Professional Documents

Culture Documents

Pad Eye Calculation1

Uploaded by

Rajasekar Meghanadh0 ratings0% found this document useful (0 votes)

118 views2 pagesThe document provides calculations for the design of a pad eye used to lift a load. It calculates design loads, checks the pad eye design for bearing stress, shear stress, tear out, tensile stress, bending stress, and horizontal shear stress. It specifies a 40mm thick plate with 2000 sq mm bearing area meets requirements. A 10mm fillet weld is selected to connect the plate that meets the allowable shear stress. Section properties are also calculated for the overall stiffened section.

Original Description:

Original Title

PAD EYE CALCULATION1

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides calculations for the design of a pad eye used to lift a load. It calculates design loads, checks the pad eye design for bearing stress, shear stress, tear out, tensile stress, bending stress, and horizontal shear stress. It specifies a 40mm thick plate with 2000 sq mm bearing area meets requirements. A 10mm fillet weld is selected to connect the plate that meets the allowable shear stress. Section properties are also calculated for the overall stiffened section.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

118 views2 pagesPad Eye Calculation1

Uploaded by

Rajasekar MeghanadhThe document provides calculations for the design of a pad eye used to lift a load. It calculates design loads, checks the pad eye design for bearing stress, shear stress, tear out, tensile stress, bending stress, and horizontal shear stress. It specifies a 40mm thick plate with 2000 sq mm bearing area meets requirements. A 10mm fillet weld is selected to connect the plate that meets the allowable shear stress. Section properties are also calculated for the overall stiffened section.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 2

ATTACHMENT - PAD EYE CALCULATION

Load Condition for Pad Eye Deisgn

Maximum Static Sling Load = 100 KN

Sling and Shackle Load = 100 KN

DAF = 1.43

Design Load for Pad Eye = 143 KN

Sling Angle Considered is = 60 Degrees

Deisgn Inplane Horizontal Load = 71.57 KN

Deisgn Inplane Vertical Load = 123.80 KN

Design Out of plane horizontal Load = 7.15 KN

Design of Pad Eye

Dia of Pin = 50 mm

Check for bearing stress

Allowable Stresses

Maximum Bearing Area Reqd = 635.56 Sq.mm Pad Eye Material Yield stress = 250 N/Sq.mm

Plate Thickness Reqd = 12.71 mm Allowable Bearing Stress = 225 N/Sq.mm

Plate thick selected = 40 mm Allowable Shear Stress = 100 N/Sq.mm

Check plate thick = 0 mm Allowable Tensile stress = 150 N/Sq.mm

Total Plate thick = 40 mm Allowable Bending Stress = 150 N/Sq.mm

Bearing Area Available = 2000 SQ.mm Allowable Stresses FOR Weld

Utility Ratio = 0.32 OK Weld Material Assumed = E70 Electrode

UTS of Weld Material (Fu) = 485 N/Sq.mm

Check for Shear stress Yield stress of Weld Material = 275 N/Sq.mm

Allo Weld Tensile stress = 165 N/Sq.mm

Main Plate Radius = 75.00 mm Allo Weld Shear stress fillet weld = 110 N/Sq.mm

Main Plate thick = 40 mm Allo Shear stress Groove weld = 145.5 N/Sq.mm

Check plate Radius = 75 mm

Check plate thick = 0 mm

Pad Eye Hole dia = 50

MInimumShear area reqd = 715 Sq.mm

Shear Area Pro by main pl = 2000

Shear Area Pro by check pl = 0

Available shear area = 2000

Utility Ratio = 0.36 OK

Check for Tear Out

Minimum Shear area reqd = 1430 SQ.mm

Z1 Z2 = 75 mm

Shear Area Provided = 11565 SQ.mm

Utility Ratio = 0.12 OK

Check for Tensile Stress

Tensile Stress = 2.47 N/Sq.mm

Utility Check = 0.02 OK

Check for Bending Stress

Cross section distance = 150 mm

Acting Inplane Bending moment = 10734.86

Acting out of plane Bending moment = 1072.5

Acting in plane Bending stress = 1.02

Utility Ratio = 0.01 OK

Acting out plane Bending stress = 3.21

Utility Ratio = 0.02 OK

Combined Utility Ratio = 0.04 Hence OK

Check for Horizontal shear stress

Shear Stress due to inplane

horizontal force = 1.43 N/Sq.mm

Utility RAtio = 0.01 OK

Shear Stress due to outplane

horizontal force = 0.07 N/Sq.mm

= 0.00 OK

Fillet weld size

Thickness of weld = 1 mm

length of weld in one side = 300 mm

Section Modulus, Z =L ^2 / 3 = 30000 mm3

Moment , M = 10734860 N-mm

M/Z = 357.82868

Area,A = 600 mm2

P/A = 0.2063394

P/A + M/Z = 358.03502 N/mm

Let required size of weld be S

Allowable stress in weld = 110 N/mm2

Reqd.Size S = 4.60 mm

Selected Size = 10 mm >S HENCE O.K

Provide Fillert weld 10 mm thk. OR Double bevel Penetration weld

property

Overall Depth h = 1254 mm 1254

Width of the stiffener b = 0 mm -20

Thickness of Main plate T = 40 mm

Thickness of stiffener Ts = 0 mm

Area of Section = 50160 Sq.mm

Neutral Axis From top and bottom = 627 mm

0 -6.573E+09

Moment of Inertia (Ixx) = 6573116880mm^4

0

6688000

Moment of Inertia (Iyy) = 6688000 mm^4

Sectional Modulas Sx = 10483440 mm^3

Sectional Modulas Sy = 334400 mm^3

Torsional Rigidity = 26752000 mm^4

You might also like

- Residential Slab Design 1Document5 pagesResidential Slab Design 1John SmithNo ratings yet

- Footing Design According To BS8110 CodeDocument4 pagesFooting Design According To BS8110 CodeMohit VatsNo ratings yet

- Blind Flange With StiffenersDocument4 pagesBlind Flange With Stiffenersshahid khan100% (1)

- Electric Circuits and Networks by K. S. Suresh KumarDocument840 pagesElectric Circuits and Networks by K. S. Suresh Kumaryo4rlp100% (2)

- Base Plate DesignDocument20 pagesBase Plate DesignMohammad KasimNo ratings yet

- Corbel Design ACI 318 PDFDocument2 pagesCorbel Design ACI 318 PDFShamim Ahsan ZuberyNo ratings yet

- Report For Design Calculation of Silo Supporting Structure 24032017Document140 pagesReport For Design Calculation of Silo Supporting Structure 24032017Rajasekar MeghanadhNo ratings yet

- Over Head ResevoirDocument8 pagesOver Head ResevoirPoulomi BiswasNo ratings yet

- Chequered DesignDocument2 pagesChequered DesignSaravana N100% (1)

- Anchor Bolt & Base Plate - H SectionDocument9 pagesAnchor Bolt & Base Plate - H SectionBalamuruganNo ratings yet

- (For Base Plate - BP1) : Weld Design For Stiffeners Vertical WeldDocument10 pages(For Base Plate - BP1) : Weld Design For Stiffeners Vertical Weldasvenk309No ratings yet

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDocument13 pagesBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- IPM-PR-WCI-007 Survey Program Preparation PDFDocument8 pagesIPM-PR-WCI-007 Survey Program Preparation PDFOscarCajamarcaNo ratings yet

- Bolt Design (Blodget)Document4 pagesBolt Design (Blodget)Mayuresh KudveNo ratings yet

- II PUC - Mathematics (TARGET CENTUM) - Question BankDocument68 pagesII PUC - Mathematics (TARGET CENTUM) - Question BankKumkum Kumbarahalli100% (1)

- Welded Moment Connection PDFDocument22 pagesWelded Moment Connection PDFRajasekar MeghanadhNo ratings yet

- Footing Design According To BS8110 CodeDocument4 pagesFooting Design According To BS8110 CodePre SheetNo ratings yet

- Beam1 Working StressDocument36 pagesBeam1 Working Stresssoumi bhattacharyaNo ratings yet

- Base PlateDocument6 pagesBase PlateJigarNo ratings yet

- Input Rev. NO: L + (c1 + c2) TWDocument6 pagesInput Rev. NO: L + (c1 + c2) TWMudasir MughalNo ratings yet

- Pile RectifyingDocument2 pagesPile RectifyingAnonymous O404LiV4CNo ratings yet

- Pad Eye DesignFDocument8 pagesPad Eye DesignFRajasekar MeghanadhNo ratings yet

- Corbel DesignDocument3 pagesCorbel DesignLim EcNo ratings yet

- Punching Shear DesignDocument36 pagesPunching Shear DesignYanfei JinNo ratings yet

- STP Rusayl Oman: Double Shell Combined Circular TankDocument1 pageSTP Rusayl Oman: Double Shell Combined Circular TankRahulNo ratings yet

- Design of Flat Head For HydrotestDocument12 pagesDesign of Flat Head For HydrotestSAGAR100% (1)

- Small Target Detection Test WhitepaperDocument4 pagesSmall Target Detection Test WhitepaperFreddy VergaraNo ratings yet

- 3) Corbel DesignDocument10 pages3) Corbel Designp_ignatiusNo ratings yet

- Crack WidthDocument5 pagesCrack WidthchanakyaNo ratings yet

- Design of BearingsDocument24 pagesDesign of BearingsFarrukh RizwanNo ratings yet

- Design of Staircase - 1 Data:: Safe in DeflectionDocument7 pagesDesign of Staircase - 1 Data:: Safe in DeflectionUttam Raj SutraveNo ratings yet

- Isolated FootingDocument40 pagesIsolated FootingRatnesh PatelNo ratings yet

- Isolated Base To Ec2Document12 pagesIsolated Base To Ec2Isaac Mureithi MainaNo ratings yet

- ISMC100 Box To ISMB300 Bracing ConnectionDocument4 pagesISMC100 Box To ISMB300 Bracing ConnectionNitin SakpalNo ratings yet

- PS43-07,08, 132-18 - Base Plate and Anchor Bolt DesignDocument64 pagesPS43-07,08, 132-18 - Base Plate and Anchor Bolt DesignSiva baalanNo ratings yet

- Section Description:: Manual Calculation Sheet For Reinforced Concrete Beam B 25 75Document8 pagesSection Description:: Manual Calculation Sheet For Reinforced Concrete Beam B 25 75Lavender HoneyNo ratings yet

- Pile Cap-4 PilesDocument5 pagesPile Cap-4 Pilesbalaji gmscNo ratings yet

- Hilti CheckDocument12 pagesHilti Checkhary9100No ratings yet

- Crack Width CheckDocument7 pagesCrack Width CheckAnand SoniNo ratings yet

- Base Plate & Anchor BoltDocument40 pagesBase Plate & Anchor BoltSiva baalanNo ratings yet

- Base Plate and Bolt CalculationDocument4 pagesBase Plate and Bolt CalculationKOTADIA KISHANNo ratings yet

- Input Data: Top Slab DesignDocument7 pagesInput Data: Top Slab DesignRameez Ahmed AbbasiNo ratings yet

- Corbel and NibDocument17 pagesCorbel and NibCatherine Mohanji GeraNo ratings yet

- Design of Footing C1: Input DataDocument24 pagesDesign of Footing C1: Input Datasamirbendre10% (1)

- Appendix - 4BDocument12 pagesAppendix - 4Bmoumita mukherjeeNo ratings yet

- Pad FootingDocument1 pagePad FootingKingsley ChukwuNo ratings yet

- Pipe Guide and Welding Connection - h150x125x14x8.5Document13 pagesPipe Guide and Welding Connection - h150x125x14x8.5BenchNo ratings yet

- One Way Slabs11Document12 pagesOne Way Slabs11Hemant SonawadekarNo ratings yet

- Punching Shear and One Way Shear Check.Document2 pagesPunching Shear and One Way Shear Check.ElancheliyanNo ratings yet

- Limit State Design of Tank With Crack Check - 03.02.2020.Document14 pagesLimit State Design of Tank With Crack Check - 03.02.2020.monaliNo ratings yet

- Design of FootingDocument20 pagesDesign of FootingDhananjay JoshiNo ratings yet

- Design Base Plate For I Beam - Bottom BracketDocument1 pageDesign Base Plate For I Beam - Bottom BracketCon CanNo ratings yet

- (150 X 150 R.C. SQ. PILE) Pilecap Data Column Data: Shear Check SatisfactoryDocument19 pages(150 X 150 R.C. SQ. PILE) Pilecap Data Column Data: Shear Check SatisfactoryJacky TiongNo ratings yet

- Pier Cap Corbel 30m SGDocument3 pagesPier Cap Corbel 30m SGSM ConsultantsNo ratings yet

- Corbel R C BracketDocument2 pagesCorbel R C BracketVijendra Singh SoniNo ratings yet

- Design of Square Footing F1Document13 pagesDesign of Square Footing F1Abdullah KhanNo ratings yet

- Base Plate Design - Concrete Beam TheoryDocument3 pagesBase Plate Design - Concrete Beam TheoryDarsHan MoHanNo ratings yet

- Design of Square Footing F2Document18 pagesDesign of Square Footing F2Shankar GautamNo ratings yet

- DGN - SGL - GayatriDocument2 pagesDGN - SGL - GayatriSaurav KumarNo ratings yet

- Bracing DetailsDocument2 pagesBracing DetailsprateeksuperNo ratings yet

- Anchor Bolt DesignDocument8 pagesAnchor Bolt DesignNadir Khattak Jr.No ratings yet

- Design of Slabs: Input DataDocument6 pagesDesign of Slabs: Input Datagewegw3gNo ratings yet

- Concrete Beam DesignDocument6 pagesConcrete Beam DesignJohan De LangeNo ratings yet

- Appendix - 4ADocument15 pagesAppendix - 4Amoumita mukherjeeNo ratings yet

- Annexure 2Document74 pagesAnnexure 2Rajasekar MeghanadhNo ratings yet

- SP5101 30093019Document38 pagesSP5101 30093019Rajasekar MeghanadhNo ratings yet

- STAAD - Pro Report: Job InformationDocument3 pagesSTAAD - Pro Report: Job InformationRajasekar MeghanadhNo ratings yet

- Report For: PAX-40919-01 LP Compressor After Cooler - HBHDocument36 pagesReport For: PAX-40919-01 LP Compressor After Cooler - HBHRajasekar MeghanadhNo ratings yet

- Lifting Frame Rev-01 AdaniDocument33 pagesLifting Frame Rev-01 AdaniRajasekar MeghanadhNo ratings yet

- SP2062 30092019Document37 pagesSP2062 30092019Rajasekar MeghanadhNo ratings yet

- Project: All Weather Climatic Chamber: Data Sheet For Duct Bearing PlateDocument4 pagesProject: All Weather Climatic Chamber: Data Sheet For Duct Bearing PlateRajasekar MeghanadhNo ratings yet

- ISMB 600: AssumptionsDocument5 pagesISMB 600: AssumptionsRajasekar MeghanadhNo ratings yet

- Anchor Rod Shear and Tension - As Per AISC LRFDDocument4 pagesAnchor Rod Shear and Tension - As Per AISC LRFDRajasekar MeghanadhNo ratings yet

- Wind LoadDocument6 pagesWind LoadRajasekar Meghanadh0% (1)

- Lifting Lug Calc1Document12 pagesLifting Lug Calc1Rajasekar MeghanadhNo ratings yet

- Pipeline Sizing: Learning ObjectivesDocument7 pagesPipeline Sizing: Learning ObjectivesRajasekar MeghanadhNo ratings yet

- Cejn HP EngDocument44 pagesCejn HP EngAnonymous 8rb48tZS100% (1)

- B&E Matrix - TemplateDocument11 pagesB&E Matrix - TemplateIvan JuniorNo ratings yet

- Collins Further Maths Answers CH 10 To 12Document15 pagesCollins Further Maths Answers CH 10 To 12nathanNo ratings yet

- Presentation On Ground Wave PropagationDocument53 pagesPresentation On Ground Wave PropagationamitNo ratings yet

- 2020-2021-PETA 1.1 States of MatterDocument4 pages2020-2021-PETA 1.1 States of Matternathaniel husolNo ratings yet

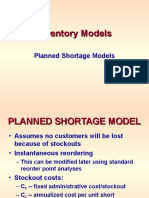

- INVENTORY - Planned Shortage ModelsDocument13 pagesINVENTORY - Planned Shortage ModelsMicah Dianne Dizon100% (1)

- 3 WadhwaDocument10 pages3 WadhwaNaveen SharmaNo ratings yet

- PDFDocument156 pagesPDFOki NurpatriaNo ratings yet

- RT Acceptance Criteria For Pressure VesselDocument1 pageRT Acceptance Criteria For Pressure VesselkapsarcNo ratings yet

- SEAM-Maths1-1.2 SD-Trigonometric Functions 28-8-19 SPCEDocument13 pagesSEAM-Maths1-1.2 SD-Trigonometric Functions 28-8-19 SPCESatish BarotNo ratings yet

- hds24 - 200 FL 991630 enDocument4 pageshds24 - 200 FL 991630 enErdinc SenmanNo ratings yet

- Lr10ia10 Flyer enDocument2 pagesLr10ia10 Flyer enmichelNo ratings yet

- Sagar Group of Institutes, Bhopal: Subject: Heat& Mass Transfer CODE: ME-6003 Unit-IDocument3 pagesSagar Group of Institutes, Bhopal: Subject: Heat& Mass Transfer CODE: ME-6003 Unit-IRiyasNo ratings yet

- Sigma MALDI Calibration KitDocument4 pagesSigma MALDI Calibration KitRamona Neka TamoNo ratings yet

- IMPORTANT MCQ-Heat Transfer 1 - WWW - ALLEXAMREVIEW.COM - PDFDocument19 pagesIMPORTANT MCQ-Heat Transfer 1 - WWW - ALLEXAMREVIEW.COM - PDFRobert Michael CorpusNo ratings yet

- Capacity of Urban ArterialsDocument38 pagesCapacity of Urban ArterialsmrdvirusNo ratings yet

- Eq Base Shear CalculationsDocument9 pagesEq Base Shear Calculationsirshad313No ratings yet

- FRCC EI 001 A5 02 - Instructions DLL Danfoss Foresee PDFDocument10 pagesFRCC EI 001 A5 02 - Instructions DLL Danfoss Foresee PDFDaud Simon ANo ratings yet

- Bab IvDocument19 pagesBab IvIzza27_No ratings yet

- Braden 2010 2 PDFDocument4 pagesBraden 2010 2 PDFTompson StevenNo ratings yet

- 2018 Tutorial - Heat and Thermodynamics (MCQ)Document7 pages2018 Tutorial - Heat and Thermodynamics (MCQ)Mmeli NtwanaYebhoza DubeNo ratings yet

- Soil Mechanics DiplomaDocument3 pagesSoil Mechanics DiplomaSr.Daisy.GNo ratings yet

- Conversion Chart For HardnessDocument5 pagesConversion Chart For HardnessIshmael WoolooNo ratings yet

- Hysys PrintDocument11 pagesHysys PrintAsh YehiaNo ratings yet