Professional Documents

Culture Documents

Effective and Efficient

Uploaded by

JOSUE FERNANDO FERNANDEZ0 ratings0% found this document useful (0 votes)

12 views2 pagesok

Original Title

ver

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentok

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views2 pagesEffective and Efficient

Uploaded by

JOSUE FERNANDO FERNANDEZok

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Effective And Efficient.

Selective Catalytic Reduction (SCR) For

High-Horsepower Tier 4 Final Engines.

760 HP To 4400 HP (567-3281 kW).

Effective And Efficient.

Experts In SCR Technology.

U.S. Environmental Protection Agency (EPA) Tier 4 Final

emissions regulations are now in effect for mobile off-

highway equipment 751 hp (560 kW) and above. These

emissions standards reduce particulate matter (PM) by

80 percent and oxides of nitrogen (NOx) by 45 percent,

compared with engines produced in 2006. Cummins

has chosen Selective Catalytic Reduction (SCR) as the Compared with our own prior Tier 2 products,

right technology to achieve these reductions while at the Cummins Tier 4 Final engines with SCR reduce both

same time improving fuel efficiency and reducing total emissions and diesel fuel consumption in almost every

operating costs. type of duty cycle. Cummins Tier 4 Final engines do

not require a Diesel Particulate Filter (DPF) or Diesel

Cummins SCR aftertreatment expertise is unrivaled in the Oxidation Catalyst (DOC).

industry. Our SCR system is designed and manufactured

by Cummins Emission Solutions, one of the world’s Totally Integrated And Optimized.

largest and most experienced suppliers of exhaust

The Cummins SCR system is highly robust, fully

aftertreatment systems, dating back to 2006 with the

passive, fully integrated and compact. It fits into

introduction of SCR to meet European on-highway

existing exhaust system envelopes, replacing the

emissions regulations. This in-house capability is unique

silencer or muffler. The SCR units have been specifically

in the industry, and ensures the highest level of system

engineered to protect against the vibration and shock

integration between the engine and aftertreatment.

loadings encountered by off-road equipment.

Our SCR system uses flow-through exhaust

SCR logic control is driven by Quantum System

aftertreatment to deliver ultra-low emissions, meeting

electronic engine management, upgraded with extra

regulations while increasing fuel efficiency. Removing

processing power for Tier 4 Final. That enables the

PM in-cylinder and NOx out-of-engine simplifies the

engine and SCR aftertreatment to operate seamlessly

emissions reduction strategy and allows the engine’s

as a single, integrated system. The system is capable of

full potential to be realized. Over the last decade, the

high NOx conversion with low backpressure, for greater

durability of our SCR system has proven to be equal to

fuel efficiency.

that of our engines.

Cummins SCR design is scalable across the complete

How SCR Works. QSK engine lineup, simplifying integration and assembly

Step 1 – Exhaust enters the SCR system with for equipment manufacturers.

emissions-compliant levels of PM.

The Lowest-Cost Solution.

Step 2 – The integrated Electronic Control Module

When you consider the potential reduction in diesel fuel

(ECM)-controlled doser injects the precise amount of

usage, increase in performance capabilities and the fact

Diesel Exhaust Fluid (DEF) in a high-efficiency spray

that there is virtually no maintenance required, it’s clear

pattern into the exhaust flow at a rate of 4 percent to

that the SCR technology used with Cummins High-

6 percent of diesel fuel consumed volumetrically

Horsepower Tier 4 Final engines is the best solution

depending on operating conditions.

for increased productivity, availability and profitability. To

Step 3 – The SCR system efficiently reduces NOx to learn more, see your local Cummins distributor or visit

clean, emissions-certified levels. cumminsengines.com.

Cummins Inc.

Box 3005

Columbus, IN 47202-3005

U.S.A.

Phone: 1-800-DIESELS™ (1-800-343-7357)

Internet: cumminsengines.com

Twitter.com/CumminsEngines

YouTube.com/CumminsEngines

Bulletin 4087389 Printed in U.S.A. Rev, 9/16

©2016 Cummins Inc.

You might also like

- Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveFrom EverandBosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveRobert Bosch GmbHNo ratings yet

- Ready For More.: Cummins Tier 4 Final High-Horsepower Engines For The Mining IndustryDocument8 pagesReady For More.: Cummins Tier 4 Final High-Horsepower Engines For The Mining IndustryzugupubexeNo ratings yet

- 4971389Document10 pages4971389Juan Diego SarangoNo ratings yet

- UA2 Urea Dosing SystemDocument4 pagesUA2 Urea Dosing SystemDmytro PichkurNo ratings yet

- Modular Aftertreatment SystemDocument4 pagesModular Aftertreatment SystemManmohan SinghNo ratings yet

- Wheel Loader: Engine Buckets WeightsDocument28 pagesWheel Loader: Engine Buckets WeightsTaha GargoumNo ratings yet

- Clearly Better. Every Time.: QSB6.7 and QSL9 Engines (140-400 HP) For Tier 4 Final/Stage IVDocument4 pagesClearly Better. Every Time.: QSB6.7 and QSL9 Engines (140-400 HP) For Tier 4 Final/Stage IVjadan tupuaNo ratings yet

- Ctalogo 962KDocument36 pagesCtalogo 962Kwilber quispeNo ratings yet

- Wheel Loader: Engine Buckets WeightsDocument32 pagesWheel Loader: Engine Buckets WeightsEng Ahmed ABasNo ratings yet

- Cummins QST30 For Locomotives and Railway Applications BrochureDocument4 pagesCummins QST30 For Locomotives and Railway Applications BrochureYuraNo ratings yet

- C734474 PDFDocument36 pagesC734474 PDFandi yusufNo ratings yet

- 950k en (17b) PDFDocument36 pages950k en (17b) PDFplanificacion morterosNo ratings yet

- Lean Burn Product BrochureDocument8 pagesLean Burn Product BrochurepradeeepgargNo ratings yet

- Wa470 8Document16 pagesWa470 8Rios Devora Ivan Candelario100% (1)

- Wa320 8 Aess903 02 Ev4Document16 pagesWa320 8 Aess903 02 Ev4Camilo ChavesNo ratings yet

- Millyard Loaders: Engine 950M 962M Maximum Power SAE J1995Document32 pagesMillyard Loaders: Engine 950M 962M Maximum Power SAE J1995Patryk GiżyńskiNo ratings yet

- Cat Generator Sets Tier 4 Interim Technology LEBE0009 00Document7 pagesCat Generator Sets Tier 4 Interim Technology LEBE0009 00Irfan YousufNo ratings yet

- Komatsu PC490LC 11Document24 pagesKomatsu PC490LC 11Dutchie169No ratings yet

- Komatsu 36t Excavator PDFDocument20 pagesKomatsu 36t Excavator PDFFaisal BhatNo ratings yet

- Tier 4 Machines Product Guide V9 WebDocument8 pagesTier 4 Machines Product Guide V9 WebrholdsandiegoNo ratings yet

- Cummins Engin Cat 6Document12 pagesCummins Engin Cat 6vaisakhpillai100% (1)

- QST30 For US EPA Tier 4 and EU Stage IIIB Railway Applications Spec Sheet (Customer Inspired Technology)Document2 pagesQST30 For US EPA Tier 4 and EU Stage IIIB Railway Applications Spec Sheet (Customer Inspired Technology)YuraNo ratings yet

- PC238USLC: Tier 4 Final EngineDocument20 pagesPC238USLC: Tier 4 Final EngineAbhinandan PadhaNo ratings yet

- Tier 4 Final Engine: Wheel LoaderDocument16 pagesTier 4 Final Engine: Wheel Loadergoonzaalo_22No ratings yet

- Wa270 8Document16 pagesWa270 8jesus manuel arze carrascoNo ratings yet

- 5410584Document14 pages5410584Massahiro FilhoNo ratings yet

- PC360LC 11Document20 pagesPC360LC 11Rob & Nicole RobardsNo ratings yet

- Cat C13 Specs PDFDocument6 pagesCat C13 Specs PDFdinny blanco100% (2)

- Cat D7RDocument20 pagesCat D7RAmdMsi100% (1)

- Specification of qsx95 MarineDocument2 pagesSpecification of qsx95 MarinePETER ADAMNo ratings yet

- Track-Type Tractor: Engine - XL/LGP WeightsDocument20 pagesTrack-Type Tractor: Engine - XL/LGP WeightsRas-Sherwin A. Jalani100% (2)

- PC130_11_AESS946_01Document16 pagesPC130_11_AESS946_01Luc DionneNo ratings yet

- CPCB IV+ 82.5-160 kVADocument6 pagesCPCB IV+ 82.5-160 kVAapandey070273No ratings yet

- 329F Aehq7270-00Document36 pages329F Aehq7270-00kiddrix gamerNo ratings yet

- Every Alternative.: C Gas PlusDocument6 pagesEvery Alternative.: C Gas PlusSandy TelloNo ratings yet

- Cummins Rating Card PDFDocument16 pagesCummins Rating Card PDFNguyen Son100% (1)

- CatalogoDocument28 pagesCatalogopolicryNo ratings yet

- Track-Type Tractor: Engine WeightsDocument20 pagesTrack-Type Tractor: Engine WeightsCristhian RuizNo ratings yet

- SCR Brochure - 2012 11 28Document2 pagesSCR Brochure - 2012 11 28Jorge Luis Tanaka ConchaNo ratings yet

- Marine Propulsion and Auxiliary Engines: Recreational ApplicationsDocument2 pagesMarine Propulsion and Auxiliary Engines: Recreational Applicationsjorge luisNo ratings yet

- 326F Aehq7271-00Document36 pages326F Aehq7271-00kiddrix gamerNo ratings yet

- Wa380 8Document16 pagesWa380 8SanouNo ratings yet

- c13 Cat Engine Brochure PDFDocument6 pagesc13 Cat Engine Brochure PDFJosè Manuel Coronado Saucedo100% (1)

- D155ax 8Document16 pagesD155ax 8eliasNo ratings yet

- Principle of SCR PDFDocument5 pagesPrinciple of SCR PDFCindy100% (1)

- Brochure ISLe5Document4 pagesBrochure ISLe5Stroe VladNo ratings yet

- Caterpillar Wheel Loader 962KDocument36 pagesCaterpillar Wheel Loader 962KJi Uvex100% (1)

- PC650LC: Tier 4 Final EngineDocument24 pagesPC650LC: Tier 4 Final EngineRino.exsaNo ratings yet

- Brochure QSB6.7 MarinoDocument2 pagesBrochure QSB6.7 MarinoandresNo ratings yet

- PowerSolutions English FINAL 16nov09Document16 pagesPowerSolutions English FINAL 16nov09sareluis30No ratings yet

- Tier 4 Final Engine: Wheel LoaderDocument16 pagesTier 4 Final Engine: Wheel LoaderJuan Felipe GómezNo ratings yet

- Cummins Qsc8.3 BrochureDocument2 pagesCummins Qsc8.3 BrochureThành DanhNo ratings yet

- D11T/D11T CD: DozerDocument28 pagesD11T/D11T CD: DozerMaria Ignacia Reveco DiazNo ratings yet

- 2806A-E18TAG1A_2Document2 pages2806A-E18TAG1A_2Ahmed AbdullahNo ratings yet

- Modular Aftertreatment System BrochureDocument4 pagesModular Aftertreatment System BrochureSalatyelNo ratings yet

- Every Innovation. ISM: Automotive Engines 335-445PSDocument4 pagesEvery Innovation. ISM: Automotive Engines 335-445PSLê Duy KimNo ratings yet

- 14m3 GraderDocument28 pages14m3 GraderErlen PolancoNo ratings yet

- Cat - 793CDocument24 pagesCat - 793CEmily CamilaNo ratings yet

- NIOSHMVS2012 Tier 4 Technology ReviewDocument46 pagesNIOSHMVS2012 Tier 4 Technology Reviewbuyadi100% (1)

- TIR PRE-ING Siemens 006 - ResponseDocument2 pagesTIR PRE-ING Siemens 006 - ResponseJOSUE FERNANDO FERNANDEZNo ratings yet

- SD R TCH Sei 0001Document1 pageSD R TCH Sei 0001JOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0090 - Certificate of Completion Offshore Work Payment Milestone 7, Site MobilizationDocument2 pagesSD-L-SEI-TCH-0090 - Certificate of Completion Offshore Work Payment Milestone 7, Site MobilizationJOSUE FERNANDO FERNANDEZNo ratings yet

- Energy, Inc.: Attached Document(s) Are Provided For Design/ConstructionDocument1 pageEnergy, Inc.: Attached Document(s) Are Provided For Design/ConstructionJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0087 - Customer Witness Point (Third Notice)Document3 pagesSD-L-SEI-TCH-0087 - Customer Witness Point (Third Notice)JOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0089 - Site Access For Grading SubcontractorDocument1 pageSD-L-SEI-TCH-0089 - Site Access For Grading SubcontractorJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-DC01-MB-839700 - SGT-PAC Piping Insulation RequirementsDocument12 pagesPE1007-DC01-MB-839700 - SGT-PAC Piping Insulation RequirementsJOSUE FERNANDO FERNANDEZNo ratings yet

- 1-A) BIS-711 Form - PRELLENADO POR FIRMARDocument1 page1-A) BIS-711 Form - PRELLENADO POR FIRMARJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0086 - Option Proposal For The Santo Domingo Project Top Soil Waste Material RemovalDocument2 pagesSD-L-SEI-TCH-0086 - Option Proposal For The Santo Domingo Project Top Soil Waste Material RemovalJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- Stuffing BoxDocument1 pageStuffing BoxJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0088 - Certificates of Insurane-Letter GG-SEI-061-2012Document7 pagesSD-L-SEI-TCH-0088 - Certificates of Insurane-Letter GG-SEI-061-2012JOSUE FERNANDO FERNANDEZNo ratings yet

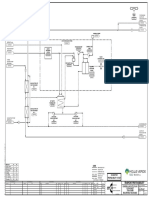

- S1 Strip Electrolyte Filtration ProcessDocument1 pageS1 Strip Electrolyte Filtration ProcessJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-XK01-MB-013100 - Customer Piping Connection Process InformationDocument11 pagesPE1007-XK01-MB-013100 - Customer Piping Connection Process InformationJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-XH01-00UZ-470001 Piping GA Drawing - Fire Hydrant Loop - Rev 1Document2 pagesPE1007-XH01-00UZ-470001 Piping GA Drawing - Fire Hydrant Loop - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-XH01-00UZ-470003 Piping GA Drawing - Above GroundDocument2 pagesPE1007-XH01-00UZ-470003 Piping GA Drawing - Above GroundJOSUE FERNANDO FERNANDEZNo ratings yet

- PFD 1Document1 pagePFD 1JOSUE FERNANDO FERNANDEZNo ratings yet

- 000-FS-007 Rev 0Document1 page000-FS-007 Rev 0JOSUE FERNANDO FERNANDEZNo ratings yet

- 000-FS-008 Rev 0Document1 page000-FS-008 Rev 0JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007 00GAC10 XJ00 446301 Piping Isometrics Rev 1Document1 pagePE1007 00GAC10 XJ00 446301 Piping Isometrics Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- OTec Rev.00Document21 pagesOTec Rev.00JOSUE FERNANDO FERNANDEZNo ratings yet

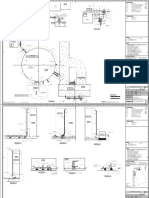

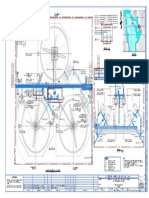

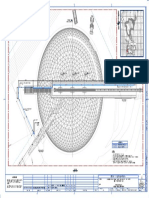

- Guar Mix Tank and Cathode Stripping Crane DetailsDocument1 pageGuar Mix Tank and Cathode Stripping Crane DetailsJOSUE FERNANDO FERNANDEZNo ratings yet

- Manual de ValvulaDocument16 pagesManual de ValvulaRene CalliriNo ratings yet

- 185 06 P 0003 PDFDocument1 page185 06 P 0003 PDFJOSUE FERNANDO FERNANDEZNo ratings yet

- Gi29301008 100 10 PL 101 PDFDocument1 pageGi29301008 100 10 PL 101 PDFJOSUE FERNANDO FERNANDEZNo ratings yet

- Therma Flow Inst and Oper. Maint. ManualDocument41 pagesTherma Flow Inst and Oper. Maint. ManualJOSUE FERNANDO FERNANDEZNo ratings yet

- 100 06 P 0001 PDFDocument1 page100 06 P 0001 PDFJOSUE FERNANDO FERNANDEZNo ratings yet

- Curvas de Operacion Tag 2810-PU-032Document2 pagesCurvas de Operacion Tag 2810-PU-032JOSUE FERNANDO FERNANDEZNo ratings yet

- CLP 7034Document2 pagesCLP 7034JOSUE FERNANDO FERNANDEZNo ratings yet

- N45TM 1Document4 pagesN45TM 1Yew LimNo ratings yet

- BakerHughes Frame91E Overview-060121Document7 pagesBakerHughes Frame91E Overview-060121achmad khumaidiNo ratings yet

- Lesson 10 - Gas Turbines IIDocument34 pagesLesson 10 - Gas Turbines IIROBANGANo ratings yet

- 3412E FlywheelDocument4 pages3412E Flywheelmohammed mostafaNo ratings yet

- Injector Pulse WidthDocument3 pagesInjector Pulse Widthmsaad19103564100% (1)

- Reassembly: 1. Assemble Piston and Connecting RodDocument7 pagesReassembly: 1. Assemble Piston and Connecting Roddolphi_742078No ratings yet

- MGM SyllabusDocument4 pagesMGM SyllabusKshirsagar Sandeep Popat me16d040No ratings yet

- VOLVO TAD 620VE Operators ManualDocument62 pagesVOLVO TAD 620VE Operators ManualGORD100% (2)

- D96 Service Kits and Parts List: CAP177 - D96 SEPT 2017 - Rev BDocument32 pagesD96 Service Kits and Parts List: CAP177 - D96 SEPT 2017 - Rev BrobertNo ratings yet

- Manual de Partes Excavadora Caterpillar 320D2 PDFDocument1,068 pagesManual de Partes Excavadora Caterpillar 320D2 PDFRemberto100% (5)

- SEBF 8380 перечень инструкции по ремонту головокDocument8 pagesSEBF 8380 перечень инструкции по ремонту головокЕвгений АбрамовNo ratings yet

- Case 504 BDT Large Main TorquesDocument1 pageCase 504 BDT Large Main Torquesducatiss900No ratings yet

- Tugas Resume Jurnal InternasionalDocument1 pageTugas Resume Jurnal InternasionalGalih Achmad PrawiradiawanNo ratings yet

- Slick Mag Overhaul ManualDocument64 pagesSlick Mag Overhaul Manualleather_nun100% (1)

- View Certificate: NOTICE: This Is NOT An Official CertificateDocument3 pagesView Certificate: NOTICE: This Is NOT An Official Certificate30 . Nguyễn Bảo NguyễnNo ratings yet

- Pistons, 207 Diesel EngineDocument3 pagesPistons, 207 Diesel EngineJESUSNo ratings yet

- 2023 Jeep ManualDocument13 pages2023 Jeep Manualt34t34No ratings yet

- Electric MotorsDocument11 pagesElectric MotorsAllan Gilbert Manalo JainNo ratings yet

- Technical File D16-Mg Krs D2E2 04: According To Marpol 73/78 Annex Vi and Nox Technical CodeDocument12 pagesTechnical File D16-Mg Krs D2E2 04: According To Marpol 73/78 Annex Vi and Nox Technical CodeinforlexNo ratings yet

- Civic IdleDocument4 pagesCivic IdlexmariachiNo ratings yet

- MAN SL2018-659 - JAP (2018.03) - Cerment-Coated Piston Rings For Low-Sulphur Fuels (0.5% or Lower)Document9 pagesMAN SL2018-659 - JAP (2018.03) - Cerment-Coated Piston Rings For Low-Sulphur Fuels (0.5% or Lower)GrandpaNo ratings yet

- MOTUL 8100 X-CESS 5W-40: Type of UseDocument4 pagesMOTUL 8100 X-CESS 5W-40: Type of UseFacundo LepphailleNo ratings yet

- 1000 Series (AA-AH YA-YD) UHDocument58 pages1000 Series (AA-AH YA-YD) UHВладислав ЛеоновNo ratings yet

- Type of Fuel PumpsDocument30 pagesType of Fuel PumpsPrem MauryaNo ratings yet

- PF Pump Specification: Stanadyne"Document2 pagesPF Pump Specification: Stanadyne"Miguel RojasNo ratings yet

- IMPCO Model CA100 CaburetorDocument6 pagesIMPCO Model CA100 CaburetorMaxiSanchezNo ratings yet

- Daytona Anima 190F Engine: Owner's ManualDocument38 pagesDaytona Anima 190F Engine: Owner's ManualNAVARRO SAIFULNo ratings yet

- Repuestos Motor C-07Document11 pagesRepuestos Motor C-07Wilson BalbinNo ratings yet

- Oil Pan Removal InstructionsDocument5 pagesOil Pan Removal InstructionsJustinLeeJohnsonNo ratings yet

- Man s70mc6Document363 pagesMan s70mc6Karim Sowley DelgadoNo ratings yet