Professional Documents

Culture Documents

PWHT Post Weld Heat Treatment Sample Report PDF

PWHT Post Weld Heat Treatment Sample Report PDF

Uploaded by

Maged Lotfy Abdel-aalCopyright:

Available Formats

You might also like

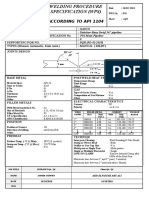

- Welding Procedure Specification (WPS) : According To Api 1104Document1 pageWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (1)

- Manual Mitsubishi Pajero IoanaDocument377 pagesManual Mitsubishi Pajero IoanamingulNo ratings yet

- Subdivision PlanDocument1 pageSubdivision PlanAna Kathrin Tolentino0% (2)

- ISOTECHDocument104 pagesISOTECHQuimicos MetrólogosNo ratings yet

- Reinforced Concrete Tee Block Reinforced Concrete Plug BlockDocument2 pagesReinforced Concrete Tee Block Reinforced Concrete Plug BlockPankajNo ratings yet

- Solidification of Iron Castings - 314983Document1 pageSolidification of Iron Castings - 314983Ankur PatelNo ratings yet

- Cabeling MEDocument27 pagesCabeling MEarnelectricsolutionsNo ratings yet

- Welding LOG / Dziennik SpawaniaDocument1 pageWelding LOG / Dziennik SpawaniaarissaNo ratings yet

- 985 163 00deDocument1 page985 163 00deKrystian ComporekNo ratings yet

- Complete Process Flow Chart: Stainless Steel Long ProductsDocument1 pageComplete Process Flow Chart: Stainless Steel Long ProductsThanh Ngoc LeNo ratings yet

- A-CAES Heat and Mass Balance Diagram 001Document3 pagesA-CAES Heat and Mass Balance Diagram 001IbraDinceNo ratings yet

- 036909C 2bae07 Iso HL 24366 01 0S5Document7 pages036909C 2bae07 Iso HL 24366 01 0S5NguyenCanhBaoNo ratings yet

- 036909C 2CPR02 Iso en 56498 01 0S7Document8 pages036909C 2CPR02 Iso en 56498 01 0S7NguyenCanhBaoNo ratings yet

- Data Sheet of Actuator Valve & Control Valve - 27 05 2021Document1 pageData Sheet of Actuator Valve & Control Valve - 27 05 2021pt tabNo ratings yet

- 036909C 2CPR01 Iso en 23251 01 0S3Document1 page036909C 2CPR01 Iso en 23251 01 0S3NguyenCanhBaoNo ratings yet

- Bill of Material Sketch List: Reason For Modifications by Subcontractor: Adjustment Pipe Length As Per Actual SiteDocument2 pagesBill of Material Sketch List: Reason For Modifications by Subcontractor: Adjustment Pipe Length As Per Actual SiteNguyenCanhBaoNo ratings yet

- 036909C 2BPR01 Iso SCS 23252 01 1S4 CDocument3 pages036909C 2BPR01 Iso SCS 23252 01 1S4 CNguyenCanhBaoNo ratings yet

- Reason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthDocument2 pagesReason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthNguyenCanhBaoNo ratings yet

- Reason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthDocument4 pagesReason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthNguyenCanhBaoNo ratings yet

- Reason For Modifications by Subcontractor: Adjustment Follow Actual Pipe Length, Add Detail Support As Per Site ConditionsDocument1 pageReason For Modifications by Subcontractor: Adjustment Follow Actual Pipe Length, Add Detail Support As Per Site ConditionsNguyenCanhBaoNo ratings yet

- Client Details:: Date of Previous TestDocument2 pagesClient Details:: Date of Previous TestBradley WainwrightNo ratings yet

- 036909C-2BAE02-ISO-SSC-24163-01-0F1S3-Isometric Sketch-Field Isometric - Modifications-CDocument2 pages036909C-2BAE02-ISO-SSC-24163-01-0F1S3-Isometric Sketch-Field Isometric - Modifications-CNguyenCanhBaoNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Form U-1Document5 pagesForm U-1msb_75No ratings yet

- Visual Inspection Report: Alkhorayef QC QA/QC ManagerDocument2 pagesVisual Inspection Report: Alkhorayef QC QA/QC Manageribrahim hegazyNo ratings yet

- Mid 5-XDocument10 pagesMid 5-XDavisTranNo ratings yet

- ENQUIRIES, WORK ORDERS AND INVOICE TRACKING REGISTER .Xls (Recovered) PDFDocument53 pagesENQUIRIES, WORK ORDERS AND INVOICE TRACKING REGISTER .Xls (Recovered) PDFSai Sashank100% (1)

- 036909C 2bae05 Iso SCS 23500 01 1S3Document4 pages036909C 2bae05 Iso SCS 23500 01 1S3NguyenCanhBaoNo ratings yet

- BoQ - Insulation Works (Group 2)Document4 pagesBoQ - Insulation Works (Group 2)Bhavanishankar ShettyNo ratings yet

- 036909C 2cae18 Iso en 23251 01 0S3Document1 page036909C 2cae18 Iso en 23251 01 0S3NguyenCanhBaoNo ratings yet

- 036909C 2cae02 Iso HL 26267 03 1F1S3Document2 pages036909C 2cae02 Iso HL 26267 03 1F1S3NguyenCanhBaoNo ratings yet

- 036909C 2bae03 Iso WG 29005 01 1F2S3 CDocument11 pages036909C 2bae03 Iso WG 29005 01 1F2S3 CNguyenCanhBaoNo ratings yet

- 036909C 2cae02 Iso HL 26330 06 0S2Document2 pages036909C 2cae02 Iso HL 26330 06 0S2NguyenCanhBaoNo ratings yet

- Bill of Material Sketch List: 3B M1 3B M1 3A M1 FDocument5 pagesBill of Material Sketch List: 3B M1 3B M1 3A M1 FNguyenCanhBaoNo ratings yet

- 036909C 2CAE06 ISO HBFW 51226 03 0F1S1 Isometric Sketch Field Isometric Modifications Code 3Document1 page036909C 2CAE06 ISO HBFW 51226 03 0F1S1 Isometric Sketch Field Isometric Modifications Code 3caochieuNo ratings yet

- 036909C 2cae05 Iso VT 27986 04 0S2Document1 page036909C 2cae05 Iso VT 27986 04 0S2NguyenCanhBaoNo ratings yet

- Bill of Material Sketch ListDocument8 pagesBill of Material Sketch ListNguyenCanhBaoNo ratings yet

- 036909C 2CAE02 ISO HL 26118 01 0S1 Isometric Sketch Field Isometric Modifications Code 3Document3 pages036909C 2CAE02 ISO HL 26118 01 0S1 Isometric Sketch Field Isometric Modifications Code 3caochieuNo ratings yet

- 036909C 2bae05 Iso FW 57372 01 1S2Document2 pages036909C 2bae05 Iso FW 57372 01 1S2NguyenCanhBaoNo ratings yet

- 036909C 2bae07 Iso CBD 24521 01 0S1 CDocument1 page036909C 2bae07 Iso CBD 24521 01 0S1 CNguyenCanhBaoNo ratings yet

- Bill of Material Sketch List: Reason For Modifications by Subcontractor: Cut and Reweld Due Field Fabrication ErrorDocument7 pagesBill of Material Sketch List: Reason For Modifications by Subcontractor: Cut and Reweld Due Field Fabrication ErrorNguyenCanhBaoNo ratings yet

- Bill of Materials: 331U15-OWS-002-02-1Document1 pageBill of Materials: 331U15-OWS-002-02-1PT Bumi Liputan PusakaNo ratings yet

- 2019 Us 3790Document1 page2019 Us 3790t1nz mdsNo ratings yet

- Catalog Pipa SumitomoDocument15 pagesCatalog Pipa SumitomoPrana FrensNo ratings yet

- FORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017Document2 pagesFORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017Ashish PatelNo ratings yet

- FORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017-2Document2 pagesFORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017-2Ashish PatelNo ratings yet

- Details of Pfj001 Details of Rfj001: FP-003A FP-004A 1 1 5 5Document1 pageDetails of Pfj001 Details of Rfj001: FP-003A FP-004A 1 1 5 5amit bagchiNo ratings yet

- Lot 144 PlanDocument1 pageLot 144 PlanHBENo ratings yet

- 036909C 2BPR01 Iso SCS 23253 01 0S4Document4 pages036909C 2BPR01 Iso SCS 23253 01 0S4NguyenCanhBaoNo ratings yet

- Pra Desain Pabrik Olein Dari Crude Palm Oil (Cpo) : SC CWDocument1 pagePra Desain Pabrik Olein Dari Crude Palm Oil (Cpo) : SC CWRyanKurniawanNo ratings yet

- BoQ - Insulation Works (Group 1)Document5 pagesBoQ - Insulation Works (Group 1)Bhavanishankar ShettyNo ratings yet

- QIP-PDI-G.3 - Design Instruction For Standard Pipe Support SelectionDocument1 pageQIP-PDI-G.3 - Design Instruction For Standard Pipe Support Selectiondimas prasetyoNo ratings yet

- Recommend PrintDocument1 pageRecommend Printjacquesgp3No ratings yet

- Pipebook Work Package 1Document39 pagesPipebook Work Package 1Renaldo akbarNo ratings yet

- Tool Steel - Material Selection Guide: High Speed SteelsDocument1 pageTool Steel - Material Selection Guide: High Speed SteelsAlok Rawat NLMKNo ratings yet

- The Influence of Inoculation: Solidification of Iron CastingsDocument1 pageThe Influence of Inoculation: Solidification of Iron CastingsDNo ratings yet

- Visual Inspection ReportDocument1 pageVisual Inspection ReportTWI CertificationNo ratings yet

- Asphalt: Company NameDocument2 pagesAsphalt: Company NametsegayNo ratings yet

- QAS - ERE 0.09 Bolt Torque Inspection ReportDocument1 pageQAS - ERE 0.09 Bolt Torque Inspection ReportJoanne InciongNo ratings yet

- Axens Technip India Ltd. Mumbai, India.: Bill of MaterialDocument9 pagesAxens Technip India Ltd. Mumbai, India.: Bill of MaterialSiddhu DudwadkarNo ratings yet

- OSYSU-1, - 2: Outside Screw and Yoke Valve Supervisory SwitchDocument4 pagesOSYSU-1, - 2: Outside Screw and Yoke Valve Supervisory SwitchMaged Lotfy Abdel-aalNo ratings yet

- UL - PotterDocument3 pagesUL - PotterMaged Lotfy Abdel-aalNo ratings yet

- BL 02 FM200 T&C CommentsDocument1 pageBL 02 FM200 T&C CommentsMaged Lotfy Abdel-aalNo ratings yet

- Kozziza REV01 PDFDocument11 pagesKozziza REV01 PDFMaged Lotfy Abdel-aalNo ratings yet

- Recommended Practice of EGWDocument7 pagesRecommended Practice of EGWMaged Lotfy Abdel-aalNo ratings yet

- PWHDocument1 pagePWHMaged Lotfy Abdel-aalNo ratings yet

- Calibration Certificate HTW1500B - 2011-286386Document1 pageCalibration Certificate HTW1500B - 2011-286386Maged Lotfy Abdel-aalNo ratings yet

- Profile of J.M.S Company: For Trade & EngineeringDocument1 pageProfile of J.M.S Company: For Trade & EngineeringMaged Lotfy Abdel-aalNo ratings yet

- ECITB Technical Testing System Certificate (4) - Eng. RomanyDocument1 pageECITB Technical Testing System Certificate (4) - Eng. RomanyMaged Lotfy Abdel-aalNo ratings yet

- Painting Procedures ADocument7 pagesPainting Procedures AMaged Lotfy Abdel-aal100% (1)

- FTR#CHSFL/TRG: SPH (Efe (Ate#NDocument2 pagesFTR#CHSFL/TRG: SPH (Efe (Ate#NMaged Lotfy Abdel-aalNo ratings yet

- Welder Qualification Test Certificate: PetrojetDocument3 pagesWelder Qualification Test Certificate: PetrojetMaged Lotfy Abdel-aalNo ratings yet

- RT SoftDocument16 pagesRT SoftMaged Lotfy Abdel-aalNo ratings yet

- WPQT CertificateDocument104 pagesWPQT CertificateMaged Lotfy Abdel-aal100% (2)

- 0 0 0 0 0 0 0 Total 0 Rest 7 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Total 9 Rest 21Document1 page0 0 0 0 0 0 0 Total 0 Rest 7 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Total 9 Rest 21Maged Lotfy Abdel-aalNo ratings yet

- Komatsu PW130 PDFDocument24 pagesKomatsu PW130 PDFالمهندسوليدالطويلNo ratings yet

- Product Design Specification Portable Wi PDFDocument9 pagesProduct Design Specification Portable Wi PDFktjayakumar3878No ratings yet

- Kta32 Spece DFJB Spec E: Generator Set Parts Catalog World Wide Parts & ServiceDocument57 pagesKta32 Spece DFJB Spec E: Generator Set Parts Catalog World Wide Parts & ServiceJames Scott Valderrama RiscoNo ratings yet

- Sylgard Hvic Image Brochure PDFDocument4 pagesSylgard Hvic Image Brochure PDFProject Sales CorpNo ratings yet

- Production Line Instant NoodleDocument13 pagesProduction Line Instant NoodleAnisah Aniz100% (1)

- Operating Manual Version 2 7 PDFDocument338 pagesOperating Manual Version 2 7 PDFPedro BancayanNo ratings yet

- Level and Pressure Instrumentation For Wastewater TreatmentDocument14 pagesLevel and Pressure Instrumentation For Wastewater TreatmentrezadNo ratings yet

- Optimisation of The Cadia Hill SAG Mill CircuitDocument11 pagesOptimisation of The Cadia Hill SAG Mill CircuitFernandoNo ratings yet

- Me 1004 Nuclear ENGINEERING Questions Bank 2014: SubscribeDocument14 pagesMe 1004 Nuclear ENGINEERING Questions Bank 2014: SubscribeLarry SmithNo ratings yet

- OSIG Guidance Notes 2017 Online VersionDocument36 pagesOSIG Guidance Notes 2017 Online VersionAriffZakariaNo ratings yet

- Peças 624cDocument236 pagesPeças 624cGabriely MuriloNo ratings yet

- Robotics SyllabusDocument52 pagesRobotics SyllabusManoj Kumar100% (1)

- Chemalert LabelsDocument1 pageChemalert Labelsshanmuga.chokkaiyanNo ratings yet

- 140g br001 - en PDocument12 pages140g br001 - en PTanveer AhmedNo ratings yet

- Testing of Bored Pile InclinationDocument5 pagesTesting of Bored Pile InclinationMudassar KhanNo ratings yet

- Basic PaperDocument20 pagesBasic PaperRavi Kumar VatturiNo ratings yet

- 34 Samss 821Document9 pages34 Samss 821Velmor VillenaNo ratings yet

- Survey 2 Assignment PDFDocument9 pagesSurvey 2 Assignment PDFUzair MukhtarNo ratings yet

- High Temperature Bearings - 14961 enDocument64 pagesHigh Temperature Bearings - 14961 enokta saputraNo ratings yet

- Cummins CELECT Electronic Injector PartsDocument6 pagesCummins CELECT Electronic Injector PartsRoussel Florez ZuloagaNo ratings yet

- Material Datasheet Cuzn30Document2 pagesMaterial Datasheet Cuzn30alex94kgNo ratings yet

- Crack and Object Detection in Pipeline Using Inspection RobotDocument6 pagesCrack and Object Detection in Pipeline Using Inspection RobotEditor IJTSRDNo ratings yet

- Telma OEM Guidelines J1939 J2284: Revised: 22mar12Document10 pagesTelma OEM Guidelines J1939 J2284: Revised: 22mar12maurop25984No ratings yet

- Sumitomo 8FBR15 1.0-1.8 TonDocument8 pagesSumitomo 8FBR15 1.0-1.8 TonFerdie Pakingan100% (1)

- Annual Repair Schedule Draft 4sept2012Document6 pagesAnnual Repair Schedule Draft 4sept2012keithmontpvtNo ratings yet

- Miha Tomaževič - Damage Limitation As A Basis For Assessment of Parameters For Seismic Resistant Design of Masonry BuildingsDocument13 pagesMiha Tomaževič - Damage Limitation As A Basis For Assessment of Parameters For Seismic Resistant Design of Masonry BuildingsScribd2015No ratings yet

- Kebijakan Dan Harga MigasDocument21 pagesKebijakan Dan Harga MigasLuki LukmanNo ratings yet

- La Lista Durman-Nicaragua 27-02-13-SpDocument44 pagesLa Lista Durman-Nicaragua 27-02-13-SpE Jovany CastleNo ratings yet

PWHT Post Weld Heat Treatment Sample Report PDF

PWHT Post Weld Heat Treatment Sample Report PDF

Uploaded by

Maged Lotfy Abdel-aalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PWHT Post Weld Heat Treatment Sample Report PDF

PWHT Post Weld Heat Treatment Sample Report PDF

Uploaded by

Maged Lotfy Abdel-aalCopyright:

Available Formats

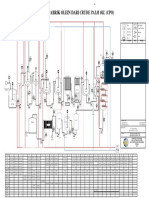

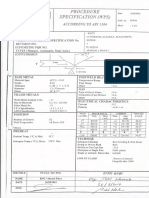

HEAT TREATMENT CERTIFICATE

Registration No. Identification

BMW1 Center Heats Bands Bend 1

Customer

BMW Bailly Generating Station

Order No. Order by Date of Order

NA S. Worrall 10-24-06

Site

NIPSCO

Job No. Heat Treatment Procedure Date of Heat Treatment

Bailly Cold Re-heat BMW-001 10/24/2006 04:59 10/24/2006 20:59

Item Drawing No. Part No. / Seam No. Material Pcs

Bend 1 Cold Re-heat CS 1

Type of Heat Treatment Method of Heat Treatment

PWHT Electric

Consol Controller Calib. Date Sensor

D1 DBE258 1008/166 10-22-06 SW F K_TYPE

Phase Set Values Measured Values

1 01 Start - 70 °F

2 10 Heating 400 °F/h -> 580 °F 100 °F/h -> 580 °F (5h06)

3 10 Heating 200 °F/h -> 1400 °F 183 °F/h -> 1400 °F (0h20)

4 20 Holding 1400 °F 2h00 1400 °F 1h05 (1h05) (1399-1404 °F)

5 30 Cooling 140 °F/h -> 780 °F -139 °F/h -> 779 °F (2h52)

6 60 Finish - 779 °F

1 TC 1 2 TC 2 3 TC 3 4 TC 4 5 TC 5 6 TC 6

1600

1400

1200

1000

10/24/2006 05:50

10/24/2006 06:50

10/24/2006 07:50

10/24/2006 08:50

10/24/2006 09:50

10/24/2006 10:50

10/24/2006 11:50

10/24/2006 12:50

10/24/2006 13:50

10/24/2006 14:50

10/24/2006 15:50

10/24/2006 16:50

10/24/2006 17:50

10/24/2006 18:50

10/24/2006 19:50

10/24/2006 20:50

10/24/2006 21:50

10/24/2006 22:50

10/24/2006 23:50

10/25/2006 00:50

10/25/2006 01:50

10/25/2006 02:50

10/25/2006 03:50

800

10 Heating

10 Heating

20 Holding

30 Cooling

600

400

10 Heating

10 Heating

20 Holding

20 Holding

20 Holding

30 Cooling

30 Cooling

200

60 Finish

01 Start

HOBART IN 10/24/2006 S. WORRALL T. JACKSON

Furmanite America Inc, Hobart In USA

You might also like

- Welding Procedure Specification (WPS) : According To Api 1104Document1 pageWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (1)

- Manual Mitsubishi Pajero IoanaDocument377 pagesManual Mitsubishi Pajero IoanamingulNo ratings yet

- Subdivision PlanDocument1 pageSubdivision PlanAna Kathrin Tolentino0% (2)

- ISOTECHDocument104 pagesISOTECHQuimicos MetrólogosNo ratings yet

- Reinforced Concrete Tee Block Reinforced Concrete Plug BlockDocument2 pagesReinforced Concrete Tee Block Reinforced Concrete Plug BlockPankajNo ratings yet

- Solidification of Iron Castings - 314983Document1 pageSolidification of Iron Castings - 314983Ankur PatelNo ratings yet

- Cabeling MEDocument27 pagesCabeling MEarnelectricsolutionsNo ratings yet

- Welding LOG / Dziennik SpawaniaDocument1 pageWelding LOG / Dziennik SpawaniaarissaNo ratings yet

- 985 163 00deDocument1 page985 163 00deKrystian ComporekNo ratings yet

- Complete Process Flow Chart: Stainless Steel Long ProductsDocument1 pageComplete Process Flow Chart: Stainless Steel Long ProductsThanh Ngoc LeNo ratings yet

- A-CAES Heat and Mass Balance Diagram 001Document3 pagesA-CAES Heat and Mass Balance Diagram 001IbraDinceNo ratings yet

- 036909C 2bae07 Iso HL 24366 01 0S5Document7 pages036909C 2bae07 Iso HL 24366 01 0S5NguyenCanhBaoNo ratings yet

- 036909C 2CPR02 Iso en 56498 01 0S7Document8 pages036909C 2CPR02 Iso en 56498 01 0S7NguyenCanhBaoNo ratings yet

- Data Sheet of Actuator Valve & Control Valve - 27 05 2021Document1 pageData Sheet of Actuator Valve & Control Valve - 27 05 2021pt tabNo ratings yet

- 036909C 2CPR01 Iso en 23251 01 0S3Document1 page036909C 2CPR01 Iso en 23251 01 0S3NguyenCanhBaoNo ratings yet

- Bill of Material Sketch List: Reason For Modifications by Subcontractor: Adjustment Pipe Length As Per Actual SiteDocument2 pagesBill of Material Sketch List: Reason For Modifications by Subcontractor: Adjustment Pipe Length As Per Actual SiteNguyenCanhBaoNo ratings yet

- 036909C 2BPR01 Iso SCS 23252 01 1S4 CDocument3 pages036909C 2BPR01 Iso SCS 23252 01 1S4 CNguyenCanhBaoNo ratings yet

- Reason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthDocument2 pagesReason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthNguyenCanhBaoNo ratings yet

- Reason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthDocument4 pagesReason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthNguyenCanhBaoNo ratings yet

- Reason For Modifications by Subcontractor: Adjustment Follow Actual Pipe Length, Add Detail Support As Per Site ConditionsDocument1 pageReason For Modifications by Subcontractor: Adjustment Follow Actual Pipe Length, Add Detail Support As Per Site ConditionsNguyenCanhBaoNo ratings yet

- Client Details:: Date of Previous TestDocument2 pagesClient Details:: Date of Previous TestBradley WainwrightNo ratings yet

- 036909C-2BAE02-ISO-SSC-24163-01-0F1S3-Isometric Sketch-Field Isometric - Modifications-CDocument2 pages036909C-2BAE02-ISO-SSC-24163-01-0F1S3-Isometric Sketch-Field Isometric - Modifications-CNguyenCanhBaoNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Form U-1Document5 pagesForm U-1msb_75No ratings yet

- Visual Inspection Report: Alkhorayef QC QA/QC ManagerDocument2 pagesVisual Inspection Report: Alkhorayef QC QA/QC Manageribrahim hegazyNo ratings yet

- Mid 5-XDocument10 pagesMid 5-XDavisTranNo ratings yet

- ENQUIRIES, WORK ORDERS AND INVOICE TRACKING REGISTER .Xls (Recovered) PDFDocument53 pagesENQUIRIES, WORK ORDERS AND INVOICE TRACKING REGISTER .Xls (Recovered) PDFSai Sashank100% (1)

- 036909C 2bae05 Iso SCS 23500 01 1S3Document4 pages036909C 2bae05 Iso SCS 23500 01 1S3NguyenCanhBaoNo ratings yet

- BoQ - Insulation Works (Group 2)Document4 pagesBoQ - Insulation Works (Group 2)Bhavanishankar ShettyNo ratings yet

- 036909C 2cae18 Iso en 23251 01 0S3Document1 page036909C 2cae18 Iso en 23251 01 0S3NguyenCanhBaoNo ratings yet

- 036909C 2cae02 Iso HL 26267 03 1F1S3Document2 pages036909C 2cae02 Iso HL 26267 03 1F1S3NguyenCanhBaoNo ratings yet

- 036909C 2bae03 Iso WG 29005 01 1F2S3 CDocument11 pages036909C 2bae03 Iso WG 29005 01 1F2S3 CNguyenCanhBaoNo ratings yet

- 036909C 2cae02 Iso HL 26330 06 0S2Document2 pages036909C 2cae02 Iso HL 26330 06 0S2NguyenCanhBaoNo ratings yet

- Bill of Material Sketch List: 3B M1 3B M1 3A M1 FDocument5 pagesBill of Material Sketch List: 3B M1 3B M1 3A M1 FNguyenCanhBaoNo ratings yet

- 036909C 2CAE06 ISO HBFW 51226 03 0F1S1 Isometric Sketch Field Isometric Modifications Code 3Document1 page036909C 2CAE06 ISO HBFW 51226 03 0F1S1 Isometric Sketch Field Isometric Modifications Code 3caochieuNo ratings yet

- 036909C 2cae05 Iso VT 27986 04 0S2Document1 page036909C 2cae05 Iso VT 27986 04 0S2NguyenCanhBaoNo ratings yet

- Bill of Material Sketch ListDocument8 pagesBill of Material Sketch ListNguyenCanhBaoNo ratings yet

- 036909C 2CAE02 ISO HL 26118 01 0S1 Isometric Sketch Field Isometric Modifications Code 3Document3 pages036909C 2CAE02 ISO HL 26118 01 0S1 Isometric Sketch Field Isometric Modifications Code 3caochieuNo ratings yet

- 036909C 2bae05 Iso FW 57372 01 1S2Document2 pages036909C 2bae05 Iso FW 57372 01 1S2NguyenCanhBaoNo ratings yet

- 036909C 2bae07 Iso CBD 24521 01 0S1 CDocument1 page036909C 2bae07 Iso CBD 24521 01 0S1 CNguyenCanhBaoNo ratings yet

- Bill of Material Sketch List: Reason For Modifications by Subcontractor: Cut and Reweld Due Field Fabrication ErrorDocument7 pagesBill of Material Sketch List: Reason For Modifications by Subcontractor: Cut and Reweld Due Field Fabrication ErrorNguyenCanhBaoNo ratings yet

- Bill of Materials: 331U15-OWS-002-02-1Document1 pageBill of Materials: 331U15-OWS-002-02-1PT Bumi Liputan PusakaNo ratings yet

- 2019 Us 3790Document1 page2019 Us 3790t1nz mdsNo ratings yet

- Catalog Pipa SumitomoDocument15 pagesCatalog Pipa SumitomoPrana FrensNo ratings yet

- FORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017Document2 pagesFORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017Ashish PatelNo ratings yet

- FORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017-2Document2 pagesFORM U-5 MANUFACTURERS DATA REPORT SUPPLEMENTARY SHEET SHELL-AND-TUBE HEAT EXCHANGERS Edit2017-2Ashish PatelNo ratings yet

- Details of Pfj001 Details of Rfj001: FP-003A FP-004A 1 1 5 5Document1 pageDetails of Pfj001 Details of Rfj001: FP-003A FP-004A 1 1 5 5amit bagchiNo ratings yet

- Lot 144 PlanDocument1 pageLot 144 PlanHBENo ratings yet

- 036909C 2BPR01 Iso SCS 23253 01 0S4Document4 pages036909C 2BPR01 Iso SCS 23253 01 0S4NguyenCanhBaoNo ratings yet

- Pra Desain Pabrik Olein Dari Crude Palm Oil (Cpo) : SC CWDocument1 pagePra Desain Pabrik Olein Dari Crude Palm Oil (Cpo) : SC CWRyanKurniawanNo ratings yet

- BoQ - Insulation Works (Group 1)Document5 pagesBoQ - Insulation Works (Group 1)Bhavanishankar ShettyNo ratings yet

- QIP-PDI-G.3 - Design Instruction For Standard Pipe Support SelectionDocument1 pageQIP-PDI-G.3 - Design Instruction For Standard Pipe Support Selectiondimas prasetyoNo ratings yet

- Recommend PrintDocument1 pageRecommend Printjacquesgp3No ratings yet

- Pipebook Work Package 1Document39 pagesPipebook Work Package 1Renaldo akbarNo ratings yet

- Tool Steel - Material Selection Guide: High Speed SteelsDocument1 pageTool Steel - Material Selection Guide: High Speed SteelsAlok Rawat NLMKNo ratings yet

- The Influence of Inoculation: Solidification of Iron CastingsDocument1 pageThe Influence of Inoculation: Solidification of Iron CastingsDNo ratings yet

- Visual Inspection ReportDocument1 pageVisual Inspection ReportTWI CertificationNo ratings yet

- Asphalt: Company NameDocument2 pagesAsphalt: Company NametsegayNo ratings yet

- QAS - ERE 0.09 Bolt Torque Inspection ReportDocument1 pageQAS - ERE 0.09 Bolt Torque Inspection ReportJoanne InciongNo ratings yet

- Axens Technip India Ltd. Mumbai, India.: Bill of MaterialDocument9 pagesAxens Technip India Ltd. Mumbai, India.: Bill of MaterialSiddhu DudwadkarNo ratings yet

- OSYSU-1, - 2: Outside Screw and Yoke Valve Supervisory SwitchDocument4 pagesOSYSU-1, - 2: Outside Screw and Yoke Valve Supervisory SwitchMaged Lotfy Abdel-aalNo ratings yet

- UL - PotterDocument3 pagesUL - PotterMaged Lotfy Abdel-aalNo ratings yet

- BL 02 FM200 T&C CommentsDocument1 pageBL 02 FM200 T&C CommentsMaged Lotfy Abdel-aalNo ratings yet

- Kozziza REV01 PDFDocument11 pagesKozziza REV01 PDFMaged Lotfy Abdel-aalNo ratings yet

- Recommended Practice of EGWDocument7 pagesRecommended Practice of EGWMaged Lotfy Abdel-aalNo ratings yet

- PWHDocument1 pagePWHMaged Lotfy Abdel-aalNo ratings yet

- Calibration Certificate HTW1500B - 2011-286386Document1 pageCalibration Certificate HTW1500B - 2011-286386Maged Lotfy Abdel-aalNo ratings yet

- Profile of J.M.S Company: For Trade & EngineeringDocument1 pageProfile of J.M.S Company: For Trade & EngineeringMaged Lotfy Abdel-aalNo ratings yet

- ECITB Technical Testing System Certificate (4) - Eng. RomanyDocument1 pageECITB Technical Testing System Certificate (4) - Eng. RomanyMaged Lotfy Abdel-aalNo ratings yet

- Painting Procedures ADocument7 pagesPainting Procedures AMaged Lotfy Abdel-aal100% (1)

- FTR#CHSFL/TRG: SPH (Efe (Ate#NDocument2 pagesFTR#CHSFL/TRG: SPH (Efe (Ate#NMaged Lotfy Abdel-aalNo ratings yet

- Welder Qualification Test Certificate: PetrojetDocument3 pagesWelder Qualification Test Certificate: PetrojetMaged Lotfy Abdel-aalNo ratings yet

- RT SoftDocument16 pagesRT SoftMaged Lotfy Abdel-aalNo ratings yet

- WPQT CertificateDocument104 pagesWPQT CertificateMaged Lotfy Abdel-aal100% (2)

- 0 0 0 0 0 0 0 Total 0 Rest 7 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Total 9 Rest 21Document1 page0 0 0 0 0 0 0 Total 0 Rest 7 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Total 9 Rest 21Maged Lotfy Abdel-aalNo ratings yet

- Komatsu PW130 PDFDocument24 pagesKomatsu PW130 PDFالمهندسوليدالطويلNo ratings yet

- Product Design Specification Portable Wi PDFDocument9 pagesProduct Design Specification Portable Wi PDFktjayakumar3878No ratings yet

- Kta32 Spece DFJB Spec E: Generator Set Parts Catalog World Wide Parts & ServiceDocument57 pagesKta32 Spece DFJB Spec E: Generator Set Parts Catalog World Wide Parts & ServiceJames Scott Valderrama RiscoNo ratings yet

- Sylgard Hvic Image Brochure PDFDocument4 pagesSylgard Hvic Image Brochure PDFProject Sales CorpNo ratings yet

- Production Line Instant NoodleDocument13 pagesProduction Line Instant NoodleAnisah Aniz100% (1)

- Operating Manual Version 2 7 PDFDocument338 pagesOperating Manual Version 2 7 PDFPedro BancayanNo ratings yet

- Level and Pressure Instrumentation For Wastewater TreatmentDocument14 pagesLevel and Pressure Instrumentation For Wastewater TreatmentrezadNo ratings yet

- Optimisation of The Cadia Hill SAG Mill CircuitDocument11 pagesOptimisation of The Cadia Hill SAG Mill CircuitFernandoNo ratings yet

- Me 1004 Nuclear ENGINEERING Questions Bank 2014: SubscribeDocument14 pagesMe 1004 Nuclear ENGINEERING Questions Bank 2014: SubscribeLarry SmithNo ratings yet

- OSIG Guidance Notes 2017 Online VersionDocument36 pagesOSIG Guidance Notes 2017 Online VersionAriffZakariaNo ratings yet

- Peças 624cDocument236 pagesPeças 624cGabriely MuriloNo ratings yet

- Robotics SyllabusDocument52 pagesRobotics SyllabusManoj Kumar100% (1)

- Chemalert LabelsDocument1 pageChemalert Labelsshanmuga.chokkaiyanNo ratings yet

- 140g br001 - en PDocument12 pages140g br001 - en PTanveer AhmedNo ratings yet

- Testing of Bored Pile InclinationDocument5 pagesTesting of Bored Pile InclinationMudassar KhanNo ratings yet

- Basic PaperDocument20 pagesBasic PaperRavi Kumar VatturiNo ratings yet

- 34 Samss 821Document9 pages34 Samss 821Velmor VillenaNo ratings yet

- Survey 2 Assignment PDFDocument9 pagesSurvey 2 Assignment PDFUzair MukhtarNo ratings yet

- High Temperature Bearings - 14961 enDocument64 pagesHigh Temperature Bearings - 14961 enokta saputraNo ratings yet

- Cummins CELECT Electronic Injector PartsDocument6 pagesCummins CELECT Electronic Injector PartsRoussel Florez ZuloagaNo ratings yet

- Material Datasheet Cuzn30Document2 pagesMaterial Datasheet Cuzn30alex94kgNo ratings yet

- Crack and Object Detection in Pipeline Using Inspection RobotDocument6 pagesCrack and Object Detection in Pipeline Using Inspection RobotEditor IJTSRDNo ratings yet

- Telma OEM Guidelines J1939 J2284: Revised: 22mar12Document10 pagesTelma OEM Guidelines J1939 J2284: Revised: 22mar12maurop25984No ratings yet

- Sumitomo 8FBR15 1.0-1.8 TonDocument8 pagesSumitomo 8FBR15 1.0-1.8 TonFerdie Pakingan100% (1)

- Annual Repair Schedule Draft 4sept2012Document6 pagesAnnual Repair Schedule Draft 4sept2012keithmontpvtNo ratings yet

- Miha Tomaževič - Damage Limitation As A Basis For Assessment of Parameters For Seismic Resistant Design of Masonry BuildingsDocument13 pagesMiha Tomaževič - Damage Limitation As A Basis For Assessment of Parameters For Seismic Resistant Design of Masonry BuildingsScribd2015No ratings yet

- Kebijakan Dan Harga MigasDocument21 pagesKebijakan Dan Harga MigasLuki LukmanNo ratings yet

- La Lista Durman-Nicaragua 27-02-13-SpDocument44 pagesLa Lista Durman-Nicaragua 27-02-13-SpE Jovany CastleNo ratings yet