Professional Documents

Culture Documents

PV External Pressure Spreadsheet ASME VIII Div 1

Uploaded by

Gohar ZamanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PV External Pressure Spreadsheet ASME VIII Div 1

Uploaded by

Gohar ZamanCopyright:

Available Formats

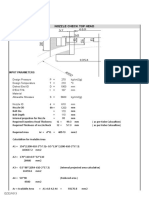

Pressure Vessel for External Pressure Gohar Zaman, MT-E(PRJ)

** Input values in American Units ( inch, psi) ASME Sec. VIII, Div. 1, UG-28 Fauji Fertilizer Co. Ltd

Goth Machi, Pakistan

Shell Design

Stiffening Rings UG-29

Shell ID 196.8

Design external Pressure 14.6 Max. unstiffened Length, Ls 129.46

Material Yield Strength, S 32000 Table 1a, ASME Sec II, Part D, Sbpt 3 Moment of Inertia to be selected 84.0144008472

Material Young's Modulus, E 28000000 ASME Sec II, Part D, sbpt 3 for material Member Selected W8x24

Shell Length, L(t-t) Moment of Inertia of Selected Member, 82.8

Design Length,L 404.79 Cross-sectional Area of Selected Membe 7.08

As/Ls 0.0546887069

Assumed Thickness,t 0.669 Thickness not allowable

Factor B 2997.9894382826

Outside Diameter, Do 198.138 Factor A 0.00023 Fig. CS-1/2, ASME SecII, PartD sbpt 3

Do/t 296.1704035874

L/Do 2.0429700512 Required Moment of Inertia,Is 60.4258472407

A 0.00006 Fig. G, ASME Sec. II, Part D, Sbpt 3 Selected Member is sufficient

B Fig CS-2, ASME Sec.II, Part D, Sbpt 3

Allowable Working Pressure, P 3.7816067589 If Value of A falls to left of material line

Allowable Working Pressure, P 0 If Value of A falls on the material line

2:1 Elliptical Head Conical Head/section

Inside Dia (Smaller End) 0 in

Inside Dia, Din 196.85 in Inside Dia (Larger End), DL 196.8 in

Design Press. Pd=1.67*Px 24.382 psi Length of Conical section, L 160.23 in

Outside Dia (Larger end), Do 198.138 in

Assumed Thickness 0.669 in Thickness is allowable Assumed Thickness,t 0.669 in

Outside Diamemeter, Do 198.188 in Cone Angle, radian 0.5507351831

Ro, = 0.9Do (for Ext. press) 178.3692 in Cone Angle, Degrees 31.5507106778

Factor A 0.0004688309

Factor B 6500 From Fig. Cs-1/2, ASME Sec II, Part D, Sbpt 3 inclined thickness, te 0.570081674 in

Allowable Pressure, Pa 24.3792089666 psi Le = L(1+Ds/DL)/2 80.115 in

Factor Le/DL 0.4070884146

Factor DL/te 345.2136930192

Factor A Fig. G, ASME SecII, Part D, sbpt 3

Factor B 5500 Fig. CS-1/2, ASME SecII, PartD sbpt 3

Allowable Pressure 21.2428808058 psi

Thickness is allowable

You might also like

- Thickness Calculation AsmeDocument2 pagesThickness Calculation AsmeSushil WadiyeNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroNo ratings yet

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Document35 pagesDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainNo ratings yet

- Pressure Vessel Assessment SpreadsheetDocument3 pagesPressure Vessel Assessment SpreadsheetrawirabbatNo ratings yet

- External PressureDocument22 pagesExternal PressureAbhijeet SahuNo ratings yet

- 8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Document42 pages8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Muhamad Amar Hakimmie Suhaimi100% (1)

- Tank Thickness Calculation: Is 2825 S.No Description Unit Value InputDocument10 pagesTank Thickness Calculation: Is 2825 S.No Description Unit Value InputdineshNo ratings yet

- Nozzle Calcs Rev ADocument6 pagesNozzle Calcs Rev AbolivarNo ratings yet

- Air Coolers HeadsDocument30 pagesAir Coolers HeadsSergio PluchinskyNo ratings yet

- Elliptical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageElliptical Head Design Tool: Pressure Vessel Engineering LTDJaveed KhanNo ratings yet

- Column Data Sheet Distillation Column (T-2010)Document12 pagesColumn Data Sheet Distillation Column (T-2010)John Patrick Sanay NunezNo ratings yet

- Nozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value UnitDocument1 pageNozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value Unitmiteshpatel191No ratings yet

- Plate RectangularDocument8 pagesPlate RectangularRUBEN BARTOLOME GARCIANo ratings yet

- Mozzle Repad Design ToolDocument2 pagesMozzle Repad Design ToolSiddiqui Muhammad AshfaqueNo ratings yet

- Design Calculations For Pressure ShellDocument33 pagesDesign Calculations For Pressure ShellGeorge GeorgianNo ratings yet

- Vdocuments - MX Rectangular Tank CalculationDocument34 pagesVdocuments - MX Rectangular Tank CalculationAtilla TekinNo ratings yet

- Tube Sheet CalculationDocument3 pagesTube Sheet CalculationAbhay UpadhyayNo ratings yet

- Vessel DatasheetDocument1 pageVessel Datasheetsdrtfg100% (1)

- Superheated Steam Condensate TankDocument4 pagesSuperheated Steam Condensate TankGanesh BhardwajNo ratings yet

- MD PV ASME v0.1Document34 pagesMD PV ASME v0.1nileshNo ratings yet

- Design Procedure For Aes He PDFDocument30 pagesDesign Procedure For Aes He PDFRyan Goh Chuang HongNo ratings yet

- Memoria ASME-Pressure-Vessel-DesignDocument143 pagesMemoria ASME-Pressure-Vessel-DesignJuan MendozaNo ratings yet

- F.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellDocument9 pagesF.O.B Cost Estimation of Shell and Tube Heat Exchangers: Surface Area Per ShellVINOD KAMBLENo ratings yet

- PPE-STD-CAL-ME-008 ANSI Flange Design CalculationDocument4 pagesPPE-STD-CAL-ME-008 ANSI Flange Design CalculationNadya Askar100% (1)

- Pipe Thickness Calculation Data SheetDocument1 pagePipe Thickness Calculation Data SheetAnonymous 6ZWS6IG2J9No ratings yet

- Output Data: Design CaseDocument3 pagesOutput Data: Design CaseAnonymous RytT6uvX1No ratings yet

- Loose Without Hub Type Body Flange CalculationDocument11 pagesLoose Without Hub Type Body Flange Calculation9913489806No ratings yet

- Vessel ThicknessDocument7 pagesVessel ThicknessShishupal ChoudharyNo ratings yet

- Power Calculation For AgitatorDocument12 pagesPower Calculation For AgitatorDeepikaNo ratings yet

- Sight Glass Selection Guide PDFDocument7 pagesSight Glass Selection Guide PDFani_datNo ratings yet

- Sample4 SpreadsheetDocument21 pagesSample4 SpreadsheetTrishul Nath Pallay100% (1)

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleDocument25 pagesPage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzleabdelrahman KhalidNo ratings yet

- Weir Plate or Baffle Plate CalculationDocument2 pagesWeir Plate or Baffle Plate CalculationamaNo ratings yet

- Nozzle Check Top Head: Input ParametersDocument2 pagesNozzle Check Top Head: Input ParametersRaj Sharma100% (1)

- Pipe Thickness Calculations - : ClassDocument1 pagePipe Thickness Calculations - : ClassOluwachidiNo ratings yet

- Heat Exchanger - Preliminary Data SheetDocument4 pagesHeat Exchanger - Preliminary Data SheetgksakthiNo ratings yet

- Exchanger Tube Min ThicknessDocument2 pagesExchanger Tube Min ThicknessMohamed ElshehnyNo ratings yet

- Shell & Dish ThicknessDocument3 pagesShell & Dish Thicknesskirandas_mullasseryNo ratings yet

- Horizontal Cylindrical Tank Volume and Level CalculatorDocument5 pagesHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraNo ratings yet

- Horizontal Pressure Vessel Calculation (Eng)Document59 pagesHorizontal Pressure Vessel Calculation (Eng)Chamseddine MerdasNo ratings yet

- Compress EvaluateDocument23 pagesCompress EvaluateVishalDhiman100% (1)

- Limpet Coil On Dish Design As Per PD5500Document1 pageLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNENo ratings yet

- Optional Integral With Hub Type Body Flange CalculationDocument13 pagesOptional Integral With Hub Type Body Flange Calculation9913489806No ratings yet

- Calculation Sheet: Design CodeDocument1 pageCalculation Sheet: Design CodeCak AndiNo ratings yet

- ThicknessDocument53 pagesThicknessRajul MuraliNo ratings yet

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocument30 pagesJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj67% (3)

- SCR Mean - Metal - Temps For Heat Exchanger TubeDocument2 pagesSCR Mean - Metal - Temps For Heat Exchanger TubescranderiNo ratings yet

- 28 Roark Flat PlatesDocument14 pages28 Roark Flat Platesgutmont0% (1)

- Skirt Support Analysis Per en 13445Document13 pagesSkirt Support Analysis Per en 13445karthik1amarNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of Nozzlehardik5818No ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- S-Stamp Calculation Nozzle ShellDocument4 pagesS-Stamp Calculation Nozzle ShellmukeshNo ratings yet

- MD He Tema Asme v0.1Document31 pagesMD He Tema Asme v0.1Sharon Lambert100% (1)

- Pvelite OutputDocument44 pagesPvelite OutputRam MurtyNo ratings yet

- Calculate The Wall Thickness of Methanol Storage TankDocument4 pagesCalculate The Wall Thickness of Methanol Storage TankhaidirNo ratings yet

- VSL CalDocument50 pagesVSL CalEmrahCayboyluNo ratings yet

- Final ExaminationDocument7 pagesFinal ExaminationAwanNo ratings yet

- SHELLDocument6 pagesSHELLSalz EngineeringNo ratings yet

- Blind Flange Design Calculations - by Abdel Halim GalalaDocument6 pagesBlind Flange Design Calculations - by Abdel Halim GalalaNirmalraj Manoharan67% (3)

- Design Calculations For Pressure VesselsDocument43 pagesDesign Calculations For Pressure VesselsMoises Alvarez LeandroNo ratings yet

- Pipeline Stress Analysis With Caesar IiDocument16 pagesPipeline Stress Analysis With Caesar IiGohar ZamanNo ratings yet

- Blind Flange Design For 8", 600#, 15B Service LineDocument2 pagesBlind Flange Design For 8", 600#, 15B Service LineGohar ZamanNo ratings yet

- HIT RE 100 Adhesive Anchor Product Data 1353047Document46 pagesHIT RE 100 Adhesive Anchor Product Data 1353047Daniel ChangNo ratings yet

- Verification of Lifting Lug (As Per OVS For MPD, P-III) : y All VDocument4 pagesVerification of Lifting Lug (As Per OVS For MPD, P-III) : y All VGohar ZamanNo ratings yet

- TTS Weld Size CalculationDocument4 pagesTTS Weld Size CalculationGohar ZamanNo ratings yet

- PV External Pressure Spreadsheet ASME VIII Div 1Document1 pagePV External Pressure Spreadsheet ASME VIII Div 1Gohar ZamanNo ratings yet

- Regression Analysis and Optimization of Hardfacing of Inconel For Maximum Strength Using RSMDocument5 pagesRegression Analysis and Optimization of Hardfacing of Inconel For Maximum Strength Using RSMGohar ZamanNo ratings yet

- WPS For NPS 24 Inch WeldsDocument5 pagesWPS For NPS 24 Inch WeldsGohar ZamanNo ratings yet

- Flat HeadDocument1 pageFlat HeadGohar ZamanNo ratings yet

- Rebar Steel Weight CalculatorDocument2 pagesRebar Steel Weight CalculatorGohar ZamanNo ratings yet

- Blind Flange Design For 8", 600#, 15B Service LineDocument2 pagesBlind Flange Design For 8", 600#, 15B Service LineGohar ZamanNo ratings yet

- Us5984052 Elevator With Reduced CounterweightDocument6 pagesUs5984052 Elevator With Reduced CounterweightGohar ZamanNo ratings yet

- TTS Weld Size CalculationDocument4 pagesTTS Weld Size CalculationGohar ZamanNo ratings yet

- What Is A Mechanical Seal PDFDocument2 pagesWhat Is A Mechanical Seal PDFIrma Tri Puspita SariNo ratings yet

- Verification of Lifting Lug (As Per OVS For MPD, P-III) : y All VDocument4 pagesVerification of Lifting Lug (As Per OVS For MPD, P-III) : y All VGohar ZamanNo ratings yet

- Thickness Calculation ASME B31.3 (Revised) HP LOOP ELBOWDocument117 pagesThickness Calculation ASME B31.3 (Revised) HP LOOP ELBOWGohar ZamanNo ratings yet

- AISC ASD Beam Column CheckDocument9 pagesAISC ASD Beam Column CheckGohar ZamanNo ratings yet

- Fitness For Service AssessmentDocument13 pagesFitness For Service Assessmentwsjouri2510No ratings yet

- Boxup Clamp DesignDocument5 pagesBoxup Clamp DesignGohar ZamanNo ratings yet

- Stellite 6 HardnessDocument28 pagesStellite 6 HardnessNitin AggarwalNo ratings yet

- Rebar Steel Weight CalculatorDocument2 pagesRebar Steel Weight CalculatorGohar ZamanNo ratings yet

- AISC ASD Beam Column CheckDocument9 pagesAISC ASD Beam Column CheckGohar ZamanNo ratings yet

- Stainless Steel Grade Composition ChartDocument8 pagesStainless Steel Grade Composition Chart23OtterNo ratings yet

- Weigh Bridge - Beam FailureDocument7 pagesWeigh Bridge - Beam FailureGohar ZamanNo ratings yet

- Report On Division of PunjabDocument21 pagesReport On Division of PunjabGohar ZamanNo ratings yet

- Stainless Steel Grade Composition ChartDocument8 pagesStainless Steel Grade Composition Chart23OtterNo ratings yet

- Pipeline Pigging (Visit http://Piping-Info - Blogspot.com)Document33 pagesPipeline Pigging (Visit http://Piping-Info - Blogspot.com)Antoshal100% (7)

- Guide Book - Investing and Doing Business in HCMC VietnamDocument66 pagesGuide Book - Investing and Doing Business in HCMC VietnamemvaphoNo ratings yet

- In-N-Out vs. DoorDashDocument16 pagesIn-N-Out vs. DoorDashEaterNo ratings yet

- Novtang (Int'l Wed)Document3 pagesNovtang (Int'l Wed)raymondsuwsNo ratings yet

- Genose Massal D - 6 Juli 2021Document102 pagesGenose Massal D - 6 Juli 2021Phyto LianoNo ratings yet

- Skott Marsi Art Basel Sponsorship DeckDocument11 pagesSkott Marsi Art Basel Sponsorship DeckANTHONY JACQUETTENo ratings yet

- Asme B31.8Document8 pagesAsme B31.8deepndeepsi100% (1)

- Growth of Luxury Market & Products in IndiaDocument60 pagesGrowth of Luxury Market & Products in IndiaMohammed Yunus100% (2)

- Farm LeaseDocument5 pagesFarm LeaseRocketLawyer100% (1)

- PH and ORP Systems: Reliable in Pure Water Treatment ApplicationsDocument10 pagesPH and ORP Systems: Reliable in Pure Water Treatment ApplicationsmateusT850No ratings yet

- 01 04 2018Document55 pages01 04 2018sagarNo ratings yet

- Liebert Exs 10 20 Kva Brochure EnglishDocument8 pagesLiebert Exs 10 20 Kva Brochure Englishenrique espichan coteraNo ratings yet

- WS Soln 2 6A RationalFunctionsDocument6 pagesWS Soln 2 6A RationalFunctionsSiddhant ShahNo ratings yet

- Service Manual: Super Audio CD/DVD ReceiverDocument88 pagesService Manual: Super Audio CD/DVD Receiveralvhann_1No ratings yet

- TIDCP vs. Manalang-DemigilioDocument2 pagesTIDCP vs. Manalang-DemigilioDi ko alam100% (1)

- Purchase Invoicing Guide AuDocument17 pagesPurchase Invoicing Guide AuYash VasudevaNo ratings yet

- JavaDocument14 pagesJavaGANESH REDDYNo ratings yet

- TechRef SoftstarterDocument11 pagesTechRef SoftstarterCesarNo ratings yet

- Norma MAT2004Document12 pagesNorma MAT2004Marcelo Carvalho100% (1)

- Hiring and Selection Process: A Harvard Business School: Case StudyDocument26 pagesHiring and Selection Process: A Harvard Business School: Case StudylonlinnessNo ratings yet

- Manual de Usuario PLECSIM 4.2Document756 pagesManual de Usuario PLECSIM 4.2juansNo ratings yet

- List of Circulating Currencies by CountryDocument8 pagesList of Circulating Currencies by CountryVivek SinghNo ratings yet

- Yrc1000 Options InstructionsDocument36 pagesYrc1000 Options Instructionshanh nguyenNo ratings yet

- Selenium Question and AnswerDocument35 pagesSelenium Question and AnswerManas Jha50% (2)

- GMD 15 3161 2022Document22 pagesGMD 15 3161 2022Matija LozicNo ratings yet

- Analog Circuits - IDocument127 pagesAnalog Circuits - IdeepakpeethambaranNo ratings yet

- CF34-10E LM June 09 Print PDFDocument301 pagesCF34-10E LM June 09 Print PDFPiipe780% (5)

- Motion For Forensic Examination - Cyber CasedocxDocument5 pagesMotion For Forensic Examination - Cyber CasedocxJazz Tracey100% (1)

- Cape Notes Unit 2 Module 2 Content 1 2Document13 pagesCape Notes Unit 2 Module 2 Content 1 2Jay B GayleNo ratings yet

- Wheel Loader Manual Agrison PDFDocument138 pagesWheel Loader Manual Agrison PDFTravisReign Dicang02No ratings yet

- Problem 4. Markov Chains (Initial State Multiplication)Document7 pagesProblem 4. Markov Chains (Initial State Multiplication)Karina Salazar NuñezNo ratings yet