Professional Documents

Culture Documents

Super Duplex Stainless Steel 1569905188 PDF

Super Duplex Stainless Steel 1569905188 PDF

Uploaded by

Akhil COriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Super Duplex Stainless Steel 1569905188 PDF

Super Duplex Stainless Steel 1569905188 PDF

Uploaded by

Akhil CCopyright:

Available Formats

The Welding Inspection Community

https://www.weldinginspections.net

contact@weldinginspections.net

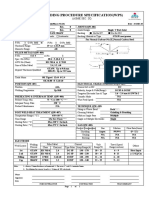

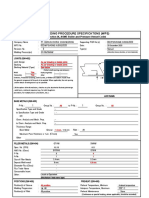

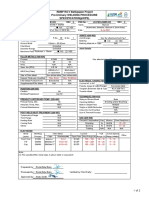

WELDING PROCEDURE SPECIFICATION

(ASME SECTION IX – 2019 EDITION)

DESCRIPTION JOINT SKETCH

.1 WPS no.: WIC-WPS-123 Rev. 00

60°

.2 Date of issue: dd-mmm-yyy

.3 Applicable code: ASME Section IX – 2019 Edition

.4 Welding process: GTAW SMAW

.5 Supporting PQR no.: WIC-PQR-123 Rev. 00 3.1 3.2

5.54 mm

5.54 mm

JOINTS (QW-402) GTAW SMAW

2

.1 Groove design: Groove weld – butt joint

.4 Backing: n/a Weld metal 1

.5 Backing: None n/a

.10 Root spacing: 3.2 mm n/a 3.2mm 0.5 mm

.11 Retainers: None n/a

BASE METALS (QW-403) POSITIONS (QW-405)

.5 Group no.: Any Gr.-1 Any Gr.-1 .1 Position: All All

.6 T limits: 12.7 to 25.4 mm .3 Vertical welding: Upward Upward

.8 T qualified: 5 to 25.4 mm

.9 Max. pass thick. <= 13 mm: n/a < 13 mm PREHEAT (QW-406)

.11 P-no. qualified: Any P-10H Any P-10H .1 Min. preheat temperature: 10 ºC

FILLER METALS (QW-404) .2 Preheat maint.: n/a None

.3 Size 2.4 mm n/a .3 Max. interpass temperature: 150 ºC

.4 F-No. 6 5 PWHT (QW-407)

.5 A-No. 8 8 .1 PWHT temperature: None None

.6 Diameter n/a 2.6/3.2/4.0 mm .2 T & T range: - -

.7 Diameter > 6mm n/a None

.12 Spec. no. or Class. A5.9 ER2209 A5.4 E2209-16

.14 Filler Yes n/a ELECTRICAL CHARACTERISTICS (QW-409)

.22 Consumable insert None n/a .1 Heat input: Max. 2.5kJ/mm Max. 2.5kJ/mm

.23 Filler metal product form Solid n/a .3 Pulsing current: None n/a

.30 Max. deposit metal thick. 5.54 mm 20.0 mm .4 Current & polarity: DC EN DC EP

.33 Classification None None .8 I & E range: See Welding Parameters

.50 Flux None n/a .12 Tungsten electrode: 2%thoriated n/a

TECHNIQUE (QW-410)

GAS (QW-408) .1 String / weave: Weave Both

.1 Trailing or composition: SG-A n/a .3 Orifice, nozzle or gas cup size: 4–7 n/a

.2 Single, mixture, or % 99.997 % n/a .5 Method cleaning: Grinding, wire brushing

.3 Flow rate 10-15 LPM n/a .6 Method back gouge: None [Note 1]

.5 Backing flow: SG-A, 15LPM n/a .7 Oscillation: None n/a

.9 Backing or composition: None n/a .9 Multi to single pass/side: Multi-passes Multi-passes

.10 Shielding or trailing: None n/a .10 Single to multi electrodes: Single n/a

.11 Closed to out chamber: None n/a

NOTES .15 Electrode spacing: None n/a

.25 Manual or automatic: Manual Manual

Note 1: Back gouge by grinding. .26 Peening: None None

.64 Use of thermal processes: None None

WELDING PARAMETERS

Filler metal Energy of

Current & Ampere Travel speed

Layer Process Voltage range power Others

Class. Dia. polarity Range [mm/minute]

(range)

Root GTAW ER2209 2.4 DC EN - - - - -

Hot GTAW ER2209 2.4 DC EN - - - - -

Fill SMAW E2209-16 3.2 DC EP - - - - -

Cap SMAW E2209-16 3.2 DC EP - - - - -

Welding Engineer QA/QC Manager Third Party Client

You might also like

- Icons Gettysburg: Greg WagmanDocument14 pagesIcons Gettysburg: Greg WagmanDaniel Salvador100% (1)

- TiKi TaKa CK Preventive MedicineDocument3 pagesTiKi TaKa CK Preventive MedicinenonsNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- R30iB Pendant Customization Guide V8 30 MAROBCG8304141E Rev A PDFDocument219 pagesR30iB Pendant Customization Guide V8 30 MAROBCG8304141E Rev A PDFdenix49No ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- Welding of P91Document37 pagesWelding of P91nishant361100% (4)

- 6GR RequirementsDocument1 page6GR Requirementswalitedison100% (1)

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- WPS Api 1104Document3 pagesWPS Api 1104miguelNo ratings yet

- Temperature and Effect On ConcreteDocument59 pagesTemperature and Effect On ConcreteBart KwanNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Baited Hole NooseDocument62 pagesBaited Hole NooseDaVinci1973No ratings yet

- WPS Dissimilar UpdatedDocument3 pagesWPS Dissimilar UpdatedVimin Prakash100% (1)

- PQRDocument2 pagesPQRalokbdas100% (1)

- AlfettaDocument110 pagesAlfettaSebasthian AlbaNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNo ratings yet

- WPS Format For Asme Ix - Wps - Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- WpsDocument39 pagesWpsAkhilesh Kumar100% (1)

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- Metrode Welding Duplex & Superduplex Stainless SteelsDocument18 pagesMetrode Welding Duplex & Superduplex Stainless SteelsClaudia Mms50% (2)

- Poster - Welding Positions - en PDFDocument1 pagePoster - Welding Positions - en PDFmjaric8150% (2)

- WPS Format For Asme Ix - Wps - Gtaw SmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SmawThe Welding Inspections Community100% (1)

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- g3500c and G3500e Generator Electrical System PDFDocument4 pagesg3500c and G3500e Generator Electrical System PDFСергей Шевченко0% (1)

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- How To Write A Welding Procedure SpecificationDocument10 pagesHow To Write A Welding Procedure SpecificationHoang LamNo ratings yet

- PWHT ProcedureDocument11 pagesPWHT Proceduretbmari100% (15)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- SPP Owners Manual LR 140805Document16 pagesSPP Owners Manual LR 140805api-260418933No ratings yet

- Dss 2205 Wps PQR WPQDocument8 pagesDss 2205 Wps PQR WPQAnand KesarkarNo ratings yet

- KSL Wps PQR 012 DuplexDocument33 pagesKSL Wps PQR 012 DuplexJunaidi Minhat100% (6)

- Clad PQRDocument5 pagesClad PQRRinshadNo ratings yet

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- APSM WPS 008R Rev. 0Document3 pagesAPSM WPS 008R Rev. 0Amir NorNo ratings yet

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisNo ratings yet

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Document12 pagesPT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Pipeline Weld Joint & Ragiograph Film Numbering SystemDocument9 pagesPipeline Weld Joint & Ragiograph Film Numbering Systemgst ajah100% (2)

- Wps 316L Gtaw R00Document3 pagesWps 316L Gtaw R00Richard Periyanayagam75% (4)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS - Welding Instruction - FUCHSDocument23 pagesWPS - Welding Instruction - FUCHSShanoor AS100% (1)

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- Alum 6xxx PwpsDocument1 pageAlum 6xxx PwpsAbu Zahid100% (1)

- ASME 9 - CalculatorDocument2 pagesASME 9 - CalculatorEmel Besir100% (1)

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- Asme Ix - WPS - Gtaw Fcaw Gmaw PDFDocument1 pageAsme Ix - WPS - Gtaw Fcaw Gmaw PDFThe Welding Inspections CommunityNo ratings yet

- PIPING WPS and PQRDocument5 pagesPIPING WPS and PQRshibaprasad0115No ratings yet

- Asmeix Wps Fcawgmaw 191019041529 PDFDocument1 pageAsmeix Wps Fcawgmaw 191019041529 PDFvinod100% (1)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- WPS 01 WQT PDFDocument1 pageWPS 01 WQT PDFkiki270977No ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- 1 WPS 132Document2 pages1 WPS 132VishnuGK100% (1)

- Pre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectDocument2 pagesPre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectBagandi ManurungNo ratings yet

- 04-Power of Persuasion Summary 04 Decision MakingDocument2 pages04-Power of Persuasion Summary 04 Decision Makingacido255No ratings yet

- Colour Metallography of Cast IronDocument13 pagesColour Metallography of Cast IronIjabiNo ratings yet

- Plug Valve Repair KitDocument1 pagePlug Valve Repair Kitcmrig74No ratings yet

- Moses' Mother in EXODUS 2:1-10 AND Mothers in Personal Names Among The Igbo People, South-East NigeriaDocument19 pagesMoses' Mother in EXODUS 2:1-10 AND Mothers in Personal Names Among The Igbo People, South-East NigeriaAllistair MatthysNo ratings yet

- 70 Đề Thi Chứng Chỉ B Tiếng AnhDocument502 pages70 Đề Thi Chứng Chỉ B Tiếng AnhTran Thi Thanh Hien100% (1)

- LTJournal V20N4 02 DF LT3652 Jay - CelaniDocument6 pagesLTJournal V20N4 02 DF LT3652 Jay - CelaniCanerNo ratings yet

- (15200477 - Bulletin of The American Meteorological Society) High-Resolution Operational Ocean Forecast and Reanalysis System For The Indian OceanDocument17 pages(15200477 - Bulletin of The American Meteorological Society) High-Resolution Operational Ocean Forecast and Reanalysis System For The Indian OceanBISWARUP DASNo ratings yet

- Photosynthesis Lab Report ExampleDocument2 pagesPhotosynthesis Lab Report ExampleTiffany RishiNo ratings yet

- RaleighDocument5 pagesRaleighapiweedNo ratings yet

- Booklet Conical MountingsDocument41 pagesBooklet Conical MountingsAhmet HamamcıoğluNo ratings yet

- Puran c1Document22 pagesPuran c1dennis gamisNo ratings yet

- A-2 - Existing and Proposed ElevationsDocument1 pageA-2 - Existing and Proposed ElevationsЈована ДимевскаNo ratings yet

- Wolaita Sodo University: Student Name: IdDocument62 pagesWolaita Sodo University: Student Name: IdMulugetaNo ratings yet

- WELCOME!!!!!: Six-Day Skills Enhancement Training For The TLE, TVL, ALS & Mobile TeachersDocument65 pagesWELCOME!!!!!: Six-Day Skills Enhancement Training For The TLE, TVL, ALS & Mobile TeachersErma JalemNo ratings yet

- A Review of Generative Adversarial Networks GANs and Its Applications in A Wide Variety of Disciplines From Medical To Remote SensingDocument28 pagesA Review of Generative Adversarial Networks GANs and Its Applications in A Wide Variety of Disciplines From Medical To Remote Sensingmahendrarm2112No ratings yet

- Elements Exposed To HazardsDocument16 pagesElements Exposed To HazardsGLADYS OLIVEROSNo ratings yet

- Preload Type of Precision Ball Screw: φ d φ D φ dp φ d φ dc φ Dg6 φ dDocument2 pagesPreload Type of Precision Ball Screw: φ d φ D φ dp φ d φ dc φ Dg6 φ dKshitij SharmaNo ratings yet

- Msds NaclDocument6 pagesMsds NaclNur Oktri Mulya DewiNo ratings yet

- Orihinal Na TextoDocument2 pagesOrihinal Na TextoShahara AbidinNo ratings yet

- Article 2 DraftDocument9 pagesArticle 2 DraftTESL3-0620 Nur Kartika Damia Mohd Affendey Binti Abdul AzizNo ratings yet

- Quick Guide Onboard For Creating A Full Reporting Cycle Doc - Ver2Document2 pagesQuick Guide Onboard For Creating A Full Reporting Cycle Doc - Ver2sochrinaNo ratings yet