesPower CarShaif Uddin AhmedNo ratings yet

- PTCL Internal Solar System PAT ReportDocument9 pagesPTCL Internal Solar System PAT ReportBilal AsgharNo ratings yet

- DC Kumbakonam UPS ReportDocument1 pageDC Kumbakonam UPS Reporthelpdesk nonitNo ratings yet

- Technician Name Done Date & Sites Id Done Date & Sites IdDocument26 pagesTechnician Name Done Date & Sites Id Done Date & Sites IdkoshurNo ratings yet

- Wo 3594725Document1 pageWo 3594725minh nhat leNo ratings yet

- DPR 20.03.19Document13 pagesDPR 20.03.19essmahesNo ratings yet

- Results Summary Log: Motor ID Time Temp Resist Megohm DA/PI DC SurgeDocument7 pagesResults Summary Log: Motor ID Time Temp Resist Megohm DA/PI DC SurgewillyNo ratings yet

- Boiler Feed Water Treatment & BlowdownDocument6 pagesBoiler Feed Water Treatment & BlowdownnurulNo ratings yet

- Elements of Mechanical EngineeringDocument2 pagesElements of Mechanical EngineeringAshutosh KoundleNo ratings yet

- Chilled Water Pump - Primary, SecondaryDocument5 pagesChilled Water Pump - Primary, SecondarySatya N.GNo ratings yet

- Skema Bisnis Konservasi Energi Di Sektor IndustriDocument59 pagesSkema Bisnis Konservasi Energi Di Sektor IndustriIwaki AdmNo ratings yet

- Cochran Boiler Working Construction DiagramDocument5 pagesCochran Boiler Working Construction Diagrampankaj chaudharyNo ratings yet

- Pnacj953 PDFDocument395 pagesPnacj953 PDFSwaroop KumarNo ratings yet

- Hydronics Resources of The Canadian Institute of Plumbing & HeatingDocument3 pagesHydronics Resources of The Canadian Institute of Plumbing & HeatingTip toeNo ratings yet

- Morin 1993Document41 pagesMorin 1993muhammad fattah RomdhoniNo ratings yet

- B Bosch Serie 8 Steam IronDocument26 pagesB Bosch Serie 8 Steam IronRabNo ratings yet

- Curriculum Vitae: Job ObjectiveDocument4 pagesCurriculum Vitae: Job ObjectivesambhuNo ratings yet

- Star Paper Mills LimitedDocument8 pagesStar Paper Mills Limitedrudran_786No ratings yet

- VT2218 ECM High-Efficiency Circulator: Water Circulation Pumps & CirculatorsDocument4 pagesVT2218 ECM High-Efficiency Circulator: Water Circulation Pumps & Circulatorshamdi gshNo ratings yet

- Combustion of Wood - Heat ValuesDocument4 pagesCombustion of Wood - Heat Valuesags19941253No ratings yet

- CompressorDocument6 pagesCompressorLipika GayenNo ratings yet

- Boiler Water Treatment For Kiln DryingDocument42 pagesBoiler Water Treatment For Kiln DryingSyavash EnshaNo ratings yet

- Design efficient stacks and breechingsDocument1 pageDesign efficient stacks and breechingsHenry CoronadoNo ratings yet

- DBR KMPCLDocument99 pagesDBR KMPCLPRAMOD KUMAR NANDANo ratings yet

- A Comprehensive Guide To Oil Sight GlassesDocument15 pagesA Comprehensive Guide To Oil Sight GlassesTalha NizamiNo ratings yet

- Steam Power CycleDocument37 pagesSteam Power CycleAnamikaSharmaNo ratings yet

- Boiler Efficiency CalculationsDocument6 pagesBoiler Efficiency CalculationsRobert BarrettNo ratings yet

- 6400-6600 Series Catalog (394C) PDFDocument8 pages6400-6600 Series Catalog (394C) PDF20106285No ratings yet

- Power Plant EngineeringDocument5 pagesPower Plant EngineeringSyedNadeemAhmedNo ratings yet

- Chapter-2 Steam Cycle TheoryDocument20 pagesChapter-2 Steam Cycle TheorybhaskarNo ratings yet

- Furnace Efficiency CalculationDocument34 pagesFurnace Efficiency CalculationVinay RamarajuNo ratings yet

- Bhel Report Final2Document76 pagesBhel Report Final2Anuj Lamba100% (1)

- Act 139 Factories and Machinery Act 1967Document45 pagesAct 139 Factories and Machinery Act 1967Adam Haida & Co100% (2)

- DS-Vitopelx 200-Type SX2A - 5728770 - 6 - VDPDocument14 pagesDS-Vitopelx 200-Type SX2A - 5728770 - 6 - VDPDamir MuslicNo ratings yet

- Sigma Thermal Products OverviewDocument2 pagesSigma Thermal Products OverviewfrankyNo ratings yet

- Installation and Service Manual: Gas Fired Wall Mounted Condensing System BoilerDocument52 pagesInstallation and Service Manual: Gas Fired Wall Mounted Condensing System BoilerposhpaddyNo ratings yet