Professional Documents

Culture Documents

FAT Form Winch Unit

Uploaded by

Yadi KusmayadiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FAT Form Winch Unit

Uploaded by

Yadi KusmayadiCopyright:

Available Formats

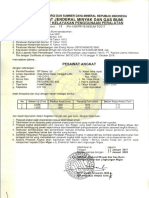

WINCH UNIT SINGLE I DOUBLE DRUM

MODEL : SOU TCP 01

Tricakra Perkasa Serial No:

energy services

PROJECT: DATE: I DOC. NO : 73-01-15-03 I REVISION : 0

FACTORY ACCEPTANCE TEST

1.0 Purpose : To ensure that the unit comply with the standard and requirement

2.0 Scope : Control all equipment of Winch Unit

3.0 Form

4.0 Documents and Verification

Reference Document

EN 12079:2006 - Offshore Containers and Associated Lifting Sets

DNV 2.7-1:2013 - Offshore Containers

AWS Dl .1 :2010- Stmctural welding Cod

Third Party Inspection Company

1. Load Test

2. NOT Before and After Load Test

3. Perfonnance Test (Witness)

Document for Review: Applicable Not Applicabl

Drawing complete with general arrangement - BS EN 120 d D

Pad eye design calculation - BS EN 12079 D D

Material traceability (Certificate of Materials) - AWS D 1.1 D D

Welding Procedure Specification (WPS) - AWS D 1.1 D D

Welder's certification - AWS D 1.1 D D

Non Destructive Test (NDT) mapping for welding D D

Load Test Report - BV D D

NDT Report on pad eye and structural before Load Test D D

NDT Report on pad eye and structural after Load Test -BV D D

Checked By Reviewed By Witnessed By Acknowledge By

Sign

Date

Accepted Rejected

Result

r i n

7.3-01- 15-13 - Factory Acceptance Test - PP Rev.a Page 1 of7

WINCH UNIT SINGLE I DOUBLE DRUM

MODEL : SOU TCP 01

T rlcakra Perkasa Serial No:

ene<gy H<Vlces

PROJECT: DATE: I DOC. NO : 73-01-15-03 I REVISION : 0 l

FACTORY ACCEPTANCE TEST

5. Performance test of winch unit Applicable

Yes No

D D

Preparation :

- The winch unit system shall be tested for performance records with full hydraulic systen

connected.

- Check and ensure no leaking

- Ensure the connection has fully connected.

Testing Procedure:

• Start power pack

• Ensure the winch unit is warmed for 10 minutes.

• Adjust System pressure range @2400 psi

• Put the reflector of tachometer into the shaft of the driven sprocket (shaft of the drum)

• Start the wireline unit and allow the system to warm up for 10 minutes with

while drum turning.

• Record the engine speed, drum speed, driven sprocket speed on each gear position and

pressure of hydraulic system with reading on pressure gauge.

I Hydraulic Motor I Brand _ __ I Mode] Number _ __

J ReliefValve I Brand _ __ J Model Number _ __

D Accepted

7.3-01-15-13 - Factory Acceptance Test - PP Rev.a Page 2 of7

.,v.. WINCH UNIT SINGLE I DOUBLE DRUM

MODEL : SOU TCP 01

Serial No:

T rlcakra Perkasa

anergyH<Vk:ff

PROJECT : DATE: I DOC. NO : 73-01-15-03 I REVISION : 0

FACTORY ACCEPTANCE TEST

SPEED TEST

1. Upper Drum

HYD. SPEED, ft/m

GEAR Engine RPM PRESSURE, DRUM RPM (n) (n: x D(ft) x n)

PSI Empty (Core) Full (Flange)

1 1800

2 1800

3 1800

4 1800

• Test the brake with medium drum speed and ensure the brake D Accepted

stop the drum turning in timely manner and must hold the

drum in fixed position

2. Lower Drum

B BYD. SPEED, ft/m

Engine RPM PRESSURE, DRUMRPM(n) (n: x D(ft) x n)

PSI I Empty (Core) I Full (Flange)

• 1 1800

• 2 1800

3 1800

•4 1800

•

• Test the brake with medium drum speed and ensure the brake d Accepted

stop the drnm turning in timely manner and must hold the

drum in fixed position

7.3-01-15-13 - Factory Acceptance Test - PP Rev.O Page 3 of7

.,".

Tricakra Perkasa

eneroy servtces

WINCH UNIT SINGLE I DOUBLE DRUM

MODEL : SOU TCP 01

Serial No:

PROJECT: DATE: I DOC. NO: 73-01-15-03 I REVISION : 0 I

FACTORY ACCEPTANCE TEST

LOAD TEST

1. Upper Drum

HYD. Tension Weight,

GEAR Engine RPM

PRESSURE , PSI (Lbs)

1 1800 I

2 1800/

3 1800 I

4 1800/

2. Lower Drum

HYD. Tension Weight,

GEAR Engine RPM

PRESSURE , PSI (Lbs)

1 1800 I

2 1800 I

3 1800 I

4 1800 I

• Record the following directly after the test

Hydraulic motor housing temperature

*Temperature recorded must be less than 80°C

Hydraulic oil temperature

*Temperature recorded after 2 hours must be under 80°C

7.3-01-15-13 - Factory Acceptance Test - PP Rev.a Page 4 of7

.,v.. WINCH UNIT SINGLE I DOUBLE DRUM

MODEL : SOU TCP 01

Tricakra Perkasa Serial No:

energy servk:es

PROJECT : DATE : I DOC. NO : 73-01-15-03 I REVISION : 0

FACTORY ACCEPTANCE TEST

Gearbox temperature

* Temperature recorded must be under 80°C

•

QA/QC Engineering

Accepted By Tested By

Witnessed By Witnessed By

Sign

Date

Accepted Rejected

Result

[j 0

7.3-01-15-13 - Factory Acceptance Test - PP Rev.a Page 5 of 7

WINCH UNIT SINGLE I DOUBLE DRUM

MODEL : SOU TCP 01

T rlcakra Perkasa Serial No:

energy servlc:es

PROJECT: DATE: I DOC. NO : 73-01-15-03 I REVISION : 0

FACTORY ACCEPTANCE TEST

7. Level wind system of winch unit Applicable

Yes No

0 D

• Install the level wind system and ensure that the operations is D Accepted

smooth and working properly.

• Spool the level wind repeatedly to both side and ensure the D Accepted

operation is smooth and effortless

• Check the counter size in wheel measuring device same with

wire size in lower and upper drum D Accepted

• Check all measuring instrument in wheel can record properly to

weight indicator and odo meter

load cell D Accepted

Angle drive D Accepted

Tested By Reviewed By Witnessed By Acknowledge By

Sign

Date

Accepted Rejected

Result

D D

7. 3-01-15-13 - Factory A cceptance Test - PP Rev. 0 Page 6 of7

.

.,"'

Tricakra Perkasa

ene<gyservlces

WINCH UNIT SINGLE I DOUBLE DRUM

MODEL : SOU TCP 01

Serial No:

PROJECT : DATE : I DOC. NO : 73-01-15-03 I REVISION : 0

FACTORY ACCEPTANCE TEST

8. Check of winch unit Applicable

Yes No

d D

• Check every assembly fixed in position, check nut and D Accepted

bolts for being totally secure

• Check hydraulic hoses and ensure that hoses don't rip 0 Accepted

and no leakage occurs in the hydraulic system

• Check general painting and ensure all required item are O Accepted

painted

• Ensure all grease points are completely primed with grease 0 Accepted

• Check the name plate & safety sign, ensure details exactness D Accepted

• Check for the Third Party marking Q Accepted

Tested By Reviewed By Witnessed By Acknowledge By

Sign

Date

Accepted Rejected

Result

D 0

7. 3-01-15-1 3 - Factory Acceptance Test - PP Rev. O Page 7 of 7

You might also like

- Boom Crane PDFDocument463 pagesBoom Crane PDFMark Fraley100% (1)

- 2.6 - SAT - C1574 - SAT Procedure PDFDocument7 pages2.6 - SAT - C1574 - SAT Procedure PDFGeorge JhonsonNo ratings yet

- Lloyds Register Training Rig Inspection Workshop For Land Rigs PDFDocument2 pagesLloyds Register Training Rig Inspection Workshop For Land Rigs PDFRyan LlanetaNo ratings yet

- A90.1 Safety Standard For Belt ManliftDocument36 pagesA90.1 Safety Standard For Belt ManliftYadi KusmayadiNo ratings yet

- Certificate of Visual Examination and Mpi: Description of Equipment Crane HookDocument12 pagesCertificate of Visual Examination and Mpi: Description of Equipment Crane HookMichael OkwuwaNo ratings yet

- Halliburton RVD Hydraulic Power Pack Maintenance ChecklistDocument3 pagesHalliburton RVD Hydraulic Power Pack Maintenance Checklistgpcd1210No ratings yet

- Crawler Crane Inspection ReportDocument9 pagesCrawler Crane Inspection ReportAdvent ManurungNo ratings yet

- 02 Operation ManualDocument30 pages02 Operation ManualramiNo ratings yet

- Motors CatalogueDocument32 pagesMotors CatalogueosbianiNo ratings yet

- Suspended personnel platform checklistDocument1 pageSuspended personnel platform checklistmark lester caluzaNo ratings yet

- Manlift ChecklistDocument1 pageManlift ChecklistFarid Brango0% (1)

- Tech Elevator School Catalog, 2020 PDFDocument29 pagesTech Elevator School Catalog, 2020 PDFjohanmulyadi007No ratings yet

- Itp Mast TruckDocument3 pagesItp Mast TruckArisNo ratings yet

- Rboat Davit MAINTENANCE MANUAL PDFDocument14 pagesRboat Davit MAINTENANCE MANUAL PDFAnoop AnupNo ratings yet

- NullDocument15 pagesNullMichael OkwuwaNo ratings yet

- Model m25 Free Fall Service ManualDocument44 pagesModel m25 Free Fall Service ManualManuel Rodriguez100% (1)

- NO. Activity Reference Document Verified Document Document ReviewDocument6 pagesNO. Activity Reference Document Verified Document Document ReviewHandoko ArimurtiNo ratings yet

- Curriculum Vitae: INDIA: +91-8344756618Document4 pagesCurriculum Vitae: INDIA: +91-8344756618Ujwal KhandokarNo ratings yet

- PSB Product BulletinsDocument132 pagesPSB Product BulletinsDarmawan PutrantoNo ratings yet

- 3-6 Quad BopDocument29 pages3-6 Quad Bopsambhaji100% (1)

- 02 Drillmec HH SeriesDocument12 pages02 Drillmec HH SeriesPopa Adrian100% (1)

- Sabs GuideDocument3 pagesSabs Guidealextentwenty0% (1)

- Make Up CatheadDocument3 pagesMake Up CatheadJeneesh ShanmughanNo ratings yet

- Bridon Service Procedure 1Document5 pagesBridon Service Procedure 1Ahmed ButtNo ratings yet

- How To Inspect A GearboxDocument9 pagesHow To Inspect A Gearboxroberto_perracini100% (1)

- Test Instructions Slewing Bearing Maximum Allowable Wear: Page 1 Von 3Document3 pagesTest Instructions Slewing Bearing Maximum Allowable Wear: Page 1 Von 3Ranil KanchanaNo ratings yet

- SN. 20859 Webbing Sling WLL 8t Length 3m: Certificate of A Thorough Examination of Lifting EquipmentDocument1 pageSN. 20859 Webbing Sling WLL 8t Length 3m: Certificate of A Thorough Examination of Lifting EquipmentorizaNo ratings yet

- Air Powered Man Rider Winch LS2-150RLP Series ModelsDocument12 pagesAir Powered Man Rider Winch LS2-150RLP Series ModelsHesam Ghaffari100% (1)

- CHESM Checklist R00 Sep18Document7 pagesCHESM Checklist R00 Sep18Nala IndrasenaNo ratings yet

- Inspection Checklist Overhead Crane PDFDocument2 pagesInspection Checklist Overhead Crane PDFMOST PASONNo ratings yet

- Mangla Hoists PVT LTD: Internal/Final Inspection Report For DG/SG EOT CraneDocument2 pagesMangla Hoists PVT LTD: Internal/Final Inspection Report For DG/SG EOT CranePRABHUDAYAL SHARMANo ratings yet

- On-Line Valve PM Process Flow DiagramDocument3 pagesOn-Line Valve PM Process Flow DiagramSyahroslizam SuhaimiNo ratings yet

- Testing ProcedureDocument6 pagesTesting Procedure810806100% (1)

- Sample Work PackDocument24 pagesSample Work PackRoozbeh PNo ratings yet

- Lifting-Lashing Gear Inspection ChecklistDocument1 pageLifting-Lashing Gear Inspection Checklistdnmule100% (1)

- Job Safety Analysis (Jsa) : DQE International Iraq BranchDocument4 pagesJob Safety Analysis (Jsa) : DQE International Iraq Branchhassan100% (1)

- Truck Load-Out ChecklistDocument3 pagesTruck Load-Out ChecklistIsaac Anthony100% (2)

- MR 30FLG - Manrider Winch User ManualDocument55 pagesMR 30FLG - Manrider Winch User Manualtspaes100% (3)

- zoomlion-truck-QY100 HDocument16 pageszoomlion-truck-QY100 Hالبديري بهاءNo ratings yet

- IMO Test Reports LSADocument12 pagesIMO Test Reports LSAMd AmirulNo ratings yet

- 02 Reset Pop Off ValveDocument5 pages02 Reset Pop Off ValveShussan PrinceNo ratings yet

- Hydraulic crash barriers ITPDocument4 pagesHydraulic crash barriers ITPmoytabura96No ratings yet

- Check ListDocument8 pagesCheck Listviddyadrian100% (1)

- LIFTING EQUIPMENT INSPECTION REPORTDocument3 pagesLIFTING EQUIPMENT INSPECTION REPORTMohamed Yasir100% (1)

- Crane Troubleshooting Guide LinesDocument9 pagesCrane Troubleshooting Guide LinesgogosNo ratings yet

- Mobile Crane Operator Candidate Handbook - 120122aDocument33 pagesMobile Crane Operator Candidate Handbook - 120122a전우영No ratings yet

- Elevador Blohm & VossDocument55 pagesElevador Blohm & Vosspedro Luis100% (1)

- Lifting equipment inspection requirementsDocument1 pageLifting equipment inspection requirementsQuality controller100% (1)

- EOT Crane ChecklistDocument3 pagesEOT Crane Checklistankit100% (1)

- Gantry Crane Rail Inspection Form NAVFACDocument6 pagesGantry Crane Rail Inspection Form NAVFACTracy JohnsonNo ratings yet

- 01 - Field Inspection Procedure For Used uLTIMATE™ Extreme™ Torque Connections (uXT™) PC-17 PDFDocument5 pages01 - Field Inspection Procedure For Used uLTIMATE™ Extreme™ Torque Connections (uXT™) PC-17 PDFKarla HernandezNo ratings yet

- Analysis of Breakdowns and Improvement of Preventive Maintenance on 1000 Ton Hydraulic PressDocument10 pagesAnalysis of Breakdowns and Improvement of Preventive Maintenance on 1000 Ton Hydraulic PressSundar Kumar Vasantha GovindarajuluNo ratings yet

- Hse Manual: VIKING 01-01Document168 pagesHse Manual: VIKING 01-01AF Dowell MirinNo ratings yet

- Testing A Double Acting Hydraulic Cylinder: Retract TestDocument1 pageTesting A Double Acting Hydraulic Cylinder: Retract TestAhmetNo ratings yet

- Electrical System Safety Rules (Esr) - OETCDocument108 pagesElectrical System Safety Rules (Esr) - OETCRayar Dhanasekar100% (1)

- 385-06-021 Air Winch Load TestDocument1 page385-06-021 Air Winch Load TestnisarNo ratings yet

- Job 3395-Emsco FB1600 PumpDocument123 pagesJob 3395-Emsco FB1600 PumpCristian BoselliNo ratings yet

- FA2-FA2 5 Service Manual Parts ListDocument61 pagesFA2-FA2 5 Service Manual Parts ListERNESTO NEGRETENo ratings yet

- Pump Check SheetDocument2 pagesPump Check Sheetyskushwah1650% (2)

- Safety Spinning Wrench SSW 40Document88 pagesSafety Spinning Wrench SSW 40Beitsaeed SinaNo ratings yet

- DH3-31MA-T-ITP-0001 ITP For Commissioning of Complete-Set Startup of Steam Turbine REV.0Document12 pagesDH3-31MA-T-ITP-0001 ITP For Commissioning of Complete-Set Startup of Steam Turbine REV.0Lan RungNo ratings yet

- Pre-Commissioning Format For Reactor: I. General DetailsDocument27 pagesPre-Commissioning Format For Reactor: I. General Detailsmayur dhandeNo ratings yet

- Certificate of Relief Valve Capacity (PROCA) 7 PDFDocument1 pageCertificate of Relief Valve Capacity (PROCA) 7 PDFAdeoye OkunoyeNo ratings yet

- 115-Z-015 Forklift SKPP Exp 17 Jan 2020 - 19Document1 page115-Z-015 Forklift SKPP Exp 17 Jan 2020 - 19Yadi KusmayadiNo ratings yet

- Daftar Load TestDocument2 pagesDaftar Load TestYadi KusmayadiNo ratings yet

- Customer: Devices: Date:: Place::: No. Description Model Identification Nomor Year Build Serial ManufacturerDocument2 pagesCustomer: Devices: Date:: Place::: No. Description Model Identification Nomor Year Build Serial ManufacturerYadi KusmayadiNo ratings yet

- Chain CalculationDocument1 pageChain CalculationYadi KusmayadiNo ratings yet

- Information For Man LiftDocument2 pagesInformation For Man LiftYadi KusmayadiNo ratings yet

- 296 869 200 PDFDocument10 pages296 869 200 PDFYadi KusmayadiNo ratings yet

- 296 869 200 PDFDocument10 pages296 869 200 PDFYadi KusmayadiNo ratings yet

- Tensile Testing LaboratoryDocument20 pagesTensile Testing LaboratoryGirish ViswanathanNo ratings yet

- Time and cost analysis of jacket structure loadoutDocument6 pagesTime and cost analysis of jacket structure loadoutYadi KusmayadiNo ratings yet

- Study On FLA Platform Crane PDFDocument12 pagesStudy On FLA Platform Crane PDFYadi KusmayadiNo ratings yet

- Jib TextDocument36 pagesJib Textluiscremaschi100% (2)

- ARTICLE I (Weld. Gen. Requirement)Document9 pagesARTICLE I (Weld. Gen. Requirement)Yadi KusmayadiNo ratings yet

- Hycomp Gas CompressorsDocument8 pagesHycomp Gas CompressorsYadi KusmayadiNo ratings yet

- Education For TecknicDocument5 pagesEducation For TecknicYadi KusmayadiNo ratings yet

- 154 HP Skid Mounted HPUDocument2 pages154 HP Skid Mounted HPUYadi KusmayadiNo ratings yet

- HD_PPU BASE & FRAME ASSY technical drawingDocument1 pageHD_PPU BASE & FRAME ASSY technical drawingYadi KusmayadiNo ratings yet

- NDT of Wire Rope by Magnetic Analysis (Bereau Sandards)Document24 pagesNDT of Wire Rope by Magnetic Analysis (Bereau Sandards)Yadi KusmayadiNo ratings yet

- Safet Assessment & Fatigue Life Analysis Crane Structure PDFDocument5 pagesSafet Assessment & Fatigue Life Analysis Crane Structure PDFYadi KusmayadiNo ratings yet

- Technical Guidance On The Safe Use of Linfting Equipment OffshoreDocument74 pagesTechnical Guidance On The Safe Use of Linfting Equipment OffshoreCarlos GarridoNo ratings yet

- Welding Procedure PreparationDocument122 pagesWelding Procedure Preparationthe_badass1234100% (21)

- Critical Component of Crane Insp. OCC25Document14 pagesCritical Component of Crane Insp. OCC25Yadi KusmayadiNo ratings yet

- Introduction To Work Station Cranes (Gobel)Document16 pagesIntroduction To Work Station Cranes (Gobel)Yadi KusmayadiNo ratings yet

- IOSH Mobile Cranes Dec 2011Document52 pagesIOSH Mobile Cranes Dec 2011Hussein BeqaiNo ratings yet

- CGF483 2005-03-31 AMI (BL TRMTBL)Document1 pageCGF483 2005-03-31 AMI (BL TRMTBL)Yadi KusmayadiNo ratings yet

- ACME Thread Pitch - Guide PDFDocument1 pageACME Thread Pitch - Guide PDFYadi KusmayadiNo ratings yet

- Contoh Jsa Mobile Crane PDFDocument5 pagesContoh Jsa Mobile Crane PDFMuhammad Rasyid SidiqNo ratings yet

- Clad PQRDocument5 pagesClad PQRRinshadNo ratings yet

- Court of Appeals decision on Batara family land disputeDocument19 pagesCourt of Appeals decision on Batara family land disputeKhanini GandamraNo ratings yet

- Ultramount Weigh Modules: Service ManualDocument48 pagesUltramount Weigh Modules: Service ManualRicardo Vazquez SalinasNo ratings yet

- Balance Sheet of LifeDocument4 pagesBalance Sheet of LifeYazdiP.MunsifNo ratings yet

- Credit Role - Jai-KisanDocument2 pagesCredit Role - Jai-Kisan21-23 Shashi KumarNo ratings yet

- How To Add Message Queuing Feature - Dell IndiaDocument2 pagesHow To Add Message Queuing Feature - Dell Indiayuva razNo ratings yet

- LED-Control-PIC16F877ADocument5 pagesLED-Control-PIC16F877AMohd Izzat Abd GhaniNo ratings yet

- Computer MCQ NotesDocument88 pagesComputer MCQ NotesWaqas AliNo ratings yet

- Setup NFS File Sharing Between Linux SystemsDocument6 pagesSetup NFS File Sharing Between Linux SystemsKurniawan Setyo NugrohoNo ratings yet

- Economics of The Environment - Theory and Policy (PDFDrive)Document328 pagesEconomics of The Environment - Theory and Policy (PDFDrive)danysubash100% (1)

- Cortisol II 2020-03 v6Document5 pagesCortisol II 2020-03 v6Parishan SaeedNo ratings yet

- June 2000Document8 pagesJune 2000Alexandre Anderson AlvesNo ratings yet

- Notes On ME (2) Unit 1Document16 pagesNotes On ME (2) Unit 1Shashwat SinhaNo ratings yet

- Flash 29f800Document48 pagesFlash 29f800savidhamNo ratings yet

- Practical Research 2: Quarter 1 Module 1: Nature of Inquiry and ResearchDocument406 pagesPractical Research 2: Quarter 1 Module 1: Nature of Inquiry and ResearchJohn Michael Reyes RamosNo ratings yet

- Case Study:: Barangay HallDocument13 pagesCase Study:: Barangay HallReiner Gatdula50% (2)

- Exam PaperDocument2 pagesExam PapersanggariNo ratings yet

- Chapter 1Document18 pagesChapter 1Tabassum AkhtarNo ratings yet

- HiltonDocument5 pagesHiltonretoxen0% (3)

- Export Promotion Capital Goods Scheme PresentationDocument32 pagesExport Promotion Capital Goods Scheme PresentationDakshata SawantNo ratings yet

- Amgen PresentationDocument38 pagesAmgen PresentationrajendrakumarNo ratings yet

- IGBC Certified BldgsDocument26 pagesIGBC Certified BldgsNidhi Chadda MalikNo ratings yet

- Managing People and OrganisationsDocument50 pagesManaging People and OrganisationsOmkar DesaiNo ratings yet

- Tutorial: Creating A Middleware Application Using CMSIS ComponentsDocument25 pagesTutorial: Creating A Middleware Application Using CMSIS ComponentsJose Romero MurilloNo ratings yet

- Joukowski Airfoil in Potential Flow Without Complex Numbers PDFDocument110 pagesJoukowski Airfoil in Potential Flow Without Complex Numbers PDFChacho BacoaNo ratings yet

- Introduction To SAP Master Data GovernanceDocument32 pagesIntroduction To SAP Master Data GovernanceAravindhNo ratings yet

- Process Flow Diagram (For Subscribers Who Visits Merchant Business Premises)Document2 pagesProcess Flow Diagram (For Subscribers Who Visits Merchant Business Premises)Lovelyn ArokhamoniNo ratings yet

- Change-oriented leadership impacts team climate & potencyDocument17 pagesChange-oriented leadership impacts team climate & potencyAkhwand Abdur Raffi SaulatNo ratings yet

- 1740 Purchasing Manager Interview Questions Answers GuideDocument11 pages1740 Purchasing Manager Interview Questions Answers GuideNaveen SharmaNo ratings yet

- Manual ATPDMan56Document288 pagesManual ATPDMan56Alex DavidNo ratings yet