Professional Documents

Culture Documents

Solidification of Iron Castings - 314983

Uploaded by

Ankur PatelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solidification of Iron Castings - 314983

Uploaded by

Ankur PatelCopyright:

Available Formats

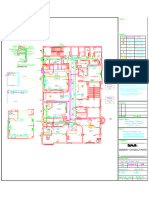

SOLIDIFICATION OF IRON CASTINGS

www.foseco.com

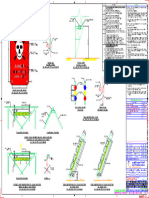

THE INFLUENCE OF INOCULATION

CRUCIBLES

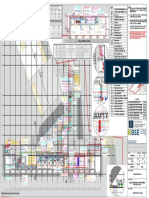

IRON-CARBON DIAGRAM INTERPRETATION OF SOLIDIFICATION USING COOLING CURVES

Carbon Equivalent in Atom % TE grey Iron-graphite eutectic solidification Fast cooling Slow cooling

temperature. High Low High Low

nucleation nucleation nucleation nucleation

Undercooling = TE max. – TE min.

TE max. TE grey TE white Iron-iron carbide solidification grey 1 2 3 4

BINDERS

Temperature

Liquid + Fe Start Finish

S4 temperature. Finish Start

Fe Start Start Finish

Temperature

TE white white

Fe + Fe TE min

Liquid TE min. Austenite and graphite are still growing; Finish

inoculation raises this temperature. grey white grey grey/white

Liquid +

M E TA L T R E A T M E N T

Austenite (Fe ) Liquid +

Graphite/Cementite

Time (sec.) Undercooling Too much undercooling tends to Time

Temperature °C

Austenite (Fe ) generate carbides. Inoculation raises TE min, reducing

Figure 1. Cooling curve for inoculated graphitic iron. undercooling. Figure 2. With both fast and slow cooling, inoculation

raises the temperatures of the curve, promoting the

Austenite (Fe ) + Graphite/Cementite The metallurgical quality of iron castings depends graphitic model of solidification.

on the solidification mode which can be modified by

S3 Recalescence. Increase in metal temperature.

Ferrite +

inoculation. The thermal analysis cooling curve can be

Austenite

interpreted as follows: TE max Maximum eutectic temperature. (1) Fast and inoculated cooling. TE min. > TE white.

Grey iron forms.

Determines recalesence (R = TE max. – TE min.),

Ferrite S1 Start of solidification. and relates to the graphitisation model.

(2) Fast and uninoculated cooling. TE min. < TE white,

(Fe α) Ferrite (Fe α) + Graphite/Cementite

M E LT S H O P R E F R A C T O R I E S

thus the iron is carbidic or white.

TL Liquidus temperature. The first solid phase starts S4 Second solidification stage. Secondary porosity

relates directly to this part of the curve.

to form. In hypoeutectic irons austenite is precipitated.

CE respectively Carbon Equivalent in Weight %

In hypereutectic irons graphite is precipitated. Differs

(3) Slow cooling, but inoculated, is entirely graphitic.

according to the silicon and carbon content.

THE EFFECTS OF INOCULATION (4) In a thick casting, slow and uninoculated cooling,

Sc Degree of Saturation mottled or mixed graphitic-carbidic structure forms.

Hypoeutectic Casting Hypereutectic Casting

S2 Start of graphite formation. Inoculation modifies the profile of the thermal

analysis curve, so that solidification follows the

%Si %C graphitic solidification model.

% Carbon Equivalent CE = %C + 3 % Saturation Coefficient Sc = 4,3 - 1/3 %Si

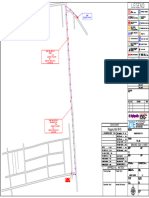

SELECTION OF INOCULANTS FOR PRODUCTION OF GREY IRON CASTINGS SELECTION OF INOCULANTS FOR PRODUCTION OF SPHEROIDAL GRAPHITE IRON CASTINGS

FEEDING SYSTEMS

Priority Aim Calcium Zirconium Priority Aim Calcium Strontium

1 Prevention of carbides or white iron Improves graphite germination. Reduces Improves solubility of inoculant, neutralises 1 Eliminate carbides or white iron Improves graphite germination. Reduces 1% strontium in high purity FeSi eliminates

2 Improve shape of type-A graphite tendency to chill. nitrogen and improves inoculation. Combined 2 Improve graphite form tendency to chill. carbides and increases the number of nodules,

(improved properties) with Mn, reduces melting point of inoculant. 3 Increase number of nodules provided that nodulisation is carried out with

3 Delay fading of nucleation Barium 4 Reduce fading of nucleation Barium Rare Earth-free FeSiMg.

4 Reduce microshrinkage Strong graphite promoter. Reduces inoculant Cerium and other Rare Earths 5 Eliminate microshrinkage Strong graphite promoter. Reduces inoculant

5 Reduction of graphite flotation fading. Cerium and other rare earths increase the 6 Minimise gas defects fading. Also has a nodulising effect. Risk of slag Zirconium

6 Minimise gas defects number of eutectic cells and reduce fading. 7 Eliminate ferrite skin when used in excess. Increases inoculant solubility when combined

7 Eliminate ferrite skin Strontium INOCULIN 920, which contains La, produces 8 Other with Mn. Neutralises nitrogen.

F I LT R A T I O N

8 Other Strontium eliminates carbide without increasing finer graphite, reducing flotation and associated Bismuth

the number of eutectic cells (reducing the tendency gas defects. Effects of ‘active’ elements in spheroidal graphite 0.1% Bi, combined with rare earths, increases Cerium and other Rare Earths

Effects of ‘active’ elements in grey iron to shrinkage due to excessive high cell count). iron inoculants. the number of nodules, reduces their size Improve inoculation of spheroidal graphite iron,

inoculants. and reduces tendency to white iron. Reduces whether added in treatment with Mg or to the

Aluminium graphite flotation. Can produce intercellular inoculant, and reduce inoculant fading.

Aluminium Strong ferrite promoter, so for thin sections, lamellar graphite unless offset by rare earths.

Improves ferritisation. Neutralises nitrogen. inoculants with 4% aluminium content are used.

C OAT I N G S

*FOSECO, the Logo and INOCULIN are trade marks of the Vesuvius Group, registered in certain countries, used under licence. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system of any nature or transmitted in any form or by any means, including photocopying and recording, without the written permission of the copyright holder.

You might also like

- The Influence of Inoculation: Solidification of Iron CastingsDocument1 pageThe Influence of Inoculation: Solidification of Iron CastingsDNo ratings yet

- Chapter 2 - Material BehaviourDocument1 pageChapter 2 - Material BehaviourMuhamad YusupNo ratings yet

- S-CT-427-XX-2013 - Concrete DetailsDocument1 pageS-CT-427-XX-2013 - Concrete DetailsMarco ReyesNo ratings yet

- CB434D Civiles Serie CNHDocument6 pagesCB434D Civiles Serie CNHJesusAntonioQuirinoCanoNo ratings yet

- Periodic TableCheap Charts Frank Schaffer Publications - BarCharts QuickStudyDocument2 pagesPeriodic TableCheap Charts Frank Schaffer Publications - BarCharts QuickStudyMatheus Eduardo100% (1)

- Chemistry - Periodic Table - Advanced PDFDocument2 pagesChemistry - Periodic Table - Advanced PDFCA_Ken86% (7)

- Tabla Periódica de Los Elementos QuímicosDocument2 pagesTabla Periódica de Los Elementos QuímicosGael Josue Vega100% (1)

- Property Comparison Chart PDFDocument2 pagesProperty Comparison Chart PDFmecano1No ratings yet

- Chem 1 BackDocument1 pageChem 1 BackananthuvngmkdNo ratings yet

- Casa de Dos Niveles Con Detalles Sanitarios ModelDocument1 pageCasa de Dos Niveles Con Detalles Sanitarios ModelMichelito Julca pastorNo ratings yet

- C.H. - 0+407 Section No1 C.H. - 0+835 Section No3Document1 pageC.H. - 0+407 Section No1 C.H. - 0+835 Section No3Fran LuqueNo ratings yet

- As Revised - R2-A-101Document1 pageAs Revised - R2-A-101Farhan AhamedNo ratings yet

- En OGC Catalogue MaxsealDocument32 pagesEn OGC Catalogue MaxsealHai Pham VanNo ratings yet

- SCR 003789Document1 pageSCR 003789jeplgpbmcNo ratings yet

- Pra Desain Pabrik Olein Dari Crude Palm Oil (Cpo) : SC CWDocument1 pagePra Desain Pabrik Olein Dari Crude Palm Oil (Cpo) : SC CWRyanKurniawanNo ratings yet

- A B C D A B C D A B C D: Legend SpecificationDocument1 pageA B C D A B C D A B C D: Legend SpecificationFreyaNo ratings yet

- Concrete 3 May 2021Document4 pagesConcrete 3 May 2021Lucifer MorningstarNo ratings yet

- Luar Na Lubre - FoliadaDocument1 pageLuar Na Lubre - Foliadavhrr21No ratings yet

- Tabela PeriodicaDocument1 pageTabela PeriodicaEdgarRafaelCardosoNo ratings yet

- Jig - Trasnportada - para Tocar - Con Bajo y Acordes - BUENOSDocument1 pageJig - Trasnportada - para Tocar - Con Bajo y Acordes - BUENOSvhrr21No ratings yet

- Introductory Chemistry A Foundation 9Th Edition Steven S Zumdahl Full ChapterDocument51 pagesIntroductory Chemistry A Foundation 9Th Edition Steven S Zumdahl Full Chaptercathy.johnson159100% (6)

- Phan Dien - Cap Nhat Ban Ve Thi Cong Theo y Kien Phan Hoi 25.10.2021Document17 pagesPhan Dien - Cap Nhat Ban Ve Thi Cong Theo y Kien Phan Hoi 25.10.2021Trần ChâuNo ratings yet

- RENR3307RENR3307Document4 pagesRENR3307RENR3307tommy lanyonNo ratings yet

- Cutting DVSDocument1 pageCutting DVSthomasNo ratings yet

- 072744C-RA1-DW-SW-31126-1-01 - 0 Change Joint TypeDocument3 pages072744C-RA1-DW-SW-31126-1-01 - 0 Change Joint TypeLocus Jhun MichaelNo ratings yet

- Christmas Medley BBC Full ScoreDocument14 pagesChristmas Medley BBC Full ScoreSpyros SpyropoulosNo ratings yet

- Ingreso SSGG: Casa de FuerzaDocument1 pageIngreso SSGG: Casa de FuerzaAlexNo ratings yet

- Welding LOG / Dziennik SpawaniaDocument1 pageWelding LOG / Dziennik SpawaniaarissaNo ratings yet

- Ramothibe T - Stage 4-Acuv300Document2 pagesRamothibe T - Stage 4-Acuv300Monde Tidimalo Lunathi MbaluNo ratings yet

- Day ShiftDocument1 pageDay ShiftKanupriya JainNo ratings yet

- 2102 S1 0101 R2 Sheet 1 of 4-1Document1 page2102 S1 0101 R2 Sheet 1 of 4-1prabhu sinnurNo ratings yet

- CE Board Nov 2020 - RCD - Set 3 MonoDocument2 pagesCE Board Nov 2020 - RCD - Set 3 MonoDale MalazzabNo ratings yet

- Lb-2027-Jlt-Id-Add-2002-30th Floor Buffet Area Elevation-1002Document1 pageLb-2027-Jlt-Id-Add-2002-30th Floor Buffet Area Elevation-1002Saravananan SelvarajNo ratings yet

- Shaft-F: Ceiling PenetrationDocument1 pageShaft-F: Ceiling PenetrationisraelNo ratings yet

- Auxiliary PlanDocument1 pageAuxiliary PlanMaynard SurioNo ratings yet

- Gorapur SIP 21388Document1 pageGorapur SIP 21388shiva bhaskarNo ratings yet

- In The Bar Heave Away Come From AwayDocument67 pagesIn The Bar Heave Away Come From AwaylupitaArchieNo ratings yet

- SF29-99-064 - Panggung Kidul RW 01 - PRE-ABD DWG (SUB FEEDER)Document1 pageSF29-99-064 - Panggung Kidul RW 01 - PRE-ABD DWG (SUB FEEDER)Attah RiriNo ratings yet

- KENR3599KENR3599Document6 pagesKENR3599KENR3599Carlos Enrique Vega OrtegaNo ratings yet

- Structural Beam & Arch Details-ModelDocument1 pageStructural Beam & Arch Details-ModelAhmed SolankiNo ratings yet

- RevisionsDocument1 pageRevisionsVisakha DasNo ratings yet

- Ea-0685780.0000.0 1Document1 pageEa-0685780.0000.0 1vs6jghbngzNo ratings yet

- Typical Reinforced Concrete Details and Construction Notes - 2Document1 pageTypical Reinforced Concrete Details and Construction Notes - 2Aly Arquillano JrNo ratings yet

- Esr 18 Mahulpali 520kl 23m - RCDocument4 pagesEsr 18 Mahulpali 520kl 23m - RCGopal SinghNo ratings yet

- Beam Section Details: Typical Gravity Reinforced Concrete Beam DetailDocument1 pageBeam Section Details: Typical Gravity Reinforced Concrete Beam DetailMARKCHRISTMASNo ratings yet

- 432 434 1elektroDocument4 pages432 434 1elektrodenisNo ratings yet

- Paper Epitermales LSDocument1 pagePaper Epitermales LSARTURO CALERONo ratings yet

- Ea 0040Document1 pageEa 0040fereetNo ratings yet

- A31.1 Fourth Floor Furniture Wing-1Document1 pageA31.1 Fourth Floor Furniture Wing-1Azkagul 28No ratings yet

- A31.1 Fourth Floor Furniture Wing-1Document1 pageA31.1 Fourth Floor Furniture Wing-1Azkagul 28No ratings yet

- HV-205 (Third Floor HVAC Layout) - ModelDocument1 pageHV-205 (Third Floor HVAC Layout) - ModelMohamed AliNo ratings yet

- Usa Import Sample ReportDocument1 pageUsa Import Sample ReportkrishnaNo ratings yet

- Mahiyangana D.S.qur ModelDocument1 pageMahiyangana D.S.qur ModelMuhammadWazimAkramNo ratings yet

- Flow Sheet Sorbitol Dari Tepung Tapioka FIXDocument1 pageFlow Sheet Sorbitol Dari Tepung Tapioka FIXfidelisboymanurungNo ratings yet

- Alta Prima Conv S-2Document1 pageAlta Prima Conv S-2Ronnel John CruzNo ratings yet

- Phase Transformations and Heat TreatmentDocument76 pagesPhase Transformations and Heat TreatmentJimmy HarvianNo ratings yet

- Iron Carbon SystemDocument14 pagesIron Carbon SystemPraicy Ann josephNo ratings yet

- 10 11648 J Ijmsa 20130203 14 PDFDocument5 pages10 11648 J Ijmsa 20130203 14 PDFRima AroraNo ratings yet

- ESDEP Vol0302Document124 pagesESDEP Vol0302aladinmf1No ratings yet

- 1 - Heat TreatmentDocument61 pages1 - Heat TreatmentMohamed Karim MohamedNo ratings yet

- Question Bank - Industrial Metallurgy Part A - 2 MarksDocument8 pagesQuestion Bank - Industrial Metallurgy Part A - 2 Marks17TUME212 ROHITH.MNo ratings yet

- Chapter 11: Phase Diagrams: Issues To Address..Document42 pagesChapter 11: Phase Diagrams: Issues To Address..ozanNo ratings yet

- FALLSEM2019-20 MEE1005 ETH VL2019201001078 Reference Material I 29-Aug-2019 Fe-Fe3C Phase DiagramDocument33 pagesFALLSEM2019-20 MEE1005 ETH VL2019201001078 Reference Material I 29-Aug-2019 Fe-Fe3C Phase DiagramFazal KhanNo ratings yet

- Microstructure of Ferrous Alloys PDFDocument148 pagesMicrostructure of Ferrous Alloys PDFHugo AlvaresNo ratings yet

- Metallograpy Study of Cast Iron StructureDocument9 pagesMetallograpy Study of Cast Iron StructureMahrukh JavedNo ratings yet

- Boiler Tube GradesDocument12 pagesBoiler Tube Gradesfelram100% (1)

- Mos & Metallurgy LabDocument53 pagesMos & Metallurgy LabSrinu Arnuri100% (1)

- Iron Carbon Diagram of Steel PDFDocument6 pagesIron Carbon Diagram of Steel PDFshihabscb1971100% (1)

- Iron Carbon Fe-C Equilibrium Diagram - An Iron Carbon EquilibriumDocument2 pagesIron Carbon Fe-C Equilibrium Diagram - An Iron Carbon Equilibriumروشان فاطمة روشانNo ratings yet

- Astm A644Document5 pagesAstm A644Luis Fernando RuedaNo ratings yet

- PD Binary PDFDocument81 pagesPD Binary PDFmanilrajkrr6302No ratings yet

- UNIT 1 Alloys and Phase DiagramsDocument97 pagesUNIT 1 Alloys and Phase DiagramsAmutha PSGRKCWNo ratings yet

- IES Mechanical Engineering Paper II 2013 PDFDocument20 pagesIES Mechanical Engineering Paper II 2013 PDFBalvinderNo ratings yet

- Iron Carbon Equillibrium Diagram GandhidhamDocument22 pagesIron Carbon Equillibrium Diagram Gandhidhamcal2_uniNo ratings yet

- Austenite Formation in Plain Carbon SteelDocument14 pagesAustenite Formation in Plain Carbon SteelAndress SsalomonnNo ratings yet

- Unit Iii: V 6Cwodc-3VrkDocument237 pagesUnit Iii: V 6Cwodc-3VrkDinesh KumarNo ratings yet

- ME22Document135 pagesME22Prem KumarNo ratings yet

- PQT Chapter 9b Phase DiagramsDocument27 pagesPQT Chapter 9b Phase DiagramsDương Hữu PhươngNo ratings yet

- Ship Structural DesignDocument25 pagesShip Structural Designnavalarchmarine100% (7)

- Important Terms and Concepts: ReferencesDocument7 pagesImportant Terms and Concepts: ReferencesABDELRHMAN ALINo ratings yet

- Project ReportDocument54 pagesProject ReportRakesh Kumar Munda100% (1)

- Identification of Cast Iron 3.1. AimDocument8 pagesIdentification of Cast Iron 3.1. AimMuruganantham anandhNo ratings yet

- Phase DiagramsDocument14 pagesPhase DiagramsDave Harrison FloresNo ratings yet

- Ferrous Metallurgy: The Chemistry and Structure of Iron and SteelDocument30 pagesFerrous Metallurgy: The Chemistry and Structure of Iron and SteelKeith Tanaka MagakaNo ratings yet

- Solution Strengthened Ferritic Ductile Iron ISO 1083/JS/500-10 Provides Superior Consistent Properties in Hydraulic RotatorsDocument9 pagesSolution Strengthened Ferritic Ductile Iron ISO 1083/JS/500-10 Provides Superior Consistent Properties in Hydraulic RotatorsJason WuNo ratings yet