Professional Documents

Culture Documents

Gas in Procedure Prasad

Gas in Procedure Prasad

Uploaded by

Aminarco -Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas in Procedure Prasad

Gas in Procedure Prasad

Uploaded by

Aminarco -Copyright:

Available Formats

Prosedure Commissioning & Gas In

System Metering Gas Turbine

METERING GAS TURBIN G.40 DI TITIK TIE-IN DAN

G.65 DI PT PRASAD SEEDS INDONESIA

KAWASAN INDUSTRI REMBANG PASURUAN

JAWA TIMUR

0 01/10/19 COMMISIONING & GAS IN PROCEDURE

Prepared Checked Approved

Revision Date Description

By By by

COMMISSIONING AND GAS IN PROCEDURE

DAFTAR ISI TABLE OF CONTENT

BAB DESKRIPSI HAL SEC. DESCRIPTION PAGE

1.0 PENDAHULUAN 4 1.0 INTRODUCTION 4

2.0 PRE-COMMISSIONING 4 2.0 PRE-COMMISSIONING 4

2.1 UMUM 4 2.1 GENERAL 4

2.2 INSPEKSI 4 2.2 INSPECTION 7

3.0 COMMISSIONING 7 3.0 COMMISSIONING 7

3.1 UMUM 7

3.1 GENERAL 7

3.2 PUNCH LIST 7

3.2 PUNCH LIST 7

3.3 COMMISSIONING 7

3.3 COMMISSIONING 7

3.4 SISTEM PURGING 8

3.4 PURGING 8

4.0 GAS IN 11

4.0 GAS IN 11

LAMPIRAN

APPENDIX

Process Flow Diagram

Process Flow Diagram

Skematik

Schematic

P&ID

P&ID

General Arrangement

General Arrangement

PENDAHULUAN

COMMISSIONING AND GAS IN PROCEDURE

Tujuan pembuatan Prosedur Commissioning dan 1.0 INTRODUCTION

Gas In ini adalah untuk menentukan prosedur This document provides guideline for Comissioning

pelaksanaan Commissioning dan penyaluran Gas and Gas In procedure from Gas Pipeline PT

(Gas In) dari jaringan pipa salur PT Pertamina Gas Pertamina Gas (PTG) to system meter gas PT

(PTG) ke Sistem Meter Gas PT Unilever Unilever Oleochemical Indonesia (UOI) in area

Oleochemical Indonesia (UOI) yang berlokasi di Kawasan Ekonomi Khusus (KEK), North Sumatera .

Kawasan Ekonomi Khusus (KEK), Sumatera-Utara.

1.0 PRE-COMMISSIONING

1.1 UMUM 2.0 PRE-COMMISSIONING

Persiapan untuk pelaksanaan Pre-commissioning 2.1. GENERAL

terdiri dari beberapa tahap pelaksanaan yang harus Preparation for Pre-Commissioning execution

dilakukan: consist of several important steps which must be

1.1.1 Memeriksa seluruh pemasangan pipa salur, followed :

lengkap dengan kondisi wrapping, proteksi 2.1.1 Check all pipeline installation complete with

katodik dan penimbunan. Rambu-rambu pipa wrapping, cathodic protection and good backfill.

salur dan proteksi katodik test point, harus sesuai Pipeline marker and test point for cathodic

dengan spesifikasi dokumen teknik. protection position shall comply with specification

1.1.2 Memeriksa sistem koneksi dalam perpipaan of engineering document.

termasuk fitting, support pipa dan pondasi harus 2.1.2 Check all of piping connection system including

sesuai dengan spesifikasi dokumen teknik. fitting, pipe support and support foundation. Then

1.1.3 Memeriksa arah aliran yang ditunjukkan dengan all shall comply with specification of engineering

arah panah pada pipa bagian luar. document.

1.1.4 Memeriksa seluruh pekerjaan civil dan struktur, 2.1.3 Check gas direction flow, which shown by the

dan harus sesuai dengan dokumen teknik. arrow on the outside of pipe.

1.1.5 Memeriksa letak alat instrumen dan sistem 2.1.4 Check all civil and structural work, and all shall

koneksinya harus sesuai dengan spesifikasi comply with engineering document.

standard dokumen teknik. 2.1.5 Check all instrument equipment placement and

its connection, and shall comply with standard

1.1.6 Membuat daftar peralatan dan hasil aktivitas specification engineering document.

perbaikan, punch list. 2.1.6 Prepare Punch List

1.1.7 Memeriksa kembali hasil seluruh pengujian untuk

pipa salur, perpipaan, instrumen, civil/struktur 2.1.7 Check all of the test result for pipeline, piping,

dan katodik. Hasil uji sudah harus di setujui. instrument, civil/structure and cathodic, and all of

1.1.8 Memeriksa sertifikasi pipa salur yang telah the test result should be approved.

disetujui oleh MIGAS. 2.1.8 Check pipeline certificate from MIGAS.

1.1.9 Seluruh katalog peralatan yang terpasang telah

tersedia. 2.1.9 All equipment installed catalogue should be ready.

Tahapan-tahapan tersebut di atas harus dipenuhi All steps above must be done first before continue to the

terlebih dahulu, sebelum menginjak ke tahap next step, Commissioning.

berikutnya, Commissioning.

1.2 INSPEKSI 2.2 INPECTION/CHECK LIST

Inspeksi harus dilakukan Tim Inspeksi Pre- Check list must be perform by Pre-Commissioning

Commissioning untuk memastikan kelengkapan Team to ensure that equipment, pipeline, fitting,

peralatan, fitting, perpipaan, instrumen, piping, instrument, civil-structure and cathodic

civil/struktur, dan proteksi katodik. protection are installed in the right place.

2.2.1 Inspeksi Pipa Salur. 2.2.1 Pipeline Inspection/Check List.

1. Memastikan NDT telah dilaksanakan di seluruh 1. Ensure that NDT should be done on every

COMMISSIONING AND GAS IN PROCEDURE

jalur pipa salur dengan hasil baik dan disetujui. pipeline system with the good results and

approved.

2. Memastikan rambu-rambu pipa salur telah

2. Ensure pipeline sign and information board

terpasang dengan baik dan benar, papan

installed good and correctly.

informasi pipa salur juga terpasang.

3. Memastikan kedalaman pipa salur ditanam 3. Ensure pipeline buried in the correct depth, and

dengan benar sesuai dengan dokumen teknik. shall comply with engineering document.

4. Memastikan kondisi penimbunan jaringan pipa 4. Ensure the pipe backfill condition is good and

telah baik dan sesuai dengan dokumen teknik. shall comply with engineering document.

5. Memastikan sepanjang pipa salur telah di

5. Ensure that pipeline must be wrapped using

wrapping dan telah di uji dengan holiday test,

wrapping tape which already tested by holiday

dan hasilnya telah disetujui. test and must be approved.

6. Memastikan pemasangan Insulation Joint telah 6. Ensure that the insulation joint has been

siap dan benar, sesuai dengan dokumen installed correctly, ready, and shall comply with

teknik. engineering document

7. Memastikan bahwa dalam pipa salur telah 7. Ensure that inner pipeline has been cleaned,

dibersihkan, gauging telah dilakukan dan gauging has already implemented and approved

before hydrotest.

disetujui sebelum hidrotest dilaksanakan.

8. Ensure that hydrotest result approved by

8. Memastikan hasil hidrotest disetujui MIGAS. MIGAS.

2.2.2 Inspeksi Perpipaan. 2.2.2 Piping Inspection/Check List

1. Memastikan seluruh sistem perpipaan sesuai 1. Ensure piping system shall comply with

dengan engineering document. engineering document.

2. Periksa sambungan antara pipa dengan flange 2. Check connection between pipe and flange or

atau pipa dengan pipa atau pipa dengan elbow, pipe and pipe or pipe and elbow or flange and

atau flange dengan flange. Memastikan bahwa flange. Ensure welding procedure shall comply

prosedur pengelasan telah sesuai dengan with engineering document

dokumen teknik. 3. Ensure piping has been flushing.

3. Memastikan perpipaan telah di flushing. 4. Ensure valve can be opened and closed

4. Memastikan bahwa valve dapat membuka dan correctly and easily, and the placement shall

menutup dengan baik dan mudah dimana comply with engineering document.

peletakan valve telah sesuai dokumen teknik. 5. Ensure elevation and lay-out of piping system

5. Memastikan elevasi dan letak dari sistem shall comply with engineering document.

perpipaan harus sesuai dokumen teknik. 6. Ensure pipe support and other accessories have

6. Memastikan bahwa support pipa dan been installed and shall comply with

accessories yang lain, telah terpasang sesuai engineering document.

dokumen teknik.

7. Pastikan bahwa anchor bolt telah terpasang 7. Ensure anchor bolts have been installed well.

dengan baik.

8. Memastikan servis skid metering telah 8. Ensure service platform have been installed

terpasang dengan benar. correctly.

9. Memastikan bahwa sistem perpipaan telah di 9. Ensure hydrostatic test has been done on the

Hidrotest dan hasilnya telah disetujui oleh pipeline system and the results have been

MIGAS. approved by MIGAS

2.2.3 Inspeksi Instrumen 2.2.3 Instrument Inspection/Check List

1. Memastikan seluruh peralatan instrumen telah 1. Ensure all instruments have been calibrated and

dikalibrasi sesuai dengan dokumen teknik. shall comply with engineering document.

2. Memastikan seluruh peralatan instrumen telah 2. Ensure all instruments have been installed

COMMISSIONING AND GAS IN PROCEDURE

siap terpasang dengan baik. correctly.

3. Periksa kondisi panel instrumen apakah sudah 3. Check condition of panel instrument as

sesuai dengan spesifikasai yang dibutuhkan following with standard requirement based on

oleh standard yang ditentukan oleh dokumen engineering document and local regulation.

teknik dan regulasi terkait. 4. Check that the tube connection is in good

4. Periksa sambungan tubing sudah benar dan condition and shall comply with engineering

baik dan sesuai dengan dokumen teknik. document.

5. Memastikan seluruh peralatan instrumen telah 5. Ensure that fuctional test has been done on all

dilakukan function test dan berhasil baik sesuai instruments with good result based on

dokumen teknik. engineering document.

6. Memastikan Pressure Regulator telah 6. Ensure Pressure Regulator have been installed

terpasang dan telah di function tes. and function tested.

7. Memastikan katalog dari tiap peralatan 7. Ensure catalogue of all instruments are

instrumen telah lengkap. complete.

2.2.4 Civil dan Structure 2.2.4 Civil and Structure Inspection/Check List

1. Periksa seluruh kondisi pondasi equipment 1. Check condition of all equipment and piping

maupun perpipaan dan dengan hasil test baik. foundation and the results are good.

2. Memastikan seluruh elevasi pondasi harus 2. Ensure elevation of foundation shall comply

sesuai dengan dokumen teknik. with engineering document

3. Memastikan kondisi pondasi pagar yang baru 3. Ensure fence and fence foundation shall comply

dan pagar sesuai dokumen teknik yang with engineering document.

ditentukan.

2.0 COMMISSIONING 3.0 COMMISSIONING

Commissioning dapat dilaksanakan setelah pre- Commissioning can start after pre-commissioning

commissioning selesai dilaksanakan. steps completely finished.

2.1 UMUM 3.1 GENERAL

Team Leader Commissioning bertanggung jawab Commissioning Team Leader is in charge on

terhadap koordinasi dan arahan langkah-langkah coordination and conduction during Commissioning.

yang akan dilakukan selama Commissioning. Purging will be perform during commissioning.

Purging akan dilakukan saat commissioning. Before purging start, punch list review should be

Sebelum purging dimulai, sebaiknya dilakukan discussed.

pembahasan punch list.

2.2 PUNCH LIST 3.2 PUNCH LIST

Tim pre-commissioning akan mengeluarkan laporan Pre-Commissioning team will produce Check List.

Check List. Di dalam check list terdapat pernyatan Check List report contains statement approved / not

yang menyatakan diterima atau diterima dengan approved / approved with comment by Pre-

persyaratan atau tidak sama sekali terima oleh tim commissioning team.

pre-commissioning. Check list produces Punch List. The Punch List will

Berdasarkan Check List akan dihasilkan Punch List. present the recommendation of which equipment

Punch List ini akan mengeluarkan rekomendasi or activity that should be repaired/reinstall or even

peralatan atau hasil pekerjaan mana saja yang perlu replaced.

diperbaiki atau dipasang ulang atau diganti.

2.3 COMMISSIONING 3.3 COMMISSIONING

Tim commissioning akan melakukan pekerjaan Commissioning team will work based on Punch List.

berdasarkan Punch List. The inspection steps should be done is as follows:

Pemeriksaan yang akan dilakukan adalah sebagai

COMMISSIONING AND GAS IN PROCEDURE

berikut :

1. Memeriksa hasil pekerjaan yang telah 1. Check all of the improved job .

diperbaiki.

2. Memeriksa peralatan yang telah diperbaiki. 2. Check all of the repaired equipment.

3. Memeriksa kembali pekerjaan ulang yang telah

dilakukan. 3. Re-check all of the improved job.

4. Memeriksa kembali peralatan yang telah

diganti. 4. Check all equipment replacement.

5. Membahas/mendiskusikan ulang terhadap

peralatan/pekerjaan yang tidak dapat di 5. Re-check all of the equipment/job that can’t be

perbaiki/diganti. repaired/improved, then discuss it.

6. Melakukan function test dan running test

peralatan tanpa menunggu purging dan gas in 6. Perform function test and running test without

(Static Test). waiting on purging and gas in steps.

7. Melakukan purging ke seluruh system 7. Purging all of the system using nitrogen.

menggunakan gas nitrogen.

Commissioning Team will perform Mechanical

Hasil Tim Commissioning adalah Mechanical Completion, which is present of all activity approval and

Completion, yaitu pernyataan bahwa seluruh hasil equipment installation approval declaration (approved /

pemeriksaan terhadap pekerjaan/ peralatan dapat approved with comment).

diterima penuh atau diterima bersyarat.

3.0 GAS IN 4.0 GAS IN

PIPA SALUR PT PGN PIPELINE PT PGN

1. Pastikan future valve 8”-300#(Line pipa menuju Inlet 1. Ensure future valve 8”-300# (Line Pipe to

Meter gas ) DIBUKA perlahan-lahan sampai tekanan Inlet gas meter) is OPEN until operating

operasi yang diinginkan. pressure desired.

STATION METER STATION METER

1. Pastikan Valve VF1, VF2, VF3, VV1, VV2, V3A, V3B, 1. Ensure Valve VF1, VF2, VF3, VV1, VV2,

V4A, V4B, V5A, V5B, V6A, V6B, V7, V8, V9A, V9B, V3A, V3B, V4A, V4B, V5A, V5B, V6A, V6B,

V10A, V10B, V11A, V11B, V12A, V12B dalam kadaan V7, V8, V9A, V9B, V10A, V10B, V11A,

tertutup semua. V11B, V12A, V12B are all closed

2. Buka Perlahan lahan Valve V1 pada area Tie-in PT 2. Open slowly Valve V1 at PT Pertamina Gas

Pertamina Gas (PIER Station). Tie-in area (PIER Station).

3. Buka Valve V2 perlahan-lahan pada inlet MRS di Titik 3. Open Valve V2 Slowly at inlet MRS at Tie-

Tie-in. in area.

4. Buka Valve V3A kemudian valve V3B 4. Open Valve V3A then Valve V3B

5. Setting Slum Shut Regulator SR-1A dan SR-1B 5. Setting Slum Shut Regulator SR-1A dan SR-

6. Lakukan dan Pastikan Reliev Valve, Regulator Monitor 1B

dan Regulator Aktif pada stream A dan B telah 6. Make sure relief valve, regultor (active &

dilakukan penyetingan. monitor) already set

7. Buka Valve V4A 7. Open Valve V4A

8. Buka Valve V5A dan V5B 8. Open Valve V5A then V5B

9. Buka Venting Valve 9. Open Venting Valve

10. Tim HSE monitoring gas yang di-venting 10. HSE Team observes vented gas using gas

menggunakan gas detector detector

COMMISSIONING AND GAS IN PROCEDURE

11. Setelah kandungan nitrogen & oksigen tidak 11. After nitrogen & oksigen undetected,

terdeteksi, venting ditutup venting closed

12. Dilakukan pengamatan leak tes 15-30 menit 12. Leak test conducted for 15-30 min

13. Jika tidak terdeteksi leak, valve nomor 6 A/B bisa 13. If leak undetected, valve Number 8 A/B

dibuka. can be opened

14. Buka Valve V7 14. Open Valve V7

15. Buka Venting Valve VV2 15. Open Venting Valve VV2

16. Tim HSE monitoring gas yang di-venting 16. HSE Team observes vented gas using gas

menggunakan gas detector detector

17. Setelah kandungan nitrogen & oksigen tidak 17. After nitrogen & oksigen undetected,

terdeteksi, venting ditutup venting closed

18. Buka Valve V8 18. Open Valve V8

19. Buka Valve V9A dan V9B 19. Open Valve V9A then V9B

20. Setting Slum Shut Regulator SR-1A dan SR-1B 20. Setting Slum Shut Regulator SR-1A dan SR-

21. Lakukan dan Pastikan Reliev Valve, Regulator Monitor 1B

dan Regulator Aktif pada stream A dan B telah 21. Make sure relief valve, regultor (active &

dilakukan penyetingan. monitor) already set

22. Buka Valve V10A dan V10B 22. Open Valve V10A then V10B

23. Buka Valve V11A dan V11B 23. Open Valve V11A then V11B

24. Buka Venting Valve 24. Open Venting Valve

25. Tim HSE monitoring gas yang diventing menggunakan 25. HSE Team observes vented gas using gas

gas detector detector

26. Setelah kandungan nitrogen & oksigen tidak 26. After nitrogen & oksigen undetected,

terdeteksi, venting ditutup venting closed

27. Dilakukan pengamatan leak tes 15-30 menit 27. Leak test conducted for 15-30 min

28. Jika tidak terdeteksi leak, valve nomor 12 A/B bisa 28. If leak undetected, valve Number 12 A/B

dibuka. can be opened

Dengan dibukanya valve nomor 12 , maka proses Gas In After the valve number 12 opened, Gas In

telah selesai dan Station siap operasi. process is finish and the station is ready for

operation .

Catatan :

Pengaturan arah aliran gas disesuaikan dengan kebutuhan Note :

operasional PT. PERTAGAS NIAGA Adjustment of gas flow direction is depend on

PT PERTAGAS NIAGA operational need

COMMISSIONING AND GAS IN PROCEDURE

DRAWING

ATTACHMENT

COMMISSIONING AND GAS IN PROCEDURE

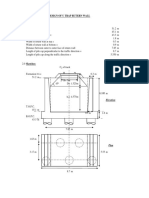

LIST OF DRAWING

1. Process Flow Diagram

2. Skematik

3. P&ID

Process Flow Diagram

COMMISSIONING AND GAS IN PROCEDURE

COMMISSIONING AND GAS IN PROCEDURE

Skematik

V1 VV1

VF2

V2 V7

VF1

V8

VF3

VV2

COMMISSIONING AND GAS IN PROCEDURE

P&ID MRS TITIK TIE-IN

V6A V6B

V5B

V5A

V4A V4B

V3A V3B

COMMISSIONING AND GAS IN PROCEDURE

P&ID MRS PRASAD

V12A V12B

V11A V11B

V10B

V10A

V9A V9B

COMMISSIONING AND GAS IN PROCEDURE

COMMISSIONING AND GAS IN PROCEDURE

You might also like

- OISD Chcek List For POL TerminalsDocument75 pagesOISD Chcek List For POL TerminalsAnoopNo ratings yet

- ASL GX7-11 RedesignDocument54 pagesASL GX7-11 RedesignMohammed Arshad100% (2)

- Itp For For Excavation, Backfilling & Compaction For Building WorksDocument4 pagesItp For For Excavation, Backfilling & Compaction For Building WorksBleep NewsNo ratings yet

- Pre-Commissioning Procedure - Air Blowing of Fuel Gas System 1Document3 pagesPre-Commissioning Procedure - Air Blowing of Fuel Gas System 1AdelNo ratings yet

- Fat - Functional Factory Acceptance Test Procedure For Flare and Burn Pit Packages 2600-PK-001 / 2600-PK-002 / 2600-PK-003Document8 pagesFat - Functional Factory Acceptance Test Procedure For Flare and Burn Pit Packages 2600-PK-001 / 2600-PK-002 / 2600-PK-003kami safaviNo ratings yet

- MSDS SFM-4728, FlexoilDocument5 pagesMSDS SFM-4728, FlexoilLeddy ZakarunaNo ratings yet

- 03 DTK DWG Pid 001 P&id Final 1 NodeDocument1 page03 DTK DWG Pid 001 P&id Final 1 NodeAnnisaNo ratings yet

- Air Blowing Package (Sample)Document3 pagesAir Blowing Package (Sample)YusufNo ratings yet

- Pressure Releaving StationDocument11 pagesPressure Releaving StationSreejesh Sundaresan100% (1)

- ISBL&OSBLDocument10 pagesISBL&OSBLvrajakisoriDasiNo ratings yet

- Baru Gas Plant DemandDocument4 pagesBaru Gas Plant DemandBop AlberthaNo ratings yet

- Commissioning Procedure - LPG Liquid ReceivingDocument5 pagesCommissioning Procedure - LPG Liquid ReceivingAba ShahrilNo ratings yet

- Scope of Work & SupplyDocument2 pagesScope of Work & SupplyTeguh YuliantoNo ratings yet

- Simops Test Leak / Hold Test For SCSSV / SSV North East ClusterDocument3 pagesSimops Test Leak / Hold Test For SCSSV / SSV North East ClusterHosseinNo ratings yet

- MCOT 017 Inter Tanks Transfer OperationsDocument14 pagesMCOT 017 Inter Tanks Transfer OperationsLembang ApangNo ratings yet

- Method Statement For Duct Leakage TestDocument5 pagesMethod Statement For Duct Leakage Testmohd faisal jamilNo ratings yet

- Cat Load by Sock Method in Normal AtmosphereDocument4 pagesCat Load by Sock Method in Normal Atmospherevishal bailurNo ratings yet

- KLM - PROJECT - STANDARD - AND - SPECIFICATIONS - Plant - Operating - Manuals - Rev01 PDFDocument10 pagesKLM - PROJECT - STANDARD - AND - SPECIFICATIONS - Plant - Operating - Manuals - Rev01 PDFLenaldy Nuari GarnokoNo ratings yet

- Saleh Muhammad Durrani CVDocument4 pagesSaleh Muhammad Durrani CVJamshaid SultanNo ratings yet

- FAT & SAT For Electrical System in Utility EndDocument16 pagesFAT & SAT For Electrical System in Utility EndBabuNo ratings yet

- Loading of ReactorsDocument3 pagesLoading of ReactorsVishal BailurNo ratings yet

- Pressure Gauge Dan Diff Gauge Datasheet - Rev.ADocument20 pagesPressure Gauge Dan Diff Gauge Datasheet - Rev.Asugeng wahyudiNo ratings yet

- NA Solid Petroserve LTD Mobile Metering Unit 2Document20 pagesNA Solid Petroserve LTD Mobile Metering Unit 2Slim.B100% (1)

- Manual Shutdown LPGDocument11 pagesManual Shutdown LPGYoga NugrahaNo ratings yet

- 18 Air Compressor System Commissioning Procedure-T Säï T +T+ƑF Âf Ò Ä Û+Document17 pages18 Air Compressor System Commissioning Procedure-T Säï T +T+ƑF Âf Ò Ä Û+kvsagar0% (1)

- Start Up and Commissioning of Pipelines: D. S. Nanaware, Chief Project Manager, IOCL, NoidaDocument33 pagesStart Up and Commissioning of Pipelines: D. S. Nanaware, Chief Project Manager, IOCL, NoidaAndi SungNo ratings yet

- EDG Commissioning - Activity ReportDocument3 pagesEDG Commissioning - Activity ReportmohamedNo ratings yet

- MSDS PVC PDFDocument4 pagesMSDS PVC PDFRegian Fajar AriesandiNo ratings yet

- (KPCC) Sop - Gas BoosterDocument12 pages(KPCC) Sop - Gas BoosterWindy Nitaejun HorvejkulNo ratings yet

- LNG Pipeline SystemDocument46 pagesLNG Pipeline SystemfanhadNo ratings yet

- Shahnawaz CV For Shutdown Maintenance EnggDocument3 pagesShahnawaz CV For Shutdown Maintenance EnggRaj AryanNo ratings yet

- National Iranian Oil Company: South Pars Gas Field Development Phase 19 Onshore FacilitiesDocument13 pagesNational Iranian Oil Company: South Pars Gas Field Development Phase 19 Onshore FacilitiesNasim MemarianNo ratings yet

- Inspection Test Record Overview: Dayang Enterprise Sdn. BHDDocument3 pagesInspection Test Record Overview: Dayang Enterprise Sdn. BHDAmyNo ratings yet

- Technologies ListDocument121 pagesTechnologies ListrasthoenNo ratings yet

- J1525-HW2-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW2-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- TA-16-073-MP-016 Prosedur Pemeriksaan Kondisi Pressure Vessel Dan Inner Parts PDFDocument4 pagesTA-16-073-MP-016 Prosedur Pemeriksaan Kondisi Pressure Vessel Dan Inner Parts PDFDjuangNo ratings yet

- Dcs Panel Commissioning OpDocument4 pagesDcs Panel Commissioning Opjohn MNo ratings yet

- Qa/Qc Procedure: PGB/HO/19/2015/0094Document2 pagesQa/Qc Procedure: PGB/HO/19/2015/0094saffririzal4237No ratings yet

- Problematic Processes For Hot TappingDocument2 pagesProblematic Processes For Hot Tapping최승원No ratings yet

- Report On Student Iw Experience SchemeDocument9 pagesReport On Student Iw Experience SchemeifiokNo ratings yet

- Cat Loading by Sock Method in Inert AtmosphereDocument5 pagesCat Loading by Sock Method in Inert Atmospherevishal bailurNo ratings yet

- Commisisoning Procedure of Air Compressor System (Rev.3) PDFDocument27 pagesCommisisoning Procedure of Air Compressor System (Rev.3) PDFfairelNo ratings yet

- ES SMP Weekly Report WE 2012 08 16Document6 pagesES SMP Weekly Report WE 2012 08 16Yudi HamdaniNo ratings yet

- GT Tray Tower1 PDFDocument12 pagesGT Tray Tower1 PDFJose Christian Viladegut GuzmanNo ratings yet

- Coral FLNG SA Is The Special Purpose Entity Responsible To Develop and Operate Coral South Floating Platform (FLNG)Document4 pagesCoral FLNG SA Is The Special Purpose Entity Responsible To Develop and Operate Coral South Floating Platform (FLNG)MateusPauloNo ratings yet

- Decommissioning IPFDocument2 pagesDecommissioning IPFDuraisamy DevarajNo ratings yet

- Liquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Document70 pagesLiquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Achmadda FebiyonoNo ratings yet

- Inspection and Test Plan FOR Filter Separator/CoalescerDocument6 pagesInspection and Test Plan FOR Filter Separator/Coalescersumit kumarNo ratings yet

- Saes L 388Document4 pagesSaes L 388Jaseel KanhirathingalNo ratings yet

- Data Sheet Meter Turbin G.65Document1 pageData Sheet Meter Turbin G.65HerruSetiawanNo ratings yet

- Fpso Kakap Natuna - Modec Fpso - Fso ProjectDocument2 pagesFpso Kakap Natuna - Modec Fpso - Fso ProjectjeffreymacaseroNo ratings yet

- Functional Test: FT-Packaged Boiler and Boiler System Including HW Pumps 1 & 2Document7 pagesFunctional Test: FT-Packaged Boiler and Boiler System Including HW Pumps 1 & 2vin ssNo ratings yet

- MC20005-WHP-WI-P-0118 Corrosion PR & Erosion PR Datasheet WI - Rev.D1Document18 pagesMC20005-WHP-WI-P-0118 Corrosion PR & Erosion PR Datasheet WI - Rev.D1nguyenmainamNo ratings yet

- SAT Procedure DCI JK5 - Fire Fighting Rev. 2Document14 pagesSAT Procedure DCI JK5 - Fire Fighting Rev. 2Awaludin Angga WNo ratings yet

- 10 - 254625-300-SP-INT-027 Specifications For Pressure Safety Valve Rev A PDFDocument10 pages10 - 254625-300-SP-INT-027 Specifications For Pressure Safety Valve Rev A PDFkhaireddinNo ratings yet

- GP 47-10 - Glycol Dehydration and RegenerationDocument10 pagesGP 47-10 - Glycol Dehydration and RegenerationandhucaosNo ratings yet

- Handbook For Use and Maintenance and Directive ATEX: Elvem S.R.LDocument18 pagesHandbook For Use and Maintenance and Directive ATEX: Elvem S.R.LE.ANANDAN100% (1)

- 2-Test Pack Cover SheetDocument1 page2-Test Pack Cover SheetPintu KumarNo ratings yet

- Tugas 2 - PFD KILANG RU III Plaju - Sungai GerongDocument22 pagesTugas 2 - PFD KILANG RU III Plaju - Sungai GerongMaulana Ikhsan HasibuanNo ratings yet

- Integrated Amine Degreasing Schedule 30mar2018Document1 pageIntegrated Amine Degreasing Schedule 30mar2018KhairulNo ratings yet

- Coastal Ocean Observing SystemsFrom EverandCoastal Ocean Observing SystemsYonggang LiuNo ratings yet

- Commissioning and Gas in - Hhi-Pertamina Gas - Kei 3001 - Rev 1.0Document13 pagesCommissioning and Gas in - Hhi-Pertamina Gas - Kei 3001 - Rev 1.0Ariz Joelee Artha100% (2)

- Appendix D3 Geotechnical Investigation Report - FINALDocument37 pagesAppendix D3 Geotechnical Investigation Report - FINALRudolf MashileNo ratings yet

- Power Point Presentation On "The Construction of Tunnels"Document41 pagesPower Point Presentation On "The Construction of Tunnels"Yem201289% (35)

- Gabbioneta Pumps: Heavy Duty Process PumpsDocument9 pagesGabbioneta Pumps: Heavy Duty Process PumpsMithun I KumarNo ratings yet

- Plan Check Correction ListDocument3 pagesPlan Check Correction ListTrà My BùiNo ratings yet

- Group 11a RivergothichouseDocument37 pagesGroup 11a RivergothichouseAn Bùi Ngọc MỹNo ratings yet

- Chapter02 Thimbles PDFDocument10 pagesChapter02 Thimbles PDFYadira BrownNo ratings yet

- JFK Lab Write Up Activity Four APESDocument2 pagesJFK Lab Write Up Activity Four APESSamuel Wieczerzak0% (1)

- Bridges in SlovakiaDocument270 pagesBridges in SlovakiaAlexandru Ionescu100% (1)

- High Pressure Gear Pump W900: Concentric ABDocument12 pagesHigh Pressure Gear Pump W900: Concentric ABDyanno RayfranNo ratings yet

- Expanded Metal SpecificationDocument1 pageExpanded Metal SpecificationMyatsuNo ratings yet

- Design Prof BlankoDocument11 pagesDesign Prof BlankoAousten AAtenNo ratings yet

- Analysis Strength of Scaffolding Structure On Stack HRSG For Cable TightDocument5 pagesAnalysis Strength of Scaffolding Structure On Stack HRSG For Cable TighthendraNo ratings yet

- Manufacturing of Tyre: Presented ByDocument29 pagesManufacturing of Tyre: Presented ByPRANJAL KUMARNo ratings yet

- I2ecs-1kd 2017-2018Document23 pagesI2ecs-1kd 2017-2018Alfredo MedinaNo ratings yet

- Presssure TunnelDocument7 pagesPresssure TunnelBinod NeupaneNo ratings yet

- BD 330 en Eu 050527Document2 pagesBD 330 en Eu 050527Cesar GuerraNo ratings yet

- Br. No.-390 - U-Trough Retaining Wall - Pile FoundationDocument14 pagesBr. No.-390 - U-Trough Retaining Wall - Pile Foundationshashibhushan singhNo ratings yet

- AMIES-A-113 - 2 - Geotechnical Engineering RequirementsDocument21 pagesAMIES-A-113 - 2 - Geotechnical Engineering RequirementsSeungtai JeongNo ratings yet

- Sanitary Equipment Design BookletDocument20 pagesSanitary Equipment Design Bookletamjad atayaNo ratings yet

- Condensate Return Systems 10.11.12 PDFDocument53 pagesCondensate Return Systems 10.11.12 PDFarunyoga100% (2)

- Underground PipingDocument27 pagesUnderground PipingMohd Effiezool Yaser100% (1)

- Conbextra STDDocument2 pagesConbextra STDm.elsanee.cubicNo ratings yet

- E1105Document5 pagesE1105Sig BlackhysteriaNo ratings yet

- Water SupplyDocument102 pagesWater SupplyLandon Mitchell100% (3)

- Mau PompeiiDocument4 pagesMau PompeiiCharlie HigginsNo ratings yet

- Zeko N Company ProfileDocument21 pagesZeko N Company Profilewisnu666No ratings yet

- Difference BETWEEN OLD STRUCTURE AND NEW STRUCTURE ON SAME BUILDINGDocument6 pagesDifference BETWEEN OLD STRUCTURE AND NEW STRUCTURE ON SAME BUILDINGSudarshan PatilNo ratings yet