Professional Documents

Culture Documents

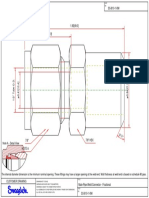

NOZZLE AND PIPE TABLE WITH DESIGN DATA

Uploaded by

Ivan SilvaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NOZZLE AND PIPE TABLE WITH DESIGN DATA

Uploaded by

Ivan SilvaCopyright:

Available Formats

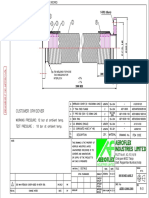

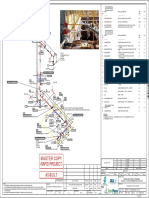

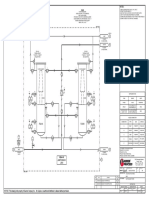

NOZZLE TABLE PIPE TABLE N O T E S :- DESIGN DATA

TAG SERVICE SIZE (NPS) OD THICKNESS PIPE SCH INT. PROJ. EXT. PROJ. PAD THK. PAD WIDTH TAG Size (NPS) Pipe OD Length SCH END THICKNESS 1. All Dimensions Are in (mm). CONSTRUCTION CODE ASME Div. 1

N4 Inlet 6 168.3 10.97 80 - 146 24 75.862 N4 6 168.3 - 80 2. Construction to be per ASME Code Section VIII Div.1 2015 Edition. INTERNAL DESIGN PRESSURE 94 Par

MH Inlet 24 610 17.48 40 - 257 24 220.2 N4 - Pipe 6 168.3 1374 80 10.97 3. All bolt holes to straddle center lines unless noted otherwise. INTERNAL DESIGN TEMPERATURE 900 C

N1 Inlet 12 323.8 17.48 80 - 195 24 93.075 MH 24 610 - 40 MTR's required for all pressure part material, attachment to pressure parts and welding EXTERNAL DESIGN PRESSURE 0 Par

4.

N3 Inlet 2 60.3 8.74 160 - 156 - - N1 12 323.8 - 80 consumables. EXTERNAL DESIGN TEMPERATURE 194 C

N5 Inlet 2 60.3 8.74 160 - 156 - - N3 2 60.3 - 160 5. Two sets of spare operational gaskets required. HYDROTEST VESSEL ORIENTATION VERTICAL

N6 Inlet 2 60.3 8.74 160 - 156 - - N5 2 60.3 - 160 DEGREE OF RADIOGRAPHIC EXAMINATION FULL

N7 Inlet 2 60.3 8.74 160 - 156 - - N6 2 60.3 - 160 JOINT EFFICIENCY 100%

N8 Inlet 2 60.3 8.74 160 - 156 - - N7 2 60.3 - 160 DESIGN LIFE 20 YEAR

SKIRT OPENING SKIRT OPENING 10 273 15.08 80 110 100 - - N8 2 60.3 - 160 SEISMIC CODE UBC

SV#1 SV#1 4 114.3 6.02 STD 60 50 - - SKIRT OPENING 10 273 - 80 WIND CODE UBC

SV#2 SV#1 4 114.3 6.02 STD 60 50 - - SV#1 4 114.3 - STD WIND SPEED 120 km/hr

SV#3 SV#1 4 114.3 6.02 STD 60 50 - - SV#2 4 114.3 - STD YEAR OF CONSTRUCTION 2019

SV#4 SV#1 4 114.3 6.02 STD 60 50 - - SV#3 4 114.3 - STD

SA SKIRT ACCESS 24 610 17.48 40 110 100 - - SV#4 4 114.3 - STD

lll Inlet 10 - 33.5 - 200 300 - - SA 24 610 - 40

N2 Inlet 16 406.4 21.4 80 - 229 24 96.8 N2 16 406.4 - 80

llll2 Inlet 12 - 35.1 - 300 300 - -

N

FLANGE TABLE

TAG Size (NPS) TYPE RATING END THICKNESS SCH N2 cc2 llll2 W E

N4 - Flange 6 WN-RF ASME B16.5 2013 300 10.97 80

800

MH - Flange 24 WN-RF ASME B16.5 2013 300 17.48 40

N1 - Flange 12 WN-RF ASME B16.5 2013 300 17.48 80

N3 - Flange 2 WN-RF ASME B16.5 2013 300 8.74 160 S

N5 - Flange Head Ratio=2:1, I.D.=2500, THK.=24, M.A.F.=22, S.F.=100 W5

2 WN-RF ASME B16.5 2013 300 8.74 160

N6 - Flange 2 WN-RF ASME B16.5 2013 300 8.74 160 W3

N7 - Flange 2 WN-RF ASME B16.5 2013 300 8.74 160

2 W6

N8 - Flange 2 WN-RF ASME B16.5 2013 300 8.74 160

N2 - Flange 16 WN-RF ASME B16.5 2013 300 21.4 80

GASKET TABLE

TAG Size (NPS) TYPE RATING END THICKNESS SCH 22.5

S.F.

100

SKIRT OPENING SV#1 lll MH

MH - Gasket 24 RF Gasket For ASME B16.5 2013 Flanges 300 3 -

W8

T.L. 0

FITTI NG TABLE

TAG Size (NPS) TYPE RATING END THICKNESS SCH Total QTY. 125 Total Weight 10714.062

L.W.L-3

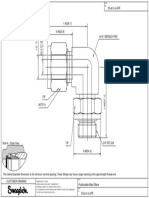

N4 - Elbow 6 Elbow 90 LR 10.97 80 42 1 Davit Estimated Davit Type E N/A 53.645

2800 LIFTING LUG

SC#2

500

2750 NPS 24, RF, Class 300, Acc. to ASME B16.20

W1 41 1 Gasket SS 316 1.835

2012

lll

45 YP

PL. Length=300, Width=350, THK.=24

T

W2 40 2 Wear Plate SA-516 70 19.931

W8

PL. Length=830, Width={Bottom_Width},

39 2 Lifting Lug SA-516 70 64.555

4 THK.=24

38 1 NamePlate Bracket Length=200, Width=500, Thickness=6 SA-516 70 4.791

W1 W4

37 2 Coller PL. O.D.=150, I.D.=50, THK.=6 SA-516 70 1.48

W4 36 1 Lifting Lug PL. Length=230, Width=265, THK.=24 SA-516 70 10.044

L.W.L-1 315

45

N3 2100 2100 N5 L.W.L-3 L.W.L-2 35 1 Reinf. Pad PL. I.D.=406.4, THK.=24, Width=96.8 SA-516 70 29.513

I.D. 2500 34 1 Reinf. Pad PL. I.D.=323.8, THK.=24, Width=93.08 SA-516 70 23.351

cc2 33 1 Reinf. Pad PL. I.D.=610, THK.=24, Width=220.2 SA-516 70 110.107

W3 W3 32 1 Reinf. Pad PL. I.D.=168.3, THK.=24, Width=75.86 SA-516 70 11.124

28 24 THK. NPS 12, LWN, RF, Class 400, Projection=600,

31 1 Flange SA-105 215.662

39 End Thickness=35.1

TAN TO TAN

29

30 1 Plug NPS 2, Class 3000 SA-105 0.5

3100

26 29 1 Coupling NPS 2, Class 3000 SA-105 1.782

1500 N7

NPS 16, WN, RF, Class 300, SCH. 80, Acc. to

2 R800 28 1 Flange SA-105 128.256

3 ASME B16.5 2016

SC#1

2400

OVERALL

C.G. 27 1 Half Coupling NPS 2, Class 3000 SA-105 0.891

5800

1242.12 1200 MH llll2 NPS 10, LWN, RF, Class 300, Projection=600,

26 1 Flange SA-105 142.108

31 End Thickness=33.5

4 W4 NPS 2, WN, RF, Class 300, SCH. 160, Acc. to

1000 N.P. 25 5 Flange SA-105 19.775

ASME B16.5 2016

W3

L.W.L-2

270 90 NPS 12, WN, RF, Class 300, SCH. 80, Acc. to

N3 N5 24 1 Flange SA-105 71.812

W2 ASME B16.5 2016

N3 N6

N8 700 23 24 ISO Stud Bolt M39, L250 SA-193 B7 2.343

3 SV#4 cc1 22 48 ISO Nut M39 SA-194 2H 0.968

LIFTING LUG LIFTING LUG NPS 24, RF, Class 300, Acc. to ASME B16.5

500 N1 21 1 Blind Flange SA-105 341.238

2016

13 400 N6 NPS 24, WN, RF, Class 300, SCH. 40, Acc. to

42 N4 20 1 Flange SA-105 259.025

25 N2 ASME B16.5 2016

25 W1

S.F.

100

NPS 6, WN, RF, Class 300, SCH. 80, Acc. to

19 1 Flange SA-105 21.764

W3 ASME B16.5 2016

38

18 1 Elbow NPS 6, SCH. 80, 90 LR,Acc. to ASME B 16.9 SA-234WPB 15.311

T.L. EL. 0.00 W4

34 17 1 Seamless Pipe NPS 16, SCH. 80, Projection=229 SA-516 70 48.049

W7

16 1 Seamless Pipe NPS 24, SCH. 40, Length=665.08 SA-106 B 323.383

12 1

Seamless Pipe NPS 4, SCH. STD, Length=665.08

g e n e r a t o r

15 4 SA-106 B 74.980

24

14 1 Seamless Pipe NPS 10, SCH. 80, Length=665.08 SA-106 B 121.439

SV#1 SV#4 300 SV#2 SV#3

7 13 5 Seamless Pipe NPS 2, SCH. 160, Projection=156 SA-516 70 10.010

25 12 1 Seamless Pipe NPS 12, SCH. 80, Projection=195 SA-516 70 29.542

11 1 Seamless Pipe NPS 24, SCH. 40, Projection=257 SA-516 70 76.31

10

10 1 Skirt Top Ring I.D.=0, O.D.=0, Thickness=20 SA-516 70 71.726

15

W2 Withd-A=110, Withd-A=110, Length=230,

9 0 Skirt Ribs SA-516 70 44.488

8 Thickness=14

1700

8 1 Base Plate I.D.=2414, O.D.=2754, Thickness=20 SA-516 70 216.098

W5 Head Ratio=2:1, I.D.=2500, THK.=24, M.A.F.=22, S.F.=100 Top Diameter=2514, Bottom Diameter=2514,

7 1 Skirt Plate SA-516 70 979.704

N4 SA 1000 Length=1700, Thickness=10

6 1 Seamless Pipe NPS 6, SCH. 80, Length=1374 SA-106 B 58.482

16

L.W.L-1

5 1 Seamless Pipe NPS 6, SCH. 80, Projection=146 SA-516 70 6.267

N1 N7 TAILING LUG N.P. SV#3 SA 4 1 Shell Course PL. I.D.=2500, THK.=24, Length=500 SA-516 70 730.625

36 37 180 3 1 Shell Course PL. I.D.=2500, THK.=24, Length=2400 SA-516 70 3510.728

Head Ratio=2:1, I.D.=2500, THK.=24,

2 1 Ellipsoidal Head SA-516 70 1408.255

A M.A.F.=22, S.F.=100

e q u i p m e n t

260

TAILING LUG 1565

SCALE 1 : 15 1 1 Ellipsoidal Head

Head Ratio=2:1, I.D.=2500, THK.=24,

M.A.F.=22, S.F.=100

SA-516 70 1452.165

SKER I.D. 2514

ITEM NO. QTY. DESCRIPTION TECHNICAL CHARACTERISTICS MATERIAL WEIGHT

BASE RING O.D. 2754 MATERI AL L I ST

Elevation 0 9/4/2019 IFR A.H M.M H

SCALE 1 : 18 REV. DATE DESCRIPTION PREPARED CHECKED APPROVED

R E V. T A B L E

Drawing No.:- Paet Number:-

W1

60 5

W2

60 5

W3

W4 Tn

W5

Tn

45

45 5

W6

Tn

45

45

5

W7

Smooth

Weld W8 Fillet Weld

SEG DOC-DWG-101

Job No.:-

19-0001-00001

Serial No.:-

Tr

5

Static Equipment 19-0001 SWS-1020

1

5

S t a t i c

Telltale Hole

45 2 1 Location:- Manufacturer:-

1

NPT 1/4

2

5

G e n e r a t o r ALEX MOP

1

2 1 SE CAD SOLUTIONS

1

2

2

T

2

2

1

SALCADA Project

T

45

Ts

5

T.L.

60

A

T

2 1

T

2 1

B

A

Units:- Metric Sheet

Tp

2 1

R3

Ground

2 1 TAIL GAS KO-DRUM 1 of 1

1

Ground

R3 Flush Flush

R3

10-V-136 Drawing Size

2

T

General Arrangement D

The Information Contained in This Drawings is The Property of Static Equipment Generator

You might also like

- 4103 TOYO20 92DJ 1300 036 - Rev 1 - Sht001Document2 pages4103 TOYO20 92DJ 1300 036 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- 6-PT-20103-6C1L Iso TP-032Document1 page6-PT-20103-6C1L Iso TP-032atma82419No ratings yet

- Assy. WT: Parent: Customer Name: Certified: Approved For Construction PROJ # 09281 Job # D4Document18 pagesAssy. WT: Parent: Customer Name: Certified: Approved For Construction PROJ # 09281 Job # D4moneyphotocopyshopNo ratings yet

- Piping List, Line Sizing and Tie-In Point...Document2 pagesPiping List, Line Sizing and Tie-In Point...Hiếu Nguyên100% (2)

- 4103 TOYO20 92DJ 1300 052 - Rev 1 - Sht001Document1 page4103 TOYO20 92DJ 1300 052 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- IsoDocument20 pagesIsoGökhanNo ratings yet

- JI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1Document1 pageJI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1weerachai phosoongNo ratings yet

- thyssenkrupp Project No. 66-6699-700 Piping List O & UDocument2 pagesthyssenkrupp Project No. 66-6699-700 Piping List O & URajeev KumarNo ratings yet

- Appendix I List of Attached Conceptual & Reference Drawings PTS-20WM319Document13 pagesAppendix I List of Attached Conceptual & Reference Drawings PTS-20WM319Durgaprasad RyaliNo ratings yet

- Crude Oil 200 BBL - Ga - RCDocument1 pageCrude Oil 200 BBL - Ga - RCApichart ChoksawadNo ratings yet

- Model: Series 81-W Butterfly Valve Model: Series 81-W Butterfly ValveDocument2 pagesModel: Series 81-W Butterfly Valve Model: Series 81-W Butterfly ValveJose Ediberto Lopez GonzalezNo ratings yet

- Straight Shell D-1.0 & 0.7 M-LDocument1 pageStraight Shell D-1.0 & 0.7 M-LDeep SherawatNo ratings yet

- Aero 1000 2203 (Dover)Document1 pageAero 1000 2203 (Dover)Nikhil KeniNo ratings yet

- Design, Manufacturing, Supply, Installation, Construction & Commissioning of BQPS RLNG Spur Pipeline Project Line ListDocument3 pagesDesign, Manufacturing, Supply, Installation, Construction & Commissioning of BQPS RLNG Spur Pipeline Project Line ListUmair A. KhanNo ratings yet

- Fabrication Materials ListDocument41 pagesFabrication Materials ListcerebralnomadNo ratings yet

- 4103 TOYO20 92DJ 1300 011 - Rev 1 - Sht001Document11 pages4103 TOYO20 92DJ 1300 011 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- SS 810 2 6PR 20160Document1 pageSS 810 2 6PR 20160armin_kunosic9871No ratings yet

- 01 25284124-8230-26-000-0011 REV.01 Piping List HCDSDocument1 page01 25284124-8230-26-000-0011 REV.01 Piping List HCDSRajeev KumarNo ratings yet

- Fabrication Materials: Saudi Arabian Oil CompanyDocument8 pagesFabrication Materials: Saudi Arabian Oil CompanyD7mey XNo ratings yet

- 01 25284124-8230-26-104-0001 REV.02 Piping List CT1Document1 page01 25284124-8230-26-104-0001 REV.02 Piping List CT1Rajeev KumarNo ratings yet

- Male NPT to MP Cone & Thread FittingDocument1 pageMale NPT to MP Cone & Thread FittingEdoardo Pansoya Di BorioNo ratings yet

- 4103 TOYO20 92DJ 1300 040 - Rev 1 - Sht001Document6 pages4103 TOYO20 92DJ 1300 040 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- Modification Anagnostou (Ang) : Reference Documents / DrawingsDocument1 pageModification Anagnostou (Ang) : Reference Documents / DrawingsNikolas MNo ratings yet

- Ca-1231366 0010 0002Document1 pageCa-1231366 0010 0002Erfan KhanNo ratings yet

- CHECK SHEETDocument1 pageCHECK SHEETJovianto PrisilaNo ratings yet

- 506-Ppa.4711-Iso-070 - 0 - 4508-087-HML-80-Q235Document1 page506-Ppa.4711-Iso-070 - 0 - 4508-087-HML-80-Q235lewihonawiNo ratings yet

- Piping Isometric - 3Document1 pagePiping Isometric - 3CosminMarianNo ratings yet

- SA-4200M00450-71547-01 - 00 - Redline Marking ProposalDocument2 pagesSA-4200M00450-71547-01 - 00 - Redline Marking Proposaleffiezool mohdNo ratings yet

- 0169-013-SHS-200-20G-H80 Sheet 1-ModelDocument1 page0169-013-SHS-200-20G-H80 Sheet 1-ModellewihonawiNo ratings yet

- Notes:: FV-01A FV-01BDocument1 pageNotes:: FV-01A FV-01BomarNo ratings yet

- SS 810 1 8W SwagelokCompany 2DSalesDrawing 05 08 2023Document1 pageSS 810 1 8W SwagelokCompany 2DSalesDrawing 05 08 2023Gabriel BonteaNo ratings yet

- C29732 03 Pid 06 - Rev - 1 PDFDocument1 pageC29732 03 Pid 06 - Rev - 1 PDFomarNo ratings yet

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Document14 pagesList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNo ratings yet

- DATASHEET CZone COI DSB Layout 1FEB17Document1 pageDATASHEET CZone COI DSB Layout 1FEB17tecnicoeemNo ratings yet

- 3D PV 2017 BrochureDocument6 pages3D PV 2017 BrochurehabilNo ratings yet

- 01 25284124-8230-26-000-0006 REV.02 Piping List EXISTING PIPE RACKDocument2 pages01 25284124-8230-26-000-0006 REV.02 Piping List EXISTING PIPE RACKRajeev KumarNo ratings yet

- Adaptors and Plugs (Metal) - BimedDocument2 pagesAdaptors and Plugs (Metal) - BimedThảo PhươngNo ratings yet

- WPS 1-1-GT-SM-6 Rev. 0Document8 pagesWPS 1-1-GT-SM-6 Rev. 0Melby de la rosaNo ratings yet

- 4103 TOYO20 92DJ 1300 027 - Rev 1 - Sht001Document5 pages4103 TOYO20 92DJ 1300 027 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- Automatic air valves guideDocument12 pagesAutomatic air valves guidePra YugoNo ratings yet

- 107 CNT D 205Document3 pages107 CNT D 205luis m hueto castilloNo ratings yet

- Fabrication Materials ListDocument1 pageFabrication Materials ListSaptarshi MandalNo ratings yet

- Pms Eil BPCLDocument79 pagesPms Eil BPCLManjunatha VNo ratings yet

- Documento - MX Comp1Document10 pagesDocumento - MX Comp1Mangesh BanaleNo ratings yet

- Technical Specification for Oil Production and Marine Piping SystemsDocument1 pageTechnical Specification for Oil Production and Marine Piping SystemsBeatriz BerçotNo ratings yet

- Report on Welding Procedure Specifications for Single V-Groove JointsDocument15 pagesReport on Welding Procedure Specifications for Single V-Groove JointsAvishek Gupta100% (1)

- Tal Wsa PNG Iso 1P020807 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1P020807 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- FABRICATION MATERIALS AND COMPONENT LISTDocument7 pagesFABRICATION MATERIALS AND COMPONENT LISTCLS AKNo ratings yet

- 01 25284124-8230-26-013-0001 REV.03 Piping List DHDTDocument7 pages01 25284124-8230-26-013-0001 REV.03 Piping List DHDTRajeev KumarNo ratings yet

- High-Performance Butterfly Valve Specs and DetailsDocument6 pagesHigh-Performance Butterfly Valve Specs and DetailsSergio Gaete CovarrubiasNo ratings yet

- Wps 225Document29 pagesWps 225Muhammad firdaus rusliNo ratings yet

- WT-3900M31650-10006-06 - 0 Drawing Patching R0 - Part A Line 2Document12 pagesWT-3900M31650-10006-06 - 0 Drawing Patching R0 - Part A Line 2effiezool mohdNo ratings yet

- HE Design CalculationsDocument166 pagesHE Design CalculationsdinakaranpatelNo ratings yet

- 8T - 250 BM Mounting DetailsDocument1 page8T - 250 BM Mounting DetailsKundan RokadeNo ratings yet

- DS-702 - 180 Degree Brass Nozzle - Rev 3Document1 pageDS-702 - 180 Degree Brass Nozzle - Rev 3miguelsanguinettiNo ratings yet

- AT-603AP enDocument2 pagesAT-603AP enAki HiroNo ratings yet

- StanadyneDocument1 pageStanadyneJunior IungNo ratings yet

- Weld MapDocument3 pagesWeld Mapeffiezool mohdNo ratings yet

- Iron Metals Project Weld List and Cut Piece ListDocument1 pageIron Metals Project Weld List and Cut Piece ListAsyifa AldanaNo ratings yet

- Tabela de Anel Elastico para Furo PDFDocument4 pagesTabela de Anel Elastico para Furo PDFhendrixking100% (1)

- BS ISO 5455 Scale PDFDocument8 pagesBS ISO 5455 Scale PDFAhmed Abo Rashed100% (1)

- Series: - Care Motion - Industrial MotionDocument12 pagesSeries: - Care Motion - Industrial MotionIvan SilvaNo ratings yet

- VFD LDocument16 pagesVFD LJai SharmaNo ratings yet

- El Maquinas - Correntes Passo LongoDocument1 pageEl Maquinas - Correntes Passo LongoIvan SilvaNo ratings yet

- Aneis Retencao EixosDocument4 pagesAneis Retencao EixosMrLanternNo ratings yet

- NPT Thread DimensionsDocument1 pageNPT Thread DimensionsRamnandan MahtoNo ratings yet

- Tubos de Aco Carbono DIN 2440 NBR 5580 Com Costura para Conducao de FluidosDocument1 pageTubos de Aco Carbono DIN 2440 NBR 5580 Com Costura para Conducao de FluidosRafael SalvagniNo ratings yet

- Siemens - Sinamics - V20Document2 pagesSiemens - Sinamics - V20Ivan SilvaNo ratings yet

- B2 Series Characterized Control Valve, Spring Return ActuatorDocument6 pagesB2 Series Characterized Control Valve, Spring Return ActuatorIvan SilvaNo ratings yet

- SMC - Senso MagneticoDocument1 pageSMC - Senso MagneticoIvan SilvaNo ratings yet

- Igubal Flange Bearings - Product Range: Short Term Long Term Short Term Long Term Holes (N) (N) (N) (N) (NM) (G)Document2 pagesIgubal Flange Bearings - Product Range: Short Term Long Term Short Term Long Term Holes (N) (N) (N) (N) (NM) (G)Ivan SilvaNo ratings yet

- Festo - Ligacao Valvula Seg - MS SeriesDocument2 pagesFesto - Ligacao Valvula Seg - MS SeriesIvan SilvaNo ratings yet

- Comparativo Sensores TemperaturaDocument2 pagesComparativo Sensores TemperaturaIvan SilvaNo ratings yet

- NOZZLE AND PIPE TABLE WITH DESIGN DATADocument1 pageNOZZLE AND PIPE TABLE WITH DESIGN DATAIvan SilvaNo ratings yet

- POSITION INDICATOR Provides Clearly Visible: The High Performance CompanyDocument2 pagesPOSITION INDICATOR Provides Clearly Visible: The High Performance CompanyIvan SilvaNo ratings yet

- 17 Power Screw Drives and Their EfficiencyDocument15 pages17 Power Screw Drives and Their EfficiencyPRASAD326100% (2)

- Engineering Fundamentals ThreadFasteners RalphShoberg SR1Document39 pagesEngineering Fundamentals ThreadFasteners RalphShoberg SR1Juan RiveraNo ratings yet

- General Tolerances DIN ISO 2768Document2 pagesGeneral Tolerances DIN ISO 2768Vasil Gospodinov79% (24)

- Parametric Design and Motion Analysis of Geneva Wheel Mechanism Based On The UG NX8.5Document5 pagesParametric Design and Motion Analysis of Geneva Wheel Mechanism Based On The UG NX8.5Sahil AcharyaNo ratings yet

- Planetary GearingDocument68 pagesPlanetary Gearingrelbuhm100% (3)

- Comandos elétricos pneumáticosDocument1 pageComandos elétricos pneumáticosIvan SilvaNo ratings yet

- Design and Construction of A Test Bench For Study of Vibration Analysis Techniques Applied To Predictive MaintenanceDocument8 pagesDesign and Construction of A Test Bench For Study of Vibration Analysis Techniques Applied To Predictive MaintenanceIvan SilvaNo ratings yet

- Prova Teste Seu NívelDocument245 pagesProva Teste Seu NívelIvan SilvaNo ratings yet

- Muncaster 11 A3 Sheet 04Document1 pageMuncaster 11 A3 Sheet 04Juan PastorNo ratings yet

- 4722352Document1 page4722352Ivan SilvaNo ratings yet

- A955310 PDFDocument118 pagesA955310 PDFIvan SilvaNo ratings yet

- A955310 PDFDocument118 pagesA955310 PDFIvan SilvaNo ratings yet

- 17 Power Screw Drives and Their EfficiencyDocument15 pages17 Power Screw Drives and Their EfficiencyPRASAD326100% (2)

- Muncaster 11 A3 Sheet 03Document1 pageMuncaster 11 A3 Sheet 03Juan PastorNo ratings yet

- YSK 142 HDPE Pipe Service Life PDFDocument2 pagesYSK 142 HDPE Pipe Service Life PDFadooo meeeNo ratings yet

- ZERI PavillionDocument10 pagesZERI Pavillionquangtung07No ratings yet

- Beam Cross Section Detail - Beam Longitudinal Section DetailDocument1 pageBeam Cross Section Detail - Beam Longitudinal Section Detailvs consultantNo ratings yet

- UNITEN ICCBT 08 Mechanical Properties of Foamed ConcreteDocument10 pagesUNITEN ICCBT 08 Mechanical Properties of Foamed ConcreteLim Han JianNo ratings yet

- Ground Improvement Case Studies Chemical Lime PilesDocument14 pagesGround Improvement Case Studies Chemical Lime PilesHanumantha Rao BNo ratings yet

- Structural EngineeringDocument12 pagesStructural EngineeringBTE100% (1)

- Smith ForgingDocument7 pagesSmith Forgingsenel pereraNo ratings yet

- Bid DocumentDocument113 pagesBid DocumentAbu MariamNo ratings yet

- E-Catalog For Butyl Adhesive Waterproof Tape SaDocument10 pagesE-Catalog For Butyl Adhesive Waterproof Tape SaVasilis EvangelidisNo ratings yet

- Fabory Fasteners Basic StandardsDocument12 pagesFabory Fasteners Basic Standardsjuan carlos galvez abantoNo ratings yet

- Rosetta Brochure For MESE 2Document10 pagesRosetta Brochure For MESE 2misharyNo ratings yet

- Peek Compression MoldingDocument3 pagesPeek Compression MoldingSh.nasirpurNo ratings yet

- Dupont Vespel Cr-6100: Application and Installation Guide For Centrifugal Pump Stationary Wear PartsDocument12 pagesDupont Vespel Cr-6100: Application and Installation Guide For Centrifugal Pump Stationary Wear PartsFernando Tapia GibsonNo ratings yet

- S08 Diesel Power PackDocument160 pagesS08 Diesel Power PackAlberto JáureguiNo ratings yet

- ScrutinyDocument11 pagesScrutinySanjay NautiyalNo ratings yet

- In Architecture Chris Van UffelenDocument5 pagesIn Architecture Chris Van UffelenPIYUSH GAUTAM0% (1)

- Glass Awning Support EngineeringDocument17 pagesGlass Awning Support Engineeringgarych72No ratings yet

- Cost Estimate XANTHENG V3Document15 pagesCost Estimate XANTHENG V3Andy ArenasNo ratings yet

- Desbrozadora 542rbs Husqvarna Partes y Piezas MaquicasaDocument7 pagesDesbrozadora 542rbs Husqvarna Partes y Piezas MaquicasaangelaNo ratings yet

- 2006 Investigation of Pipe Installation Using HDD 214Document8 pages2006 Investigation of Pipe Installation Using HDD 214samer ayashNo ratings yet

- A Boxes - Covers EDocument85 pagesA Boxes - Covers EKatamba RogersNo ratings yet

- HVAC EPCC PROJECT CHECKLISTDocument34 pagesHVAC EPCC PROJECT CHECKLISTTakrimi IsmailNo ratings yet

- SolidWorks Education Detailed Drawing ExercisesDocument51 pagesSolidWorks Education Detailed Drawing Exercisesdita ayuNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Ceramic Tiles (For Walls)Document4 pagesEtihad Towers Project: Inspection & Test Plan - Ceramic Tiles (For Walls)jini100% (2)

- Transmission Structures and Foundations:: CourseDocument8 pagesTransmission Structures and Foundations:: CoursejulianobiancoNo ratings yet

- Strength Lab Report (Exp 2) Update 1Document14 pagesStrength Lab Report (Exp 2) Update 1Syafiq RonaldoNo ratings yet

- Catalogue KF 2010Document26 pagesCatalogue KF 2010gasolineandoilNo ratings yet

- Measuring structural works in buildingsDocument16 pagesMeasuring structural works in buildingsKelly Mae VirayNo ratings yet

- Production Service HookupDocument40 pagesProduction Service Hookupray mojicaNo ratings yet

- Curriculum Vitae: Personal DetailsDocument7 pagesCurriculum Vitae: Personal Detailszikrillah1No ratings yet