Professional Documents

Culture Documents

MD 04 MT RSSTA PD 025 Rev.05 Bolted Flange Joints Management

Uploaded by

Xuân HòaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MD 04 MT RSSTA PD 025 Rev.05 Bolted Flange Joints Management

Uploaded by

Xuân HòaCopyright:

Available Formats

Amendment Table

Rev. Prepared Reviewed

Date Description Approved by

No. by by

N.S.Binh/T. T.

00 11.12.15 Initial release N.B. Huy

Kimura Sugimura

N.S.Binh/T. T.

01 14.03.16 1st Revised N.B. Huy

Kimura Sugimura

N.S.Binh/T. T.

02 21.03.17 2nd Revised N.B. Huy

Kimura Sugimura

N.Q.Tung Ferdy C.

03 14.10.17 3rd Revised N.B. Huy

/N.S.Binh Valencia

4th Revised N.Q.Tung Ferdy C.

04 19.04.18 N.B.Huy

/N.S.Binh Valencia

Osama

N.Q.Tung

05 12.06.18 5th Revised N.B.Huy Abdou

/N.S.Binh

Abdelnaby

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 2 of 36

AMENDMENT REPORT FORM

Rev Item Original Revised Reason

01 5. - Add reference BMC Audit result.

document.

02 6.2.4 - Add calibration Made requirement

certificates for clearly.

Air/hydraulic bolt

tensioners and Torque

wrench.

Add requirement to

refer Piping material

Specification and

Specification for

Identification of Piping

Materials.

02 6.3 - Add requirement for Made requirement

whom will do the task. clearly.

02 6.3.3 - Add check sheet for For audit after repair

gaskets.

02 6.3.5 - Add required using Indicate requirement

tools for each type of clearly.

flanges.

Add Information of

torque value will be

applied for all area.

Add table of EPC

Contractor's Flange

Management

02 6.3.6 - Develop more detail of Made requirement

hot bolting methods. clearly.

03 2. Add scope of To update procedure

procedure

03 6.3.3 Add octagonal ring To update required

gasket work flow for ring gasket

03 6.3.5 Attachment 06 To update torque

value for B400 area

03 6.3.5 Attachment 12 To update torque

value for B400 area

04 6.3.2 Parallelism is Addition the

followed ASME PCC- requirement by ASME

1

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 3 of 36

31.3

04 6.3.3 Delete the ring joint Management

gasket repair work decided to use all

flow new gasket,

04 6.3.7 Addition the guideline Management

for acceptance decided based on

criteria for hydrogen Technical Div.

test proposal

04 Attachment Addition the To record data for

11 alignment check for flange before and

flange after open flange

05 6.3.6 - Addition the other To provide more

technique of hot technique for hot

bolting bolting.

05 6.4 Bolted flange leakage

rectification

05 Attachment Recommended

14 torque value

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 4 of 36

Contents

1. PURPOSE ........................................................................................................... 6

2. SCOPE ................................................................................................................ 6

3. RESPONSIBILITY ............................................................................................... 6

4. DEFINITION & ABBREVIATION .......................................................................... 6

5. REFERENCE ...................................................................................................... 7

6. FLANGE MANAGEMENT PROCEDURE ............................................................ 8

6.1 General ............................................................................................................... 8

6.2 Preparation of work........................................................................................... 8

6.2.1 Confirmation of Work Order and safety requirements ...................................... 8

6.2.2 Personal protective equipment......................................................................... 9

6.2.3 Environmental precautions............................................................................. 10

6.2.4 Materials and tools ......................................................................................... 10

6.3 Execution of work ........................................................................................... 11

6.3.1 Cleaning and checking flange surface ............................................................ 11

6.3.2 Alignment of bolted flanged joints ................................................................... 11

6.3.3 Installation of gasket ...................................................................................... 13

6.3.4 Tightening of bolts .......................................................................................... 13

6.3.5 Tightening methods........................................................................................ 14

6.3.6 Hot bolting ...................................................................................................... 16

6.3.7 Guidelines for leakage test by hydrogen ........................................................ 18

6.4. Bolted flange leakage rectification ..................................................................... 18

6.5. Work order closure ............................................................................................ 19

ATTACHMENT – 01 .................................................................................................... 20

ATTACHMENT – 02 .................................................................................................... 21

ATTACHMENT – 03 .................................................................................................... 23

ATTACHMENT – 04 .................................................................................................... 24

ATTACHMENT – 05 .................................................................................................... 25

ATTACHMENT – 06 .................................................................................................... 26

ATTACHMENT – 07 .................................................................................................... 27

ATTACHMENT – 08 .................................................................................................... 28

ATTACHMENT – 09 .................................................................................................... 31

ATTACHMENT – 11 .................................................................................................... 32

ATTACHMENT – 12 .................................................................................................... 33

ATTACHMENT - 13 ..................................................................................................... 35

ATTACHMENT - 14 ..................................................................................................... 36

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 5 of 36

1. PURPOSE

This procedure is to identify and describe fundamental requirements for the management of

all bolted flange joints in Nghi Son Refinery& Petrochemical LLC (NSRP) to ensure that all

joints meet specified design, operating conditions and no flange is missed and lost control in

preventive maintenance period. Depending on individual situations, Vendor documents are

required to refer.

2. SCOPE

This document covers all bolted flange joints in NSRP, it includes non-metallic and metallic

bolted flange joints. The scope of this procedure will be used for all pressure vessels such as

reactors, heat exchangers, associated valves, instruments, pipe lines and expansion joints.

This procedure is not intended other kind of joints such as clamp connectors.

This procedure will be applied for the case following:

- The battery flanges with package and the main unit.

- The flanges which are tightened at the site.

This procedure will not be applied for the flanges which tightening ware completed

before shipping from factory.

3. RESPONSIBILITY

This procedure is approved by Division Manager (DM) of Maintenance Division. DM is

responsibility for issuing and distributing this procedure. The procedure will be reviewed

periodically, revised and updated as needed. The DM reserves the right to make any

amendment and modification this procedure subject to requirements of proper management.

4. DEFINITION & ABBREVIATION

LOTO Lock out and tag out

HSE Health, Safety, Environment Division.

CMMS Computerized Maintenance Management System

DM Division Manager

MSDS Material Safety Data Sheet

MRO Maintain, Repair and Operate material

NSRP Nghi Son Refinery & Petrochemical LLC.

PM Preventive Maintenance

P& ID Piping& Instrument Drawing

PTW Permit To Work

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 6 of 36

SWMS Safe Work Method Statement

WO Work Order

WR Work Request

5. REFERENCE

Document Number Title

Chapter 10.

ISRS V8.1 Book of Knowledge

Asset Management

MD-02-MT-PR-001 Principle for Maintenance Division

MD-03-MT-WF-005 Breakdown Maintenance Workflow for Production Facilities

MD-03-MT-WF-006 Predictive Maintenance Workflow for Production Facilities

MD-03-MT-WF-001 Preventive Maintenance Workflow for Production Facilities

MD-03-MT-WF-012 Workshop management Workflow

MD-04-HSE-HS-PD-

Permit to Work Procedure

003

MD-04-HSE-HS-PD-

Personal Protective Equipment Management Procedure

001

MD-04-HSE-HS-PD- Job Safety Analysis (JSA)& Safe Work Method Statement (SWMS)

004 Procedure

ASME B16.5 Pipe flanges and flanged fittings (NPS ½ through NPS 24)

ASME B16.1 Gray iron pipe flanges and flanged fittings

ASME B16.20 Metallic gasket for pipe flanges

ASME B16.21 Nonmetallic gasket for pipe flanges

ISO 9001:2008 Quality Management System-requirements

ASME-PCC1-2013 Guidelines for Pressure boundary bolted flange joint assembly

Method statement for flange tightening for GRP pipes and Piping

VV2110-002-A-804

components for Non-pressurized line

VV3130-007-A-645 Flange Management Procedure

VV3160-008-A-617 Flange Management Procedure

VV3160-008-A-618 Flange Management Procedure

VV3160-008-A-637 Flange Management Procedure

Procedure for bolt tightening and hydraulic bolt tensioning of

VM2153-202-A-637

flanged joint

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 7 of 36

VV3160-001-A-146 Method Statement and JSA for Flange Management Work

VV3160-001-B-016 Bolt tightening/ Tensioning Procedure

VV3160-001-C-676 Bolt tightening Procedure, include flange management

VV3160-002-A-628 Flange Management Procedure

VV3160-005-A-023 Flange Management Procedure

VV3160-006-A-632 Flange Management Procedure

VV3160-006-B-629 Flange Bolt Tightening Procedure

VV3160-009-A-618 Flange Management Procedure

VV3163-003-A-637 Flange Management Procedure

VV3160-008-B-623 Flange Management Procedure

VV3160-001-A-103 Method statement and JSA for Piping Installation

VV3163-101-A-109 Method statement for U/G pipe coating & wrapping work

S-000-1360-0002V Piping Material Specification

S-000-1360-0004V Specification for Identification of Piping Materials

6. FLANGE MANAGEMENT PROCEDURE

6.1 General

The leakage on bolted flange joint has always been a problem. This procedure will instruct to

eliminate that issue. This section gives a brief outline of how joints work and provides guidance

on the safe and efficient assembly and disassembly of flanged joints.

The principle of a bolted joint is based on the bolting delivering sufficient joint compression

and gasket seating stress to withstand maximum service pressure and force. A bolted flange

joint shall provide leak-free service for process system.

6.2 Preparation of work

6.2.1 Confirmation of Work Order and safety requirements

Any preventive maintenance activity shall be performed in accordance with approved PM

schedule. Through CMMS, WO will be generated and approved before execution.

Maintenance team leader and his team members who are assigned the work shall carefully

check the requirements on WO and carry-out following activities:

- Check and confirm location, access way condition to the bolted flange joint. Scaffoldings and

insulation will be prepared if necessary.

- Identify any escape route in case of emergency.

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 8 of 36

- Prepare P&ID drawings, ISO metric drawings, datasheet, MSDS.

- Make sure to understand the process condition and type of fluids/chemicals inside flange.

- Checking LOTO, drains, vents have been done by Operation Division.

- Check and confirm flange information such as size, type, rating of flange and gaskets.

- Verify the gaskets are available to be used in warehouse.

- All Stud bolts information will be prepared.

- Confirm legal permit of air/hydraulic bolt tensioners.

- Confirm and obtain necessary advices from Operation.

- If the maintenance work is high risk, conduct SWMS session with representative from

operation and HSE. All risk assessments will be identified and added. The contingency and

mitigation plan also will be discussed.

- Obtain approval of hot work permit where the work could create a sparking (fire) hazard

including use of electric testing equipment (with or without battery cells).

- Obtain all Permits to Work required within the scope of work as per PTW Procedure (Later).

- Conduct a Safety Toolbox Meeting with dedicated craftsmen and workers to discuss the

following:

Work purpose, scope, expected duration, risk assessment, MSDS, Vendor documents,

drawings, etc.

Do not operate or do any maintenance activity even opening equipment cover of other

equipment that are not in PTW’s scope.

Un-controlled PTW’s scope or incorrect isolation will become hazardous e.g.: equipment

damage, human injury, explosion, or Refinery shutdown.

Required isolation, check and ensure all isolations have been completed in accordance

with approved LOTO.

Consider any possible interference in the work area, and any possible action to be taken.

Before operating any air/hydraulic bolt tensioners, verify the maximum operating

pressure for each equipment item and do not exceed the specified maximum levels in

operation.

Do not handle air/hydraulic tools by their hoses or air/hydraulic connections.

Always alert to the position and avoid standing on the line or other equipment.

Verify that all quick coupling are well connected and fully engaged before pressurizing.

6.2.2 Personal protective equipment

The personnel who involve into the activity are required to wear the standard personal

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 9 of 36

protective equipment (PPE) such as Eye protection, Helmet, clothing…. Additional PPE must

be worn for this procedure due to the nature of the work or the location.

- Personal protective hydrogen sulfide (H2S) detector must be worn in designated areas.

- Suitable gloves must be worn when handling hazardous materials or contacting a cold or hot

surface.

- Double ear protection (Ear plug & ear muff) must be attached before entering the area with

noise level above 85 dB.

6.2.3 Environmental precautions

Maintenance is conducted in accordance with governmental requirements for protection of the

environment.

- Make sure good housekeeping is carried out during and after each work.

- Do not drain or vent any liquid or gas to an open space, on the ground, or into the sea. Use

only the approved method to drain or vent the systems.

- Gather all waste maintenance materials produced during work. After work, move and store

them at the reserved place.

6.2.4 Materials and tools

Before starting work, specification of minimum requirement for identification of piping material

by color coding and/or marking (stamping, stenciling, pressing, cast molding, etc) have to be

identified properly, it is very importance to prepare maintenance work, details of color coding

and marking is described in S-000-1360-0004V (Specification for Identification of Piping

Materials).

Details of material selection, design pressure, temperature design, thickness and identify code

have to be verified by Piping class index, it is described in S-000-1360-0002V (Piping Material

Specification).

And the following preparation materials and tools shall be done:

- Gaskets.

- Clouts.

- Solvent.

- Air/hydraulic bolt tensioners (include calibration certificates).

- Torque wrench (include calibration certificates).

- Spanners.

- Hammers.

- Feeler gauges.

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 10 of 36

- Bolts and nuts. (used to replace if necessary)

- Grease.

6.3 Execution of work

Tightening, tensioning of the bolted flange connections shall be done by trained technician or

trained engineer. This is to ensure the correct usage of the tools and to avoid damage and

misalignment to the mating flange surfaces.

6.3.1 Cleaning and checking flange surface

Dismantling the flange and removing the gasket, all indications of previous gasket installation

from the gasket contact surfaces shall be removed by using approved solvents and/or soft-

wire brushes. Using carbon steel brushes on stainless steel flange is prohibited.

Flanges which have leakage in history or any damages of gasket contact surface such as

scratches, nicks, gouges and burrs shall consider to be assessed. The results of the

assessment shall satisfied fully requirement of ASME PCC-1 appendix C and D. All flanges

with damage which are outside of ASME PCC-1 requisition shall be repaired or replaced.

6.3.2 Alignment of bolted flanged joints

Pulling the flanges into position could cause unacceptable loads and deflections in other parts

of the system, and mean that bolt load is being used to pull the flanges together instead of

compressing the gasket. Flanges should align initially in the un-stressed condition without any

external force applied unless stipulated within the design

During alignment of bolted flange joints, the following requirements of 04 parameter should be

met:

- Centerline high/low: the tolerance is measured at 04 points around the flange and it should

not exceed 1.5 mm. Refer to figure 1 below

Figure 1

- Parallelism: The tolerance is usually determined by measuring the closest and farthest

distance between the flanges and comparing. An acceptable practice is a difference no

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 11 of 36

greater than 0.8 mm (1⁄32 in.) at the O.D. of the sealing surface, achieved using a force of

no greater than 10% of the maximum torque or bolt load for any bolt. Refer to figure 2

below.

Or, alternatively, the mating gasket contact surfaces shall be aligned to each other (before

bolting) within 1 mm in 200 mm (1⁄16 in./ft), measured across any diameter.

However, for flange connection to rotating equipment or machinery as defined by PCC-1

App. E-1 (e) and E-2.1/API 686 the out of parallelism shall be max 0.8mm.

Figure 2

- Rotational - two hole: The tolerance is measured by observing a 90-deg angle where the

fastener passes through the flanges or the holes are within 3 mm. Refer to figure 3 below

Figure 3.

- Excessive spacing or gap: This parameter is not greater than twice the thickness of the

gasket. Refer to figure 4 below

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 12 of 36

Figure 4.

6.3.3 Installation of gasket

All gaskets will not be re-used after open the flanges, all ring joint type gasket must be replaced

by new one also. Re-using gasket will be decided Management in detail situation and condition.

During installation of gaskets, the following steps shall be taken:

- Verify that the gasket complies with the dimensional and material specifications.

Information of gaskets including color coding have to be filled into check sheet as attachment

01 and 02.

- Position the gasket to be concentric with the flange I.D, talking suitable measures to ensure

that it is adequately supported during the positioning process. No portion of the gasket

should project into the flow path.

- Insure that the gasket is adequately supported during placement to avoid twist or bends that

will crease the surface or break the gasket structure.

- Particular care is taken to ensure flanges and gasket are compatible with process fluid to

avoid creating resulting in stress corrosion cracking or pitting of flange surface

- Do not tape the gasket in place across the sealing surface, which may result in potential leak

paths across the gasket face.

- Do not use glue or grease to keep the gasket in place, which will contaminate the sealing

surface once the gasket is put into operation.

- Do not assume that the gasket inserted ahead flange positioning will automatically stay in

position.

For Ring Joint gasket, it should be done contact surface checking before closing the flange by

(red) color material.

6.3.4 Tightening of bolts

Verify compliance with bolt and nut specification. Also, bolt lengths will be checked for suitable.

Washers are also inspected, all damages shall be corrected/replaced. If separate washers are

cupped/cracked from previous use, replace with new through-hardened washers.

All rust, corrosion on threads must be removed. Bolts/nuts combination shall turn freely by

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 13 of 36

hand. If they do not hand tighten, check for cause and make necessary corrections, it will be

replaced if needed.

Lubricate the threads of the bolts or stub, and the surface of the nut face adjacent to the flange

or washer.

The bolt holes shall be numbered with the cross bolting pattern sequence to be used. The

numbers shall be marked on the flange nearby the relevant bolt hole.

Depending on actual situation, the following method will be used:

- Tightening bolts with single tools

The bolted flange joint shall be tightened manually by wrench or automatically with

air/hydraulic tensioner and criss-cross sequence method shall be used. Attachment 03

illustrates numbering system and tightening sequence.

Torque increments for tightening using a single tool is recommended in attachment 04.

- Tightening bolts with multiple tools (group numbering system)

Number the flange with the bolt sequence groups corresponding to the number of bolt in the

flange and the number of tools employed:

Mark the bolts at the 12, 3, 6 and 9 o’clock positions with the number one.

Moving clockwise, split the angles between the marked bolts and number the next

group as number two.

Spit the remaining large angles as evenly as you can and continue numbering the

groups until all bolts are numbered. All bolts are now numbered in groups at 90 deg

from each of their own numbers.

Bolts shall be tightened by criss-cross sequence method. Torque increments for tightening

using a multi tool is recommended in attachment 05.

6.3.5 Tightening methods

In NSRP, 03 methods below for bolt tightening have to be applied:

- Manual tightening.

- Torque wrench.

- Tensioner.

To avoid damage and mis-alignment between the mating flanges, the suitable tools must be

used correctly.

The different categories and applicable tools for the flange ratings and sizes are followed

“Criteria for Flange Management (standard in NSRP)” table as Attachment 06, it will be applied

for all area except area AC00.

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 14 of 36

For area AC00, it must follow the attachment 09.

Torque value for manual tightening and torque wrench have to be applied for tightening

with priority following:

1st. Vendor document such as data sheet and approved drawing for equipment, package

(including piping in package).

2nd. For piping:

- Values in attachment 08 will be applied for all area except AC00.

- Values in attachment 10 will be applied for AC00.

For special case such as out of standardized size and pressure refer to sub-contractor

procedure in table 1.

3nd. ASME-PCC1 will be referred for calculation and recommended torque in table 1M

(page 3, ASME-PCC 1-2013) can be applied.

Torque value for tensioner must be followed the values indicated in attachment 12.

Toque value for non-metallic flange or non-metallic flange connect to full face steel flange using

gasket or O-ring seal: Attachment 07 gives referential torque values.

All torque results shall be recorded as in Attachment 11.

Table 1

EPC Contractor's Flange Management Procedures for each Area

Zone Subcontra Category Area Document Remarks

ctor Number

LILAMA SMP AC00(020) VV3160-001-A- exception of

146 standardizati

on

LILAMA SMP AF00(022,023,024,025,08 VV3160-001-A- Standardized

1,124,130) 103

PMS SMP A200(086,087,088,089,09 VV3160-001-B- Standardized

1 0,091,092,093)/A300(084) 016

/

A400(028)

PC1 SMP A800(040,042,043)/A900( VV3160-001-C- Standardized

041) 676

LILAMA UGP Zone 1 & Zone 2 Common VV3163-101-A-

109

LILAMA SMP AA00(061)/AB00(010,011, VV3160-002-A- Standardized

2

012)/A100(080)/AD00(013 628

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 15 of 36

)/AE00(014)

PVE SMP A500(044,045,046)/A600( VV3160-005-A- Standardized

047,048,049) 023

Sung Do SMP B300(102)/B400(110,111,1 VV3160-006-A- Standardized

12,113) 632

KTI SMP B100(121,122)/B200(101, VV3160-006-B- Standardized

170)/B500(103)/B700(110) 629

LILAMA SMP AG00 VV3130-007-A- Standardized

645

LILAMA UGP Zone 2 VV3163-101-A-

109

PTSC SMP A700(070,071)/C400(190)/ VV3160-008-A- Standardized

C500(180)/C600(Admin 617

Buildings)

PTSC SMP C100(151)/B600(104)/C70 VV3160-009-A- Standardized

0(Fire 618

3 Training)/C200(152,154)/C

300(152,153,154)

PTSC UGP All Zone 3 VV3163-003-A-

637

Hoa Hiep SMP C400(Waste Water VV3160-008-B-

Treatment unit) 623

SMP: Structure Machinery Piping (include over 150#Rating Steel piping).

UGP: Under Ground Piping (except over 150#Rating Steel piping).

6.3.6 Hot bolting

Hot bolting is practical method to prevent the leakage from piping and equipment

happened by difference of thermal expansion between bolts/nut and flange during

increasing of liquid temperature and pressure.

Hot bolting shall be applied for:

1. Operating temperature more than 230 Celsius degree.

2. Operating temperature less than 230 Celsius degree, but having some special

requirement such in case of operation mode change or batch operation and

licensor’s requirement if any.

3. Operating temperature less than 230 Celsius degree, but within 24h of initial starting

up, for some bolted flanges if leakage happened, hot bolting shall be carried out as

a leakage treatment method. And, in the next time, after maintenance activities for

these positions, hot bolting is mandatory required. (Notes: Because of leakage

at little high temperature, only authorized personnel who is allowed by Section

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 16 of 36

manager can be decided.)

The information for hot bolting have to be recorded into attachment 11

However, for below conditions, hot bolting method are not allowed to apply.

1. Flanges that are being controlled toque value by tensioner.

2. The first flange at Pump side

3. Flanges that using PTFE based gasket, sheet gasket are not allowed. (Basically,

hot bolting method is applied for flanges that using spiral wound gasket, ring joint

gasket).

Timing of hot bolting implementation:

1. Operation temperature is from 230 degree to 480 degree, all bolts shall be re-

tightened only 1 time at operating temperature with specified toque value.

2. Operation temperature is above 480 degree, all bolts shall be re-tightened by 2

steps. Step1 at haft of operating temperature, and step 2 at operating temperature.

Hot bolting is also the sequential removal and replacement of bolts on flanged joints while

under reduced operating pressure. It is carried out one bolt at a time in a predetermined

cross pattern sequence. Each replaced bolt is fully tensioned before the next one is

removed.

Hot bolting can be used to clean, lubricate, and reinstall existing bolts for pre-shutdown

activities, replace corroded or damaged bolts, or upgrade the material specification or

grade of bolts.

Following flanges will not be applied “hot bolting” for removal and replacement of bolts for

any purpose:

Normal Flange Flange Normal Remark

pipe size class type bolt count

2” 150 RF 4 Insufficient gasket-seat force without

use of hot bolt clamp.

3” 150 RF 4 Insufficient gasket-seat force without

use of hot bolt clamp.

4” 150 RF 8 Insufficient gasket-seat force without

use of hot bolt clamp.

6” 150 RF 8 Insufficient gasket-seat force without

use of hot bolt clamp.

8” 150 RF 8 Insufficient gasket-seat force without

use of hot bolt clamp.

10” 150 RF 12 Insufficient gasket-seat force without

use of hot bolt clamp.

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 17 of 36

12” 150 RF 12 Insufficient gasket-seat force without

use of hot bolt clamp.

16” 150 RF 16 Insufficient gasket-seat force without

use of hot bolt clamp.

18” 150 RF 16 Insufficient gasket-seat force without

use of hot bolt clamp.

20” 150 RF 20 Insufficient gasket-seat force without

use of hot bolt clamp.

24” 150 RF 20 Insufficient gasket-seat force without

use of hot bolt clamp.

Noted: When conducting hot bolting removal procedures, the risks of fluid leakage are increased

due to increased bolting stresses and relaxation of gasket compression, both potentially resulting

in joint leakage or gasket segment blowout.

Half bolting can be used for the removal of every other bolt (so the flange is left with half

the number of bolts) during plant depressurization, usually when the system is close to

atmospheric pressure. This hot bolting shall not only start when system is depressurized

to 50% of operating pressure.

Noted: When conducting half bolting removal procedures, the risks of fluid leakage are increased

due to reduced gasket compression and the possibility that the system may inadvertently be re-

pressurized. For this reason, the system pressure at which half bolting is conducted should be well

below design pressure and preferably at or near atmospheric pressure with local management

controls in place to prevent re-pressurization. Flange clamps can be used to add clamp force if

necessary.

6.3.7 Guidelines for leakage test by hydrogen

This guidelines is to provide the acceptance criteria for leakage test system by hydrogen. The

detail of requirement should be followed the Appendix 13 of this procedure. The leak test will

be handled by Operation Division.

6.4. Bolted flange leakage rectification

This is to guideline to rectify leak for bolted flange in NSRP plan.

When leak occurs on bolted flange, the following steps shall be followed in sequence for the

rectification:

- 1st step: Re-tighten the bolted flange with torque value outlined in clause 6.3.5 and

sequence for tighten in clause 6.3.4. If leakage does not stop, go to 2nd step.

- 2nd step: Apply the torque value in attachment 14, it is recommended by ASME

PPC 1-2013 for tighten. If leakage continues, system should be isolated, open

flange to check flange surface health and flange alignment.

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 18 of 36

In case system can’t be shutdown/isolated, check with operation for plan of

nearest possible window to shutdown or isolate the flange, if cannot be isolated at

all in near future, then transfer to 3rd step.

- 3rd step: Manual tightening will be applied under witness/supervised by NSRP’

Authorized Engineer. If it is still leakage, go to 4th step.

- 4th step: Apply clamp on leak location by online sealing service. Clamp and

compound will be calculated and selected by Online Sealing Contractor and

approved by NSRP.

6.5. Work order closure

Before finishing the work, uniform gap between surfaces of bolted joint flanges shall be

checked again. After that, the following steps shall be taken:

- Return unused spare parts and reusable parts.

- Clean all tools before returning to warehouse.

- Handover to Operation Division.

- Record all information of the maintenance work such as actual manpower, actual MRO and

actual tools.

- Update the information into CMMS

- Close WO on CMMS.

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 19 of 36

ATTACHMENT – 01

Precommissioning

Checklist

COMMISSIONING CHECKLIST Doc. No.

Rev. No.

Rev. Date

GASKET (WALK AROUND)

Line no.

Isometric Dwg No.

P&ID No.

System No.

CHECK

ACTIVITIES METHOD TOOL DATE REMARKS

(Yes/No)

1. For Connection status: Does the Connection have any VI

2. Confirm permanent gasket installed (visual check or scale) VI Feeler gauge

3. Confirm gasket type (by color code)

4. Confirm Gasket material (by color code) VI

4a. Spiral wound gasket

4a1. Confirm Winding Material color

4a2. Confirm Filler material color

4a3. Confirm rating/outer ring color VI

5. Check gasket assembly status VI

6. Flange check

6a. Visual check Bolt/nut grease VI

Hammer,

6b. Bolt/nut tightening check VI

feeler gauge

6c. Position of flange VI

6c1. Alignment

6c2. Offset VI

6c3. Angle

7. Others VI

Prepare for check Site check

Gasket Type Spiral wound Gasket Type

Winding Material Winding Material

Blue

color color

Filler material Filler material

None

color color

Rating/outer ring Rating/outer ring

Dark Violet

color color

PIC TASK LEADER APPROVED BY STATUS EVALUATION

NAME

SIGNATURE

DATE

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 20 of 36

ATTACHMENT – 02

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 21 of 36

Gasket Material Indentification Guideline

Coding by Winding Material

Winding Material Color

316 Stainless Steel Green (Per ASME B16.20)

UNS N06625 Gold (Per ASME B16.20)

321 Stainless Steel Turquoise (Per ASME B16.20)

Monel 400 Orange (Per ASME B16.20)

UNS S31803 Red

347 Stainless Steel Blue (Per ASME B16.20)

Coding by Filler Material

Filler Material Color

Flexible graphite Gray (Per ASME B16.20)

Non-asbestos None

Mica-graphite Pink (Per ASME B16.20)

Coding by Rating / Outer Ring Material Octagonal Ring Joint Gaskets

Rating Outer ring Color Material Color

CS Arctic Blue Soft Iron None

CL150 SS316 Red 5Cr – ½ Mo Arctic Blue

UNS N06625 Light Orange 304 Stainless Steel Grass Green

CS Dark Violet 304 Stainless Steel Red

CL300 SS316 White 316 Stainless Steel Light Orange

UNS N06625 Black 347 Stainless Steel Dark Violet

CS Middle Brown UNS N08825 White

CL600

SS316 Canary Yellow

CL900 SS316 Light Gray

Winding Material Color Filler Material Color Rating / Outer Ring and Ring Joint Gaskets Color

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 22 of 36

ATTACHMENT – 03

Example for numbering with 12 bolted flange

Tightening sequence

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 23 of 36

ATTACHMENT – 04

Table 2 Torque Increments for Legacy Cross- Pattern Tightening Using a single tool

Step Loading

Install Hand tighten, then “snug up” to 15 Nm to 30 Nm (not to exceed 20% of

target Torque). Check flange gap around circumference for uniformity. If

the gap around the circumference is not reasonable uniform, make the

appropriate adjustments by selective tightening before proceeding.

Round 1 Tighten to 20% to 30% of Target Torque. Check flange gap around

circumference for uniformity. If the gap around the circumference is not

reasonably uniform, make the appropriate adjustments by selective

tightening/loosening before proceeding.

Round 2 Tighten to 50% to 70% of Target Torque. Check flange gap around

circumference for uniformity. If the gap around the circumference is not

reasonably uniform, make the appropriate adjustments by selective

tightening/loosening before proceeding.

Round 3 Tighten to 100% of Target Torque. Check flange gap around

circumference for uniformity. If the gap around the circumference is not

reasonably uniform, make the appropriate adjustments by selective

tightening/loosening before proceeding.

Round 4 Continue tightening the bolts, but on a circular clockwise pattern until no

further nut rotation occurs at the Round 3 Target Torque value. For

indicator bolting, tighten bolts until the indicator rod retraction readings

for all bolts are within the specified range.

Round 5 Time permitting, with a minimum of 4 hours and repeat round 4; this will

restore the short-term creep relaxation/embedment losses. If the flange

is subjected to a subsequent test pressure higher than its rating, it may

be desirable to repeat this round after the test is completed.

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 24 of 36

ATTACHMENT – 05

Pass #1a: Tighten bolts equally space 180 deg apart on opposite sides of the join to 30%

of target torque, then rotate tools 90 deg and simultaneously tighten these two bolts to

30% of target torque.

Pass #1b: Simultaneously tighten the first two bolts to 60% of target torque, then rotate

tools 90 deg and simultaneously tighten these two bolts to 60% of target torque.

Pass #1c: Simultaneously tighten the first two bolts to 100% of target torque, then rotate

tools 90 deg and simultaneous tighten these two bolts to 100% of target torque.

Pass #1d onward: Tighten all bolts, simultaneously in groups of two 180 deg apart, in

circular passes at 100% of target torque until the nuts no longer turn.

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 25 of 36

ATTACHMENT – 06

Criteria for Flange Management (Standard in NSRP)

A S M E B 16 . 5 / B 16 . 4 7 F l a n g e R a t i n g No n standard flnage

15 0 l b 300 lb 600 lb 900 lb 15 0 0 l b 2500 lb 2500 lb

N o . o B o l t N o t eN o . o B o l t N o t e N o . o B o l t N o t e N o . o B o l t N o t e N o . o B o l t N o t e N o . o B o l t N o t e N o . o f B o l t D i a .N (oi tn e) N

F l a n g e B o l t D i a . N o . B o l t D i a . ( i Nn )o . B o l t D i a . ( i Nn )o . B o l t D i a . ( i Nn )o . B o l t D i a . N o . B o l t D i a . N o . B o lt

F lange Size N P S

NP S (in) (in) Note (in) (in)

B o lts

Dia.

No . (in)

½ 4 1/ 2 1 4 1/ 2 1 4 1/ 2 1 4 3/4 1 4 3/4 1 4 3/4 1 14 16 2 . 12 5 3

¾ 4 1/ 2 1 4 5/8 1 4 5/8 1 4 3/4 1 4 3/4 1 4 3/4 1 16 20 2.375 3

1 4 1/ 2 1 4 5/8 1 4 5/8 1 4 7/8 1 4 7/8 1 4 7/8 1 18 24 2.5 3

1 ½ 4 1/ 2 1 4 3/4 1 4 5/8 1 4 1 1 4 1 1 4 1 1/ 8 1 24 16 3.375 3

2 4 5/8 1 8 5/8 1 8 5/8 1 8 7/8 1 8 7/8 1 8 1 1

3 4 5/8 1 8 3/4 1 8 3/4 1 8 7/8 1 8 1 1/ 8 1 8 1 1/ 4 3 = No n standard

4 8 5/8 1 8 3/4 1 8 7/8 1 8 1 1/ 8 1 8 1 1/ 4 3 8 1 1/ 2 3 (SK B o iler Unit

6 8 3/4 1 12 3/4 1 12 1 1 12 1 1/ 8 1 12 1 3/8 3 8 2 3

8 8 3/4 1 12 7/8 1 12 1 1/ 8 1 12 1 3/8 3 12 1 5/8 3 12 2 3

10 12 7/8 1 16 1 1 16 1 1/ 4 3 16 1 3/8 3 12 1 7/8 3 12 2 1/ 2 3

12 12 7/8 1 16 1 1/ 8 1 20 1 1/ 4 3 20 1 3/8 3 16 2 3 12 2 3/4 3

14 12 1 1 20 1 1/ 8 1 20 1 3/8 3 20 1 1/ 2 3 16 2 1/ 4 3

16 16 1 1 20 1 1/ 4 1 20 1 1/ 2 3 20 1 5/8 3 16 2 1/ 2 3

18 16 1 1/ 8 1 24 1 1/ 4 1 20 1 5/8 3 20 1 7/8 3 16 2 3/4 3

20 20 1 1/ 8 1 24 1 1/ 4 1 24 1 5/8 3 20 2 3 16 3 3

24 20 1 1/ 4 1 24 1 1/ 2 1 24 1 7/8 3 20 2 1/ 2 3 16 3 1/ 2 3

26 36 3/4 1 32 1 1/ 4 1 28 1 5/8 3 20 2 3/4 3

28 40 3/4 1 36 1 1/ 4 1 28 1 3/4 3 20 3 3

30 44 3/4 1 36 1 3/8 1 28 1 7/8 3 20 3 3

32 48 3/4 1 32 1 1/ 2 1 28 2 3 20 3 1/ 4 3

34 40 7/8 1 36 1 1/ 2 1 24 2 1/ 4 3 20 3 1/ 2 3

36 44 7/8 1 32 1 5/8 1 28 2 1/ 4 3 20 3 1/ 2 3

38 40 1 1 36 1 5/8 1 28 2 1/ 4 3

40 44 1 1 40 1 5/8 1 32 2 1/ 4 3 = A S M E B 16 . 5

42 48 1 1 36 1 3/4 1 28 2 1/ 2 3

44 52 1 1 40 1 3/4 1 32 2 1/ 2 3 = A S M E B 16 . 4 7 S e r i e s B

46 40 1 1/ 8 1 36 1 7/8 1 32 2 1/ 2 3 (N o t e: F langes t o be c o nnec t ed wit h GR P o r res ilient lined but t erf ly v alv es s hall be Series

48 44 1 1/ 8 1 40 1 7/8 1 32 2 3/4 3 = A S M E B 16 . 4 7 S e r i e s A

50 48 1 1/ 8 1 44 1 7/8 1 32 3 3

52 52 1 1/ 8 1 48 1 7/8 1 32 3 3 = Co ntro lled B o lt Lo ad Value by Tensio ner

54 56 1 1/ 8 1 48 1 7/8 1 32 3 3

56 60 1 1/ 8 1 36 2 1/ 4 1 32 3 1/ 4 3 = C o nt ro lled B o lt T o rque Value by T o rque Wrenc h

58 48 1 1/ 4 1 40 2 1/ 4 1 32 3 1/ 4 3

60 52 1 1/ 4 1 40 2 1/ 4 1 28 3 1/ 2 3 = M anual Tightening

Notes

1 F l a n g e b o l t i n g t o b e t i g h t e n e d t o r e c o m m e n d e d T o r q u e va l u e f o r t h e s e s i z e s ( G r e e n ) .

2 F l a n g e b o l t i n g t o b e h y d r a u l i c a l l y t e n s i o n e d f o r a l l s e r vi c e s i n t h e s e s i z e s ( B l u e ) .

Th e b o l t l e n g t h s s p e c i fi e d i n c l u d e a n a d d i t i o n a l l e n g t h o f 1 b o l t d i a m e t e r t o fa c i l i t a t e t h e u s e o f b o l t t e n s i o n i n g e q

3 A l l fl a n g e s c o n n e c t i n g t o ro t a t i n g e q u i p m e n t (P u m p / Co m p re s s o r/ B l o we r) s h a l l b e m a n a g e d b y Co n t ro l e d To rq u i n g

va l u e r e g a r d l e s s o f s i z e a n d r a t i n g .

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 26 of 36

ATTACHMENT – 07

Referential torque values for non-metallic flanges.

Pipe ID (mm) Max. Torque value (Nm)

25 10

40-50 15

80-100 25

150-200 35

250-300 50

350-500 75

600-700 100

750-800 200

900-1400 300

1500-4000 100 (O-ring seal)

In case the flange is not sealed, it is allowed to increase the bolt torque value 1.5 times

of recommended torque value mentioned in above table.

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 27 of 36

ATTACHMENT – 08

CL150, Spiral Wound Gasket, ASME B16.5/B16.47-B (Torque control to

be applied only where specifically required)

Flange Recommended Max. Torque

Size Torque

(N・m)

(NPS) (N・m)

1/2 17 62

3/4 23 62

1 30 62

1 1/2 46 62

2 68 120

3 115 120

4 84 120

6 168 214

8 226 236

10 210 340

12 265 340

14 331 504

16 306 504

18 439 727

20 383 727

24 546 1008

30 192 214

36 315 340

42 431 504

48 676 727

52 669 727

56 662 727

60 953 1008

CL300, Spiral Wound Gasket, ASME B16.5/B16.47-B (Torque control to

be applied only where specifically required)

All except for bolts B8M-CL2 For bolts B8M-CL2

Flange

Recommended Recommended

Size Max. Torque Max. Torque

Torque Torque

(NPS) (N・m) (N・m)

(N・m) (N・m)

1/2 17 62 17 58

3/4 28 120 28 113

1 36 120 36 113

1 1/2 72 214 72 201

2 44 120 44 113

3 96 214 96 201

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 28 of 36

4 140 214 140 201

6 173 214 173 201

8 293 340 284 284

10 344 504 344 421

12 516 727 516 639

14 474 727 474 639

16 676 1008 676 885

18 722 1008 722 885

20 853 1008 853 885

24 1387 1768 1195 1195

30 1118 1352 914 914

36 2028 2261 1529 1529

42 2703 2869 1940 1940

48 3410 3578 2420 2420

52 3215 3578 N/A N/A

56 5913 6167 N/A N/A

60 6035 6167 N/A N/A

CL600, Spiral Wound Gasket, ASME B16.5 (Torque control to be applied

only where specifically required)

All except for bolts B8M-CL2 For bolts B8M-CL2

Flange

Recommended Recommended

Size Max. Torque Max. Torque

Torque Torque

(NPS) (N・m) (N・m)

(N・m) (N・m)

1/2 26 62 26 58

3/4 48 120 48 113

1 68 120 68 113

1 1/2 144 214 144 201

2 84 120 84 113

3 188 214 188 201

4 340 340 284 284

6 462 504 421 421

8 727 727 639 639

CL900, Ring Joint

Gasket, ASME B16.5

Flange Recommended Max. Torque

Size Torque

(N・m)

(NPS) (N・m)

1/2 82 214

3/4 96 214

1 132 340

1 1/2 237 504

2 204 340

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 29 of 36

3 309 340

4 529 727

6 640 727

CL1500, Ring Joint

Gasket, ASME B16.5

Flange Recommended

Max. Torque

Size Torque

(N・m)

(NPS) (N・m)

1/2 121 214

3/4 143 214

1 199 340

1 1/2 354 504

2 304 340

3 683 727

CL2500, Ring Joint

Gasket, ASME B16.5

Flange Recommended Max. Torque

Size Torque

(N・m)

(NPS) (N・m)

1/2 200 287

3/4 258 287

1 380 455

1 1/2 908 973

2 565 675

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 30 of 36

ATTACHMENT – 09

Criteria for Flange Management (AC00, RHDS)

Document No.: MD-04-MT-RSSTA-PD-025 Title: Maintenance procedure for bolted flange

joint management

Date: 12-June-2018 Rev. No.: 05 Page 31 of 36

NSR Project

RHDS Piping

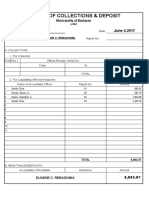

ATTACHEMNT 10

Torque Value Table for Flange Management

Line/Joint Flange Gasket Bolt Result

Tightening Target

Target Remarks

Class C.A. Size1 Rating End OptCd Sch1 Type Flange Material MLK Ident Code Type Material Size Quantity Material Method Torque

Bolt Load

Value

A0JP 0 2 150 RF 1 SCH10S WN ASTM A182 Grade F304/F304L dual grade P61K-0023K Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 22359 71

A0JP 0 3 150 RF 1 SCH10S WN ASTM A182 Grade F304/F304L dual grade P61K-0023L Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 44059 140

A0JP 0 4 150 RF 1 SCH10S WN ASTM A182 Grade F304/F304L dual grade P61K-0023M Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 26174 83

A0JP 0 6 150 RF 1 SCH40S WN ASTM A182 Grade F304/F304L dual grade P61K-0024K Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 44058 168

A0JP 0 8 150 RF 1 SCH10S WN ASTM A182 Grade F304/F304L dual grade P61K-003A8 Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 59170 226

A0JS 0 10 150 RF 1 SCH10S WN ASTM A182 Grade F304/F304L dual grade P61K-0024B Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7 / A194 Grade 2H MT 45798 204 Safety Factor 1.0 & Flange Yield Stress 98%

A0LW 0 2 150 RF 1 SCH10S WN ASTM A182 Grade F316/F316L dual grade P61K-0017R Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 25835 82

A0LW 0 4 150 RF 1 SCH10S WN ASTM A182 Grade F316/F316L dual grade P61K-0017L Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 26549 84

A0RA 0 0.75 150 RF 1 XS SW ASTM A105 Galvanized Fluid-3 P61B-00BRN Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 6828 17

A0RA 0 1 150 RF 1 XS SW ASTM A105 Galvanized Fluid-3 P61B-00BRP Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 9622 24

A0RA 0 1.5 150 RF 1 XS SW ASTM A105 Galvanized Fluid-3 P61B-00BRR Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 18493 47

A0RA 0 2 150 RF 1 XS WN ASTM A105 Galvanized P61B-006ST Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 31036 98

A0RA 0 3 150 RF 1 STD WN ASTM A105 Galvanized P61B-001NH Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 45577 145

A0RA 0 4 150 RF 1 STD WN ASTM A105 Galvanized P61B-001NY Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 37163 118

A0RA 0 6 150 RF 1 STD WN ASTM A105 Galvanized P61B-001P5 Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 61357 234

A0RU 0 2 150 RF 1 NPT ASTM A105 Galvanized P61B-001J5 Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 23416 74

A0RU 0 3 150 RF 1 STD WN ASTM A105 P61B-001PW Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 45577 145

A0RU 0 4 150 RF 1 STD WN ASTM A105 P61B-001R8 Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 37163 118

A0RU 0 6 150 RF 1 STD WN ASTM A105 P61B-001RT Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 61357 234

A0RU 0 8 150 RF 1 SCH20 WN ASTM A105 P61B-002BF Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 70044 267

A0RU 0 10 150 RF 1 SCH20 WN ASTM A105 P61B-002B4 Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7 / A194 Grade 2H MT 70471 313

A0RU 0 14 150 RF 1 SCH20 WN ASTM A105 P61B-002B6 Spiral wound gasket SS316 winding / Graphite filler 1 12 ASTM A193 Grade B7 / A194 Grade 2H MT 86907 442

A1AA 1.5 0.75 150 RF 1 XS SW ASTM A105 P61B-001RA Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 6845 18

A1AA 1.5 1 150 RF 1 XS SW ASTM A105 P61B-001RR Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 9624 24

A1AA 1.5 1.5 150 RF 1 XS SW ASTM A105 P61B-001RV Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 18629 47

A1AA 1.5 2 150 RF 1 XS WN ASTM A105 P61B-003NK Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 33551 106

A1AA 1.5 3 150 RF 1 STD WN ASTM A105 P61B-001PW Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 45577 145

A1AA 1.5 4 150 RF 1 STD WN ASTM A105 P61B-001R8 Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 37957 121

A1AA 1.5 6 150 RF 1 STD WN ASTM A105 P61B-001RT Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 64046 244

A1AP 1.5 0.75 150 RF 1 XS SW ASTM A105 P61B-001RA Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 6894 17

A1AP 1.5 1 150 RF 1 XS SW ASTM A105 P61B-001RR Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 9718 25

A1AP 1.5 1.5 150 RF 1 XS SW ASTM A105 P61B-001RV Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 18693 47

A1AP 1.5 2 150 RF 1 XS WN ASTM A105 P61B-003NK Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 33582 106

A1AP 1.5 2 1500 RJ 797 XS WN ASTM A105 P61B-0065C

A1AP 1.5 3 150 RF 1 STD WN ASTM A105 P61B-001PW Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 44177 140

A1AP 1.5 4 150 RF 1 STD WN ASTM A105 P61B-001R8 Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 38294 121

A1AP 1.5 4 900 RJ 789 STD WN ASTM A105 P61B-007A0

A1AP 1.5 6 150 RF 1 STD WN ASTM A105 P61B-001RT Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 63417 242

A1AP 1.5 8 150 RF 1 SCH20 WN ASTM A105 P61B-002BF Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 68759 262

A1AP02 1.5 0.75 150 RF 1 XS SW ASTM A105 P61B-001RA Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 6980 18

A1AP02 1.5 1 150 RF 1 XS SW ASTM A105 P61B-001RR Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 9844 25

A1AP02 1.5 1.5 150 RF 1 XS SW ASTM A105 P61B-001RV Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 18998 48

A1AP02 1.5 2 150 RF 1 XS WN ASTM A105 P61B-003NK Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 34023 108

A1AP02 1.5 3 150 RF 1 STD WN ASTM A105 P61B-001PW Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 41400 132

A1AP02 1.5 4 150 RF 1 STD WN ASTM A105 P61B-001R8 Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 38985 124

A1AP02 1.5 6 150 RF 1 STD WN ASTM A105 P61B-001RT Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 60476 231

A1AP02 1.5 8 150 RF 1 SCH20 WN ASTM A105 P61B-002BF Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 70044 267

A1AP02 1.5 10 150 RF 1 SCH20 WN ASTM A105 P61B-002B4 Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7 / A194 Grade 2H MT 73296 326

A1AP02 1.5 12 150 RF 1 SCH20 WN ASTM A105 P61B-002B5 Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7 / A194 Grade 2H MT 82413 367

A1AS 1.5 0.75 150 RF 1 XS SW ASTM A105 P61B-001RA Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 7369 19

A1AS 1.5 1 150 RF 1 XS SW ASTM A105 P61B-001RR Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 10092 26

A1AS 1.5 1.5 150 RF 1 XS SW ASTM A105 P61B-001RV Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 19072 49

A1AS 1.5 2 150 RF 1 XS WN ASTM A105 P61B-003NK Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 34153 109

A1AS 1.5 3 150 RF 1 STD WN ASTM A105 P61B-001PW Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 45816 146 Safety Factor 1.1 & Bolt Yield Stress 60%

A1AS 1.5 4 150 RF 1 STD WN ASTM A105 P61B-001R8 Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 38074 121

A1AS 1.5 6 150 RF 1 STD WN ASTM A105 P61B-001RT Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 66634 254 Safety Factor 1.1 & Bolt Yield Stress 60%

A1AS 1.5 8 150 RF 1 SCH20 WN ASTM A105 P61B-002BF Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 85065 324 Safety Factor 1.1 & Bolt Yield Stress 75%

A1AS 1.5 10 150 RF 1 SCH20 WN ASTM A105 P61B-002B4 Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7 / A194 Grade 2H MT 76393 339

A1AS 1.5 12 150 RF 1 SCH20 WN ASTM A105 P61B-002B5 Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7 / A194 Grade 2H MT 82112 365

A1AS 1.5 14 150 RF 1 SCH20 WN ASTM A105 P61B-002B6 Spiral wound gasket SS316 winding / Graphite filler 1 12 ASTM A193 Grade B7 / A194 Grade 2H MT 92990 472

A1AS 1.5 16 150 RF 1 SCH20 WN ASTM A105 P61B-002B7 Spiral wound gasket SS316 winding / Graphite filler 1 16 ASTM A193 Grade B7 / A194 Grade 2H MT 80342 408

A1AS 1.5 20 150 RF 1 STD WN ASTM A105 P61B-001JA Spiral wound gasket SS316 winding / Graphite filler 1.125 20 ASTM A193 Grade B7 / A194 Grade 2H MT 125391 717

A2A4 3 0.75 150 RF 1 SCH160 WN ASTM A105 P61B-0037H Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 6980 18

A2A4 3 1 150 RF 1 SCH160 WN ASTM A105 P61B-0037F Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 9718 25

A2A4 3 1.5 150 RF 1 SCH160 WN ASTM A105 P61B-0037N Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 18849 48

A2A4 3 2 150 RF 1 XS WN ASTM A105 P61B-003NK Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 30080 95

A2A4 3 3 150 RF 1 STD WN ASTM A105 P61B-001PW Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 34672 110

A2A4 3 4 150 RF 1 STD WN ASTM A105 P61B-001R8 Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7M / A194 Grade 2HM MT 33063 105

A2A4 3 6 150 RF 1 STD WN ASTM A105 P61B-001RT Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7M / A194 Grade 2HM MT 50446 192

A2A4 3 8 150 RF 1 SCH30 WN ASTM A105 P61B-003FP Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7M / A194 Grade 2HM MT 61273 233 Safety Factor 1.1 & Bolt Yield Stress 60%

A2AA 3 0.75 150 RF 1 SCH160 SW ASTM A105 P61B-002DE Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 6845 18

A2AA 3 1 150 RF 1 SCH160 SW ASTM A105 P61B-002DU Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 9650 24

A2AA 3 1.5 150 RF 1 SCH160 SW ASTM A105 P61B-002EM Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 18633 47

A2AA 3 2 150 RF 1 XS WN ASTM A105 P61B-003NK Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 36442 116

A2AA 3 3 150 RF 1 STD WN ASTM A105 P61B-001PW Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 45358 144

NSR Project

RHDS Piping

Line/Joint Flange Gasket Bolt Result

Tightening Target

Target Remarks

Class C.A. Size1 Rating End OptCd Sch1 Type Flange Material MLK Ident Code Type Material Size Quantity Material Method Torque

Bolt Load

Value

A2AA 3 4 150 RF 1 STD WN ASTM A105 P61B-001R8 Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 36871 117

A2AD 3 0.5 150 RF 1 SCH160 SW ASTM A105 P61B-002D4 Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 5605 14

A2AD 3 0.75 150 RF 1 SCH160 SW ASTM A105 P61B-002DE Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 6845 18

A2AD 3 1 150 RF 1 SCH160 SW ASTM A105 P61B-002DU Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 9665 24

A2AD 3 1.5 150 RF 1 SCH160 SW ASTM A105 P61B-002EM Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 18709 48

A2AD 3 2 150 RF 1 XS WN ASTM A105 P61B-003NK Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 36436 115

A2AD 3 3 150 RF 1 STD WN ASTM A105 P61B-001PW Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 43857 139

A2AD 3 4 150 RF 1 STD WN ASTM A105 P61B-001R8 Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 37092 118

A2AD 3 6 150 RF 1 STD WN ASTM A105 P61B-001RT Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 62354 238

A2AD 3 8 150 RF 1 SCH30 WN ASTM A105 P61B-003FP Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 67491 257

A2AP 3 0.75 150 RF 1 SCH160 SW ASTM A105 P61B-002DE Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 7216 18 Safety Factor 1.1

A2AP 3 1 150 RF 1 SCH160 SW ASTM A105 P61B-002DU Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 10177 26 Safety Factor 1.1

A2AP 3 1.5 150 RF 1 SCH160 SW ASTM A105 P61B-002EM Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 19542 50 Safety Factor 1.1

A2AP 3 1.5 1500 RJ 797 SCH160 SW ASTM A105 P61B-0065B

A2AP 3 2 150 RF 1 XS WN ASTM A105 P61B-003NK Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 33970 108

A2AP 3 2 1500 RJ 797 XS WN ASTM A105 P61B-0065C

A2AP 3 3 150 RF 1 STD WN ASTM A105 P61B-001PW Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 45762 145 Safety Factor 1.1 & Bolt Yield Stress 60%

A2AP 3 4 150 RF 1 STD WN ASTM A105 P61B-001R8 Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 35809 114

A2AP 3 6 150 RF 1 STD WN ASTM A105 P61B-001RT Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 60326 230

A2AP 3 8 150 RF 1 SCH20 WN ASTM A105 P61B-002BF Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 63051 240 Safety Factor 1.1

A2AP 3 10 150 RF 1 SCH20 WN ASTM A105 P61B-002B4 Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7 / A194 Grade 2H MT 69631 310

A2AP 3 14 150 RF 1 SCH20 WN ASTM A105 P61B-002B6 Spiral wound gasket SS316 winding / Graphite filler 1 12 ASTM A193 Grade B7 / A194 Grade 2H MT 95538 485

A2AP 3 20 150 RF 1 STD WN ASTM A105 P61B-001JA Spiral wound gasket SS316 winding / Graphite filler 1.125 20 ASTM A193 Grade B7 / A194 Grade 2H MT 128344 734

A2AP 3 24 150 RF 1 STD WN ASTM A105 P61B-001NJ Spiral wound gasket SS316 winding / Graphite filler 1.25 20 ASTM A193 Grade B7 / A194 Grade 2H MT 162732 1034

A2AP02 3 1 150 RF 1 SCH160 SW ASTM A105 P61B-002DU Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 9649 24

A2AP02 3 1.5 150 RF 1 SCH160 SW ASTM A105 P61B-002EM Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 18629 47

A2AP02 3 2 150 RF 1 XS WN ASTM A105 P61B-003NK Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 36913 117

A2AP02 3 4 150 RF 1 STD WN ASTM A105 P61B-001R8 Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 37200 118

A2AP02 3 6 150 RF 1 STD WN ASTM A105 P61B-001RT Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 60476 231

A2AP02 3 8 150 RF 1 SCH20 WN ASTM A105 P61B-002BF Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 69018 263

A2AP02 3 10 150 RF 1 SCH20 WN ASTM A105 P61B-002B4 Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7 / A194 Grade 2H MT 71016 315

A2AP02 3 12 150 RF 1 SCH30 WN ASTM A105 P61B-002TS Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7 / A194 Grade 2H MT 80587 359

A2AQ 3 0.75 150 RF 1 SCH160 WN ASTM A105 P61B-0037H Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 9429 24

A2AQ 3 0.75 1500 RJ 797 SCH160 WN ASTM A105 P61B-0065U

A2AQ 3 1 150 RF 1 SCH160 WN ASTM A105 P61B-0037F Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 12311 32

A2AQ 3 1.5 150 RF 1 SCH160 WN ASTM A105 P61B-0037N Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 19295 49

A2AQ 3 1 1500 RJ 797 SCH160 WN ASTM A105 P61B-0065V

A2AQ 3 2 150 RF 1 XS WN ASTM A105 P61B-003NK Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 29030 92

A2AQ 3 2 1500 RJ 797 XS WN ASTM A105 P61B-0065C

A2AQ 3 3 150 RF 1 STD WN ASTM A105 P61B-001PW Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 37592 120 Safety Factor 1.1 & Bolt Yield Stress 60%

A2AQ 3 4 150 RF 1 STD WN ASTM A105 P61B-001R8 Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7M / A194 Grade 2HM MT 31248 100

A2AQ 3 4 900 RJ 789 STD WN ASTM A105 P61B-007A0

A2AQ 3 6 150 RF 1 STD WN ASTM A105 P61B-001RT Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7M / A194 Grade 2HM MT 47895 183

A2AQ 3 8 150 RF 1 SCH30 WN ASTM A105 P61B-003FP Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7M / A194 Grade 2HM MT 62123 237 Safety Factor 1.1 & Bolt Yield Stress 65%

A2AQ 3 8 1500 RJ 797 SCH30 WN ASTM A105 P61B-00DPC

A2AQ 3 10 150 RF 1 SCH30 WN ASTM A105 P61B-003FS Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7M / A194 Grade 2HM MT 63886 284

A2AQ 3 12 150 RF 1 SCH30 WN ASTM A105 P61B-002TS Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7M / A194 Grade 2HM MT 65801 293 Safety Factor 1.1

A2AQ 3 12 1500 RJ 797 SCH30 WN ASTM A105 P61B-00BNA

A2AQ 3 14 150 RF 1 SCH20 WN ASTM A105 P61B-002B6 Spiral wound gasket SS316 winding / Graphite filler 1 12 ASTM A193 Grade B7M / A194 Grade 2HM MT 84758 431

A2AQ 3 16 150 RF 1 SCH20 WN ASTM A105 P61B-002B7 Spiral wound gasket SS316 winding / Graphite filler 1 16 ASTM A193 Grade B7M / A194 Grade 2HM MT 82434 419

A2AQ 3 24 150 RF 1 XS WN ASTM A105 P61B-002F2 Spiral wound gasket SS316 winding / Graphite filler 1.25 20 ASTM A193 Grade B7M / A194 Grade 2HM MT 135946 863

A2AQ 3 24 1500 RJ 797 XS WN ASTM A105 P61B-00E1B

A2AQ 3 48 150 RF 1 14.27MM WN ASTM A105 P61B-003LK Spiral wound gasket SS316 winding / Graphite filler 1.125 44 ASTM A193 Grade B7M / A194 Grade 2HM MT 105195 602

A2AQVV 3 0.75 150 RF 1 XXS WN ASTM A105 P61B-003M1 Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 8062 20

A2AQVV 3 0.75 1500 RJ 797 XXS WN ASTM A105 P61B-005V2

A2AQVV 3 2 1500 RJ 797 XXS WN ASTM A105 P61B-0066U

A2AQVV 3 14 150 RF 1 XS WN ASTM A105 P61B-003MF Spiral wound gasket SS316 winding / Graphite filler 1 12 ASTM A193 Grade B7M / A194 Grade 2HM MT 84758 431

A2AQVV 3 30 150 RF 1 XS WN ASTM A105 P61B-001SJ Spiral wound gasket SS316 winding / Graphite filler 0.75 44 ASTM A193 Grade B7M / A194 Grade 2HM MT 44888 171

A2AS 3 0.75 150 RF 1 SCH160 SW ASTM A105 P61B-002DE Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 7216 18 Safety Factor 1.1

A2AS 3 1 150 RF 1 SCH160 SW ASTM A105 P61B-002DU Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 10177 26 Safety Factor 1.1

A2AS 3 1.5 150 RF 1 SCH160 SW ASTM A105 P61B-002EM Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 18803 48

A2AS 3 2 150 RF 1 XS WN ASTM A105 P61B-003NK Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 36236 115

A2AS 3 3 150 RF 1 STD WN ASTM A105 P61B-001PW Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 42263 134

A2AS 3 4 150 RF 1 STD WN ASTM A105 P61B-001R8 Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 38074 121

A2AS 3 6 150 RF 1 STD WN ASTM A105 P61B-001RT Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 60973 233

A2AS 3 8 150 RF 1 SCH30 WN ASTM A105 P61B-003FP Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 65276 249

A2AS 3 10 150 RF 1 SCH30 WN ASTM A105 P61B-003FS Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7 / A194 Grade 2H MT 73329 326

A2AS 3 12 150 RF 1 SCH30 WN ASTM A105 P61B-002TS Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7 / A194 Grade 2H MT 82268 366

A2AS 3 18 150 RF 1 SCH20 WN ASTM A105 P61B-002B8 Spiral wound gasket SS316 winding / Graphite filler 1.125 16 ASTM A193 Grade B7 / A194 Grade 2H MT 133117 761

A2AW 3 0.75 150 RF 1 SCH160 SW ASTM A105 P61B-002DE Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 6845 18

A2AW 3 1 150 RF 1 SCH160 SW ASTM A105 P61B-002DU Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 9652 24

A2AW 3 1.5 150 RF 1 SCH160 SW ASTM A105 P61B-002EM Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7 / A194 Grade 2H MT 18640 47

A2AW 3 2 150 RF 1 XS WN ASTM A105 P61B-003NK Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 36452 116

A2AW 3 3 150 RF 1 STD WN ASTM A105 P61B-001PW Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7 / A194 Grade 2H MT 45099 143

A2AW 3 4 150 RF 1 STD WN ASTM A105 P61B-001R8 Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 36889 117

A2AW 3 6 150 RF 1 STD WN ASTM A105 P61B-001RT Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 61770 235

A2AW 3 8 150 RF 1 SCH30 WN ASTM A105 P61B-003FP Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 69335 264

A2AW 3 10 150 RF 1 SCH30 WN ASTM A105 P61B-003FS Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7 / A194 Grade 2H MT 71011 315

A2AW 3 12 150 RF 1 SCH30 WN ASTM A105 P61B-002TS Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7 / A194 Grade 2H MT 79243 352

NSR Project

RHDS Piping

Line/Joint Flange Gasket Bolt Result

Tightening Target

Target Remarks

Class C.A. Size1 Rating End OptCd Sch1 Type Flange Material MLK Ident Code Type Material Size Quantity Material Method Torque

Bolt Load

Value

A2AW 3 18 150 RF 1 SCH20 WN ASTM A105 P61B-002B8 Spiral wound gasket SS316 winding / Graphite filler 1.125 16 ASTM A193 Grade B7 / A194 Grade 2H MT 127220 727

A2AW 3 20 150 RF 1 STD WN ASTM A105 P61B-001JA Spiral wound gasket SS316 winding / Graphite filler 1.125 20 ASTM A193 Grade B7 / A194 Grade 2H MT 122698 701

B0JS 0 1.5 300 RF 1 SCH80S SW ASTM A182 Grade F304/F304L dual grade P61K-003AC Spiral wound gasket SS316 winding / Graphite filler 0.75 4 ASTM A193 Grade B7 / A194 Grade 2H MT 20543 78

B0JS 0 2 300 RF 1 SCH10S WN ASTM A182 Grade F304/F304L dual grade P61K-0023W Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7 / A194 Grade 2H MT 15211 48

B0JS 0 3 300 RF 1 SCH10S WN ASTM A182 Grade F304/F304L dual grade P61K-0023X Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 31480 120

B0JS 0 4 300 RF 1 SCH10S WN ASTM A182 Grade F304/F304L dual grade P61K-0023Y Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7 / A194 Grade 2H MT 44999 171

B1A402 1.5 0.5 300 RF 1 XS WN ASTM A105 P61B-0032Z Spiral wound gasket SS316 winding / Graphite filler 0.5 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 9073 23

B1A402 1.5 0.75 300 RF 1 XS WN ASTM A105 P61B-0032X Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 11613 37

B1A402 1.5 1 300 RF 1 XS WN ASTM A105 P61B-0032U Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 16838 54

B1A402 1.5 1.5 300 RF 1 XS WN ASTM A105 P61B-0032S Spiral wound gasket SS316 winding / Graphite filler 0.75 4 ASTM A193 Grade B7M / A194 Grade 2HM MT 30716 117

B1A402 1.5 2 300 RF 1 XS WN ASTM A105 P61B-001HW Spiral wound gasket SS316 winding / Graphite filler 0.625 8 ASTM A193 Grade B7M / A194 Grade 2HM MT 21103 67

B1A402 1.5 3 300 RF 1 STD WN ASTM A105 P61B-001LJ Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7M / A194 Grade 2HM MT 42254 161

B1A402 1.5 4 300 RF 1 STD WN ASTM A105 P61B-001MC Spiral wound gasket SS316 winding / Graphite filler 0.75 8 ASTM A193 Grade B7M / A194 Grade 2HM MT 48055 183

B1A402 1.5 6 300 RF 1 STD WN ASTM A105 P61B-001N2 Spiral wound gasket SS316 winding / Graphite filler 0.75 12 ASTM A193 Grade B7M / A194 Grade 2HM MT 48898 186

B1A402 1.5 6 1500 RJ 797 STD WN ASTM A105 P61B-009W9

B1A402 1.5 8 300 RF 1 SCH20 WN ASTM A105 P61B-002LJ Spiral wound gasket SS316 winding / Graphite filler 0.875 12 ASTM A193 Grade B7M / A194 Grade 2HM MT 67740 301

B1A402 1.5 10 300 RF 1 SCH30 WN ASTM A105 P61B-003LX Spiral wound gasket SS316 winding / Graphite filler 1 16 ASTM A193 Grade B7M / A194 Grade 2HM MT 84828 431

B1A402 1.5 12 300 RF 1 STD WN ASTM A105 P61B-001LE Spiral wound gasket SS316 winding / Graphite filler 1.125 16 ASTM A193 Grade B7M / A194 Grade 2HM MT 114264 653

B1A402 1.5 14 300 RF 1 STD WN ASTM A105 P61B-001M9 Spiral wound gasket SS316 winding / Graphite filler 1.125 20 ASTM A193 Grade B7M / A194 Grade 2HM MT 98280 562

B1AG 1.5 1 300 RF 1 XS SW ASME SA105 P61B-009SZ Spiral wound gasket SS316 winding / Graphite filler 0.625 4 ASME SA193 Grade B7 / SA194 Grade 2H MT 22053 70

B1AG 1.5 1 1500 RJ 797 XS SW ASME SA105 P61B-00BVH

B1AG 1.5 1.5 300 RF 1 XS SW ASME SA105 P61B-009T0 Spiral wound gasket SS316 winding / Graphite filler 0.75 4 ASME SA193 Grade B7 / SA194 Grade 2H MT 31491 120