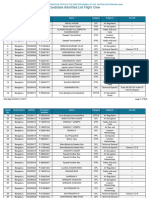

Pad-Eye Calculations and Frame Stress Verification

W-Industries, Inc.

Subsea Control Project: 14035 - BLIND FAITH UPS PANEL

11500 Charles Road Engineer: Haider Kazzaz

Houston, TX 77041 Date: April 10, 2007

Revision: 0B, (ECN: 14035-08)

Height (H) 1.75 inches

Padeye Width (W) 5 inches

Padeye Thickness (t) 0.5 inches

Hole Diameter (D) 1.125 inches

Padeye Radius (R) 2.5 inches

Shackle Pin Diamter (Dp) 1 inches

Load per Lug (F) 789.5 lbs

%Out of Plane (%OOP) 5 %

Design Factor (I) 3

Vertical Load (Fv=FxI) 2,369 lbs

Horizontal Load (Fh) 1,367 lbs

Sling Angle (θ) 60 degrees from horizontal

Sling Load (Fr) 2,735 lbs

Weld Metal tensile strength (Wt) 69,610 psi

Figure - 1 Lug Material 316L

Lug Material Yield Stress (Fy) 24,650 psi

Case -1 : Pad-eye Shear Stress

Fr

Actual Shear Stress (fv)= = 1,412 psi

D

2 × t × R −

2

Allowable Shear Stress (fv) =0.4xFy 9,860 psi

Shear stress case pass (safe) when the actual shear stress is lower than the allowable shear stress

Checking

Shear stress is OK

Case-2 : Pad-eye Combined stress

Fh × H F %OOP × Fr × H

Actual Combined Bending, Tension and Out of Plane Stress: = + v + = 3,245 psi

W 2 t ×W t2

t × W ×

6 6

Allowable Combined Stress =0.6xFy 14,790 psi

Combined stress case pass (safe) when the actual combined stress is lower than the allowable combined stress

Checking

Combined stress is OK

Case-3 : Pad-eye Bearing stress

F

Bearing Stress =

r

= 5,470 psi

t × D p

Allowable Bearing Stress =0.9xFy 22,185 psi

Bearing stress case pass (safe) when the actual combined stress is lower than the allowable combined stress

Checking

Bearing stress is OK

Page 1 of 5

�Case-4 : Pad-eye FEA

Material Steel : Structural ( SS 316L)

Young Modulus 2.751e+007psi

Poisson Ratio 0.27

Density 0.289lb_in3

Thermal Expansion 0.0000117

Applied sling load (4619 lb)

Yield Strength 24656.4psi

Figure - 2

Results

Figure - 3

Criteria of checking the FEA results

The loading is safe when Von Mises Stress (Figure-3) is lower than the yield stress: σ V .M ises< σ Yield

σ V .Mises =

1

2

(

[ (σ x − σ y ) 2 + (σ x − σ z ) 2 + (σ y − σ z ) 2 + 6 τ 2 xy +τ 2 xz +τ 2 yz ] ) = 7840 psi

Allowable Stress =0.85xFy= 20,953

Checking

Loading Stress OK

Page 2 of 5

�Pad-eye Weld Calculations:

Weld Modulus

Total Weld Length Wl: 2 ×W + 2 × t = 11 inches

W2

Sx = W ×t + =

2

Weld Section Modulus 11 in (Treated as a line)

3

Combined Stress Calculation

Fh × H

Weld Bending fb = = 221 lb/in

Sx

Fh

Weld Shear fv = = 124 lb/in

L

Fv

Weld Tension ft = = 215 lb/in

L

= ( fb+ft) +fv =

2 2

Combineded stress

factual 454 lb/in

Allowable stress and force per in of leg

Allowable force per in of leg = .707*.47*yield stress= 8190.9 (lb/in)/(1 in leg)

Allowable Weld Stress (0.47xWt) Weld Allowable 11,586 psi

Weld Fillet Calculation

f actual f actual

= =ω = Minimum Fillet Weld Size (ω) = 0.0554 inch

f allowable allowable f orce per in of leg

Applied Fillet Weld Size Used (ωa)= 0.25 inch

2

Actual Effective Weld Throat Area (wa)= 1.94 in

Transverse Load Capability= 22,525 lbs

Criteria of checking the weld length

Each stress (Twisting, Bending, Shear, Tension and Combined) should be less than the allowable porce per in of leg

Checking

Weld length and stresses are OK

Criteria of checking the Weld Fillet

The actual applied weld fillet should be greater than the calculated minimum fillet size (w)

Checking

Applied Fillet Weld size (W a) OK

Page 3 of 5

�FEA for Frame

Material Steel : Structural ( SS 316L)

Young Modulus 2.751e+007psi

Poisson Ratio 0.27

Density 0.289lb_in3

Thermal Expansion 0.0000117

Yield Strength 24656.4psi

Self Weight + Applied load =

(7900 lb)

Figure - 4

Results

Figure - 5

Criteria of checking the FEA results

The loading is safe when Von Mises Stress (Figure-5) is lower than the yield stress: σ V .M ises< σ Yield

σ V .Mises =

1

2

(

[ (σ x − σ y ) 2 + (σ x − σ z ) 2 + (σ y − σ z ) 2 + 6 τ 2 xy +τ 2 xz +τ 2 yz ] ) = 16800 psi

Allowable Stress =0.85xFy= 20,953

Checking

Loading Stress OK

Page 4 of 5

�Summary and Conclusion

A) Pad-eye design verification

Actual Allowable Fail if Actual Stress >= Allowable stress

Case # and Description Stress PSI Stress PSI Ok / Fail

Case -1 : Pad-eye Shear Stress 1,412 9,860 OK

Case-2 : Pad-eye Combined stress 3,245 14,790 OK

Case-3 : Pad-eye Bearing stress 5,470 22,185 OK

Case-4 : Pad-eye FEA 7840 20952.5 OK

B) Pad-eye Weld length Verification

Actual Allowable Fail if Actual Stress >= Allowable stress

Case # and Description Stress lb/in Stress (force per in of leg) lb/in Ok / Fail

Weld Bending 221 8190.9 OK

Weld Shear 124 8190.9 OK

Weld Tension 215 8190.9 OK

Combineded stress 454 8190.9 OK

C) Pad-eye Weld Fillet Verification

Applied Minimum Calculated Fail if Applied fillet <= Minimum Fillet

Case # and Description Fillet (in) Fillet (in) Ok / Fail

Weld Fillet Calculation 0.25 0.0554 OK

D) FEA for Frame

Actual Allowable Fail if Actual Stress >= Allowable stress

Stress lb/in Stress PSI Ok / Fail

16800 20952.5 OK

Conclusion

The pad-eye is designed using 1/2” SS 316L @ 3 SWL. The pad-eye shape and dimensions were determined using engineering

analysis, geometry constrains as well as FMC guidelines G03.33.

All the above mentioned items for the pad-eye part and weldment show a safe operation under the 3 SWL applied load.

The stresses generated in the Frame were verified using FEA method @ 2.5 SWL and the maximum octahedral shear stress found to be

lower than allowable shear stress indicating a safe operation condition

Page 5 of 5