Professional Documents

Culture Documents

Study Material For CNC Simulation

Study Material For CNC Simulation

Uploaded by

Manas Ranjan Pani0 ratings0% found this document useful (0 votes)

6 views4 pagesOriginal Title

DAY 6.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views4 pagesStudy Material For CNC Simulation

Study Material For CNC Simulation

Uploaded by

Manas Ranjan PaniCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

STUDY MATERIAL FOR CNC SIMULATION

DAY 6 GE FANUC SERIES 21 TURNING [GROUP B]

Part programming for Plain turning cycle, Profile Turning with

finishing cycle, Facing cycle.

1. PLAIN TURNING CYCLE [ G71 ]

PROGRAM NUMBER O0001;

TOOLPOST NO. & OFFSET NO. CANCEL N5 T0000;

G28 ->RETURN TO REF. POINT (X-HOMING) N10 G28 X0;

G28 ->RETURN TO REF. POINT (Z-HOMING) N15 G28 Z0;

TOOLPOST NO.1 & OFFSET NO.1 SELECTION N20 T0101;

G92 ->COORDINATE SYSTEM SETTING N25 G92 S1500 M04;

OR -> SPINDLE SPEED LIMIT

OR -> MAXIMUM SPINDLE SPEED

S1500 ->VALUE OF MAX. SPINDLE SPEED

M04 ->SPINDLE ROTATION IN COUNTER CLOCKWISE

G96 ->CONSTANT CUTTING SPEED N30 G96 S80;

S80 ->VALUE OF CONSTANT CUTTING SPEED [IN m/min]

G00 ->RAPID TRAVERSE N35 G00 Z2.0;

Z2.0 ->SAFETY POSITION IN Z-AXIS

G00 ->RAPID TRAVERSE N40 G00 X42.0;

X42.0 ->SAFETY POSITION IN X-AXIS

FLOOD COOLANT ON N45 M07;

OPERATION -> PLAIN TURNING [ G71 ]

G71 ->ROUGH CUTTING TURNING N50 G71 U0.2 R0.1;

U0.2 ->INCREMENTAL DEPTH OF CUT ALONG X-AXIS IN [mm]

R0.1 ->RETRACTION ALONG X-AXIS IN [mm] TO AVOID RUBBING

G71 ->ROUGH CUTTING TURNING N55 G71 P60 Q70 F0.2;

P60 ->STARTING BLOCK NUMBER

Q70 ->ENDING BLOCK NUMBER

STARTING PROFILE N60 G01 X30.0;

TOTAL LENGTH TO BE CUT N65 G01 Z-10.0;

ENDING PROFILE (AS X-SAFETY POSITION) N70 G00 X42.0;

RETURN TO Z-SAFETY POSITION N75 G00 Z2.0;

M05 ->SPINDLE ROTATION OFF N80 M05 M09 G97;

M09 ->COOLANT OFF

G97 ->CONSTANT SPINDLE SPEED

G28 ->RETURN TO REF POINT (X-HOMING) N85 G28 X0;

G28 ->RETURN TO REF POINT (Z-HOMING) N90 G28 Z0;

MAIN PROGRAM END & REWIND N95 M30;

2. PROFILE TURNING WITH FINISHING CYCLE [ G71 ] & [ G70 ]

PROGRAM NUMBER O0002;

TOOLPOST NO. & OFFSET NO. CANCEL N5 T0000;

G28 ->RETURN TO REF. POINT (X-HOMING) N10 G28 X0;

G28 ->RETURN TO REF. POINT (Z-HOMING) N15 G28 Z0;

TOOLPOST NO.1 & OFFSET NO.1 SELECTION N20 T0101;

G92 -> COORDINATE SYSTEM SETTING N25 G92 S1500 M04;

OR -> MAXIMUM SPINDLE SPEED

S1500 ->VALUE OF MAX. SPINDLE SPEED

M04 ->SPINDLE ROTATION IN COUNTER CLOCKWISE

G96 ->CONSTANT CUTTING SPEED N30 G96 S80;

S80 ->VALUE OF CONSTANT CUTTING SPEED

G00 ->RAPID TRAVERSE N35 G00 Z2.0;

Z2.0 -> SAFETY POSITION IN Z-AXIS

G00 ->RAPID TRAVERSE N40 G00 X42.0;

X42.0 ->SAFETY POSITION IN X-AXIS

FLOOD COOLANT ON N45 M07;

OPERATION -> PLAIN TURNING [G71]

G71 ->ROUGH CUTTING TURNING N50 G71 U0.2 R0.1;

U ->INCREMENTAL DEPTH OF CUT ALONG X-AXIS

R ->RETRACTION TO AVOID RUBBING

G71 ->ROUGH CUTTING TURNING N55 G71 P60 Q90 U0.2 W0.2 F0.2;

P60 ->STARTING BLOCK NUMBER

Q90 ->ENDING BLOCK NUMBER

F0.2 ->CUTTING FEEDRATE IN [ mm/rev ]

STARTING PROFILE -> X-COORDINATE N60 G01 X19.0;

STARTING PROFILE -> Z-COORDINATE N65 G01 Z0;

LINEAR INTERPOLATION N70 G01 X25.0 Z-3.0;

LINEAR INTERPOLATION HORIZONTALLY N75 G01 Z-23.0;

CIRCULAR INTERPOLATION IN CW DIR. N80 G02 X29.0 Z-25.0 R2.0;

LINEAR INTERPOLATION VERTICALLY N85 G01 X34.0;

CIRCULAR INTERPOLATION IN CCW DIR. N90 G03 X40.0 Z-28.0 R3.0;

ENDING PROFILE (AS X-SAFETY POSITION) N95 G00 X42.0;

RETURN TO Z-SAFETY POSITION N100 G00 Z2.0;

M05 ->SPINDLE ROTATION OFF N105 M05 M09 G97;

M09 ->COOLANT OFF

G97 ->CONSTANT SPINDLE SPEED

TOOLPOST NO. & OFFSET NO. CANCEL N105 T0000;

G28 ->RETURN TO REF POINT (X-HOMING) N110 G28 X0;

G28 ->RETURN TO REF POINT (Z-HOMING) N115 G28 Z0;

OPTIONAL STOP N120 M01;

FINISHING CYCLE

TOOLPOST NO.2 & OFFSET NO.2 SELECTION N125 T0202;

G92 -> COORDINATE SYSTEM SETTING N130 G97 S2000 M04;

OR -> MAXIMUM SPINDLE SPEED

S1500 ->VALUE OF MAX. SPINDLE SPEED

M04 ->SPINDLE ROTATION IN COUNTER CLOCKWISE

G00 ->RAPID TRAVERSE N135 G00 Z2.0;

Z2.0 ->SAFETY POSITION IN Z-AXIS

G00 ->RAPID TRAVERSE N140 G00 X42.0;

X42.0 ->SAFETY POSITION IN X-AXIS

FLOOD COOLANT ON N145 M07;

OPERATION -> FINISHING CYCLE [G70]

G70 -> FINISHING CYCLE N150 G70 P60 Q90 F0.08 ;

P60 -> STARTING BLOCK NUMBER

Q90 -> ENDING BLOCK NUMBER

F0.08 ->CUTTING FEEDRATE IN [ mm/rev ]

RETURN TO X-SAFETY POSITION N155 G00 X42.0;

RETURN TO Z-SAFETY POSITION N160 G00 Z2.0;

M05 ->SPINDLE OFF N165 M05 M09 G97;

M09 ->COOLANT OFF

G97 ->CONSTANT SPINDLE SPEED

G28 ->RETURN TO REF. POINT (X-HOMING) N170 G28 X0;

G28 ->RETURN TO REF. POINT (Z-HOMING) N175 G28 Z0;

MAIN PROGRAM END & REWIND N180 M30;

3. PLAIN FACING CYCLE [ G72 ]

PROGRAM NUMBER O0003;

TOOLPOST NO. & OFFSET NO. CANCEL N5 T0000;

G28 ->RETURN TO REF POINT (X-HOMING) N10 G28 X0;

G28 ->RETURN TO REF POINT (Z-HOMING) N15 G28 Z0;

TOOLPOST NO.1 & OFFSET NO.1 SELECTION N20 T0101;

G92 ->COORDINATE SYSTEM SETTING N25 G92 S1500 M04;

OR ->MAXIMUM SPINDLE SPEED

S1500 ->VALUE OF MAX. SPINDLE SPEED

M04-SPINDLE ROTATION IN COUNTER CLOCKWISE

G96 ->CONSTANT CUTTING SPEED N30 G96 S80;

S80 ->VALUE OF CONSTANT CUTTING SPEED

G00 ->RAPID TRAVERSE N35 G00 Z2.0;

Z2.0 ->SAFETY POSITION IN Z-AXIS

G00 ->RAPID TRAVERSE N40 G00 X42.0;

X42.0 ->SAFETY POSITION IN X-AXIS

FLOOD COOLANT ON N45 M07;

OPERATION PLAIN TURNING

G71 ->ROUGH CUTTING TURNING N50 G71 U0.2 R0.1;

U ->INCREMENTAL DEPTH OF CUT ALONG X-AXIS

R ->RETRACTION TO AVOID RUBBING

G71 ->ROUGH CUTTING TURNING N55 G71 P60 Q70 F0.2;

P60 ->STARTING BLOCK NUMBER

Q70 ->ENDING BLOCK NUMBER

STARTING PROFILE N60 G01 Z-10.0;

TOTAL DEPTH TO BE CUT N65 G01 X-1.0;

ENDING PROFILE (AS Z-SAFETY POSITION) N70 G00 Z2.0;

RETURN TO X-SAFETY POSITION N75 G00 X42.0;

M05 ->SPINDLE ROTAION OFF N80 M05 M09 G97;

M09 ->COOLANT OFF

G97 ->CONSTANT SPINDLE SPEED

G28 ->RETURN TO REF POINT (X-HOMING) N85 G28 X0;

G28 ->RETURN TO REF POINT (Z-HOMING) N90 G28 Z0;

MAIN PROGRAM END & REWIND N95 M30;

You might also like

- HAAS - Mill Programming Workbook AnswersDocument9 pagesHAAS - Mill Programming Workbook Answersenamicul50No ratings yet

- Waves TestDocument6 pagesWaves TestArgeena Agao-Agao100% (3)

- g75 Fanuc Canned Cycle Grooving CNC ProgramDocument2 pagesg75 Fanuc Canned Cycle Grooving CNC ProgramHarshal DhawasNo ratings yet

- CNC Turning ExamplesDocument69 pagesCNC Turning ExamplesThenarasumohanvelu100% (2)

- CNC ProgramsDocument5 pagesCNC ProgramsBravo VermaNo ratings yet

- Betriebsanleitung Master Kap-06 - ENG PDFDocument110 pagesBetriebsanleitung Master Kap-06 - ENG PDFPaulo RogerioNo ratings yet

- Study Material For CNC SimulationDocument10 pagesStudy Material For CNC SimulationManas Ranjan PaniNo ratings yet

- Day 8Document13 pagesDay 8Manas Ranjan PaniNo ratings yet

- Document From RDocument26 pagesDocument From RRahul SehgalNo ratings yet

- Study Material For CNC Simulation: Sinumerik Milling 840D/810D Part Programming For Pocketing, Drilling, Slot MillingDocument6 pagesStudy Material For CNC Simulation: Sinumerik Milling 840D/810D Part Programming For Pocketing, Drilling, Slot MillingManas Ranjan PaniNo ratings yet

- Bishop: CIRC. INTERP. CW TO X16.03 Z-58.92 W/ R6Document6 pagesBishop: CIRC. INTERP. CW TO X16.03 Z-58.92 W/ R6JohnReyAlquizaNo ratings yet

- Report CNC TurningDocument23 pagesReport CNC Turningdkeaumani57% (7)

- Fanuc CNC Stock Removal Rough Turning Cycle g71 II Example 2Document3 pagesFanuc CNC Stock Removal Rough Turning Cycle g71 II Example 2Harshal DhawasNo ratings yet

- Milling ProgramDocument20 pagesMilling ProgramSudeep Kumar SinghNo ratings yet

- CNC Fanuc G73 Pattern Repeating Cycle CNCDocument3 pagesCNC Fanuc G73 Pattern Repeating Cycle CNCHarshal DhawasNo ratings yet

- Lucrarea 6Document16 pagesLucrarea 6Dorin BarcanNo ratings yet

- Sinumerik 808D Gcode Ref Guide F-SFSDocument4 pagesSinumerik 808D Gcode Ref Guide F-SFSPranit KarneNo ratings yet

- g90g20g77 Turning CycleDocument8 pagesg90g20g77 Turning CycleTatiana OlegovnaNo ratings yet

- Mat LabDocument1 pageMat LabnagarajNo ratings yet

- Tugas 3 CadDocument45 pagesTugas 3 CadPutro Adi nugrohoNo ratings yet

- VMC ProgrammingDocument22 pagesVMC ProgrammingDynamic bhagwanNo ratings yet

- Formato CNCDocument2 pagesFormato CNCPérez Castro MisaelNo ratings yet

- Project CNC Vertical Milling Machine: Manufactura Asistida Por Computadora UpaoDocument4 pagesProject CNC Vertical Milling Machine: Manufactura Asistida Por Computadora UpaoCésar Valderrama CiezaNo ratings yet

- Aplicaţie: Elaborarea Itinerarului Tehnologic Si A Programului CNC Pentru Strunjirea Completa A Piesei de Proba PPR54Document3 pagesAplicaţie: Elaborarea Itinerarului Tehnologic Si A Programului CNC Pentru Strunjirea Completa A Piesei de Proba PPR54Andreea MariaNo ratings yet

- TurningDocument4 pagesTurningC MohanNo ratings yet

- INDICATOR LOCKNUT CODING - NCDocument2 pagesINDICATOR LOCKNUT CODING - NCniroNo ratings yet

- Circular Interpolation Programming Example 123456Document14 pagesCircular Interpolation Programming Example 123456Kennaa GadaaNo ratings yet

- Tugas Rutin Iv CNC - JulyadyDocument11 pagesTugas Rutin Iv CNC - JulyadyNovita P SilalahiNo ratings yet

- CNC LectureDocument16 pagesCNC LectureJyoti Patole JadhavNo ratings yet

- 6 Semester: Student ProfileDocument19 pages6 Semester: Student Profilealokkumar707977No ratings yet

- CNC ProgrammingDocument62 pagesCNC ProgrammingSanjog Maiti100% (2)

- NC ProgrammingDocument54 pagesNC ProgrammingVed Vrat NuclearNo ratings yet

- All RECORD ExercisesDocument10 pagesAll RECORD ExercisesPrajeeth PoojaryNo ratings yet

- Faculty Innovative Design and TechnologyDocument7 pagesFaculty Innovative Design and TechnologyNoordin AsimiNo ratings yet

- Laser G-Code Processing ExampleDocument5 pagesLaser G-Code Processing ExampleYakov ZinovievNo ratings yet

- Manufacturing of Rock Lever Shaft and Cam Follower in CNC MachineDocument28 pagesManufacturing of Rock Lever Shaft and Cam Follower in CNC Machinepallivenu289No ratings yet

- U W CNC Lathe CNC Program ExamplesDocument30 pagesU W CNC Lathe CNC Program ExamplesTrần Xuân Thanh100% (1)

- Siemens Lab Manual CNC ProgrammeDocument30 pagesSiemens Lab Manual CNC ProgrammesagunthiNo ratings yet

- CNC ProgramDocument37 pagesCNC ProgramBas RamuNo ratings yet

- Lec. 09 10 11 12 Fixed Cycles or Canned CyclesDocument11 pagesLec. 09 10 11 12 Fixed Cycles or Canned CyclesiammedhaofcNo ratings yet

- Avance 3 EJEMPLODocument27 pagesAvance 3 EJEMPLOhector zuñaNo ratings yet

- Program ProjectDocument6 pagesProgram Projectamelya putriNo ratings yet

- Programa Torno CNC - MangoDocument1 pagePrograma Torno CNC - Mangomartin vaamondeNo ratings yet

- CNCDocument43 pagesCNCVenky VenkateshNo ratings yet

- Lect 10 Turning Programing Solved ProblemsDocument4 pagesLect 10 Turning Programing Solved Problemsomar tahaNo ratings yet

- 3 G Codes Part 1 CNC PDFDocument23 pages3 G Codes Part 1 CNC PDFMichael CampbellNo ratings yet

- CNC Shop ManualDocument15 pagesCNC Shop Manualmsuhani011No ratings yet

- Cam Lab - Part ProgramsDocument5 pagesCam Lab - Part Programssatheeshm9014No ratings yet

- Formato CNC - 003Document2 pagesFormato CNC - 003Pérez Castro MisaelNo ratings yet

- CNC Programs ExamplesDocument5 pagesCNC Programs ExamplesNemikumar Gandhi100% (1)

- CNC English Code Controller SystemDocument17 pagesCNC English Code Controller Systemmarciano1980No ratings yet

- Assign2 B19ME004Document4 pagesAssign2 B19ME004AMAN GOYALNo ratings yet

- Haas G72 Type I Rough and G70 Finish Facing Program ExampleDocument3 pagesHaas G72 Type I Rough and G70 Finish Facing Program ExampleCnc Page100% (1)

- Pemrograman NCDocument3 pagesPemrograman NCPurwadyaziNo ratings yet

- Hobbing Example ProgramDocument1 pageHobbing Example Programenamicul50No ratings yet

- G y M Codes HAAS TORNO MejoradoDocument2 pagesG y M Codes HAAS TORNO MejoradoKevin AlvarezNo ratings yet

- N45 G1 Z-20 N50 G2 X35 Z-25 R5 N55 G1 X44 N60 G1 X45 Z-26 N65 G1 Z-40 N70 G1 X59 N75 G1 X60 Z-41 N80 G1 X70 N85 G1 X70 N90 G1 Z-70 M30 % Tiện vát gó/bo gócDocument3 pagesN45 G1 Z-20 N50 G2 X35 Z-25 R5 N55 G1 X44 N60 G1 X45 Z-26 N65 G1 Z-40 N70 G1 X59 N75 G1 X60 Z-41 N80 G1 X70 N85 G1 X70 N90 G1 Z-70 M30 % Tiện vát gó/bo gócKhang Lương TuấnNo ratings yet

- G54 T1 G95 F0.5 S800: Persiapan AwalDocument3 pagesG54 T1 G95 F0.5 S800: Persiapan AwalMajid TeguhNo ratings yet

- KINGDocument1 pageKINGHarmon Sayco DaquilaNo ratings yet

- Day 8Document13 pagesDay 8Manas Ranjan PaniNo ratings yet

- Study Material For CNC Simulation: Sinumerik Milling 840D/810D Part Programming For Pocketing, Drilling, Slot MillingDocument6 pagesStudy Material For CNC Simulation: Sinumerik Milling 840D/810D Part Programming For Pocketing, Drilling, Slot MillingManas Ranjan PaniNo ratings yet

- Study Material For CNC SimulationDocument10 pagesStudy Material For CNC SimulationManas Ranjan PaniNo ratings yet

- AcadDocument13 pagesAcadManas Ranjan PaniNo ratings yet

- READMEDocument1 pageREADMEManas Ranjan PaniNo ratings yet

- Wrestling Revolution 3DDocument14 pagesWrestling Revolution 3DManas Ranjan PaniNo ratings yet

- Joint Entrance Examination - 2018, Odisha Provisional Admit CardDocument1 pageJoint Entrance Examination - 2018, Odisha Provisional Admit CardManas Ranjan PaniNo ratings yet

- COMMERCIAL YACHT CODE - Rev.4Document44 pagesCOMMERCIAL YACHT CODE - Rev.4ndulauroyNo ratings yet

- Nota Audit PoliteknikDocument24 pagesNota Audit PoliteknikShiraz Ahmad100% (1)

- Assignment Gaseous State JH Sir-2621Document38 pagesAssignment Gaseous State JH Sir-2621Noob Iplay100% (1)

- 4" Reception Unit: Description - Installation - Start-Up Operation - MaintenanceDocument10 pages4" Reception Unit: Description - Installation - Start-Up Operation - MaintenanceClarkFedele27No ratings yet

- Code of Practice For The Design of Road Lighting: BSI Standards PublicationDocument82 pagesCode of Practice For The Design of Road Lighting: BSI Standards PublicationKamagara Roland AndrewNo ratings yet

- Telzas Power MibDocument49 pagesTelzas Power MibtttaaazmNo ratings yet

- Berat Material ERSDocument2 pagesBerat Material ERSMuhammad IswahyudiNo ratings yet

- Diversion Headworks-3Document28 pagesDiversion Headworks-3inamNo ratings yet

- ZXMSG 9000 Series NGN PDFDocument3 pagesZXMSG 9000 Series NGN PDFAze Aze100% (1)

- Working of FPSODocument14 pagesWorking of FPSOPartha SarathiNo ratings yet

- Bill of MaterialsDocument3 pagesBill of MaterialsRany YambaoNo ratings yet

- Module 1 OOMDDocument25 pagesModule 1 OOMDKevin KuriakoseNo ratings yet

- Seminar Report Liquid LensDocument27 pagesSeminar Report Liquid LensTanmoy Tatwadarshi50% (2)

- Crankshaft Front Seal - Remove and Install: SMCS - 1160-010Document20 pagesCrankshaft Front Seal - Remove and Install: SMCS - 1160-010oscar el carevergaNo ratings yet

- CMM - Nose Wheel - 3-1481Document87 pagesCMM - Nose Wheel - 3-1481Lucas AlvesNo ratings yet

- Tutorial Fail2BanDocument9 pagesTutorial Fail2BanjetbardsNo ratings yet

- ME2356 LabReportTemplate Fall2016-1Document3 pagesME2356 LabReportTemplate Fall2016-1hbfdskgNo ratings yet

- DIN 2605 (Elbows) PDFDocument3 pagesDIN 2605 (Elbows) PDFAleksandarSashaStankovichNo ratings yet

- BR67 User Manual 2-2015 V19Document26 pagesBR67 User Manual 2-2015 V19MuhaiminNo ratings yet

- A Review of Well Test Procedures and Recommendations To Maximise Economic Recovery in The UkcsDocument41 pagesA Review of Well Test Procedures and Recommendations To Maximise Economic Recovery in The UkcsJesseNo ratings yet

- Issued For Construction: Panel MV UnigearDocument4 pagesIssued For Construction: Panel MV UnigearIrfan MaulanaNo ratings yet

- Pamin, Michelle P.: BJT Modes of OperationDocument9 pagesPamin, Michelle P.: BJT Modes of OperationMitz PaminNo ratings yet

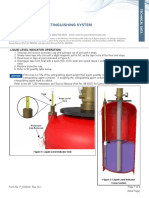

- Clean Agent Liquid Level Indicators - 012014 - 1Document4 pagesClean Agent Liquid Level Indicators - 012014 - 1anon_720851101No ratings yet

- Klixon 1 NTDocument6 pagesKlixon 1 NTGermán PreiszNo ratings yet

- Micrometer and Slip GaugeDocument17 pagesMicrometer and Slip GaugeKrishh GuptaNo ratings yet

- Devesh BhaiDocument17 pagesDevesh BhaiRohit SinghNo ratings yet

- Asphalt PlantDocument6 pagesAsphalt Plantdesibaba_mamaNo ratings yet

- ME 355: Compressible Flows, Spring 2016Document3 pagesME 355: Compressible Flows, Spring 2016ashwin josephNo ratings yet